HyQuest Solutions Pty Ltd

DDT700

© Copyright

Page 2 of 15 ISSUE 6: March 20

CONTENTS

Contents

CONTENTS...................................................................................................................................................................2

INTRODUCTION .........................................................................................................................................................3

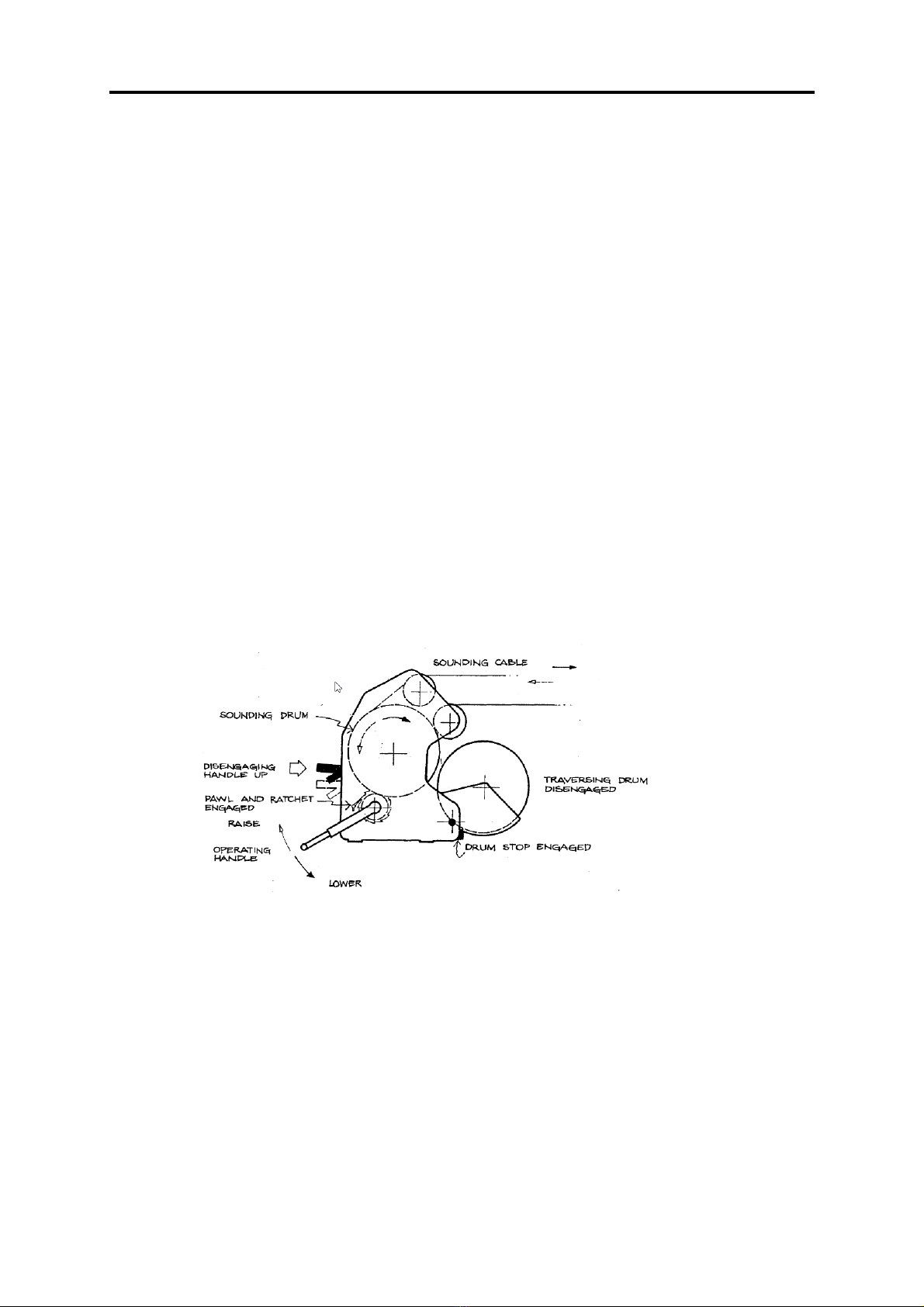

OPERATION.................................................................................................................................................................3

Initial set up & Operational Procedure: ...................................................................................................................3

Dismantling Procedure: ...........................................................................................................................................5

Winch Mode: ...........................................................................................................................................................5

Traversing Mode: ....................................................................................................................................................6

COUNTERS ............................................................................................................................................................7

MAINTENANCE .......................................................................................................................................................... 7

Lubrication ..............................................................................................................................................................7

Weston Brake ..........................................................................................................................................................7

INSPECTION..........................................................................................................................................................8

Electrical System .....................................................................................................................................................8

FAULT FINDING .........................................................................................................................................................9

SPECIFICATIONS...................................................................................................................................................... 10

FITTING C1 CONNECTOR TO AMERGRAPH CABLE......................................................................................... 11

FITTING ANGLE PLUG TO AMERGRAPH CABLE.............................................................................................. 12

Angle Plug Assembly AP02.......................................................................................................................................13

FITTING TEE PLUG TO AMERGRAPH CABLE.................................................................................................... 14

Angle Plug Assembly TP02 .......................................................................................................................................14

APPENDIX A ............................................................................................................................................................ 15

INSTALLATION....................................................................................................................................................... 15