SFT 28-199 - Fuel Conversion to Natural Gas (LP to NG) Kit P-803 |5

Note: Allow the unit to operate at High Fire for 3 minutes to stabilize. (The unit operates in manual mode for 10

minutes then switch back to the normal operating mode. To extend manual mode operation, press the Service

and Plus buttons together twice while the unit is operating in manual mode to reset the timer for 10 more

minutes.) Do not make adjustments if the service display shows an “h”.

5. Clock the gas meter (see instructions Clocking the Meter (for Natural Gas only) on page 6) to confirm full

maximum rating plate input.

a. With a combustion analyzer probe in the flue gas test port, check the measured results against Table 1 -

High Fire.

b. If the results are outside the permitted range, check the inlet pressure, and confirm that the correct orifice

and venturi are installed.

6. Switch the unit to low fire by pressing the Service button and Minus buttons at the same time. The unit will drop

to low fire. “L” will show in the service display.

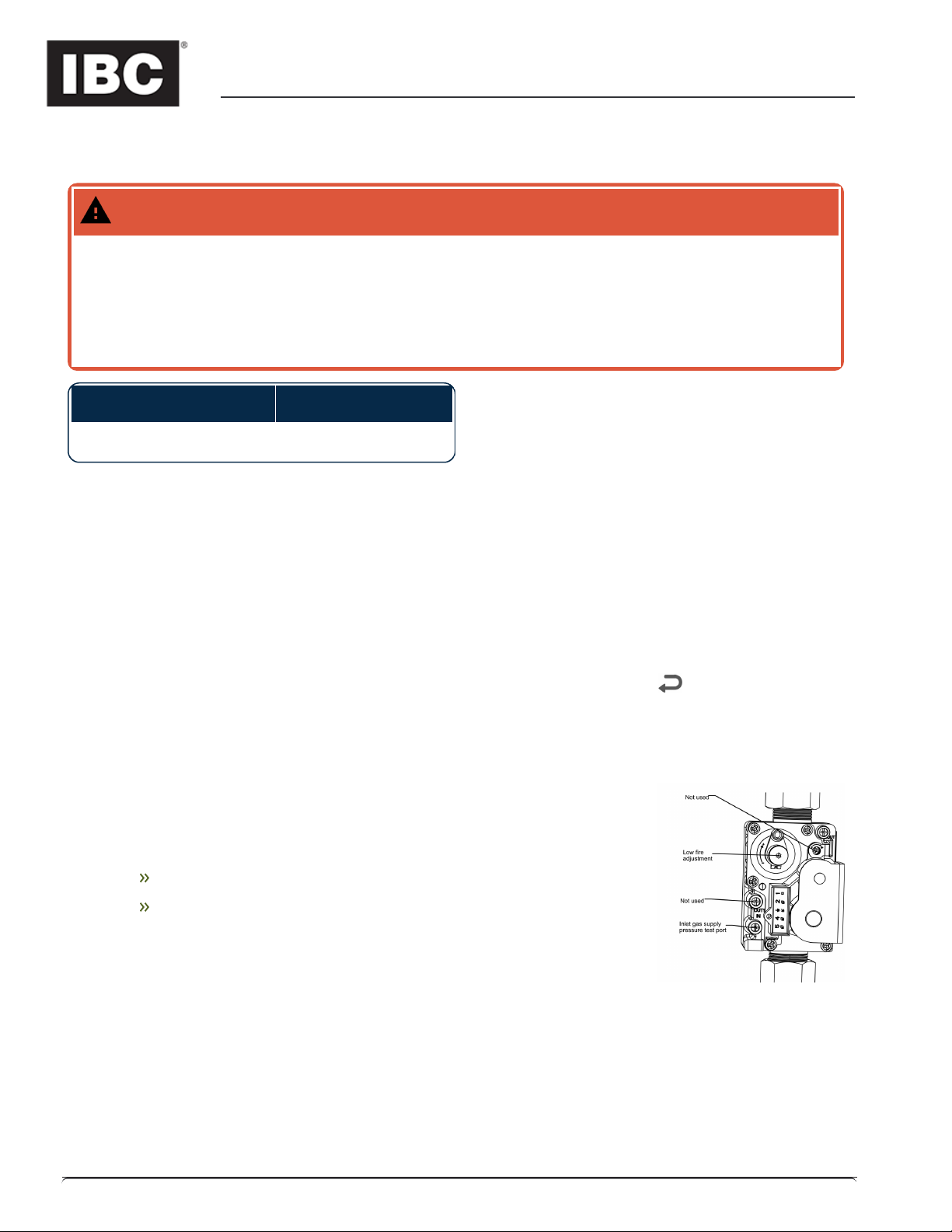

a. Compare the readings with Table 1 - Low Fire. If adjustment is necessary, remove the Low Fire

Adjustment cap to reveal a Torx head screw.

b. Make tiny adjustments, typically less than 1/8th of a turn at a time. Turn the screw clockwise to increase

CO2 and counter-clockwise to reduce CO2. If the target cannot be met, even after a half turn, contact the

factory.

c. When finished, replace the Low Fire cap, and leave the manual mode by pressing + AND -

simultaneously.

