ibaPADU-8-O Manual

Issue 1.9 3

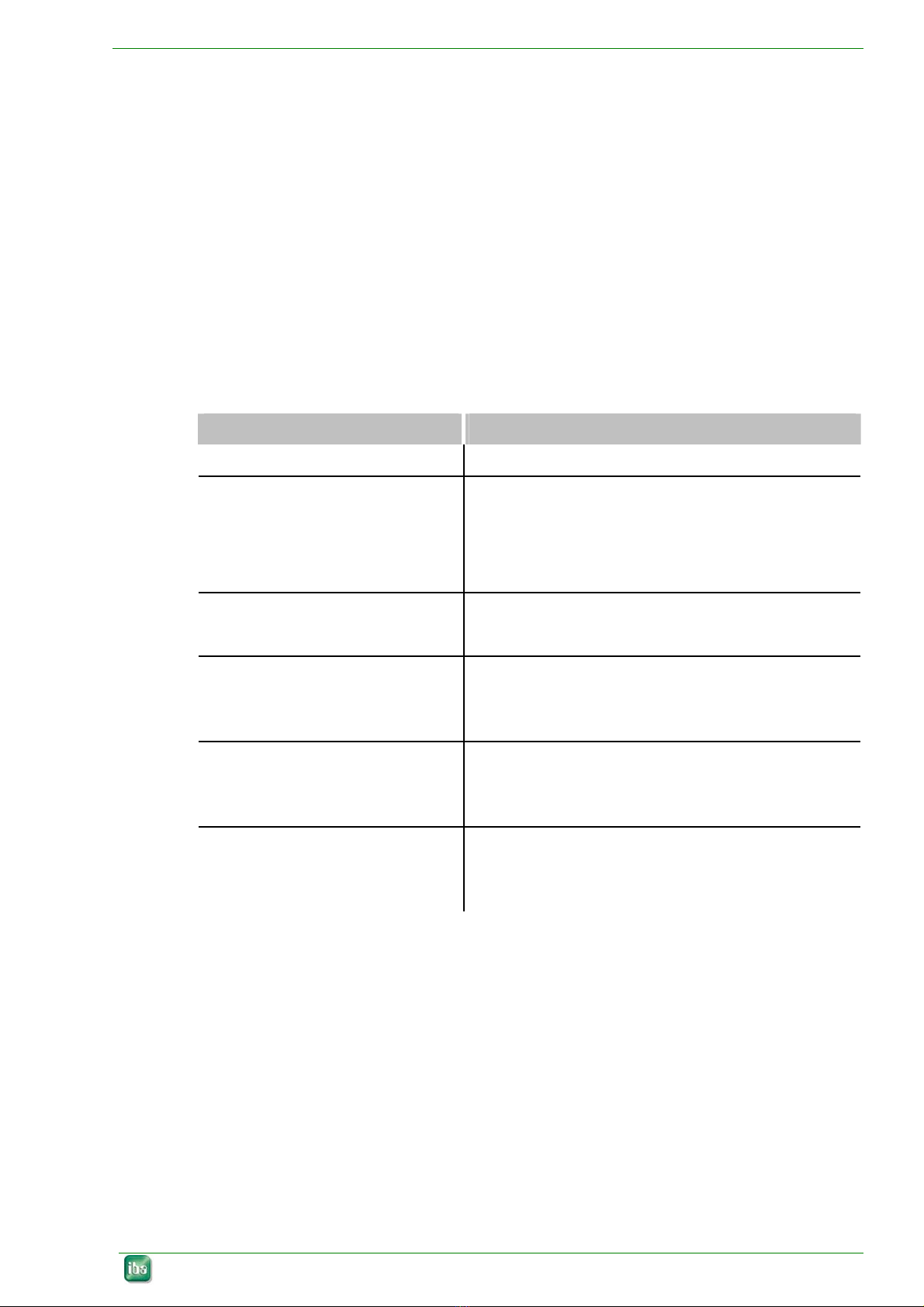

Contents

1About this manual.............................................................................................5

1.1 Target group...................................................................................................... 5

1.2 Notations........................................................................................................... 5

