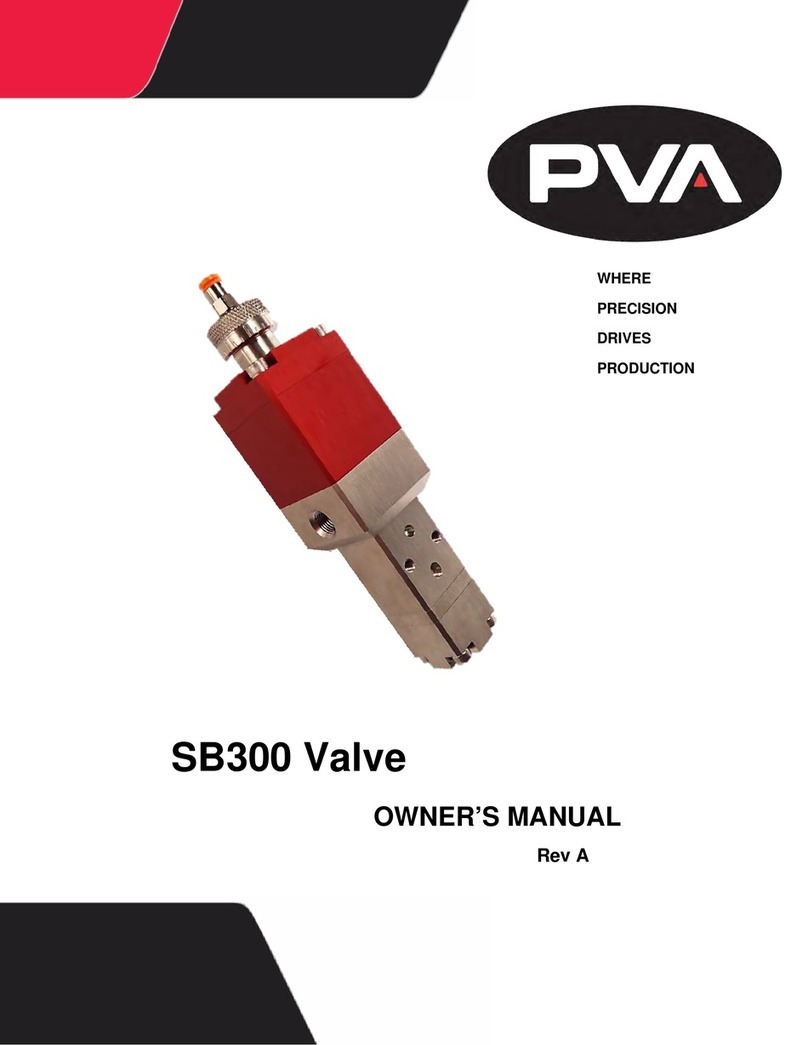

Table of Contents

1. Introduction ............................................................................................. 5

Document History ............................................................................................... 5

Safety .................................................................................................................. 6

Theory of Operation............................................................................................ 7

Air Section ...................................................................................................7

Fluid Section................................................................................................7

Pneumatic Schematic.......................................................................................... 7

Personal Protective Equipment .......................................................................... 8

Waste Disposal.................................................................................................... 8

Tool Kit ................................................................................................................ 8

Overview.................................................................................................. 9

Valve Operation ..................................................................................... 10

Startup .............................................................................................................. 10

Install the Static Mixer ...................................................................................... 11

Shutdown.......................................................................................................... 13

Maintenance .......................................................................................... 13

Disassemble the Valve ...................................................................................... 14

Procedure.................................................................................................. 14

Clean the Disassembled Valve .......................................................................... 21

Assemble the Valve........................................................................................... 23

Procedure.................................................................................................. 23

With a Press ..............................................................................................28

To Engage by Hand:...................................................................................29

Periodic Maintenance............................................................................. 33

How to Replace a Static Mixer.......................................................................... 33

How to Replace Lip Seals .................................................................................. 33

Seal Plate Lip Seals ....................................................................................33

Fluid Section Lip Seals ............................................................................... 33