Iftheburnerdoesnotlight,theprocessisrepeateduntiltheburnerlightsandflameisdetected.After3trialsfor

ignition,theboilerlocksoutandwillneedtobemanuallyresetbyclearingtheerroronthetouchscreencontroller

(Diagnostics>AdvancedDiagnostics>ClearErrors).Theboilerautomaticallyresetsafter60minutes,ifnoaction

istaken.

To perform a combustion test and adjustment:

1. Turnofftheboiler’sgasshut-offvalve.

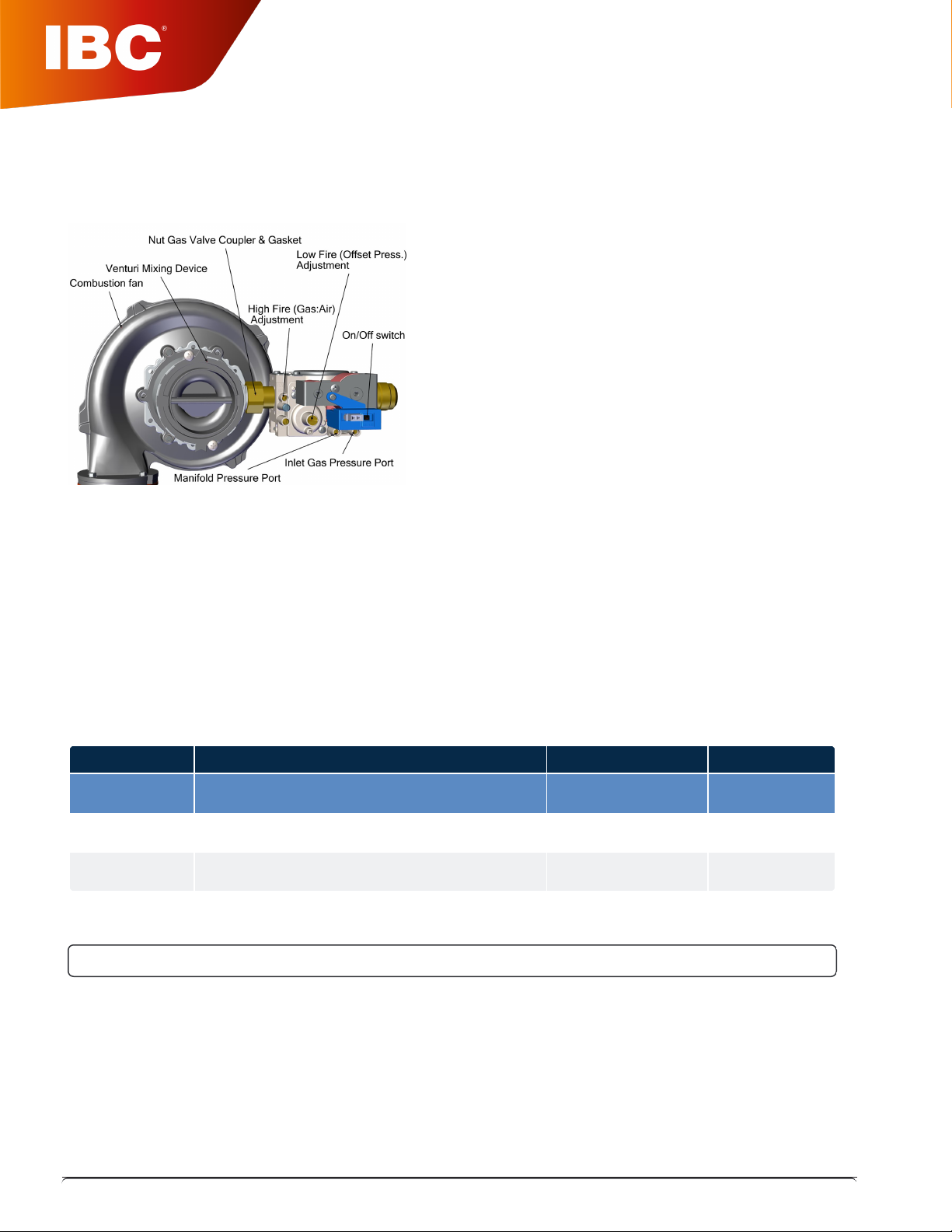

2. Withasmall(1/8"or3mm)flatscrewdriver,opentheinletgassupplypressuretestportbyturningitscenter-

screw1fullturncounterclockwise.

3. Attachamanometertotheinletpressuretestportandturnongastoappliance.

Staticmanometerreadingshouldbeideally7"w.c.forNaturalGasand11"w.c.forPropane.

Minimumandmaximumstaticpressureshouldbebetween5"and14"w.c.Monitorpressure

throughoutthecommissioning(start-up)procedure.Pressuremaydropupto1"to2"w.c.athighfire.

4. Beforeyouchangetheloadtomanualcontrol,notetheloadsetting.

5. Settheloadtomanualcontrol,andsettheheat-outvaluetothemaximumMBHfortheboiler.Thisload

shouldbelargeenoughtoallowtheboilertooperateathighfireforover10minutes.

6. Withacombustionanalyzerprobeinthefluegastestport,checkthefluegasreadingandadjustthegas:air

ratioscrewtobringthefluegastowithintheparametersindicatedinTable 1 .

7. Adjustslowly(clockwise)theHighFire(Gas:AirRatioAdjustment)screwtoobtainthecorrectCO2value

(seeTable 1 ).Maketinyadjustments(mayrequireseveralturns).TurningtheHighFire(Gas:AirRatio

Adjustment)screwclockwisewillleanouttheflame.

Note

Clockthegasmeter(seeinstructionsonPage6)toconfirmfullmaximumratingplateinput.

CheckthemeasuredresultswithTable2.

8. Settheheat-outvalueinmanualmodetotheminimumMBHfortheboiler(seeTable 1 ).

9. WhiletheboilerisatLowFire,comparethecombustionreadingagainstthereadinginTable2.Thereading

shouldbewithintherangelisted.

10. Restoretheloadtothepreviousloadtype.Alltheprogrammedsettingswillberestoredandtheloadwill

operateasbefore.Confirmasmoothignitionsequence.

11. Turnoffthegassupplyatthegasshut-offvalve.

12. Disconnectthepowertotheboiler.

13. Disconnectthemanometer.

14. Closethegassupplytestportscrewbyturningclockwise.

15. Turnonthegassupplyshutoffvalveandtestforgasleaks.

16. Restorepowertotheboiler.

Nextyoumustfillintheinformationandaffixtheincludedfuelconversionlabelstotheboilerasindicatedafterthe

conversioniscompleted.