3

A strip chart recorder can be used to further optimize the adjustments.

If further performance improvements are required, refer to Section (8) SYS-

TEM TROUBLESHOOTING.

© 2019 Copyright All Rights Reserved

ESD5300 Speed Control Unit 01.04.19 PIB 1041 G

8ADJUSTMENTS

Once the engine is running at operating speed and at no load, the following

governor performance adjustment can be made to increase engine stability.

PARAMETER ADJUSTMENT PROCEDURE

P

(GAIN)

1.

2.

3.

4.

Rotate the GAIN adjustments CW until instability develops.

Then, gradually move the adjustment CCW until stability

returns.

Finally, Move the adjustment one division further CCW to

insure stable performance.

If instability persists, adjust the next parameter.

I

(STABILITY)

1.

2.

Follow the same adjustment procedure as the P parameter

using the Stability potentiometer.

If instability persists, adjust the next parameter.

D

(DEADTIME)

1. Follow the instability procedure in Section (8) SYSTEM

TROUBLE SHOOTING.

NOTE

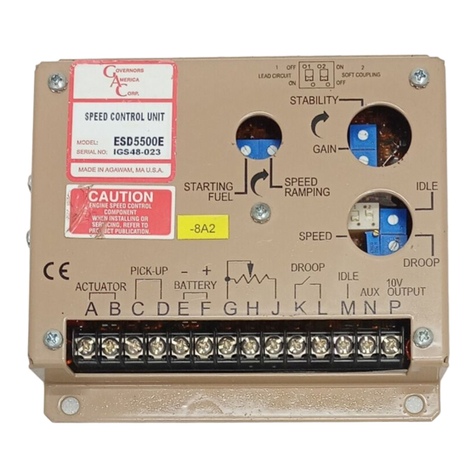

6START THE ENGINE

If the cranking termination occurs too quickly, preventing the engine from start-

ing, turn the crank termination adjustment CW. The actuator should snap to

full fuel until the engine starts and runs at a low idle setting. Adjust the SPEED

setting CW for the desired operating speed.

If the IDLE speed adjustment is set too low, the engine may nev-

er exceed the crank termination point, possibly causing starter

damage.

Should the engine be unstable, turn the GAIN and STABILITY adjustments

CCW until the engine is stable. If the system remains unstable or not operating

properly, refer to the SECTION 10 SYSTEM TROUBLESHOOTING.

CAUTION

7GOVERNOR SPEED SETTING

The governed speed set point is increased by clockwise rotation of the SPEED

adjustment pot. Remote speed adjustment can be obtained with an optional 5K

Frequency Trim Control. (See Section 4 WIRING DIAGRAM)

ADDITIONAL FEATURES

9

Many applications require a flexible coupling between the engine and its load.

This can take the form of a soft rubber segmented coupling or a drive shaft

which behaves as a natural spring. The reasons such couplings are used is for

alignment purposes, torsional considerations, or because of the excess length

of the drive shaft has a natural spring effect. In any case, the drive train can act

as a resonant device causing variable loads at a cylindrical rate to be impressed

on the engine and its flywheel. Such variations sometimes occur at a frequency

that the governor responds to very well.

This can cause excessive throttle movement at the same frequency as the reso-

nance. The ESD5300 speed control unit has a special circuit that minimizes the

offset on the resonances on the governor.

If the system exhibits these characteristics, turn ON SW1, C2 to activate this

feature. Readjust the control system per the above procedure and the result

should be a significant reduction in throttle dither. Because the governor does

not respond to the resonance any longer does not mean the resonance is not

still present in the drive train.

SOFT COUPLING / RESONANT DRIVE TRAINS

IDLE AND RAMP SETTING

Close the IDLE switch connecting Terminals N and P. This will cause the engine

to slow to an idle speed. Adjust the IDLE setting for desired idle speed.

Open the IDLE switch between Terminals N and P. The engine will start accel-

erating toward rated speed. Adjustment of the ACCEL control will allow the en-

gine to accelerate with just enough fuel to bring the system to operating speed

with lowest emissions. The desired acceleration and deceleration rates can be

achieved by manipulating the ACCEL and DECEL adjustments. Cycle the IDLE

switch after each ACCEL or DECEL adjustment change until the desired results

are achieved. It is suggested to use an oil pressure switch to operate these con-

tacts. Open N and P and the engine speed will decelerate at a rate set by the

DECEL control CW is faster for both ACCEL and DECEL functions.

SPEED DROOP OPERATION

If droop operation is desired (speed setting reduces with increased engine

load), close the switch contact across Terminals J and K. Rotate the DROOP

adjustment CW to increase the droop percentage “0” setting (Full CCW) = Zero

droop. 100 = maximum droop.

STARTING FUEL ADJUSTMENT

Turn the STARTING FUEL RAMPING to minimum CCW position (0). Crank

the engine and quickly rotate the starting fuel adjustment to CW until the en-

gine starts without excess smoke. Repeat several times to find the best setting.

Some engines require large amounts of fuel to start but most modern engines

respond to limiting fuel during cranking. Once the engine starts repeatedly in

a satisfactory manner, adjust the Fuel Ramping adjustment CW so the engine

accelerates to rated speed quickly, without excess smoke. The acceleration ad-

justment may be set to the fastest positions if start fuel ramping is not desired.

The ESD5340 has an advanced startup circuit that adjusts crank-

ing fuel for faster startups.

NOTE

INTERNAL SPEED RAMPING FUNCTION

Each time the ESD5300 is started the speed ramping function operates by tak-

ing control of the engine at near idle position and automatically raises the engine

speed until the speed set point is reached. The acceleration time is controlled by

the acceleration control. If the idle switch is then closed, the speed will deceler-

ate at the rate set by the deceleration adjustment control.

During these ramping periods, the speed control has a small amount of droop

added to attain stability at low engine speeds. The droop is eliminated once

rated speed is reached unless droop is added by closing the switch at J and K

terminals.

The internal ramp generator can also be used for wide range variable speed ap-

plications. Connecting a 0-10 VDC variable voltage to terminal “N” with respect

to terminal “G” will provide a means to achieve variable speed governing. To

calibrate the speed range, either limit the voltage to a level which provides the

desired range with an external potentiometer or add resistance in series with

terminal N as shown in the diagram.

DUAL GAIN FEATURE

The ESD5300 can operate with two distinct gain settings. The two gain adjust-

ments, Gain 1 and Gain 2 are independent adjustments. With the connection

from R and L “Open,” the Gain 1 adjustment is in operation. With a connection

from R to L “Closed”, Gain 2 is in operation. Switching between the two gain

settings should have an imperceptible difference in speed change. The dual

gain function is especially useful for engines, which exhibit different character-

istics under different situations. An engine may run very stable at high speeds

and less stable at lower speeds. Setting a single gain control for the lower

speeds then yields less than an optimum setting at the higher speeds. A simple

switch can be toggled for low or high speed operation. Additionally in gaseous

fuel engine applications where the quality or type of gas is changed, the two

gain settings can be used to idealize the governor for each type of fuel.

For cold engine instability, a temperature-sensing switch can reset the gover-

nor’s gain once the engine has reached a normal operating temperature.

These are some examples where the ESD5300 can be used to provide more

optimum control of dynamic engine characteristics while providing the best of

governing control.

ADJUSTABLE CHOPPING FREQUENCY

The actuator chopping frequency can be varied using the potentiometer labeled

‘CF ADJ’. This chopping frequency applied to the actuator provides an addition-

al stability enhancement as the “dither” shakes the actuator to overcome static

friction and insure its immediate response.