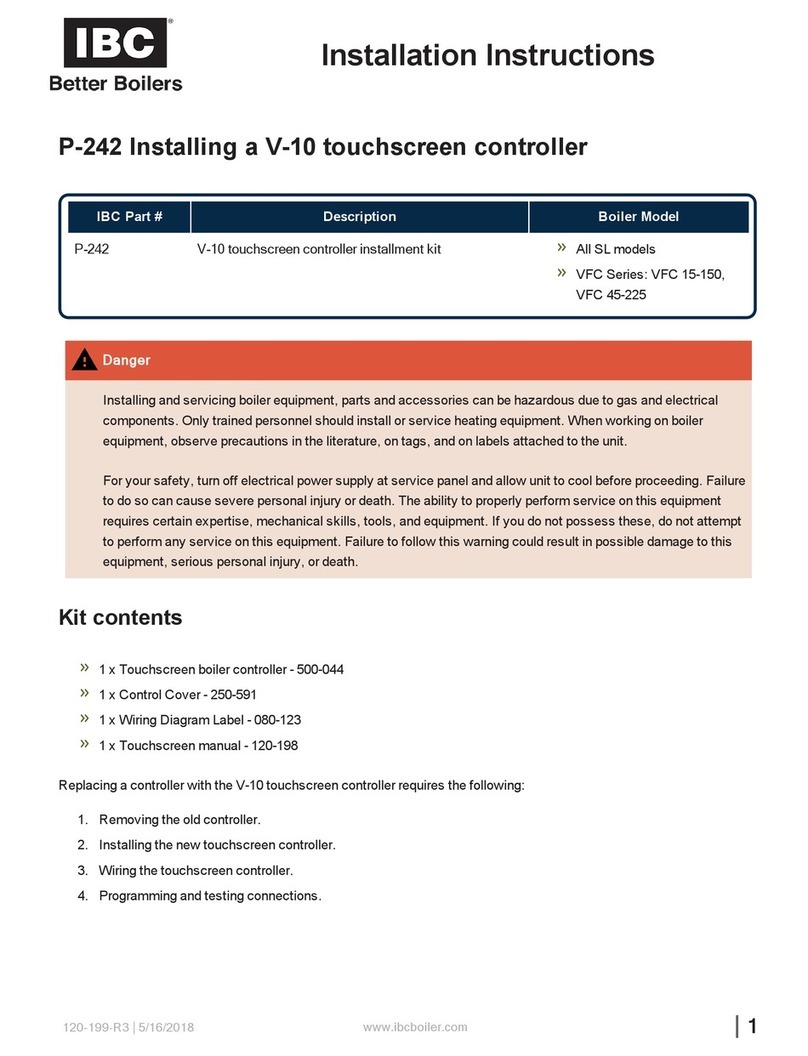

1.4 Getting to know the controller’s interface

The controller's main screen displays four menus: Home, Setup, Status, and More.

1.4.1 Home

The Home screen displays basic boiler status information such as a title bar

with boiler model number and boiler ID as well as its current operating state.

Other information shown includes the load currently being serviced (if any) and

a list of current operating values. The colored background on the status bar

represents different boiler states (see Status Bar Color on page 12).

If one or more errors occur in the boiler, an "Error Logs" button will display on

the Home screen. You can select the Error Logs button to view the current

error log. You can also view other logs to help detect recurring errors. Once you

have corrected the error(s), you need to clear the error(s) ( > Clear Errors).

This enables you to check for any unresolved errors still present in the system.

1.4.2 Setup

Tip

Our Setup feature is not only a quick way to configure a boiler, but is designed to cover

95% of operational requirements.

Setup walks you through a basic setup of the controller. You can configure a boiler’s parameters

using default values, including all the appropriate values to operate each load type under most

operating conditions. If you wish, you can change these default settings later. For instructions on

using Setup, see Configuring loads using Setup (recommended) on page 49.

In Setup, you can configure up to four loads with the following control modes:

DHW (domestic hot water)

Reset Heating

Set Point

Ext. Control

Zone of

When you select a control mode, the controller automatically loads the appropriate factory default

settings. For more information on control modes, see Operating concepts on page 17.

Section: Introduction and overview of the features in the V10 controller