i-MO Öko 2000 User manual

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

GmbH

Öko 2000

User Guide

Öko 2000

1

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

2

GmbH

Contents page

1. Safety instructions 4

2. Schedule of connection 5

2.1 Schedule of connection of effluent hose 6

3. Starting up 7

3.1 Connecting up the circuit board washing machine 7

3.2 Installation of the filter unit 7

3.3 Removing the air from the deioniser cartridge 7

3.4 Cleaining agent dosage 8

3.5 Operating control front panel 9

3.6 Cleaning 10

1. Preparation 10

2. Cleaning 10

3. Removing the washed load 10

4. Operating summary 11

4.1 Main menue 11

4.2 Start program 11

4.3 Program new / alter 12

4.4 Program delete 14

4.5 Setup 14

4.5.1 Date / time setting 14

4.5.2 Change languare 14

4.5.3 Monitor Sprayarm on/off 15

4.5.4 Detergent 15

4.5.4.1 List of detergent setting / alter 15

4.5.4.2 Assign detergents to dosing pump 16

4.5.4.3 Suck detergent 16

4.5.4.4 Alter pumpfactor 16

4.5.5 Alter code 16

4.6 Network settings 17

5. Program flow 18

5.1 Step of cleaning 18

5.2 Step of rinsing 19

5.3 Step of drying 20

5.4 End of program 20

5.5 Example of program 21

5.6 Indications and manifestations 22

5.6.1 oaming 22

5.6.2 Exchange of filter unit 22

5.6.3 Exchange of the air filter 22

5.6.4 Cleaning of the dirt trap 22

5.6.5 Cleaning of the screen insert 22

5.6.6 Exchange of the sprayarms 22

5.6.7 Exchange of the dosing hoses 23

5.6.8 Version with white dosing head 23

5.6.9 Version with black dosing head and transparent lid 24

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

3

GmbH

Continuation Contents page

6. Interfaces / network connection 25

7. Error messages 26

8. Function of the connector plugs 30

9. Technical informations 31

Dear Customer,

we are glad because of your interest in our products.

Thank you for the confidence you have shown us.

Please attend technical safety instructions on this page, before startup

of your new cleaning machine for circuit boards Öko 2000.

Now we wish you success at cleaning of your products.

If you have questions, you can get in contact with us anytime.

IMO GmbH

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

4

GmbH

1. Safety Instructions

The washing machine ÖKO 2000 must only be connected to a supply protected

by a fuse rated not more than 16A! Please see for the power supply voltage

at the type label on the machine.

The installation of the machine should be arranged from employees, who are familiar

with installation of such or similar machines. Our technicians will like to help you.

Please only use cleanser, which you have bought at our company.

Our cleansers are coordinated especially at the cleaning requirements of that

cleaning machine for circuit boards. If you anyway should want to use an other cleanser,

please obtain an O.K. from our technicians. If you use external cleanser and you didn’t

get O.K. from us, you will loose guarantee for your machine, because such cleanser

can destroy the machine.

Please make sure, if your laundry is suitable for such cleaning processes. We assume no

liability for damages because of process, material and temperature compability on cleaned

circuit boards and components.

You can’t clean glas-tube fuses! Those components please fit after cleaning process.

Please regulary check the boarder of the bottom metal filter for traces of rust. These may

be caused by pieces of iron and may lead to contact corrosion on the stainless steel.

If you do not dry after cleaning process, you have got to start every day after work a separat

drying process. So your can avoid damages of corrosion (rust) at the drying turbine.

The opened door to charge only with max. 25 kg (with extended grate and laundry)

Don’t use as work disk or seating. Don’t stand on it, there is danger of tilting!

To avoid water damage, the cleaning machine can be put into operation only in connection

with the external solenoid valve.