7. Switch off the unit by pressing the space above the dot.

8. Turn off the gas at the unit's gas shut-off valve.

9. Remove the flue gas analyzer from the test port, and reinstall the test port cap.

10. Remove the gas pressure manometer from the gas valve, and fully close the test port.

11. Turn on the gas at the unit’s gas shut-off valve.

12. Ensure there are no gas leaks before reinstalling the front cover.

13. Turn on the unit by pressing the space above the dot.

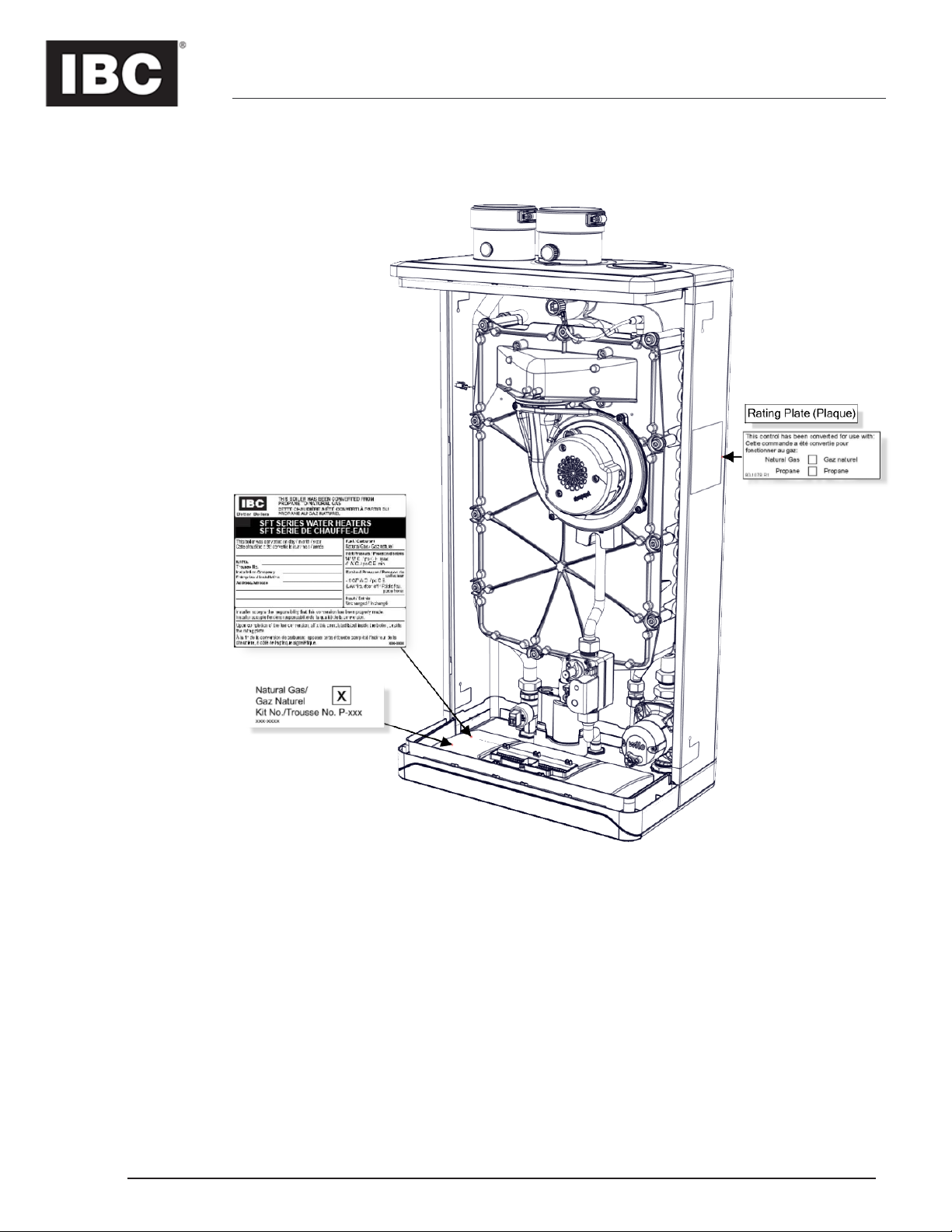

Completing and Affixing the Conversion Labels

1. Fill in the conversion labels (included in the kit) associated with the new fuel type.

2. Place the conversion labels onto the unit at the positions indicated on the last page.