4Getting to know your Hypervolt Technical Specication

Product Informat on

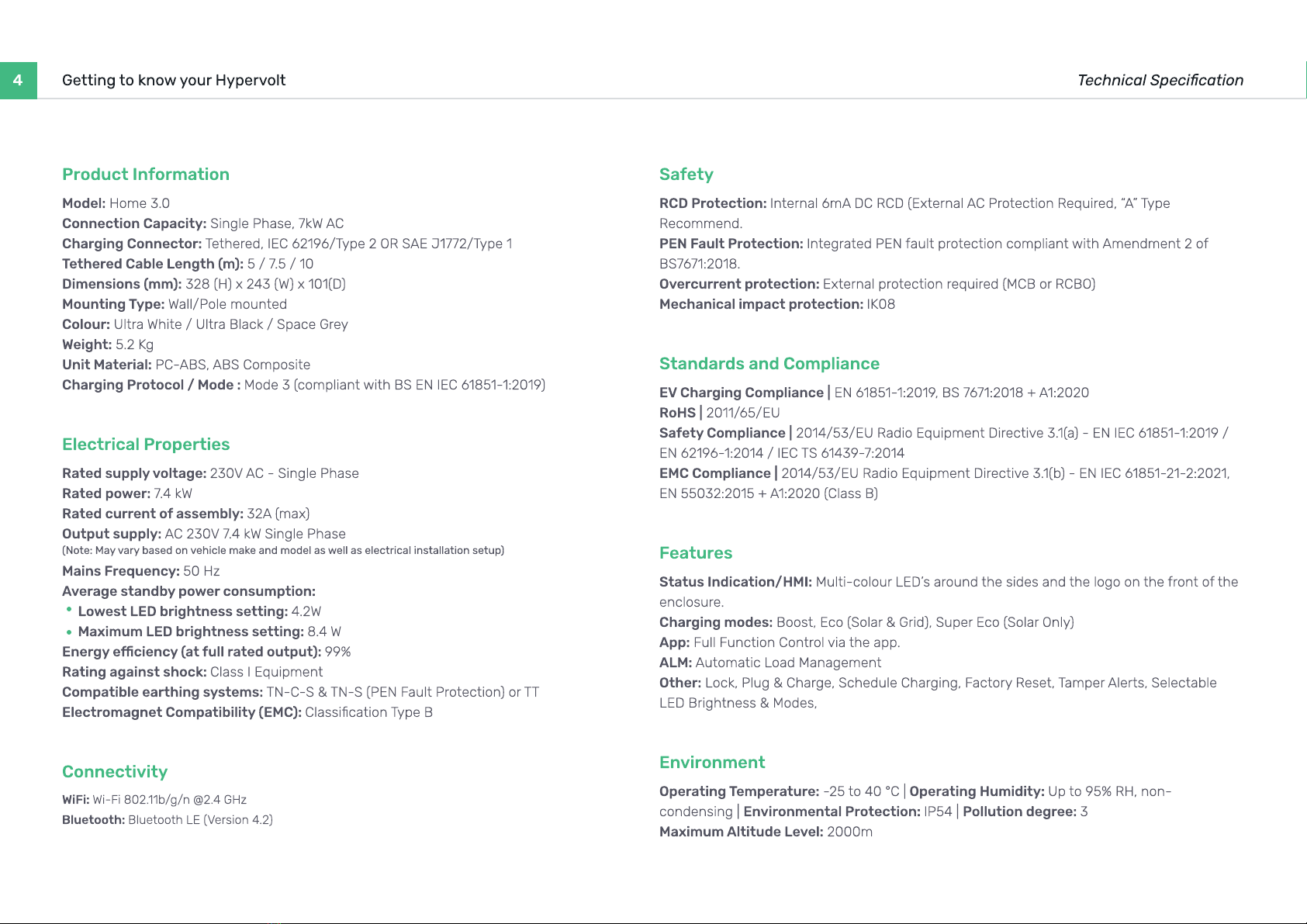

Model: Home 3.

Connect on Capac ty: Single Phase, 7kW A

Charg ng Connector: Tethered, IEC 62196/Type 2 OR SAE J1772/Type

Tethered Cable Length (m): 5 / 7.5 / 1

D mens ons (mm): 328 (H) x 243 (W) x 101(D

Mount ng Type: Wall/Pole mounte

Colour: Ultra White / Ultra Black / Space Gre

We ght: 5.2 K

Un t Mater al: PC-ABS, ABS Composit

Charg ng Protocol / Mode : Mode 3 (compliant with BS EN IEC 61851-1:2019)

Safety

RCD Protect on: Internal 6mA DC RCD (External AC Protection Required, “A” Type

Recommend

PEN Fault Protect on: Integrated PEN fault protection compliant with Amendment 2 of

BS7671:2018

Overcurrent protect on: External protection required (MCB or RCBO

Mechan cal mpact protect on: IK08

Standards and Compl ance

E

V

Charg ng Compl ance

|

EN 61851-1:2019, BS 7671:2018

+

A1:2020

Ro

H

S

|

2011/65/E

Safety Compl ance

|

2014/53/EU Radio Equipment Directi

v

e 3.1(a) - EN IEC 61851-1:2019 /

EN 62196-1:2014 / IEC TS 61439-7:201

EMC Compl ance

|

2014/53/EU Radio Equipment Directi

v

e 3.1(

b

) - EN IEC 61851-21-2:2021,

EN 55032:2015

+

A1:2020 (Class B)

Features

Status Ind cat on/

H

MI: Multi-colour

L

ED

’

s around the sides and the logo on the front of the

enclosure

Charg ng modes: Boost, Eco (Solar

&

Grid), Super Eco (Solar Only

A

pp:

F

ull

F

unction Control

v

ia the app

A

LM: Automatic

L

oad Managemen

Other:

L

ock, Plug

&

Charge, Schedule Charging,

F

actory Reset, Tamper Alerts, Selecta

b

le

L

ED Brightness

&

Modes,

Env ronment

Operat ng Temperature: -25 to 40

°

C

|

Operat ng

H

um d ty: Up to 95

%

RH, non-

condensing

|

Env ronmental Protect on: IP54

|

Pollut on degree:

Ma

x

mum

A

lt tude Level: 2000m

Connect v ty

W F : Wi-

F

i 802.11

b

/g/n

@

2.4 GH

B

luetooth: Bluetooth

L

E (

V

ersion 4.2)

Electr cal Propert es

Rated supply voltage: 230

V

AC - Single Phas

Rated po

w

er: 7.4 k

Rated current of assembly: 32A (max

Output supply: AC 230

V

7.4 kW Single Phas

(N

ote

:

Ma

y v

a

ry

bas

e

d

on ve

h

i

c

le

ma

ke

a

n

d

m

o

d

el

as

well

as

ele

c

tri

ca

l in

s

t

a

ll

a

tion

s

etup

)

Ma ns Fre

q

uency: 50 H

A

verage standby po

w

er consumpt on

Lo

w

est LED br ghtness sett ng: 4.2

Ma

x

mum LED br ghtness sett ng: 8.4

Energy e

c ency (at full rated output): 99

Rat ng aga nst shoc

k

: Class I Equipmen

Compat ble earth ng systems: TN-C-S

&

TN-S (PEN

F

ault Protection) or T

Electromagnet Compat b l ty (EMC): Classi

cation Type B