IMO GmbH Gässlesweg 6 D-75334 Strauben ard t Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.co m

5

GmbH

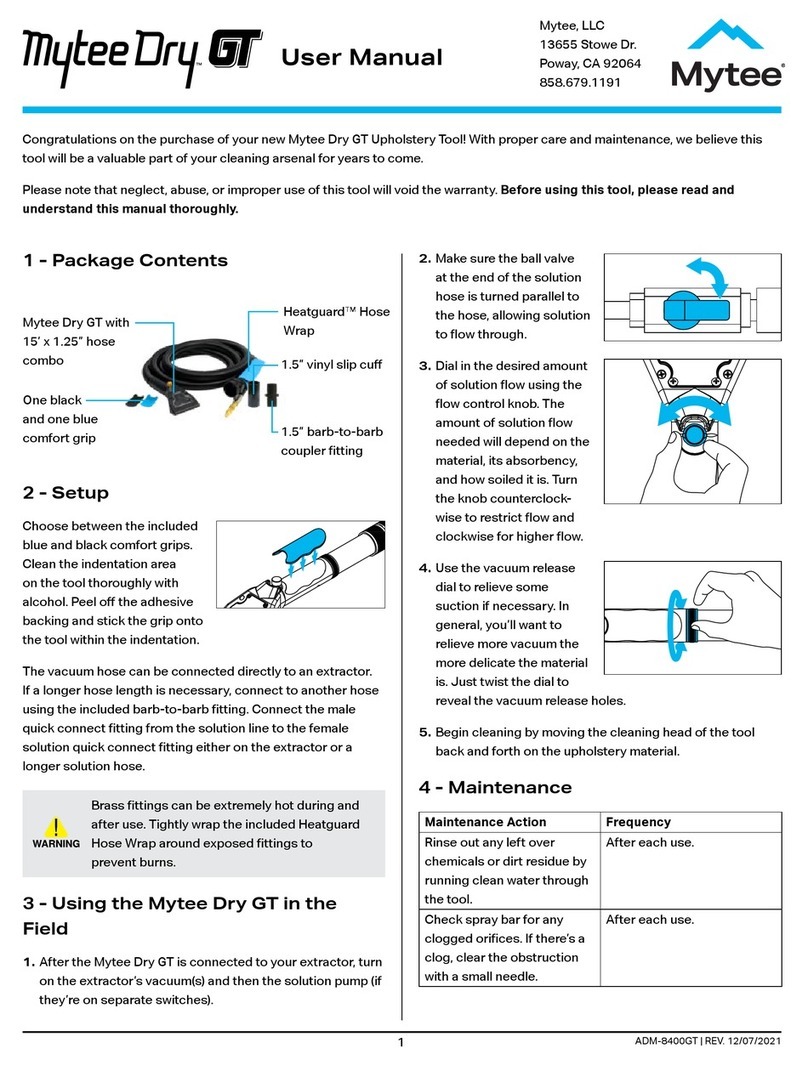

2.Schedule of connection Öko 2000

NE water deionizer with conductivity measurement

Back side

ÖKO2000

Filter candle

Filter housing

Waste water

Hose end in no

case lower than

the level

alternatively

detergent container

Observe local wastewater discharge

regulations

Network

Wastewater hose

Mount the filter cartridge at the height

of the upper edge of the machine.

