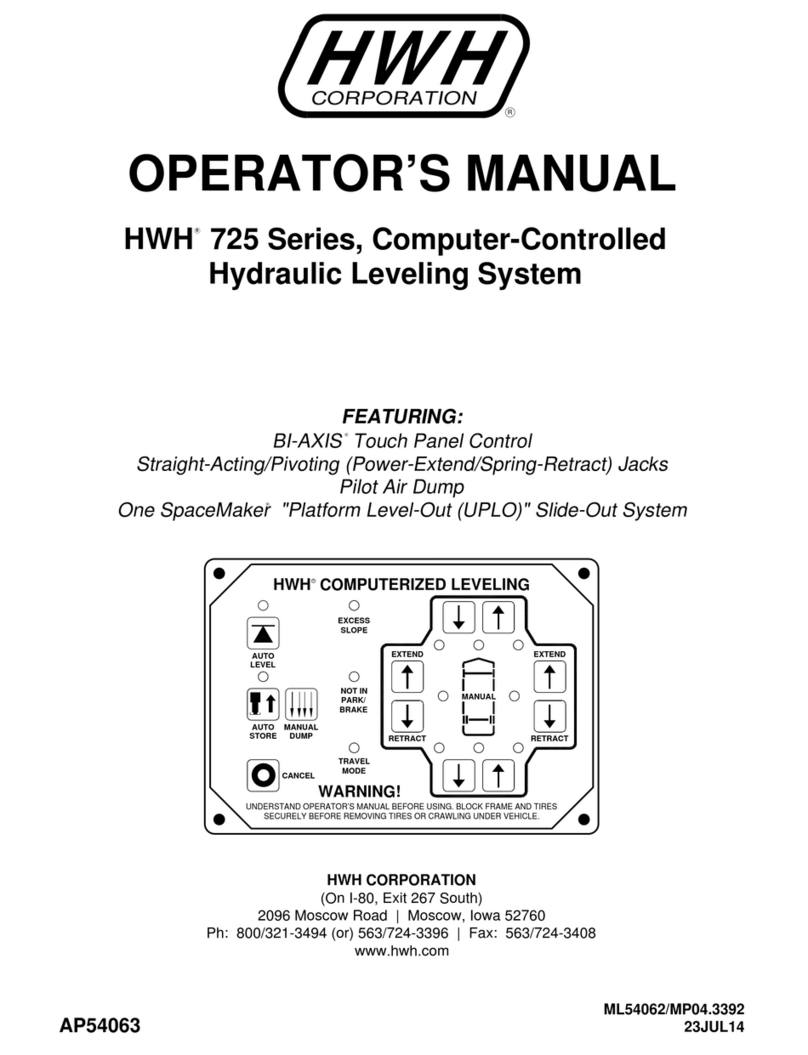

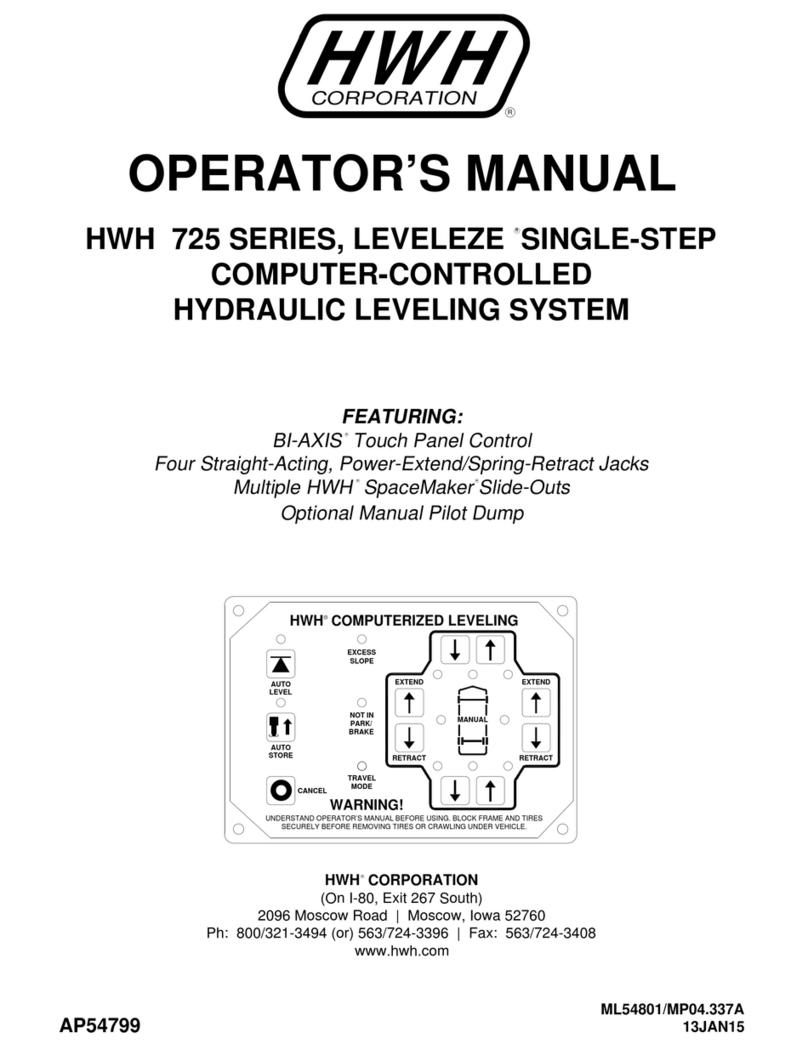

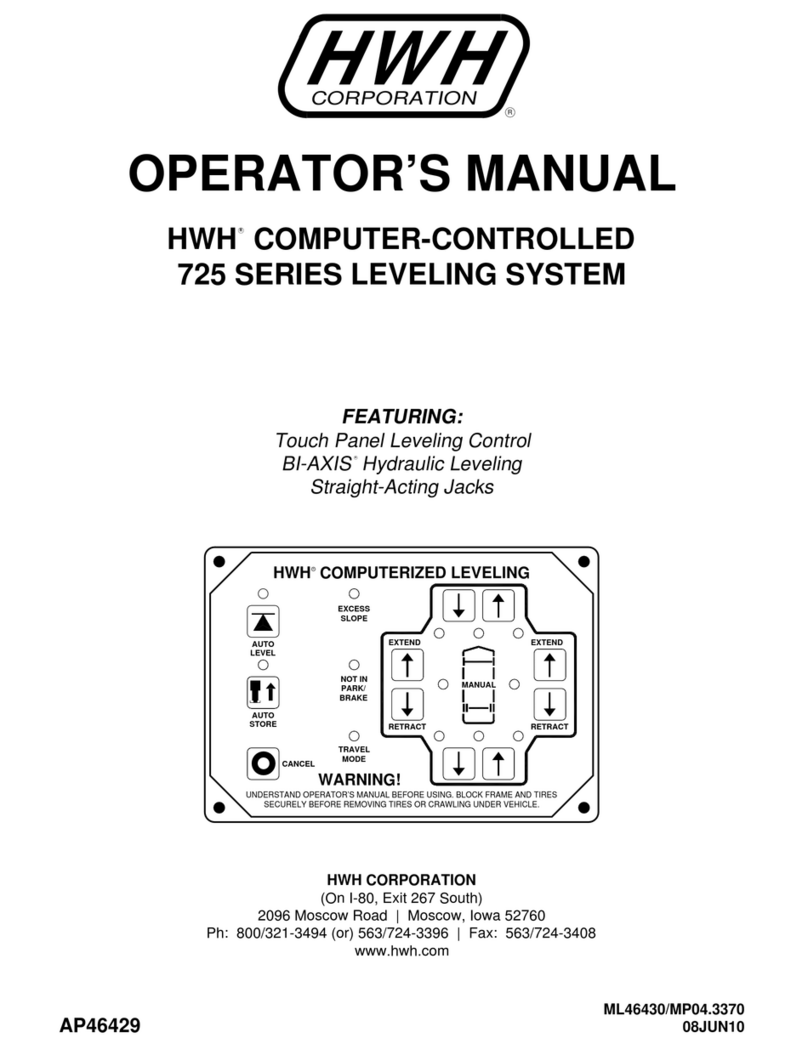

MAINTENANCE

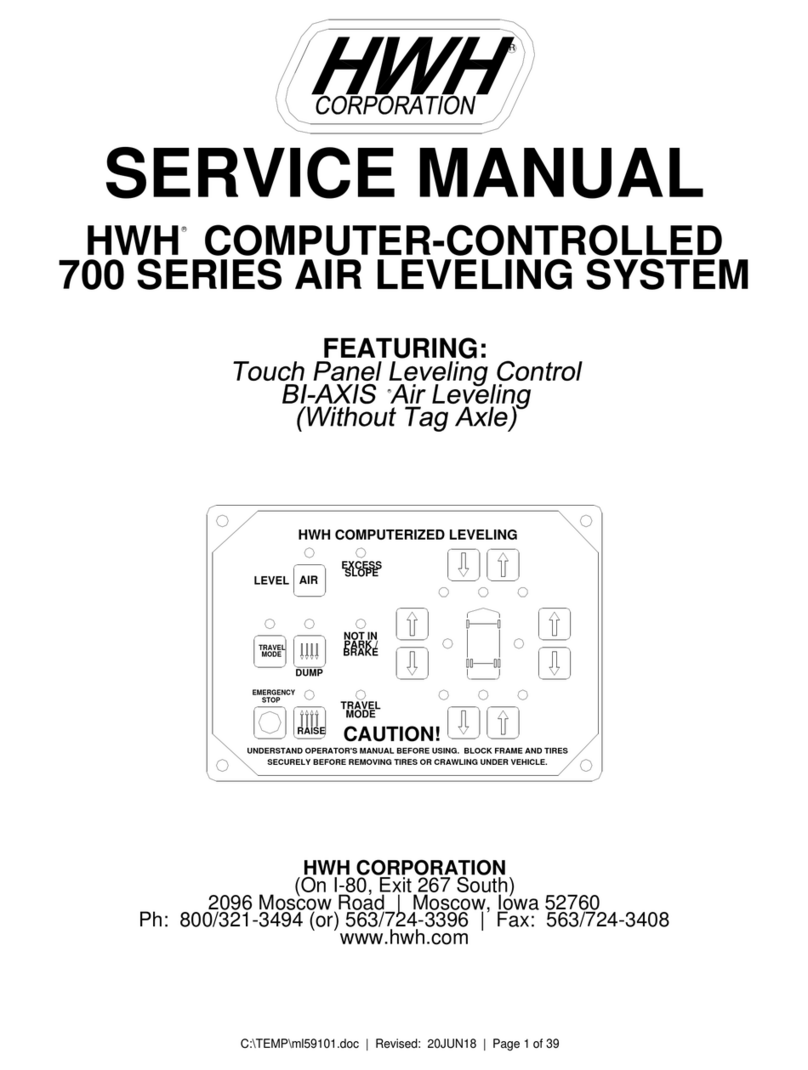

