3

SL 45-260

PROPANE CONVERSION PARTS KIT# P-170B

120-166 R2

Combustion Testing and Adjustment

To verify the proper operation of the gas valve in the eld, the following procedure

can be carried out by a qualied technician (diagrams on this page).

Normal ignition system sequence of operation: The boiler control, upon a call

for heat or DHW, will turn on the combustion fan for a 20 second pre-purge, then

energize the spark electrode and gas valve for a 4 second trial for ignition. If the

burner does not light and prove ame, the process is repeated until the burner

lights and ame is detected or after 3 trials for ignition the boiler will lock out and

will need to be manually reset by clearing the error. The boiler will automatically

reset after 60 minutes if no action is taken.

1. Turn o the boiler’s gas shut o valve. With a small (1/8” or 3 mm) at

screwdriver, open the inlet gas supply pressure test port by turning its center-

screw 1 full turn counterclockwise. Attach a manometer to the pressure test

port and turn on gas to appliance. Static manometer reading should be ideally

7” w.c., for Natural Gas and 11” w.c. for Propane. Minimum and maximum

static pressure should be between 5” and 14” w.c. Monitor pressure throughout

the comissioning procedure. Pressure may droop up to 1” to 2” w.c. at high

re. Outlet Pressure (Manifold Pressure) should be between -0.04” w.c. and

0.00” w.c. with a target of -0.02” w.c. NOTE: The outlet pressure should

only be measured with an accurate digital manometer. Consult factory before

considering eld adjustment.

2. Set a load as manual control and run the boiler at 260MBH. This load should

be large enough to allow the boiler to operate at high re for 10 plus minutes.

Take note of what the load was set for before you change it to manual control.

3. Turn the High Fire (Gas : Air Ratio Adjustment) screw 1-1/4 turns clockwise

using a 2.5mm hex key.

4. With a combustion analyzer probe in the ue gas test port, turn the High Fire

(Gas : Air Ratio Adjustment) screw clockwise (see diagrams on this page) to

achieve results. This screw oers very ne adjustment, and may require several

turns. Turning the High Fire (Gas : Air Ratio Adjustment) screw clockwise will

lean out the ame. NOTE: Clock the gas meter to conrm full maximum rating

plate input. Check the measured results with Table 3 - High Fire.

5. Set the heat out value in manual mode to 45MBH.

6. While the boiler is at Low Fire, compare the combustion reading against the

readings in Table 2. The readings should be within the range listed in Table 2.

7. Restore the load to the previous load type. All the programmed settings will

be restored and the load will operate as it was previously. Conrm a smooth

ignition sequence.

8. Turn o the gas supply at

the gas shut o valve and

disconnect the power to

the boiler. Disconnect the

manometer. Close the gas

supply test port screw by

turning clockwise. Turn on the

gas supply shut o valve and

test for gas leaks. Restore

power to the boiler.