Air filter

Dosing unit

Connections

Water inlet

live - with

230V 50Hz when filling

Water desalination unit

Fresh water

inlet

Solenoid valve directly on

permanently installed water

connection / Observe

installation direction

T-piece brass

E.C. Measuring cell LM-LED

1804.0000.39

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

6

GmbH

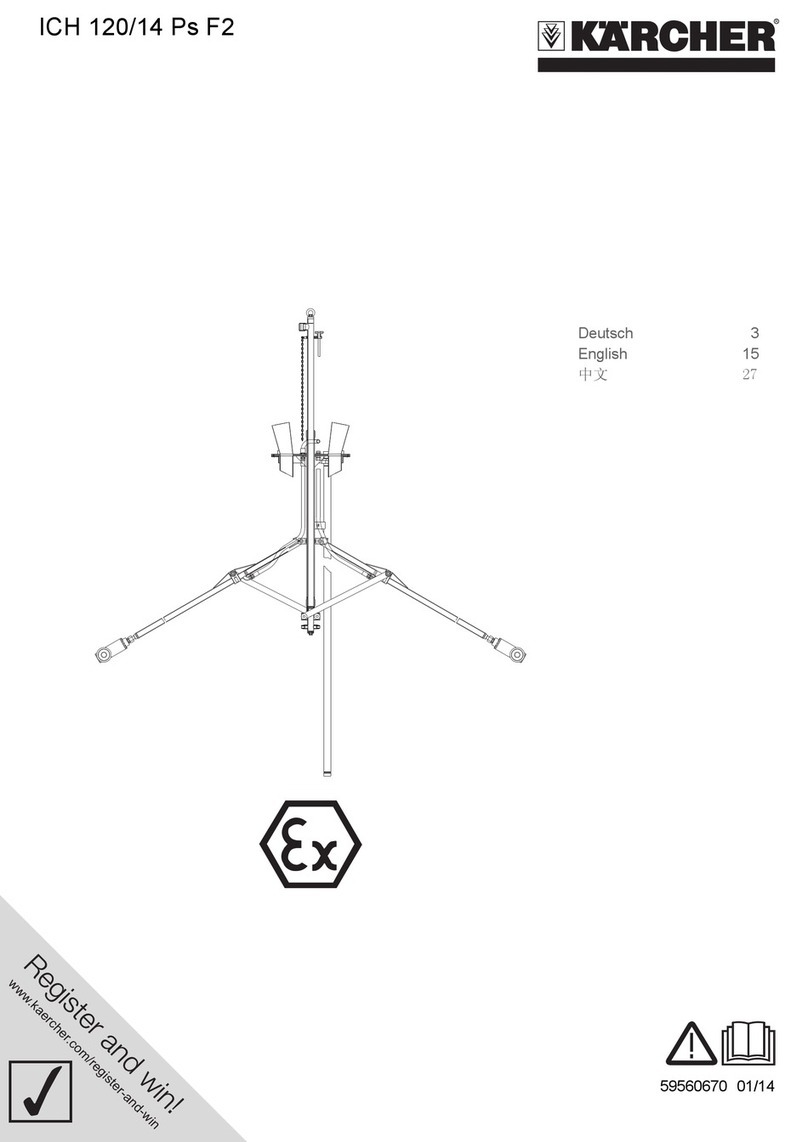

End of waste water hose

min. 300 mm

End of waste water hose

Alternative

min. 300 mm

2.1 Schedule of connection of effluent hose

or to avoid an uncontrolled drain of water out of the cleaning system, the open, and thereby

aerated end of waste water hose has to be mounted after the waste water filter at least

30 cm above the installation surface of the ÖKO 2000.

If the hose ends lower, it may be possible that because of the vacuum lifting effect, the

water drains out of the machine.

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

7

3. Starting up

3.1 Connecting up the circuit board washing machine

The circuit board washing machine ÖKO2000 must be set up in a horizontal position.

Water supply: Connect up according to the connection diagram page 5.

The water pressure should be at least 2 bar and not more

than 8 bar.

The machine must not be connected to a no-pressure

water heater.

Drain: Connect up according to the connection diagram page 5.

The local waste water regulations have to be observed!

Elect. connection: The washing machine must only be connected to a

220V - 230V AC supply though a correctly installed mains socket.

3.2 Installation of the filter unit

The supplied filter unit has to be mounted on the wall at or above the top of the machine

(see connection diagram).

3.3 Removing the air from the deioniser cartridge

Please notice, that by starting up of a new deioniser cartridge the air inside removes by itself.

This can cause error messages, which you have to disregard.

The program interrupts and is to start again. This procedure is to retry till the cleaning progam

runs through (normal case 5-10 times).

or a faster deaeration a temporary operation with reverse flow direction is possible.

Therefore, the connections „inlet“ and „outlet“ have to be changed.

After some filling operations of the system, the connections have to be mounted at the

right positions again.

The remaining air can be removed at the vent valve in the cover.

GmbH

ormal operation

fresh water to Öko 2000

3.4 Cleaning agent dosage

Liquid components

Powder:

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

8

GmbH

Liquid components are dosed automatically during cleaning via the built-in dosing pumps,

as programmed, automatically during the cleaning process.

(Activator AT can also be added manually to the washroom before the cleaning process).

Dispense powdered cleaning agent, as shown, onto the inside of the open front flap before

starting the cleaning process, or when prompted by the equipment.

