!

!

SIDEWINDER PG. 7

PG. 6 SIDEWINDER

NOTE: High and low idle speeds may vary depend-

ing on the equipment on which the engine is used.

Refer to the equipment specifications.

Engine Oil

Check the engine oil daily before starting the

engine otherwise shortage of the engine oil may

cause serious damage to the engine such as

seizure.

•Place the engine on a level surface. Clean the

area around the oil gauge before removing it.

•Remove the oil gauge and wipe it with a clean cloth.

•Pour the oil slowly to “FULL” mark on the oil gauge.

•Insert the oil gauge into the tube WITHOUT

SCREWING IT IN.

•Remove the oil gauge to check the oil level.

The oil level should be between “ADD” and

“FULL” marks. Do not overfill.

•Install and tighten the oil gauge.

The following engine oils are recommended.

API Service Classification: SF, SG, SH, or SJ.

Oil Viscosity

Choose the viscosity according to the tempera-

ture as follows:

NOTE: Using multi grade oils (5W-20, 10W-30,

and 10W-40) will increase oil consumption.

Check oil level more frequently when using them.

Engine Oil Capacity

FH381V 1.5 L (1.6 US qt.) when oil filter is not removed

FH500V 1.7 L (1.8 US qt.) when oil filter is removed

FH541V 1.7 L (1.8 US qt.) when oil filter is removed

Oil Change

Change oil after first 8 hours of operation.

Thereafter change oil every50 hours.

•Run the engine to warm oil.

• Be sure the engine (equipment) is level.

•Stop the engine.

•Open the oil drain valve and drain the oil

into suitable container while engine is warm.

WARNING!

Hot engine oil can cause severe burns.

Allow engine temperature to drop from hot to

warm level before draining and handling oil.

Oil Drain Plug

•Close the oil drain valve.

•Remove oil gauge and refill with fresh oil

(See “Recommended Oils” on page 5).

• Check the oil level (see “Preparation” on page

3for oil level check).

Oil Filter Change

•Change the oil filter every 100 hours of

operation.

WARNING!

Hot engine oil can cause severe burns. Allow

engine temperature to drop from hot to warm

level before attempting to remove oil filter.

CAUTION! Before removing the oil filter,

place a suitable pan under filter connection.

•Drain engine oil into a suitable container.