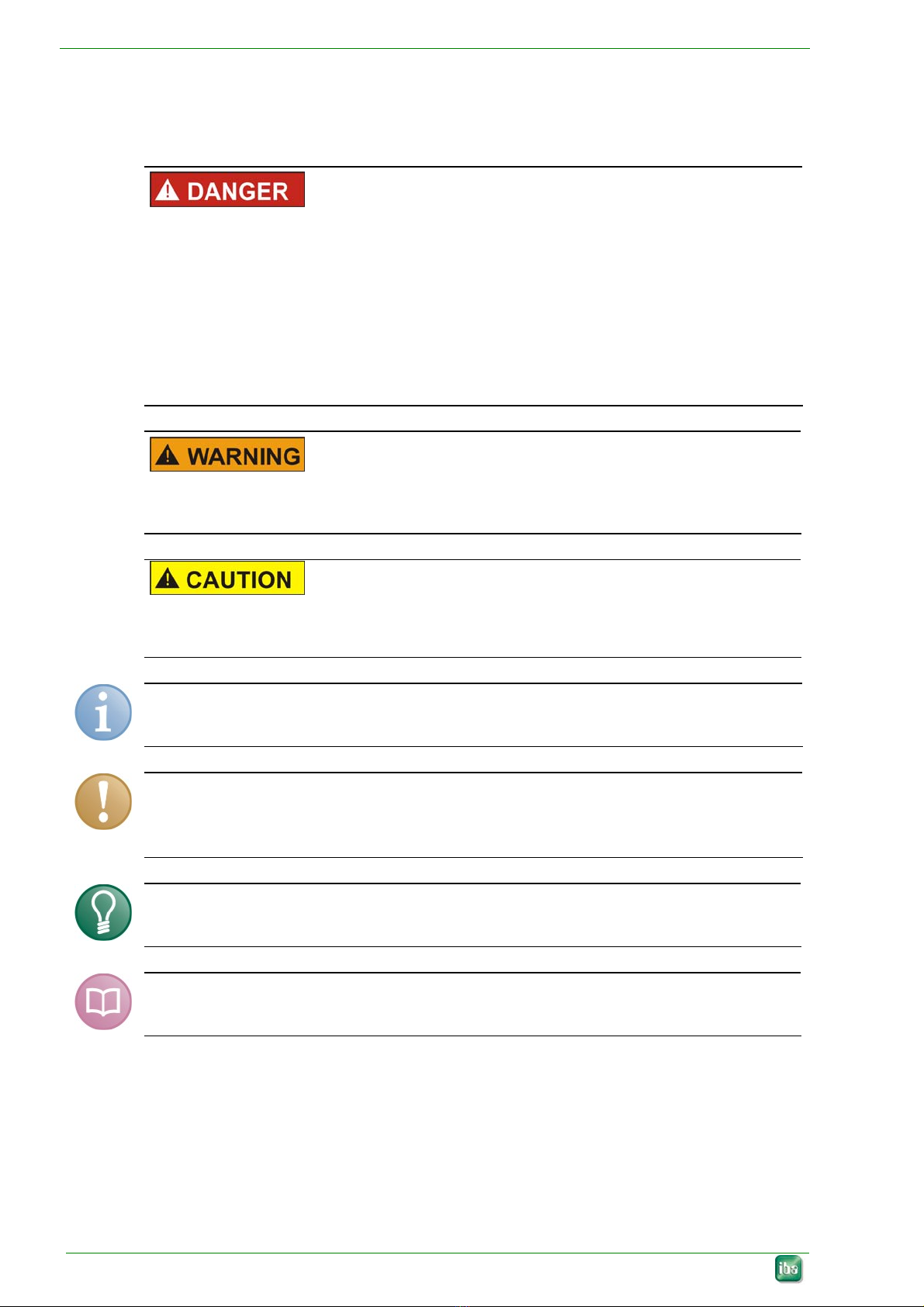

1.3 Used symbols ................................................................................................... 6

2Introduction.......................................................................................................7

3Package contents..............................................................................................7

4System requirements........................................................................................8

5Mounting and dismounting..............................................................................8

5.1 Mounting ........................................................................................................... 8

5.2 Dismounting ...................................................................................................... 8

6Product properties............................................................................................9

6.1 Device ............................................................................................................... 9

6.2 PC-side connection with ibaFOB-cards ............................................................ 9

6.3 PLC side connection with ibaLink-SM-64-io/ ibaLink-SM-128V-i-2o ................. 9

6.4 ibaBM-FOX-i-3o fiber optic splitting device....................................................... 9

6.5 Device views, connectors and switches.......................................................... 10

6.5.1 Power supply input X14 .................................................................................. 11

6.5.2 Fiber optic connectors TX (X10) and RX (X11)............................................... 11

6.5.3 Adjusting the device address with switch S1 .................................................. 11

6.5.4 Adjusting the device mode with switch S2 ...................................................... 11

6.5.5 Connector pin outs X14, X1, X2, X5, X6......................................................... 12

6.5.6 Status LEDs .................................................................................................... 13

6.5.7 LEDs L00…L07............................................................................................... 13

6.5.8 Service interface connector (X12)................................................................... 13

6.5.9 Shield connector ............................................................................................. 13

7Selecting the mode of operation ...................................................................14

7.1 Mode 0-standard operation mode................................................................... 14

7.2 Mode 2-impulse generator for binary output #0 .............................................. 14

8System topologies..........................................................................................16

8.1 Single daisy-chain with ibaPADU-8-O............................................................. 16

8.2 Multiple daisy-chains with ibaPADU-8-O......................................................... 16

8.3 Daisy-chain with ibaPADU-8-O to ibaLink-SM-64-io ....................................... 17

8.4 Process IO redundancy .................................................................................. 17

9Working with ibaPADU-8-O and ibaLogic V3................................................18

9.1 Hardware ........................................................................................................ 18

9.2 Software Application........................................................................................ 18