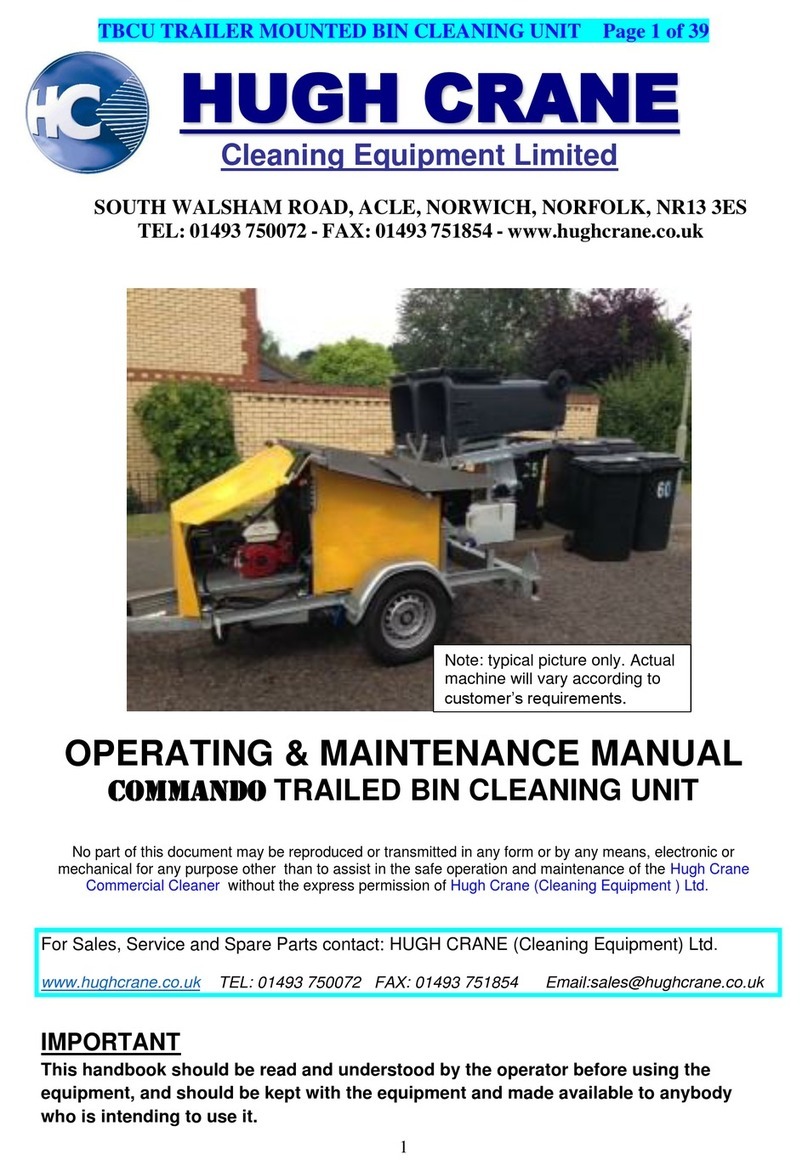

3.5 Operating Controll Front Panel

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

9

GmbH

Following washing programs are setted ex work, but can be altered if required:

Program 1:

Cleaner: Component A+ and Mix 3

Program 2:

or cleaning pcb-boards with only colophony flux and drying afterwards.

Cleaner: Mix 3, ca. 40gr

Program 3:

Cleaner: Mix 3

Program 4:

Only drying

Pointer upward / increase value

Confirm / continue

Pointer downward / decrease value

Back / interruptionOn / off switch

3.5.1 Removing the upper support grid

For large items to be washed, the upper support grate with spray arm can simply be removed.

Then the entire interior height is available for cleaning.

To remove the upper support grate, pull it out as far as it will go, then lift slightly and

upwards at an angle. It is inserted in the opposite direction.

The water supply to the upper spray arm is automatically closed by a ball

valve during removal. This means that the complete spraying capacity is available at

the lower spray arm.

For cleaning printed circuit boards in general, also suitable for removing

of "no clean" flux residues.

With subsequent drying.

For cleaning lightly soiled objects, e.g. degreasing

and dust removal with subsequent drying.