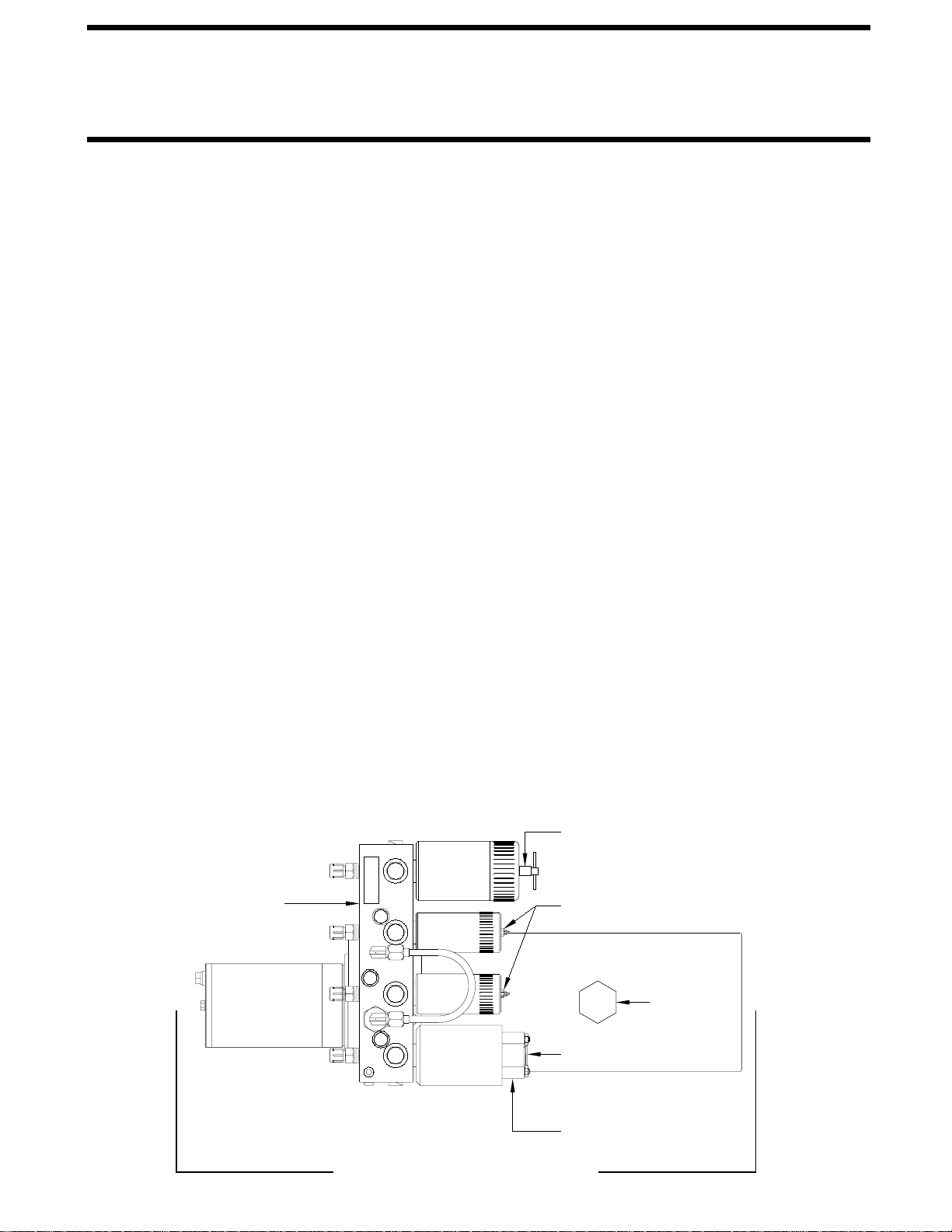

SENSING UNIT - TOP VIEW

D

C

A

B

LED’S - LOCATION

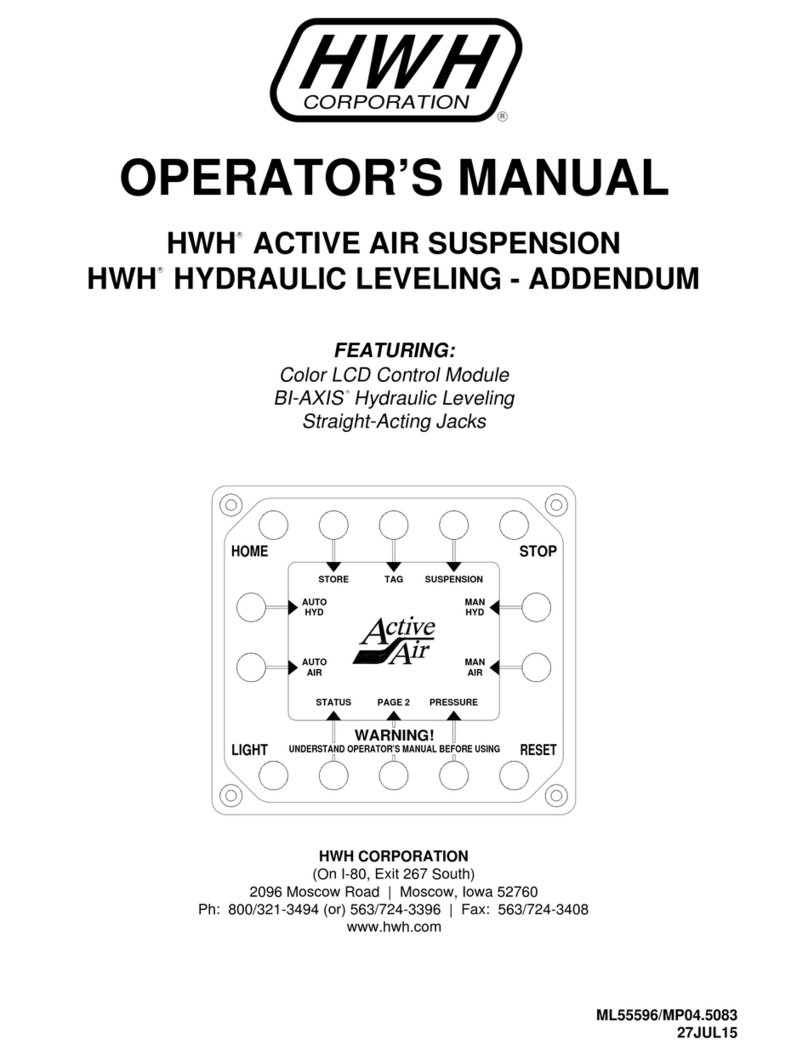

CONTROL BOX - SIDE VIEW

