OPERATING PROCEDURES

GENERAL INSTRUCTIONS

The Hydraulic Leveling system, cannot be activated

MP34.0901

16MAR10

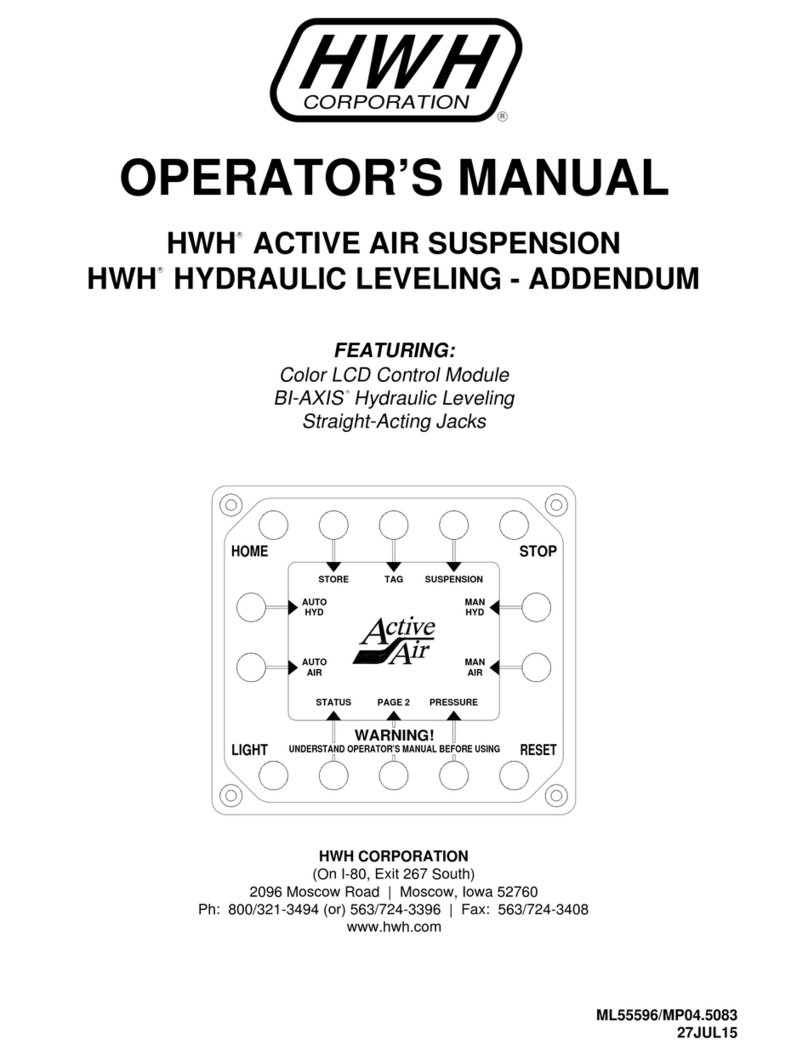

Turn the ignition to the "ON" or "ACC" position to turn the

SYSTEM CONTROL panel on.

Push the "HOME" button to return the SYSTEM CONTROL

panel to the HOME PAGE. Any function that is to be operated

from the SYSTEM CONTROL panel can only be accessed

from the HOME PAGE. Individual screen functions are

Push the "STOP" button to stop any function. Pushing the

"STOP" button will turn the SYSTEM CONTROL panel off.

if the park brake is not set.

Maintain adequate clearance in all directions for vehicle,

room extensions and generator slide, doors, steps, etc..

Vehicle may move in any direction due to raising and

lowering of vehicle during leveling, settling of vehicle,

equipment malfunction etc..

explained in this section.