3.6 Cleaning

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

10

GmbH

- Open the front door

- Dosage of the cleaning agent (see item 3.4)

- Place the frames carrying the circuit boards into the washing space

1. Preparation

- Close the front door

- Switch on ÖKO 2000

- Select “start program” and confirm

- Use pointer up / pointer down to select the required program

- Confirm the required program with “ENTER”

- Machine begins to run; the program sections are indicate on the display

- inish message after the end of the cleaning program

2.Cleaning

- Switch off the machine

- Open the front door

- Remove the wash frames with the circuit boards from the wash space

Warning: washed load is hot!

- Close the front door

3.Removing the washed load

Please note:

The machine works only when the front door is closed properly. To open the front

door immediately interrupts the program sequence. This is indicated by flashing on

display. During the heating-up phase the display shows the elapsed time of

cleaning or rinsing as follows: ‘--’ . After the temperature has reached its debit, the

programed time starts. The elapsed time is shown on the display.

4. Operating summary

unction of keys

On/Off switch

To increase value / use pointer up

To decrease value/ use pointer down

Interruption / return to menue item

Confirmation / select menue item

4.1 Main menue

4.2 Start Program

IMO GmbH Gässlesweg 6 D-75334 Strauben ard t Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

11

GmbH

I

0

a

or selecting cleaning program and starting

Revise present cleaning program or construct a new one

Delete present program

Set up equipment

Display of network parameter, for example IP adress

Manual drain

Select or to choose stored programs and press

to start.

a

programme start

no. 1

4.3 Program new / alter

IMO GmbH Gässlesweg 6 D-75334 Strauben ard t Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

12

GmbH

Present cleaning program:

Can be altered

Empty storage space:

Inclusion of a new cleaning program is possible

Press / to select number of new program /

to alter existing program

Use for editing mode

Attention: Numbers of program 1-20 possible.

By selecting and using / several pages can leaf through.

Attention: If the actually step is emtpy, it can’t be paged down.

Type of programm step: can be altered by selecting

Attention: possible types of programm:

cleaning rinsing drying empty(cleared)

Type of program step ‘cleaning’:

Required water temperature in the range of 20°C up to 70°C.

Current time in the range of 5 up to 40 minutes, after the required

temperature of water and required dosage of detergent.

Select for detergent with

Chose of dosage pump for program step (DOS1 or DOS2).

The assigned detergent is shown on display (see page 15).

Quantity of dosed cleaner in proportion to filled quantity of water

(not with foaming or defoaming detergent; see page 20).

Addition of cleaning powder: yes / no switched by .

If ‘ yes’ is adjusted, program stops and gives message for manual

dosage of cleaning powder.

a

a

a

a

a

programme new / alter

no. 2 engaged

no. 3 engaged

no. 4 empty

no. 5 empty

no. 6 empty

no. 7 empty

programme nr. 4

step no.: 01

type: empty

step No.: 01

type: cleaning

temperature: 30°C

duration: 5min

detergent: ==>

programme no. 2

DOS1: component A

quantity: 3,0%

add.

detergent powder: no

programme no. 2

or

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

13

GmbH

Step of program ‘rinsing’

Required temperature of water between 20 and 70°C

Running time between 2 and 20 minutes after heating water of

required temperature.

EC-limit between 10 and 200µS or ‘without’

(Measurement for conductivity for this step of rinsing)

Indication: If a conductivity limit is indicated, so it will be assinged

the same ec-limit to all following rinsing processes.

If a preceding rinsing process exists with an ec-limit , then this can’t

be changed in the current rinsing process.

Step of program ‘drying’

Required air-temperature at the air outlet of blower

range between 50 and 100°C.

Required drying level of the warm air within the range of stage 1 to 8.

At stage 8 you get a drying with the lowest rest of humidity.

Time within the range of 0 to 600 minutes, in which after reaching

dry level of air drying continues, for example for drawing parts such

as socket contacts drying completely.

Indication: After step of ‘drying’ no further step program possible.

Rules of program-construction:

- No further step of program after ‘drying’ possible.

- Between two program steps no empty (deleted) program step may be.

- After rinsing with EC-limit no cleaning step can follow. In the reversal conclusion also EC-limit can

not be assigned to a rinsing step before a cleaning step.

- If an EC-limit is assigned to a rinsing step, all following rinsing steps have the same EC-limit,

(the cleaning is adequate).