MAY BE DIFFERENT

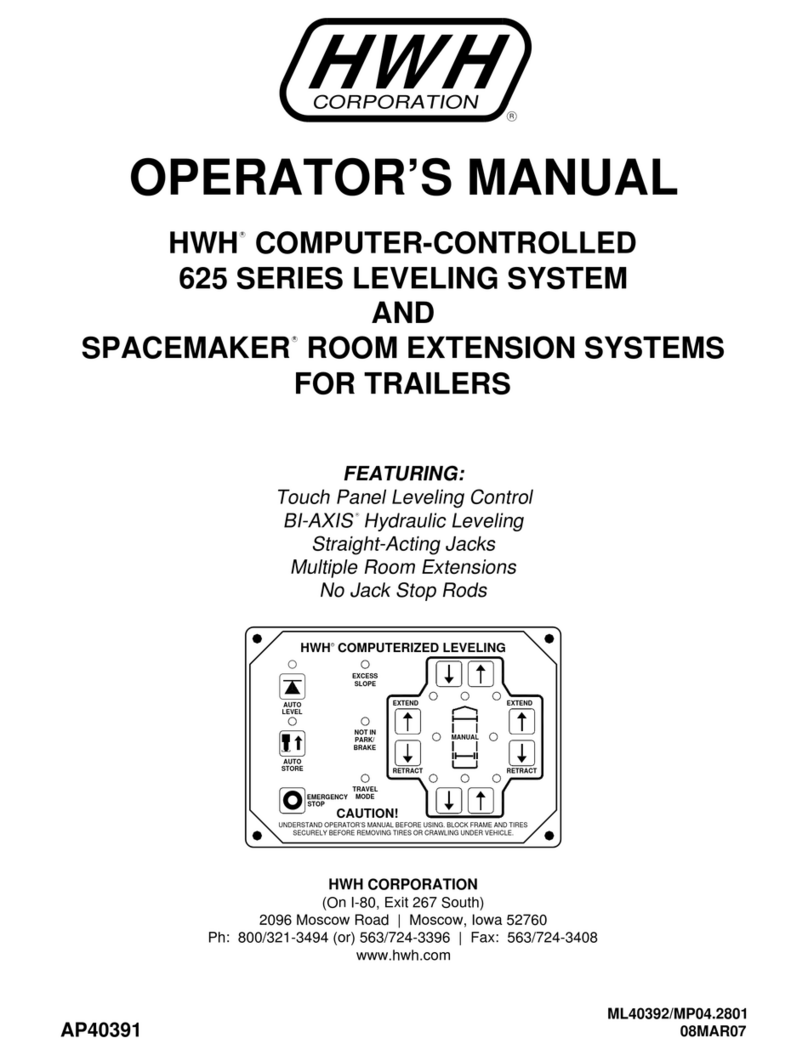

NOT IN PARK/BRAKE CHECK

Set the park/brake. Switch the ignition to the "ACC" or "ON"

position. Push the "ON/OFF" switch toward "ON". Release

the parking brake and confirm that the "PARK" indicator light

comes on. Reset the parking brake. The "PARK" indicator

light should go out. Switch the ignition to "OFF".

THE COACH WHEELS SECURELY SO THE COACH

CANNOT ROLL FORWARD OR BACKWARD.

CAUTION: WHEN MAKING THIS CHECK, BLOCK

If any of the above checks or inspections reveal a problem

or if there are other problems or questions, consult a

qualified RV repair center, your vehicle or coach

manufacturer, or HWH CORPORATION for service or repair.

