EX 700 - Convert to NG fuel (P-Kit 1200) |5

Testing and adjusting

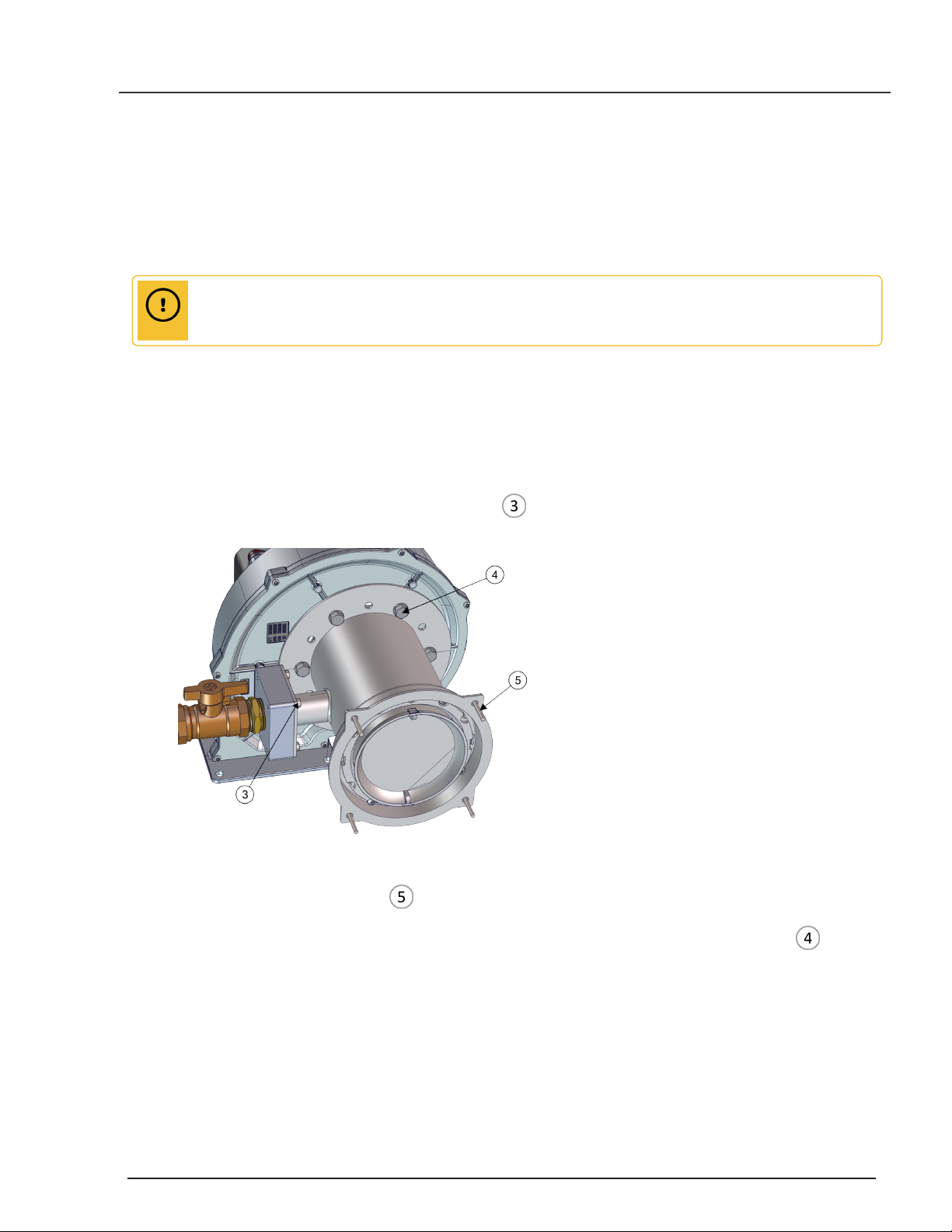

Measuring the inlet gas pressure

1. Beforeperformingacombustiontestandadjustment,turnofftheboiler’sexternalgasshut-offvalve.

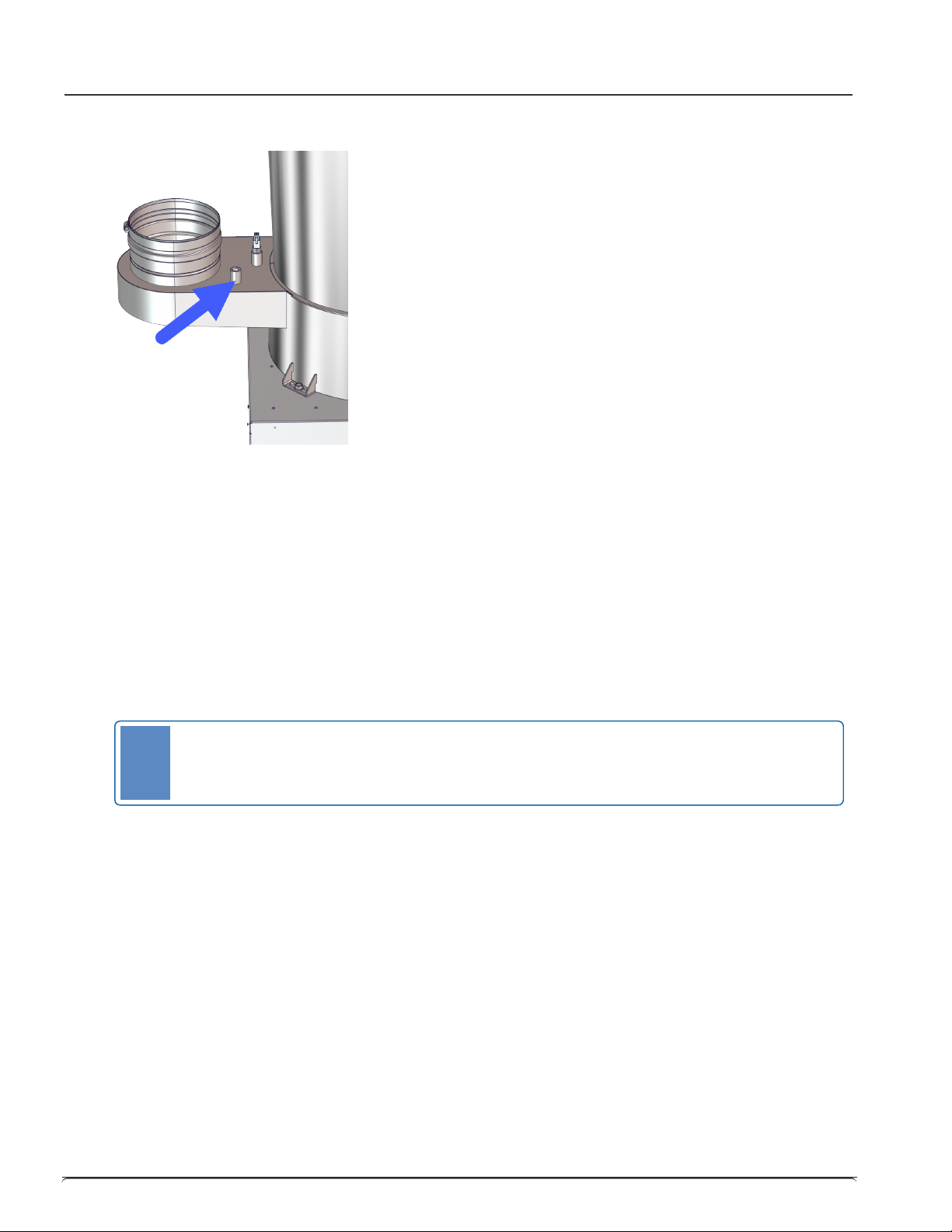

2. Removetheinletgaspressuretestportplugwitha3mmAllenkey.NotethefittinghasBSPthreads.

3. Usethesuppliedfittingtotransitionfrom1/8"BSPtobarbedforconnectiontoamanometer.

4. Attachamanometertotheinletpressuretestport,andturnongastoappliance.

Staticmanometerreadingshouldbeideally7"w.c.forNaturalGasand11"w.c.forPropane.

Minimumandmaximumstaticpressureshouldbebetween5"and14"w.c.Monitorpressurethroughout

thecommissioning(start-up)procedure.Pressuremaydropupto1"to2"w.c.athighfire.

5. Beforefiringtheboiler,turnthehighfire(gas-airratio)adjustmentscrewcounter-clockwise¾to1fullturnto

increasethefuel(enrichenthemixture)beforefiringuptheboiler.

6. Beforeyouchangetheloadtomanualcontrol,notetheloadsetting.

7. Settheloadtomanualcontrol,andsettheheat-outvaluetothemaximumMBHfortheboiler.Thisloadshould

belargeenoughtoallowtheboilertooperateathighfireforover10minutes.