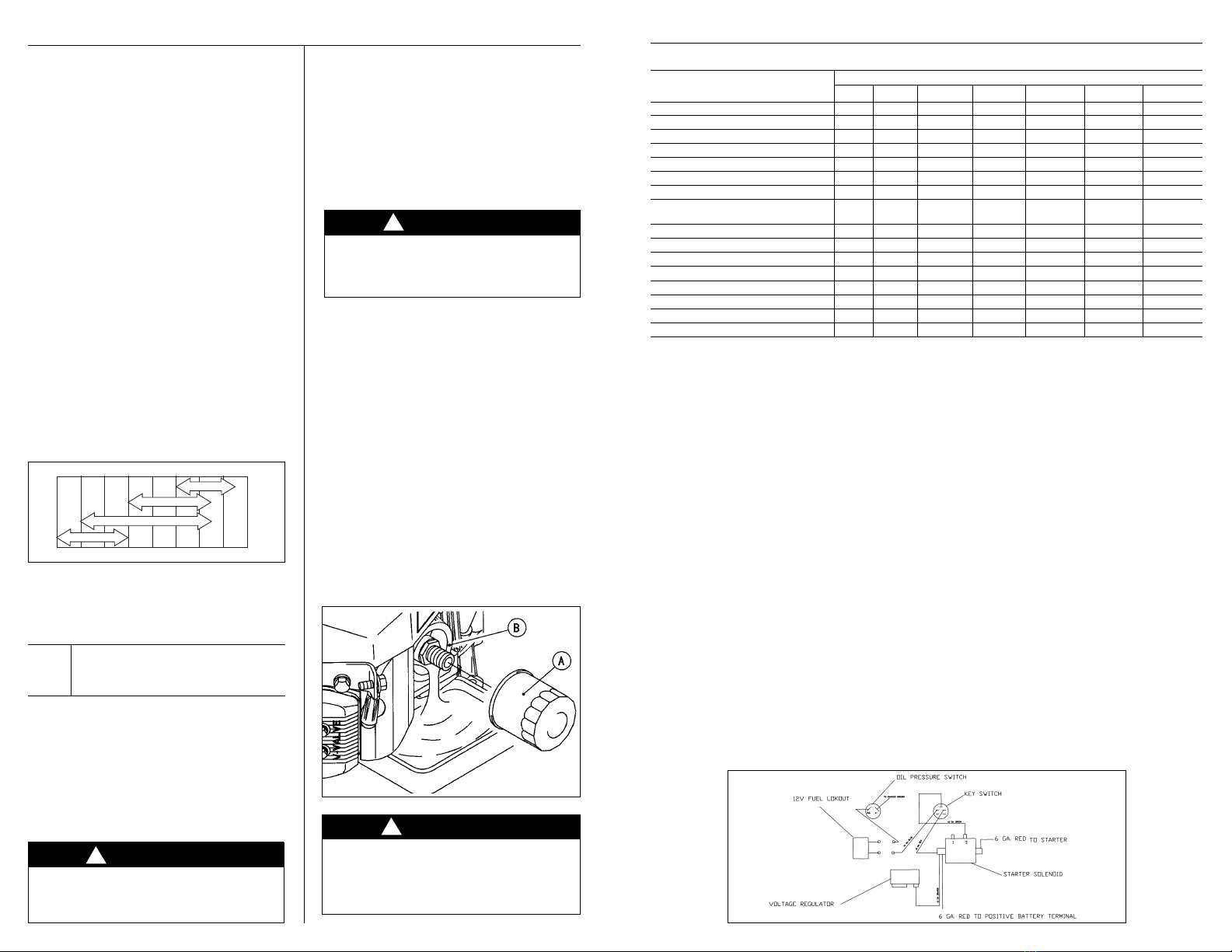

•Rotate the oil filter (A) counterclockwise to

remove it.

•Coat a film of clean engine oil on seal of new

filter.

•Install new filter rotating it clockwise until

seal contacts mounting surface (B). Then

rotate filter 3/4 turn more by hand.

•Supply engine oil as specified.

•Run the engine for about 3 minutes, stop

engine, and check oil leakage around the filter.

•Add oil to compensate for oil level drop due

to oil filter capacity (See “Oil Level Check”

on page 3).

WARNING!

Engine oil is a toxic substance. Dispose of

used oil properly. Contact you local authorities

for approved disposal methods or possible

recycling.

KAWASAKI ENGINE MAINTENANCE SCHEDULE

INTERVAL

MAINTENANCE Daily First 8 hr. Every 25 Hr. Every 50 hr. Every 100 hr. Every 200 hr. Every 300 hr.

Check and add engine oil •

Check for loose or lost nuts and screws •

Check for fuel and oil leakage •

Check battery electrolyte level •

Check or clean air intake screen •

Clean air cleaner foam element •

Clean air cleaner paper element •

Clean dust and dirt from cylinder and

cylinder head fins •

Tighten nuts and screws •

Change engine oil • •

Clean and gap spark plugs •

Change oil filter •

Replace air cleaner paper element •

Clean combustion chambers •

Clean and adjust valve clearance •*•

Clean and lap valve seating surface •

*After the 1st 50 hours

!

ENGINE TROUBLESHOOTING

COMMON PROBLEMS & PROBABLE CAUSES SOLUTIONS

Engine cranks but will not start

•Fuel cylinder is empty Refill cylinder

•Shutoff valve is closed Open valve

•Clogged, obstructed, kinked or cut fuel or vacuum line Remove obstruction or replace line

•Spark plug lead disconnected Connect lead to spark plug

•Faulty choke or throttle settings Set controls to correct positions

•Faulty ignition coil Replace coil

•Faulty kill switch Replace switch

•Faulty regulator Replace regulator

Engine starts hard

•Faulty choke or throttle settings Set controls to correct position

•Clogged, obstructed, kinked or cut fuel or vacuum line Remove obstruction or replace line

•Faulty regulator Replace regulator

•Low compression Have engine serviced by a trained technician

Engine will not crank

•Battery is discharged Charge or replace battery

•Loose or faulty connections or wires Tighten, repair or replace wires

•Faulty ignition key switch or starter control switch Repair or replace switch(es)

Engine overheats

•Incorrect fuel settings Have engine serviced by a trained technician

•Air intake filter screen or cooling fins clogged Clean and clear debris or replace filter

•Low oil level Check and add oil

Exhaust emissions or propane odor

•Carburetor or regulator setting incorrect Have engine serviced by a trained technician

•Dirty or clogged air filter Replace air filter

•Choke engaged Adjust to correct settings

•Loose fittings, clamps or hoses cracked, hoses cut or leaking Tighten or seal; check with soap and water solution,

if bubbles appear, part is still leaking; replace

KAWASAKI ENGINE BATTERY START WIRING DIAGRAM

-20˚C -10˚C 0˚C 10˚C 20˚C 30˚C 40˚C

-4˚F 14˚F 32˚F 50˚F 68˚F 88˚F 104˚F

SAE5W-20

SAE30

SAE40

SAE10W-30/SAE10W-40