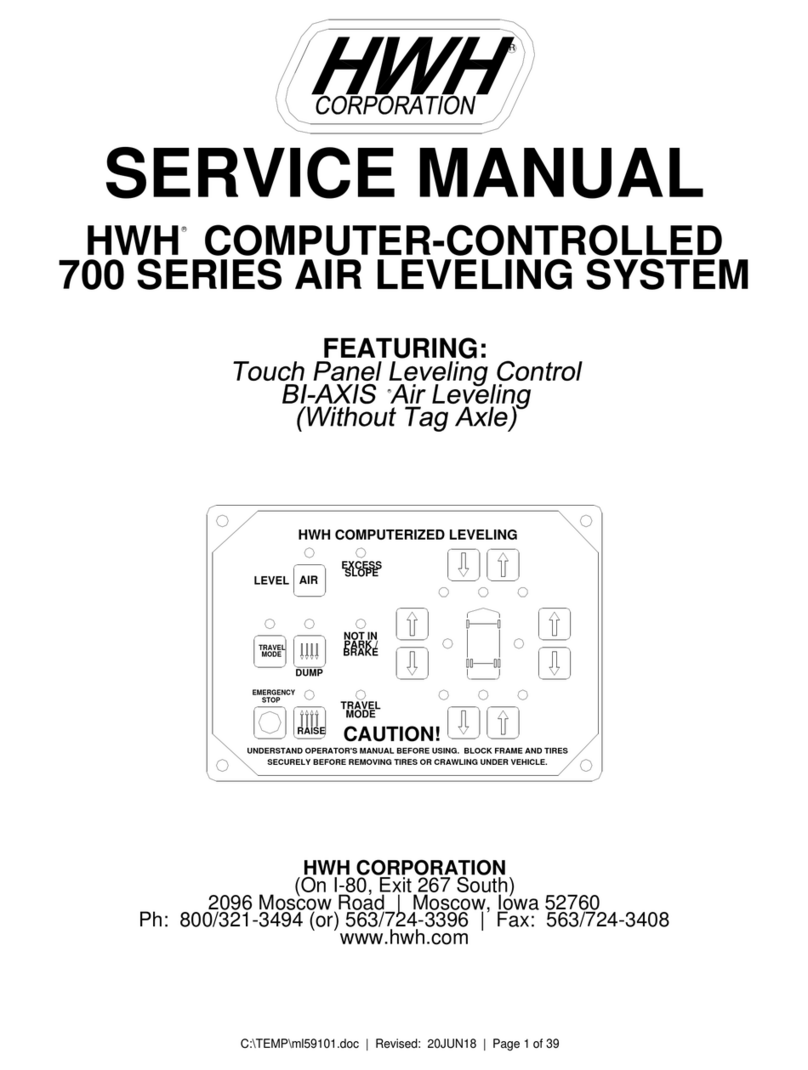

The SYSTEM CONTROL screen will exhibit messages to

the operator when there is a problem or malfunction in the

system or when a function cannot be used. The "HOME"

button must be pushed to acknowledge the message. The

malfunction or situation must be corrected before proceeding.

APPEARS ON THE CONTROL SCREEN, IT IS THE

CAUTION:ANYTIME A "WARNING" MESSAGE

OPERATORS RESPONSIBILITY TO CORRECT THE

PROBLEM TO ENSURE SAFE OPERATION OF THE

VEHICLE AND IT’S SYSTEMS.

