HyQuest Solutions Pty Ltd

Tipping Bucket Flow Gauge TB1L 100-07 Issue 1:26/9/2016

i. Site Selection

Water Flow measurements are intended to be representative of the actual water running out of

the pipe. Some of the more important factors which influence the representativeness of a

gauge are as follows:

Site the gauge on a level surface.

Site should have adequate protection from strong winds.

Water coming out of the pipe should not contain any particles that

could block the collector.

Provide suitable ground surface to avoid splashing into the gauge.

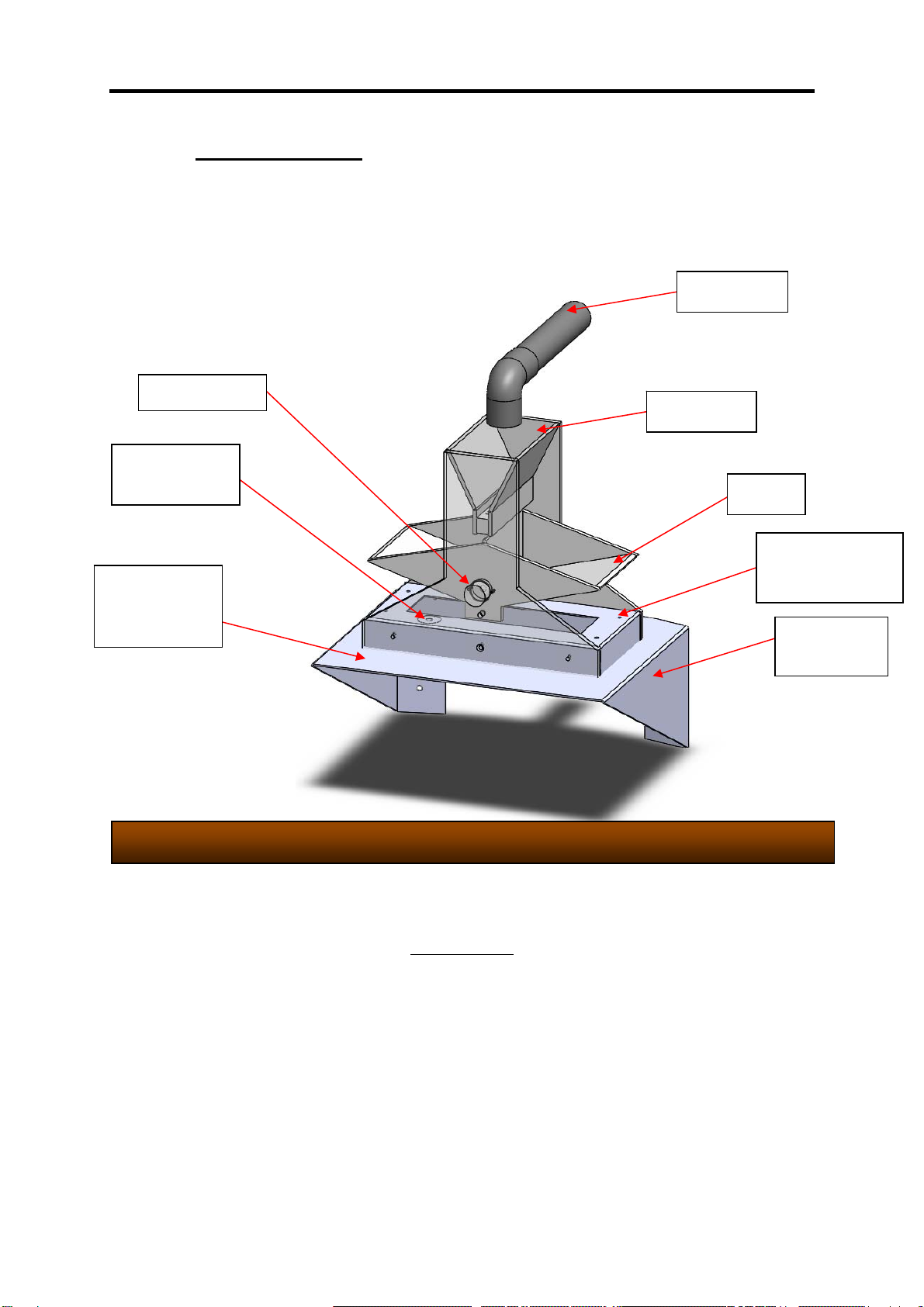

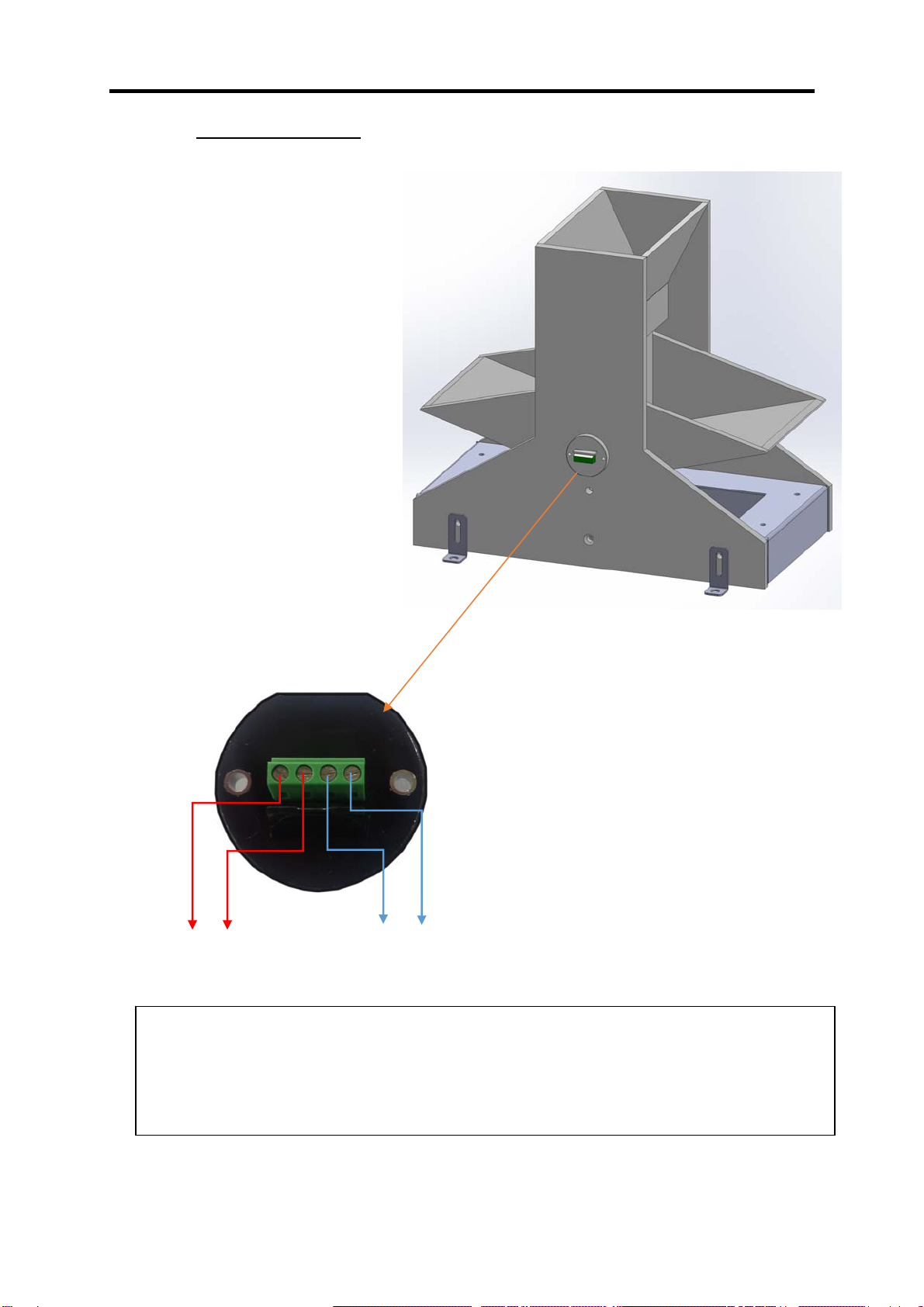

ii. Setting up

Install the gauge on a suitable bracket or shelf, as suggested in

Diagram 1,2 & 3.

The gauge is provided with a level. Proceed to level by ensure the

bracket the gauge is mounted on is level

Connect lead to the Flow gauge terminals, in accordance with Diagram

3, and to the recording device, in accordance with manufacturer’s

instruction manual.

V. TEST OPERATION

Manually tip the bucket a number of times, ensuring that each tip is

being recorded and that the tilting mechanism is operating freely.

VI. MAINTENANCE

The only routine maintenance required is cleaning. The following items should be checked

regularly for cleanliness:

Collector area

Interior of bucket

Top surface of adjusting screws

Lubrication of the pivot using (WD40 or equivalent)