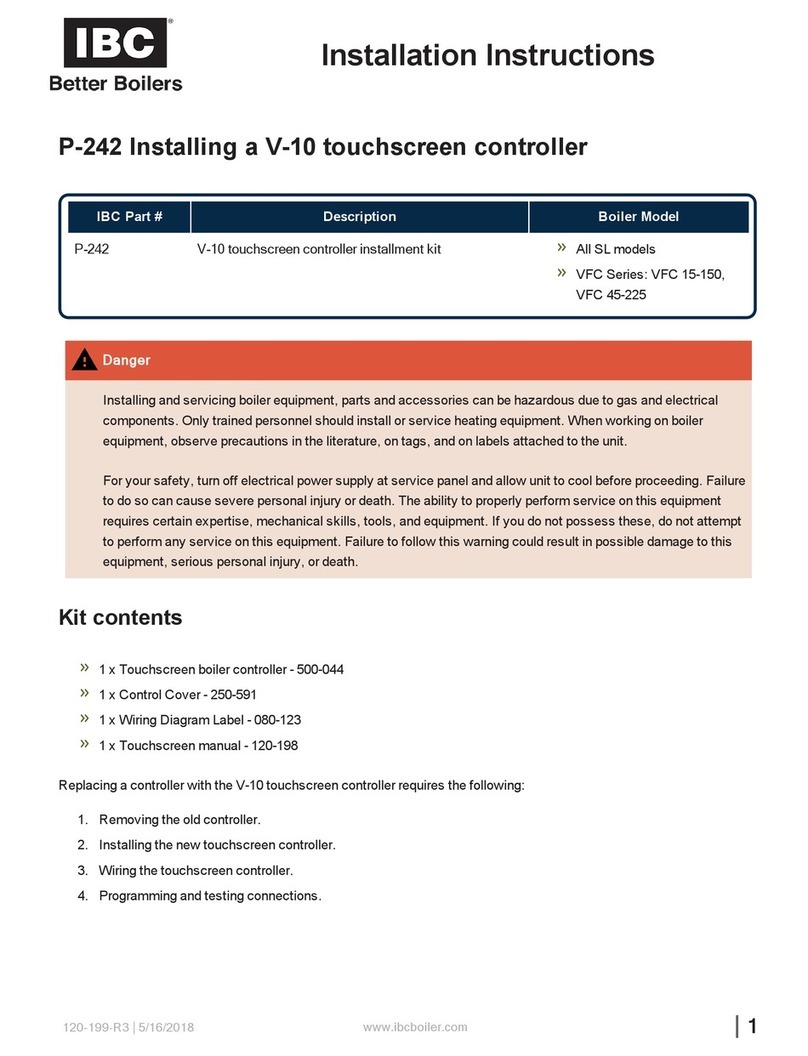

INSTALLATION AND OPERATING INSTRUCTIONS

V-10 TOUCH SCREEN BOILER CONTROLLER

1.0 IBC MODEL V10 TOUCH SCREEN CONTROLLER ..................................1

1.1 GENERAL ...............................................................1

1.2 CONTROL ...............................................................1

1.3 CONTROL INTERFACE.....................................................2

1.3.1 BOILER STATUS BAR ................................................2

1.3.2 NAVIGATION OVERVIEW .............................................3

1.3.2.1 MENU SCREENS .............................................3

1.3.2.2 STATUS DISPLAY SCREENS....................................3

1.3.2.3 SETTING SCREENS...........................................3

1.3.2.4 PASSWORD POP-UP WINDOW .................................4

1.3.2.5 LEFT SIDE SLIDE BAR.........................................4

1.3.2.6 COMMON BUTTON ICONS .....................................4

1.4 HOME SCREEN ...........................................................5

1.5 MAIN MENU..............................................................5

1.5.1 MAIN MENU SELECTIONS ............................................5

1.5.2 EXPRESS SETUP ...................................................6

1.5.3 LOAD STATUS ......................................................7

1.5.4 USER SETUP.......................................................7

1.5.5 INSTALLER SETTINGS ...............................................8

1.5.5.1 LOAD SETTINGS ............................................8

1.5.5.2 SYSTEM SETTINGS .........................................10

1.5.6 DIAGNOSTICS.....................................................10

1.6 SEQUENCE OF OPERATION ...............................................12

1.6.1 STANDBY.........................................................13

1.6.2 PURGING.........................................................13

1.6.3 IGNITION .........................................................13

1.6.4 HEATING .........................................................14

1.6.5 CIRCULATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

1.6.6 ERROR MODE.....................................................15

1.7 OTHER OPERATING FEATURES............................................15

1.7.1 PRIORITY.........................................................15

1.7.2 LOAD COMBINING .................................................16

1.7.2.1 CONSIDERATIONS FOR COMBINING LOADS .....................17

1.7.3 RESET HEATING ...................................................18

1.7.4 TEMPERATURE DIFFERENTIAL SETTINGS .............................19

1.7.5 DAILY TEMPERATURE OVERRIDES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1.7.6 UNOCCUPIED MODE ...............................................20

1.7.7 SUMMER SHUTDOWN ..............................................20

1.7.8 EXTERNAL CONTROL ..............................................21

1.7.9 ALARM CONTACTS.................................................21

1.7.10 MULTI-BOILER OPERATIONS ........................................21

1.7.11 INTERNET NETWORKING ...........................................22

1.7.12 WEB BROWSER INTERFACE.........................................23

1.7.13 BACnet SUPPORT..................................................23

2.0 DIAGRAMS .................................................................24

2.1 ELECTRICAL WIRING DIAGRAM ............................................24

2.2 INTERNAL WIRING DIAGRAM ..............................................26

2.3 CONTROLLER BOARD LAYOUT ............................................27

2.4 SEQUENCE OF OPERATION ...............................................28

CONTENTS