System Description

Table

of

Contents

<Contents>

1. System Description .................................................................................................................

···

..

·

..

············3

1.1. Introduction .......................................................................·

..

··

..

·....·······....·

..

···

....···

..

··..

·

..

·....····

..

········

..

··3

1.1.1. Features .......................................................................................................................................... 4

1.1.2. Installation ...........................................................................·....·

..

··

..

·

..

····

..

·..........

··..

·....

··..

·

..

·....·....

··4

1.1.3. Man-Machine Interface ...................................................................····

..

·

..

··

..

··

....

··

..

·····

..

·

..

········

..

··4

1.1.4. Communication Bus System ............................................................................................

··

....·

..

4

1.1.5.

Unmanned

Monitoring ..........................................................................····....·....·····

..

····

..

·

..

·....·

..

·4

1.1.6. System Structure .....................................................................

···

....······

..

···

..

·····

..

···

..

··

..

·······

..

····

..

···6

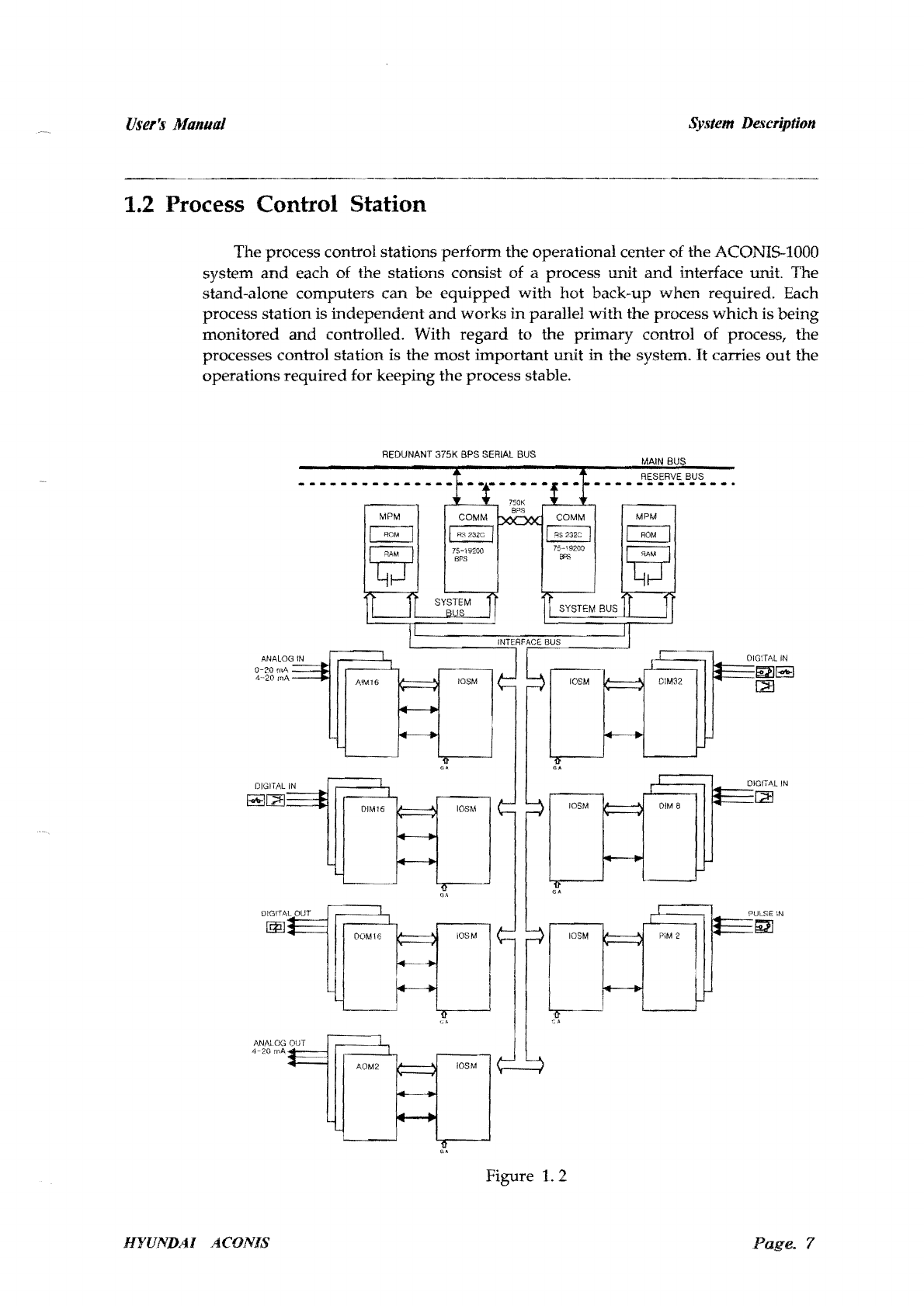

1.2. Process Control Station ............................................................................................·..........·

....

··

....····7

1.2.1. Process

unit

.....................................................................

···

..

·

..

·

..

·····

..

··

......

···

..

····

..

·

..

·

..

··..

·

..

·····

..