- If an EC-limit of a rinsing step is abode, so each further rinsing step will be overleaped, because

enough cleaning is reached.

- Maximal 10 program steps are possible.

step no.: 02

type: rinsing

temperature: 30°C

duration: 2min

ec-limit: 40µS

programme no. 2

step no.: 03

type: drying

temperature: 90°C

drying grade: 5

run after: 10min

programme no. 2

4.4 Programme delete

4.5 Setup

4.5.1 Date / time setting

4.5.2 change Language

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

14

GmbH

Select and to choose program from settled list of

cleaning program and confirm.

Select “YES” to confirm cancellation.

Adjustment of time and date for journal

Modification of language

Spray-arm-control on / off

Settings and maintenance of cleanings agents

and dosing pumps.

Code-input for access control

Select / and to choose time respect. date

Select / to change input (day/month/year resp.h/min).

Enter to go on.

Select and for the required language and

use to confirm.

a

a

a

a

no.1

no.2

no.5

no.7

no.8

no.9

programme delete

shall programme no.5

be deleted?

Yes

No

programme delete

time/date

language

spray-arm control: on

detergent settings

code changing

setup

date: 16.06.2004

time: 10:59

date/time

deutsch

english

language

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

15

GmbH

4.5.3 Monitor spray arm on / off

4.5.4 Detergent

4.5.4.1 List of detergent setting / altered

Select / to choose “spray-arm control” and enter

to shift.

Indication: Monitor spray arm should be regularly be activate,

otherwise the regulation of foam and resp. regocnition-blockade

of the lower spray arm don’t work.

Cleaner programs which use foaming resp. defoaming

can not be started, if the monitor spray arm is switched off.

Create or change register of detergents

Assign detergent from register to a dosing pump

Aspirate detergent manual

Indicate power off pump

Enter / to leaf through the memory and select

to choose an input.

Enter / to alter numbers and letters. Select for the

next input.

Kind of detergents in respect of his attributes will be tuned here.

Possible settings are:

foaming:detergent produce foam, therefor it must be dosed

gradually during the cleaning process until a little “foam-carpet”

is formed.

defoaming:

detergent is for counteract foaming.

(f.e. A foaming cleaner is used at the same time)

During the cleaning process detergent will be dosed if necessary.

neutral:detergent has no attributes as below. It will be dosed

proportional to the filled quantity of water.This proportion will be

setted by construction of the cleaning program.

empty:register contains no detergent.

Indication: If the cleaner will be used in other cleaning

program, the modification interferes in the concerned program.

a

a

a

set up

time/date

language

Monitor spray arm: on

detergent settings

code changing

detergent

list of detergent

assign detergent

suck detergent

pump correction

list of Detergent

no.: 1

name: component A

type: neutral

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

16

GmbH

4.5.4.2 Assign detergents to dosing pump

4.5.4.3 Suck detergents

4.5.4.4 Alter pumpfactor

4.5.5 Alter Code

Select / and press to choose the required dosing pump.

Afterwards press / , leaf the register of the available

detergents and choose with

Indication: The same detergent can’t be assigned to both

dosing pumps.

Select / to choose the required dosing pump and affirm .

The appropiate dosing pump is pumping as long as the -key

is pressed.

This function is need to flow the dosing tubes f.e. after replacement

of a used up detergent box.

Input of pump-capacity per dosing pump.

To aquire the quantity, pump up the water one minute by

suction-function and measure quantity of water.

The pump capacity should be checked once a year and

by supply corrected.

Indication: Not the capacity of dosing pump will be altered,

the capacity of dosing pump will be advertised to the control

of the equipment.

Used dosing hoses may be replaced.

Please find more information on chapter 5.6.7

By using a code-number you can make an access restriction of

the equipment. Code-no. 0000 this function is switched off.

The following fuction will be protected with the code-number:

programme new/alter

programme delete

changing of code

a

a

a

a

assign detergents

DOS1: no.: 2

component B2

DOS2: no.: 1

component A

asorb detergents

Dosage 1

Dosage 2

pump correction

DOS1: 150ml/min

DOS2: 150ml/min

alter code

code number: 0000

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

17

GmbH

4.6 etwork settings

After connecting the system with the companys network, ÖKO2000 obtains

an IP adress over the DHCP-System.