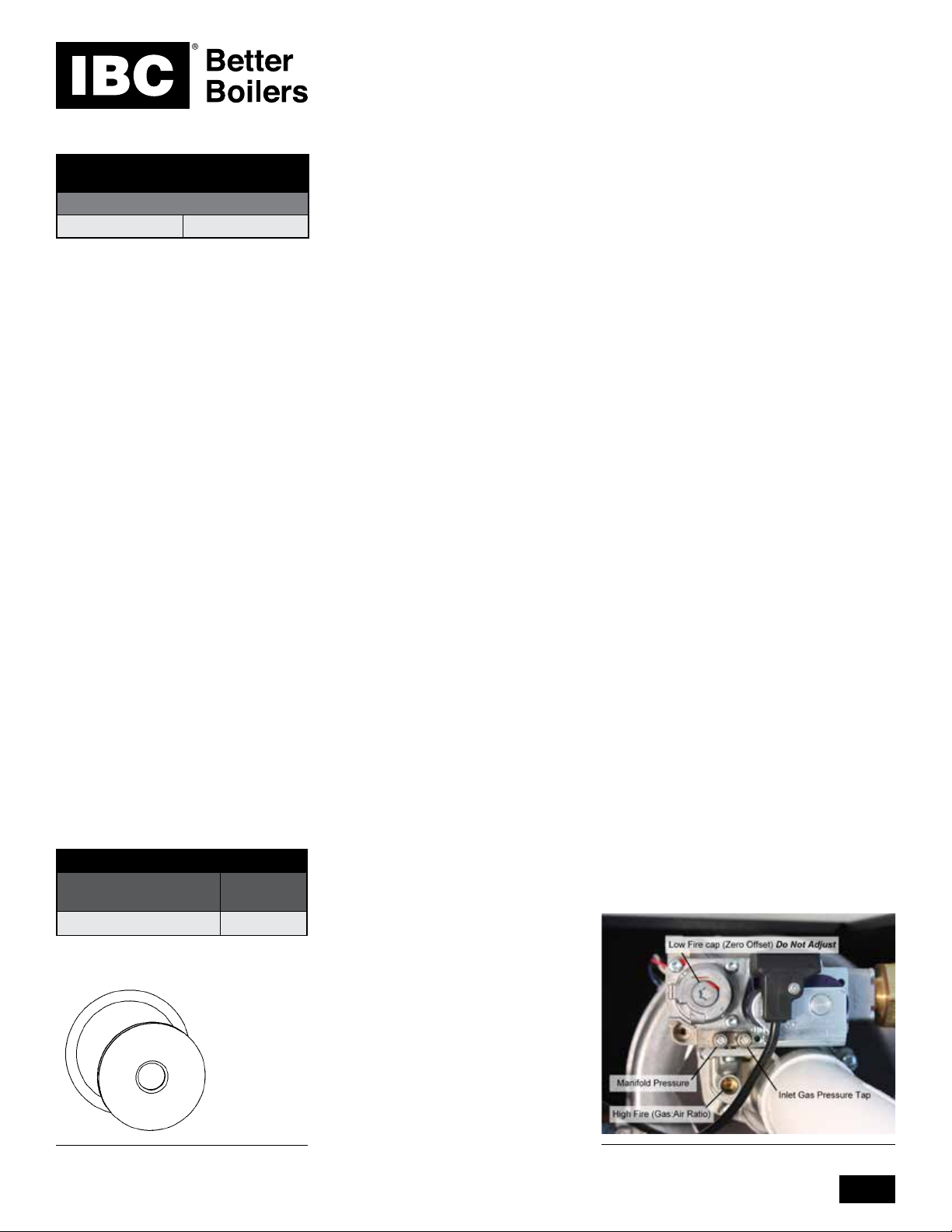

Orice and O-ring

PROPANE ORIFICE CHART

MODEL

NUMBER

ORIFICE

SIZE

SL 45-260 6.8 mm

MODEL

NUMBER

HIGH FIRE

INPUT

NATURAL GAS OR PROPANE

SL 45-260 260 MBH

Table 3: Rated input of a converted boiler

Clocking the Meter

(Natural Gas)

1. Turn o all other appliances and

pilots

2. Turn on the boiler and set the

boiler to high re. Ensure the

boiler has a large load to heat so

that the boiler will not shut o.

3. With a Stop-Watch, record

the number of seconds for the

smallest dial to make 1 full

revolution.

4. CFH = (3600 x Dial Size) /

Seconds

5. CFH x 1000 (check local Btu

content) = Input Btu’s

NOTE:

• For 2 PSI meters multiply CFH x

1.097

• For Metric meters multiply CFH x

35.3

• For 2 PSI metric meters multiply

CFH x 1.097 x 35.3

• For Altitude above 4,500’ deduct

2% per 1,000' of altitude from the

Input Btu’s

Gas Valve Adjust