······8

1.2.2. Interface unit .................................................................................................................................. 8

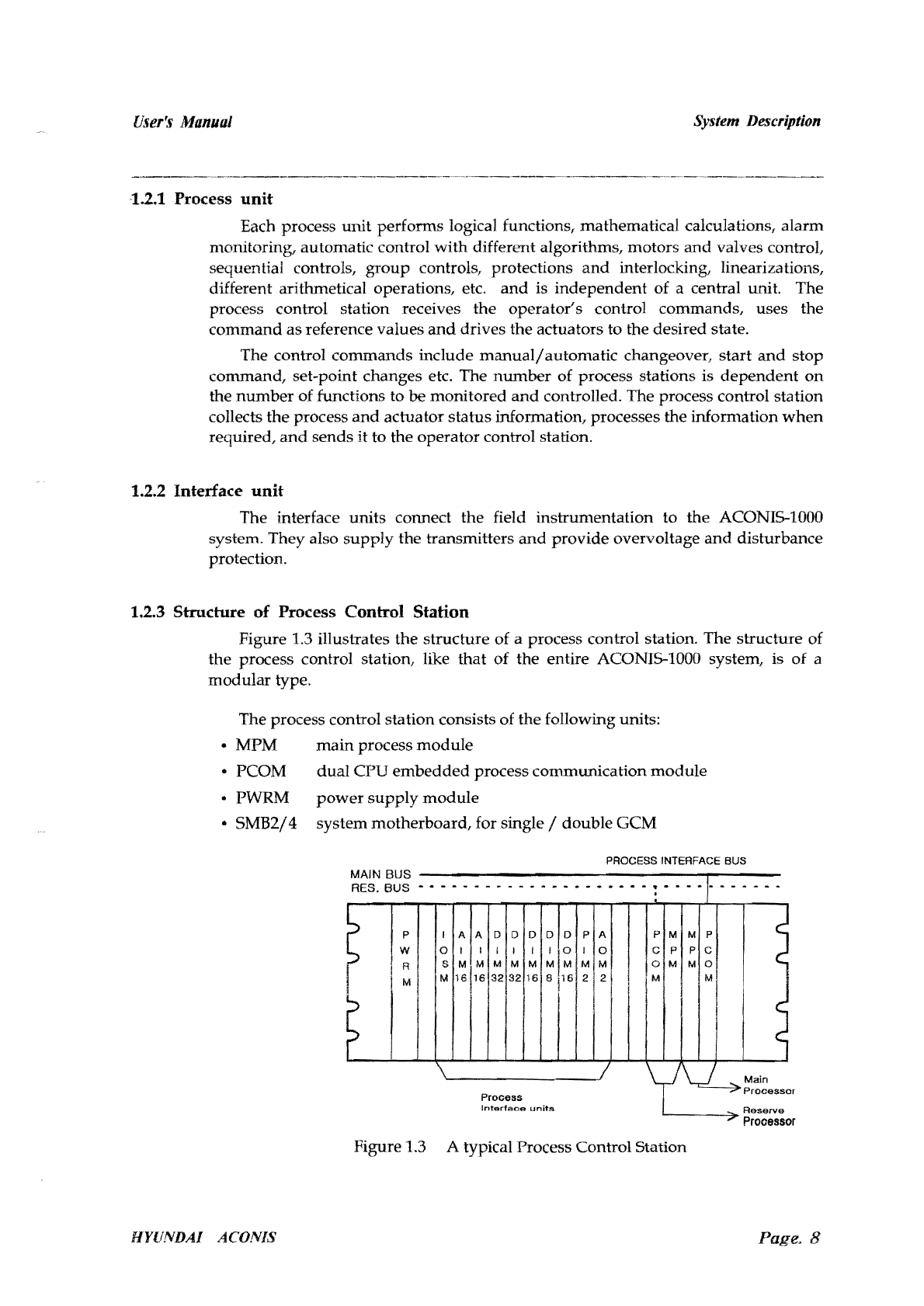

1.2.3. Structure of Process Control Station ....................................................................................... 8

1.3. Server Control Station ........................................................................................................................ 9

1.3.1.

Hardware

Structure

of

Server control Station ....

··

..

·

..

·........·

....

·

..

·

..

·....·

..

···

................·......·

..

10

1.4. Miniature Remote Terminal Unit

and

Real-Time Control Station ·......·

..

·

....

·......·......·....·

..

·

..

11

1.4.1.

Hardware

Structure .............................................................................

··

..

······....·....·····..........

··

..

·11

1.5. Operator Control Stations .....................................................................·····

..

·····

..

···

..

········

..

··

..

····

..

·

..

·12

1.5.1. Video Client .................................................................................

··

..

··

..

·

..

·

..

··

..

··

......·

..··

....

··

..

·

..

··

..

··12

1.5.1.].

Hardware

Structure

of

Video Client

··

....·

..

·....···

..··..··

....·

..

···

..........·......·....····......·

..

·

..

·12

15.1.2.

Display Structure of Video Client ......·

..

·..........····........................·......·......

··

............·...... 13

1.5.2. Alarm Server ..............................................................................................·....·

..

·........·

..

·

..

·

..

·......·14

1.5.2.1.

Hardware

Structure of Alarm Server ·....·

..

···

..

·........

··

......

··

..

·

..

·

....

·

..

·

....

·......................·

..

·14

1.5.2.2. Alarm Printing ........................................................................·····..........

··..··

....

···

..

·····

....

···

..

14

1.5.2.3. Log Printing .........................................................................

··..

·

..

·

..

······........·······

..

·....······

..

·15

1.5.2.4. EAS Management ...............................................................········

..

·

..

··········

..

·····

..

·········

....

···16

1.5.3. Operator Control Station's Communication ....

··

..

·............·......·

..

·

....

·......·......

··..

·........·........·17

1.6. Communication Interface Gateway ....·

....

··

....

·

....

·

....

·

....

··

..........

··

..

·......

·18

1..6.1.

l1ardware structure ...................................................................

···

..

·

..··

..

····....···············

..

··········

..

18

Page. 2

HYUNDAI

ACONIS