This adress and additional network parameters are shown here.

Some more information to the network connection you will find at point 6 (page 24).

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

18

GmbH

5. Program flow

5.1 Step of cleaning

Water will be filled.

The filled-in quantity of water is shown.

Water will be heated and detergents are dosed.

The updated water temperature and the target temperature

are shown.

Water will be circulated, time of cleaning runs.

The exhausted time and the target duration is shown.

End of cleaning step, water is drained.

programme no. 2

water: 0,7 litre

temp.: 20°C / 50°C

duration: --min / 20min

DOS1: component A 0,5%

cleaning

programme no. 2

temp.: 20°C / 50°C

duration: --min / 20min

DOS1: component A 0,5%

cleaning

programme no. 2

temp.: 50°C / 50°C

duration: 14min / 20min

DOS1: component A 0,5%

cleaning

programme no. 2

temp.: --°C / 50°C

duration: --min / 20min

DOS1: component A 0,5%

cleaning

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

19

GmbH

5.2 Step of rinsing

Water is filled:

The filled-in quantity of water is shown.

Water is heated.

The actually temperatur of water and the target

temperature is shown.

Water is be circulated, rinsing time runs.

The exhaused time and the target duration are indicated.

Conductivity of water is measured:

If there is no limit quoted, this part is dropped.

If the value of measure is smaller than the desired adjusted value,

all following rinsing-steps been void. If the value of measure is

higher than the desired adjusted value, the next rinsing step goes

on.

If there is no further rinsing step programmd, an error message

is issued. The rinsing program must be repeated, because an

inadequate result is to apprehend.

End of rinsing step, water is drained / pumped out.

programme no. 2

temp: 23°C / 40° C

duration: --min./ 10min.

Ec-value: --µS / 30µS

water: 0,7 litre

temp.: 20°C / 40° C

duration: ---min./ 10 min.

Ec-value: ---µS / 30µS

rinsing

programme no. 2

temp.: 40°C / 40°C

duration: 8 min./ 10 min.

Ec-value: --µS / 30µS

rinsing

programme no. 2

rinsing

temp.: --°C / 40°C

duration: --min./ 10 min.

Ec-value: 13µs / 30µS

programme no. 2

rinsing

temp.: --°C / 40°C

duration: --min./ 10min.

Ec-value: --µS / 30µS

programme no. 2

rinsing

IMO GmbH Gässlesweg 6 D-75334 Strauben ardt Tel.: 070 82 491 80 Fax: 604 36 www.imo-ag.com info@imo-ag.com

20

GmbH

5.3 Step of drying

5.4 End of program

Air is heated:

The updated air temperature and the target temperature

is indicated.

Drying step runs:

After reaching of the target temperature beam of humidity

get shorter by proceeding of dryness..

Required dryness is reached, afterward drying runs.

In case of an after drying time appointed (duration higher than 0)

this time runs with reduced capacity of turbine.

The exhausted time and the adjusted duration are indicate.

Phase of cooling down:

The internal space is cooling down to 50°C.

Turbine runs with reduced capacity.

End of program.

Provided, that report is activate in Setup, it will be printed.

By opening the door or entering of -key the equipment

switched of.

I

0

temp.: 58°C / 90°C

humidity:

duration: ---min./30min.

programme no. 2

drying

temp.: 90°C / 90°C

humidity: +++++

duration: ---min./30min.

programme no. 2

drying

temp.: 90°C / 90°C

humidity:

duration: 12min./ 30min.

programme no. 2

drying

temp.: 54°C / 90°C

humidity:

duration 30min./ 30min.

programme no. 2

programme

finished

drying

Other manuals for Öko 2000

1

Table of contents

Other i-MO Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

General Pipe Cleaners

General Pipe Cleaners TheMetro operating instructions

Westfalia

Westfalia 86 98 98 Original instructions

JDS Uniphase

JDS Uniphase CleanBlast FCL-P1005 user manual

Uni-ram

Uni-ram UG400 Series manual

FRONIUS

FRONIUS Robacta Reamer Braze+ operating instructions

IPC Eagle

IPC Eagle APTA40015 instruction manual