the noise of the machine.

Keep people and animals away from the work area. Children and people who do not know how to use

this tool should not touch it and handle it.

Use the product only under daylight or under good artificial light.

When using the machine, always wear full protective equipment including a helmet, protective

mask, ear protection, gloves, non-slip footwear and protective clothing.

Wear appropriate clothing. Do not wear loose or unbuttoned shirts. Do not wear jewellery that may come

in contact with moving parts. If you have long hair, tie them down and wear an appropriate safety helmet.

Do not operate the product with damaged guards or shields not in place.

Keep hands and feet away from the unit at all times, especially when turning the tool off and on.

Do not use the tool in an area where ventilation is poor. Gas emissions can cause injury.

Do not work when it rains and in bad weather. Do not use the tool in damp locations.

Do not use the tool in the presence of flammable liquids or gases.

Caution: The machine releases gases when it is used. Avoid coming into contact with these gases.

Keep the work area clear. Before working, inspect the work area and remove any materials or objects

that could cause accidents.

Do not force the tool.

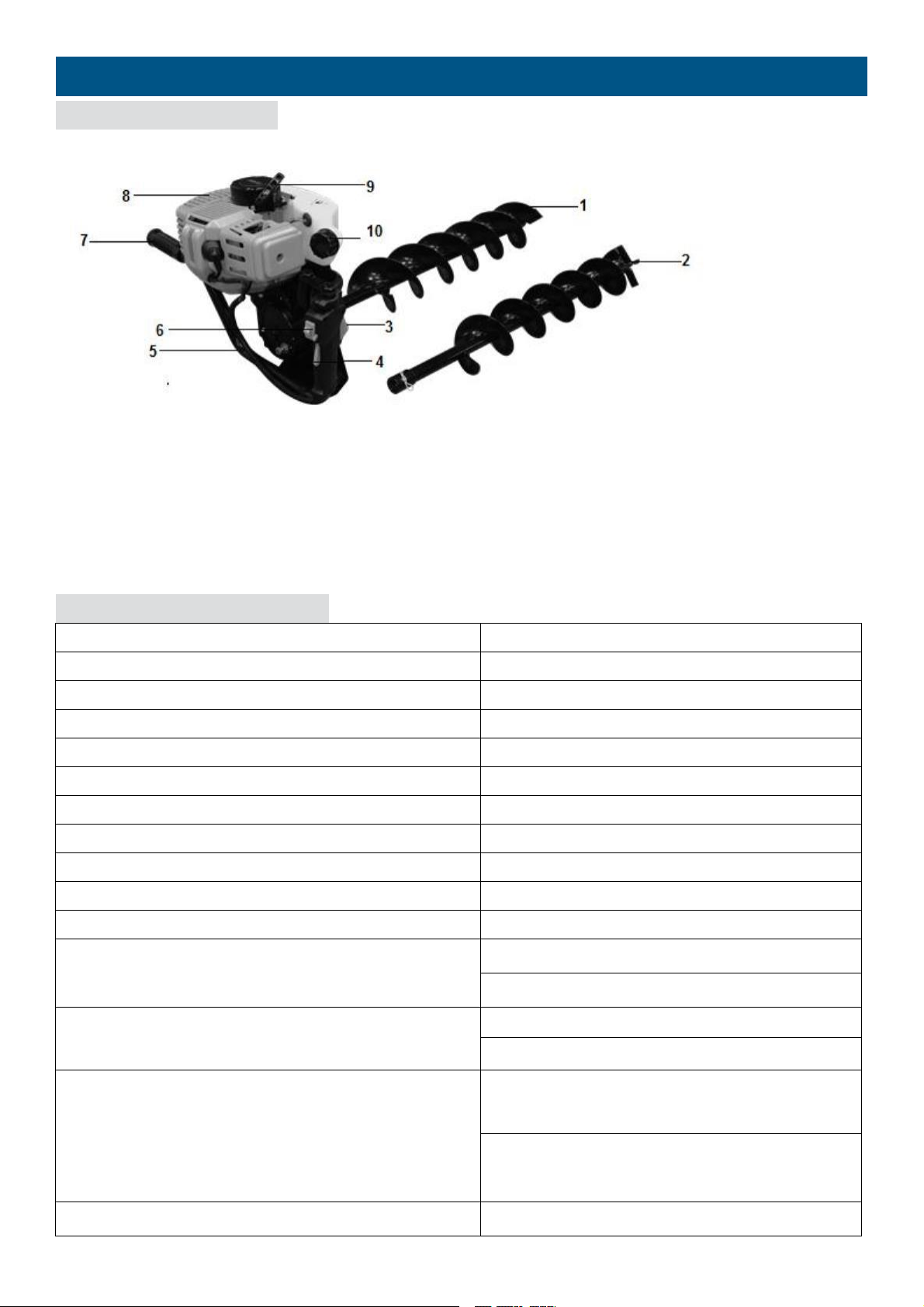

Keep the tool and drill clean for better and safer performance. Follow the instructions in this manual to

lubricate and change the accessories.

Always inspect the machine before and after operation. If the tool is damaged or faulty, stop using the

tool and bring it to an authorized service for inspection and repair.

Turn off the tool after use, when you leave it unattended, when changing these accessories and before

servicing.

Keep handles dry, clean and free from oil and grease.

Be concentrated when using the tool. Look at what you do, make sense and do not use the tool when

you are tired.

Place the equipment in a well-lit area on a flat, stable, dry and well-ventilated surface, away from

flammable materials and with plenty of space for sparking and sharpening waste.

Do not allow anyone, especially children, to come within a radius of at least five meters around the work

area when all work is in progress.

Immediately stop the tool in the event of a malfunction of the motor or the ON/OFF button or in case of

unusual noise.

When not in use, the machine must be stored in a dry, locked place out of the reach of children.

Before using the product and after any shock, please check it for signs of wear or damage.

Please carry out repairs if necessary.

Always switch off the machine:

oEvery time you leave the device unattended;

oBefore releasing an obstruction;

oBefore checking, cleaning or working on the product;

oAfter hitting a foreign object;

oEvery time the product starts to vibrate abnormally.

Pay attention to foot and cutting injuries.

Inspect and regularly service the product. Repairs should be carried out only by an authorized

service center or a similar qualified specialist.

When not in use, store the product out of the reach of children.

Children should not play with plastic bags, sheets and small parts! Keep them out of the reach of children.

There is a danger of suffocation!

Always carry the tool while holding the handle, never the drill.

04