07MAR07

MP44.1501

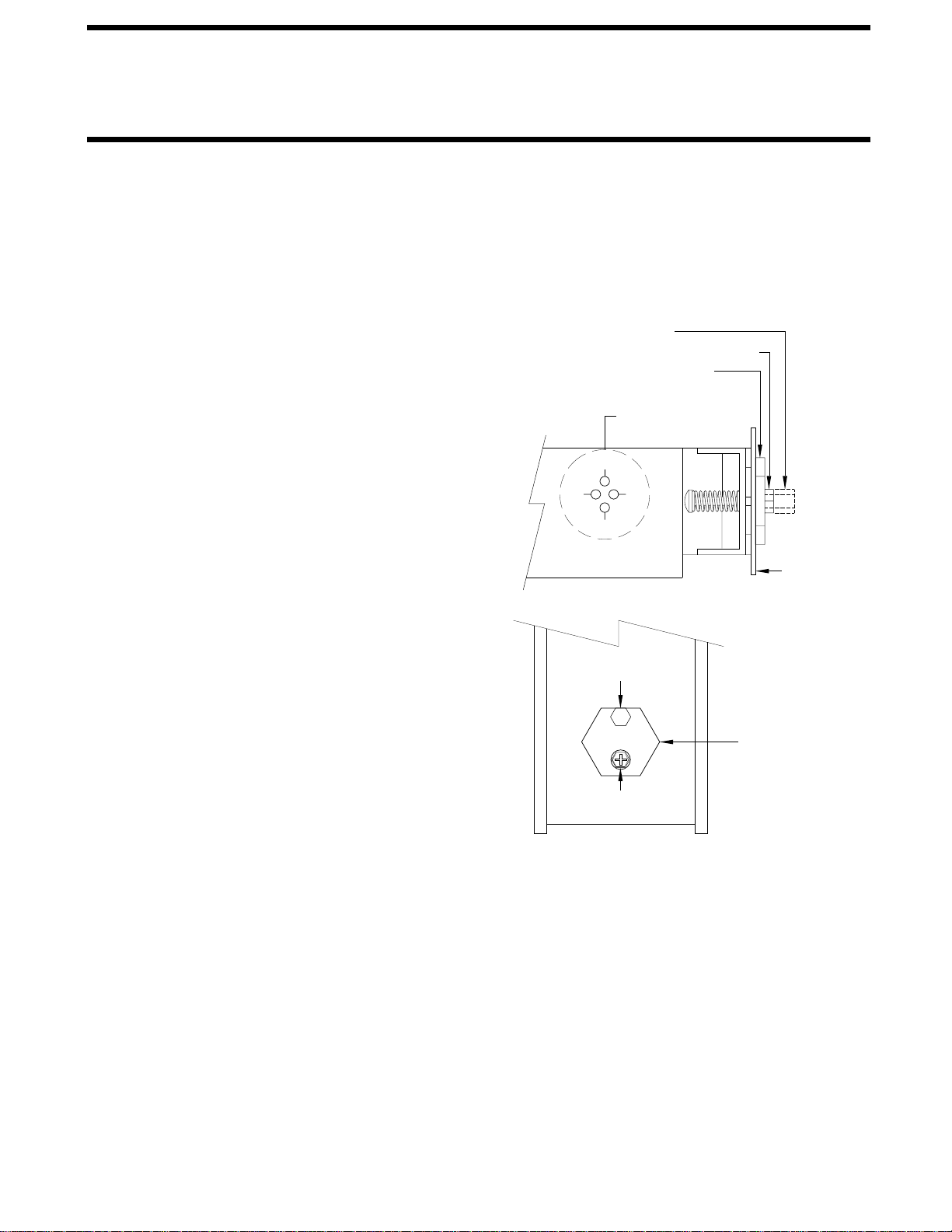

ADJUSTMENT

NUT (7/8" or 3/4")

BOX WALL

CONTROL

SCREW (Phillips or 1/4")

ADJUSTMENT

NUT (5/16")