PREPARATION FOR TRAVEL

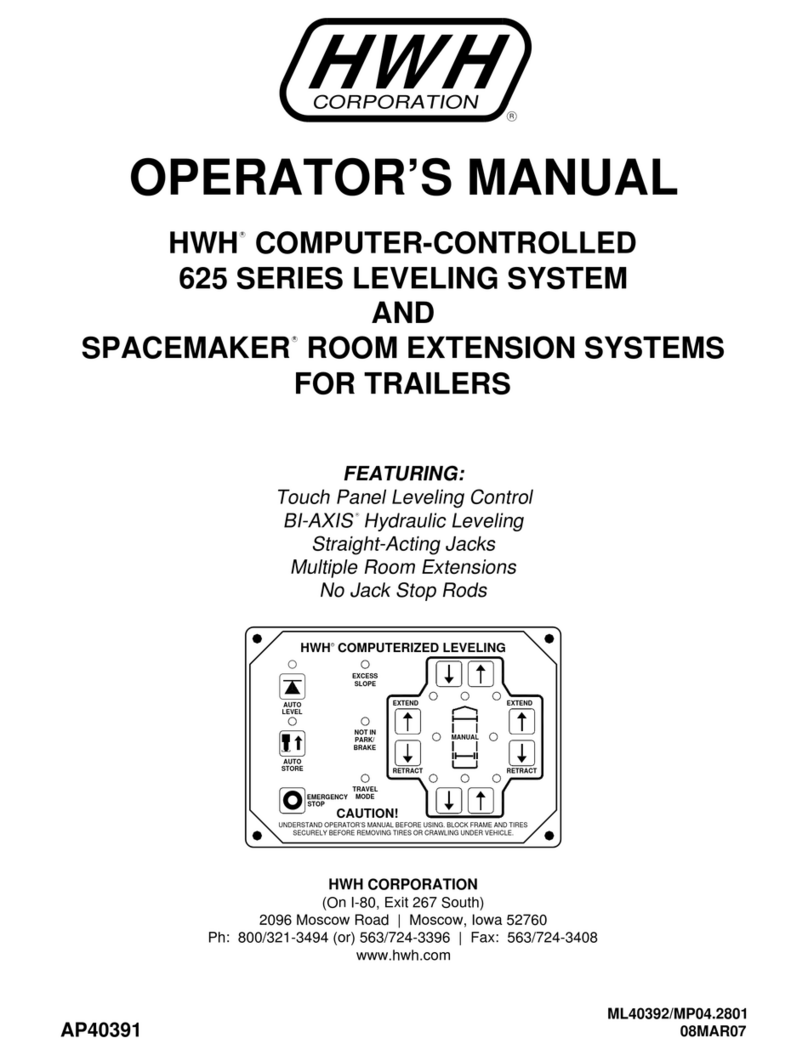

1. When either leveling system has been used, push the

"AUTO STORE" button to retract the jacks and/or return

the system to the traveling mode. It is a good idea to

always, push the "AUTO STORE" button after starting the

engine. This will ensure thermal expansion of the fluid in

the hydraulic leveling system will not cause a jack down

indicator to come on while traveling.

2. Check that all four leveling jacks are fully retracted

to the STORE position.

3. If the flashing "STORE" light does not shut off after

three to four minutes there may be a malfunction. Bring

up the correct STATUS page to determine which jack

may not be retracted. The jacks may take longer to

retract in cold weather.

4. The SYSTEM CONTROL PANEL should be

on when traveling.

5. Check that the vehicle is at the proper ride height

for traveling.

CAUTION:DO NOT MOVE THE VEHICLE WHILE

THE LEVELING JACKS ARE STILL IN CONTACT WITH

THE GROUND OR IN THE EXTEND POSITION. THIS

VEHICLE IS EQUIPPED WITH STRAIGHT-ACTING JACKS.

MOVING THE VEHICLE WITH THE LEVELING JACKS

EXTENDED CAN CAUSE SEVERE DAMAGE TO THE

JACKS AND OR THE VEHICLE AND CREATE A DRIVING

HAZARD. DO NOT RELY SOLELY UPON WARNING

LIGHTS. IT IS THE OPERATOR’S RESPONSIBILITY TO

CHECK THAT ALL THE JACKS ARE FULLY RETRACTED

INTO THE STORE/TRAVEL POSITION AND THE VEHICLE

IS AT THE PROPER RIDE HEIGHT FOR TRAVELING.

CONTACT MANUFACTURER TECHNICAL SERVICE

BEFORE MOVING A VEHICLE THAT IS NOT AT

PROPER TRAVEL HEIGHT.

Place a pad or block under each jack if the ground is too

soft to support the vehicle or when parking on soft asphalt.