OPERATING PROCEDURES

MP35.372C

12JUL06

CAUTION:

IMPORTANT:

JACK RETRACTION

THE OPERATOR MUST BE SURE THAT

THERE ARE NO OBJECTS UNDER THE VEHICLE AND

THAT ALL PEOPLE ARE CLEAR OF THE VEHICLE.

DO NOT interrupt power to the leveling

system while the "STORE" indicator light is blinking.

DO NOT push the "OFF" button. The system must be allowed

4. If jacks cannot be retracted by the above procedure see

MANUAL JACK RETRACTION Section.

to completely finish the store mode. If the engine was started

2. Press the "STORE" button. The store indicator light will

flash. As each jack retracts, its red WARNING light will go

1. Turn the ignition switch to "ON", "ACC", or start the engine.

Press the "I" button one time. The "I" indicator light will glow

steady.

out. The vehicle can be moved as soon as the red WARNING

lights are out and the green "TRAVEL" light is on, providing

the jacks are in the STORE/TRAVEL position.

before putting the system in the store mode, the vehicle may

be moved when the jacks are in the STORE/TRAVEL position.

This will not interrupt the store procedure.

3. The system will automatically shut down six minutes after

the four individual red "WARNING" lights are out. If any one

red "WARNING" light does not go out, the system will

continue to store for thirty (30) minutes, then shut down

regardless of the "WARNING" lights condition.

THE STORE/TRAVEL POSITION BEFORE TRAVELING.

RESPONSIBILITY TO CHECK THAT ALL JACKS ARE IN

WARNING LIGHTS. IT IS THE OPERATOR’S

CAUTION: DO NOT RELY SOLELY UPON THE

NOTE: If the ROOM CONTROL SWITCH is pushed while

the Leveling System is in the "STORE" mode, the STORE

procedure is interrupted until the ROOM CONTROL SWITCH

is released. If the four red WARNING lights are all out, the

STORE light will continue to blink for six minutes, then the

system will shut off.

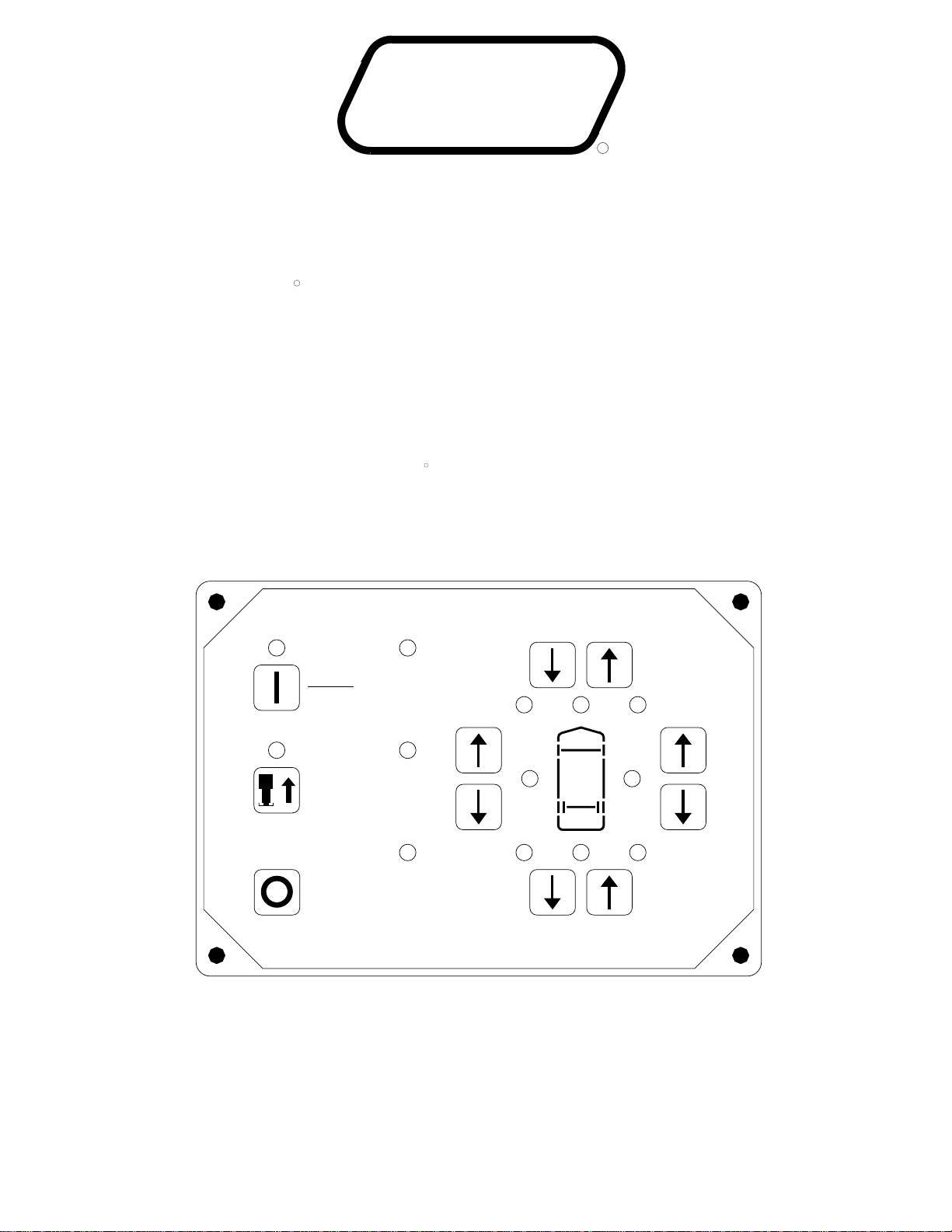

MANUAL HYDRAULIC OPERATION

"ACCESSORY" or "ON" position.

the vehicle, and set the parking brake. Turn the ignition to the

SENSING light is on, that side or end of the vehicle is low.

buttons on the right half of the panel. If a yellow LEVEL

3. The vehicle may be leveled using the manual EXTEND

2. Press the "I" button. The indicator light will glow steady.

1. Place transmission in the recommended position for parking

Do not continue to push an EXTEND button

leveling panel and turn the ignition switch to the "OFF"

4. When leveling is completed, push the "OFF" button on the

for more than ten (10) seconds after that pair of jacks are

leveling can be extended to the ground. This provides

Any jack not used for

additional stability against wind and activity in the vehicle.

fully extended.

IMPORTANT:

Jacks will extend (or retract) in pairs to raise (or lower) a side

or end of the vehicle.

Level the vehicle side to side, if necessary, before

leveling the vehicle front to rear.

position.

NOTE: As the jacks extend 1/4" to 1/2" the

red warning light for the jack will come on.

STORE/TRAVEL POSITION

JACK POSITIONS

EXTENDED POSITION