ADJUSTMENT

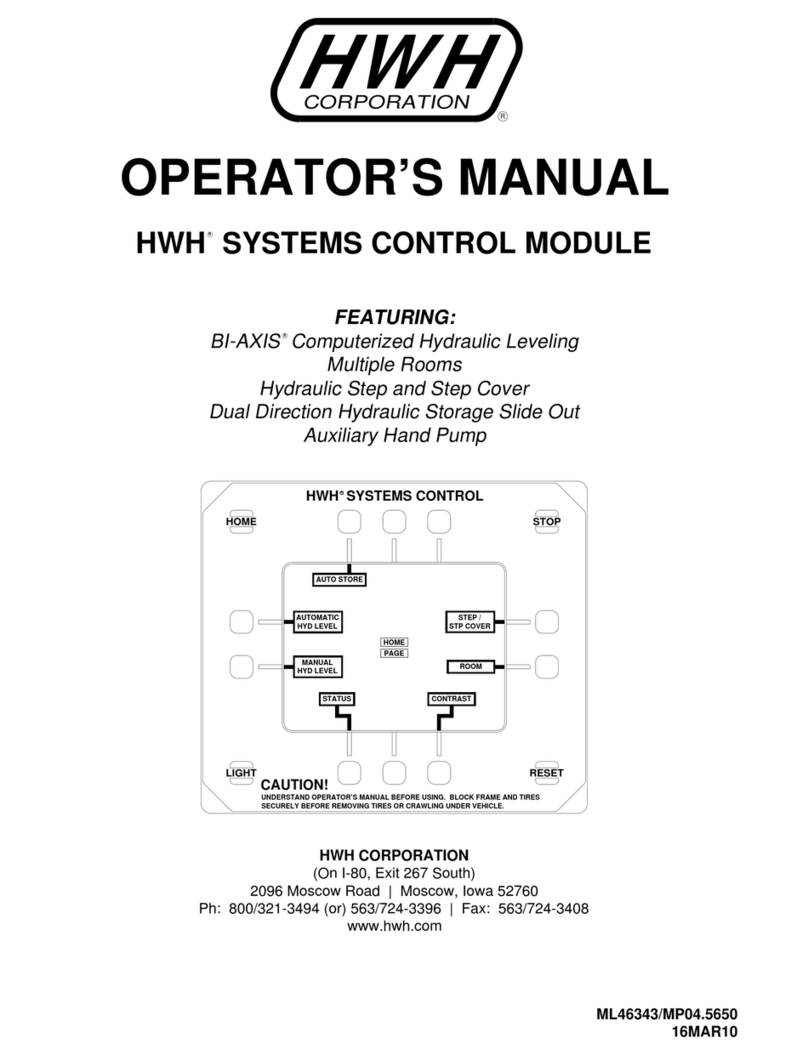

SENSING UNIT ADJUSTMENT

adjustments first, then hold the adjustment nut from moving

while making the A-C adjustment.

wrench and a philips screw driver will be needed.

needed. A 7/8", 3/4" or 5/16" socket w/driver or box end

Touch Panel, manual adjustments to the Sensing Unit are

properly adjusted. If there are yellow LEVEL lights lit on the

are no yellow lights lit on the Touch Panel, the sensing unit is

With the vehicle level according to the bubble level, if there

Control Box. If two LED’s are on, it is best to make the B-D

be a problem with the Sensing Unit or the mounting of the

be turned more than 3/4 turn to turn the LED out, there may

to be turned more than 1/2 flat or the adjustment screw has to

screw will turn out LED’s A and C. If the adjustment nut has

the adjustment nut to turn out LED’s B and D. The adjustment

to the drawing below. The Sensing Unit is adjusted by turning

There are four LED’s on the Sensing Unit, A,B,C and D. Refer

Control Box is mounted to the power unit/valve assembly.

The Sensing Unit is mounted inside the Control Box. The

level the vehicle until the bubble is centered.

level, ignoring the yellow LEVEL lights on the Touch Panel,

that is to be level. Using the Leveling System and the bubble

the freezer floor or upon whichever surface within the vehicle

Level the vehicle by placing a bubble level in the center of

the vehicle, the front is still low. This means the front

"tweaking" process until the system levels the vehicle

touch panel. Recheck with a level. Repeat the

relevel the vehicle using the yellow level lights on the

the front up more. Again, unlevel the vehicle then

the front yellow light to stay on slightly longer to bring

instructions for LED’s A, B, C, and D. This will allow

the OPPOSITE direction that is given in the above

Move the adjustment for that light very, very, slightly in

which sensing unit light is the front light, A-B-C or D.

yellow level light is turning off too soon. Determine

properly.

Example: After the initial adjustment and releveling

sensing unit, ignoring the LED’s on the sensing unit.

yellow level lights go out, instead just "tweak" the

needed, DO NOT try to adjust the sensing unit until the

LEVEL lights. Recheck the level. If more adjustment is

lights are on. Level the vehicle according to the yellow

vehicle to an unlevel position so one or two yellow

IMPORTANT: When all 4 LED’s are off, move the

If LED (D) is lit: Turn the adjustment nut CLOCKWISE

If LED (B) is lit: Turn the adjustment nut COUNTER

If LED (C) is lit: Turn the adjustment screw CLOCKWISE

If LED (A) is lit: Turn the adjustment screw COUNTER

NOTE: If opposing LED’s are lit, there is a problem with

until the LED is off.

CLOCKWISE until the LED is off.

until the LED is off.

CLOCKWISE until the LED is off.

the Sensing Unit.

ADJUSTMENT NUT (7/8" or 3/4")

ADJUSTMENT SCREW (Phillips or 1/4")

ADJUSTMENT NUT (5/16")