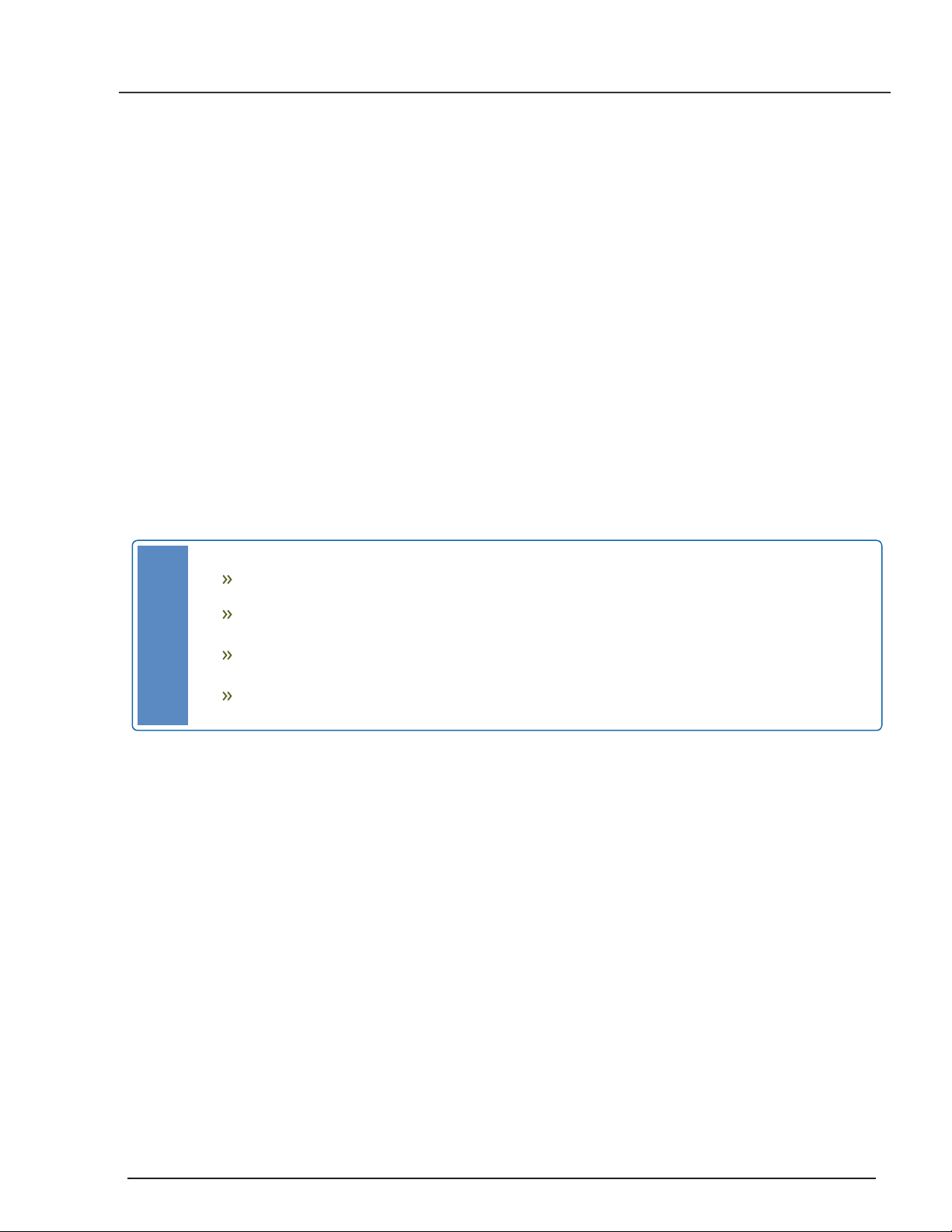

Performing a combustion test

Fuel High Fire Low Fire CO Max PPM

Table 2 Combustion test target ranges - CO2 / Maximum CO

1. Aftertheboilerislitandisathighfire,insertthecombustionanalyzertestprobeintothefluegastestport.Then

adjustthehighfire(gas-airratio)adjustmentwithasmallslotscrewdriveraccordingtoTable 2 values.This

adjustmentscrewisverysensitiveandwillonlyneedverysmalladjustmentstofinetunethegasvalve(1/16of

aturnatatimeonly).Turncounter-clockwise(inthedirectionofthe'+'sign)toraisetheCO2%(torichen).Turn

clockwisetolowerCO2%.