Contents

1. Mechanism......................................................................................................................................1

1.1 Notes for Your Safety ...........................................................................................................1

1.2 Description ............................................................................................................................1

1.3 Identification..........................................................................................................................1

1.4 Transport and Unpacking.....................................................................................................2

1.5 Accessories Supplied...........................................................................................................2

1.6 Preparations for installing the barfeeder............................................................................2

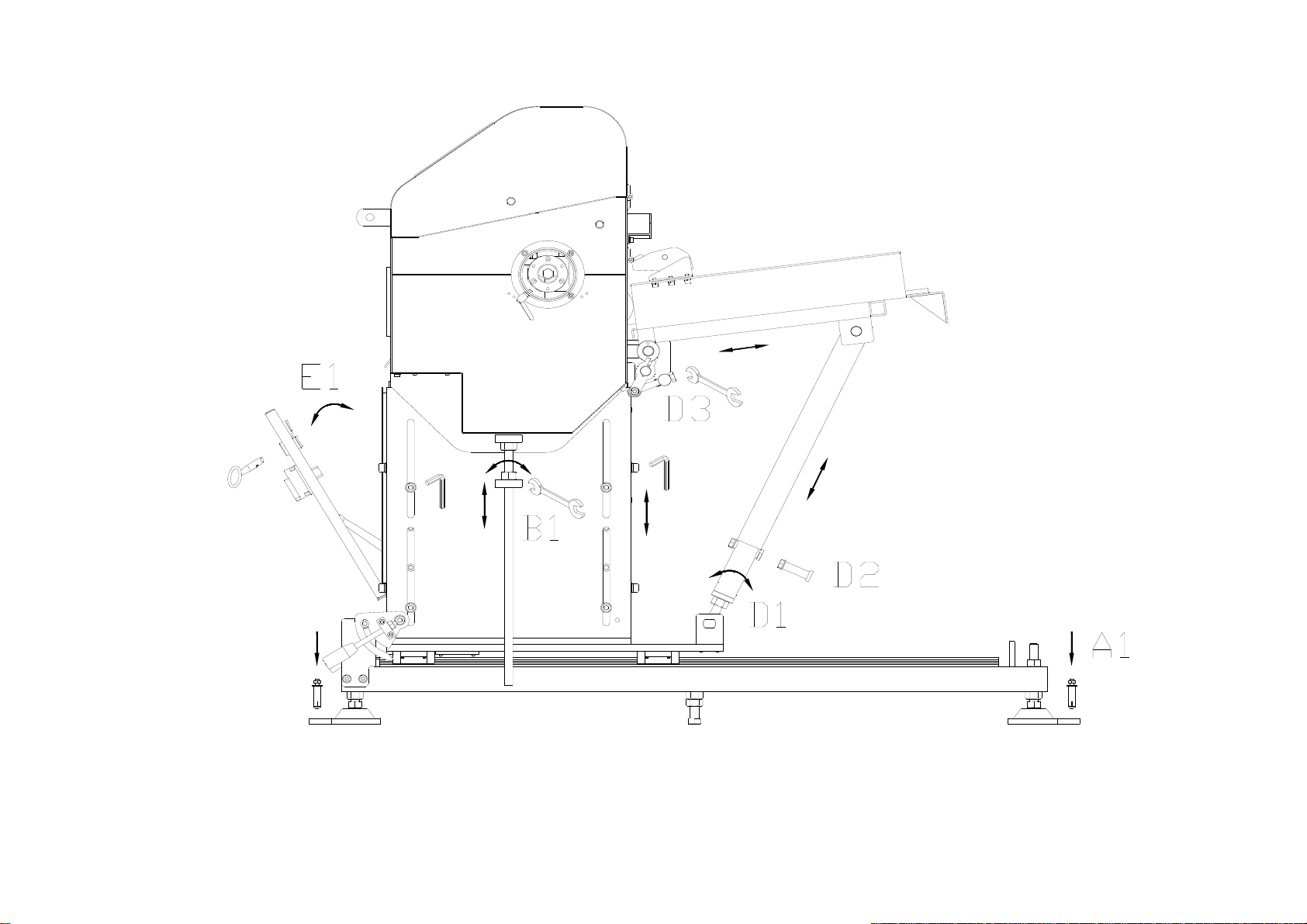

1.7 Mounting, Anchoring and Alignment ..................................................................................3

1.8 Changing the Pushrod Position...........................................................................................4

1.9 Retraction of the Barfeeder for Spindle Service.................................................................4

1.10 Material Rack Height and Diameter Adjustment...............................................................4

1.11 Maintenance ........................................................................................................................4

Figure 1 – Floor Plan ...........................................................................................................5

Figure 2 – Assembly Plan....................................................................................................6

Figure 3 – Manual Adjustments..........................................................................................7

Figure 4 – Changing Pushrod Piston.................................................................................8

Figure 5 - Retracting The Barfeeder..................................................................................9

Figure 6 - Transportation by forklift truck........................................................................10

Figure 7 - Transportation by crane/hoist cables.............................................................11

Figure 8 – Greasing the Ball screw ..................................................................................12

2. Operation Panel............................................................................................................................13

2.1 Power On and First Screen ................................................................................................13

2.2 Select Manual / Auto mode.................................................................................................14

2.3 Manual operation ................................................................................................................15

2.4 Auto cycle............................................................................................................................16

3. User Setup ....................................................................................................................................22

3.1 User Setup Introduction .....................................................................................................22

3.2 BAR TYPE / Diameter..........................................................................................................24

3.2.1 Bar Type.....................................................................................................................24

3.2.2 Bar diameter Setting.................................................................................................25

3.2.3 Material Selection .....................................................................................................25

3.2.4 Push torque Adjustment ..........................................................................................26

3.3 Component Length .............................................................................................................27

3.4 Position Setup.....................................................................................................................28

3.4.1 End of Bar Position..................................................................................................28

3.4.1.1 Spindle length Setup......................................................................................29

3.4.1.2 Clamping length Setup...................................................................................29

3.4.2 Loading selection .....................................................................................................30

3.4.3 Pushrod retract Position.........................................................................................32

3.5 Feeding type........................................................................................................................34

3.5.1 Sub spindle Pull.................................................................................................35

3.5.2 Barfeeding with / without Turret......................................................................38

3.6 Back Stop ............................................................................................................................50

3.7. Shaft Load...........................................................................................................................54

3.8 Chucking mode...................................................................................................................56

3.9 Center line correction.........................................................................................................57

3.10 Barfeed Programs.............................................................................................................58

3.10.1 Ways To search DATA Address ............................................................................58

3.10.2. To Save MMI Data to DATA 01 ..............................................................................60

3.10.3. To Transfer DATA 10 to MMI Data Base...............................................................64

3.10.4. To Reset DATA 10..................................................................................................66

3.11 Other ..................................................................................................................................68

3.11.2 Eject remnant.......................................................................................................68