6

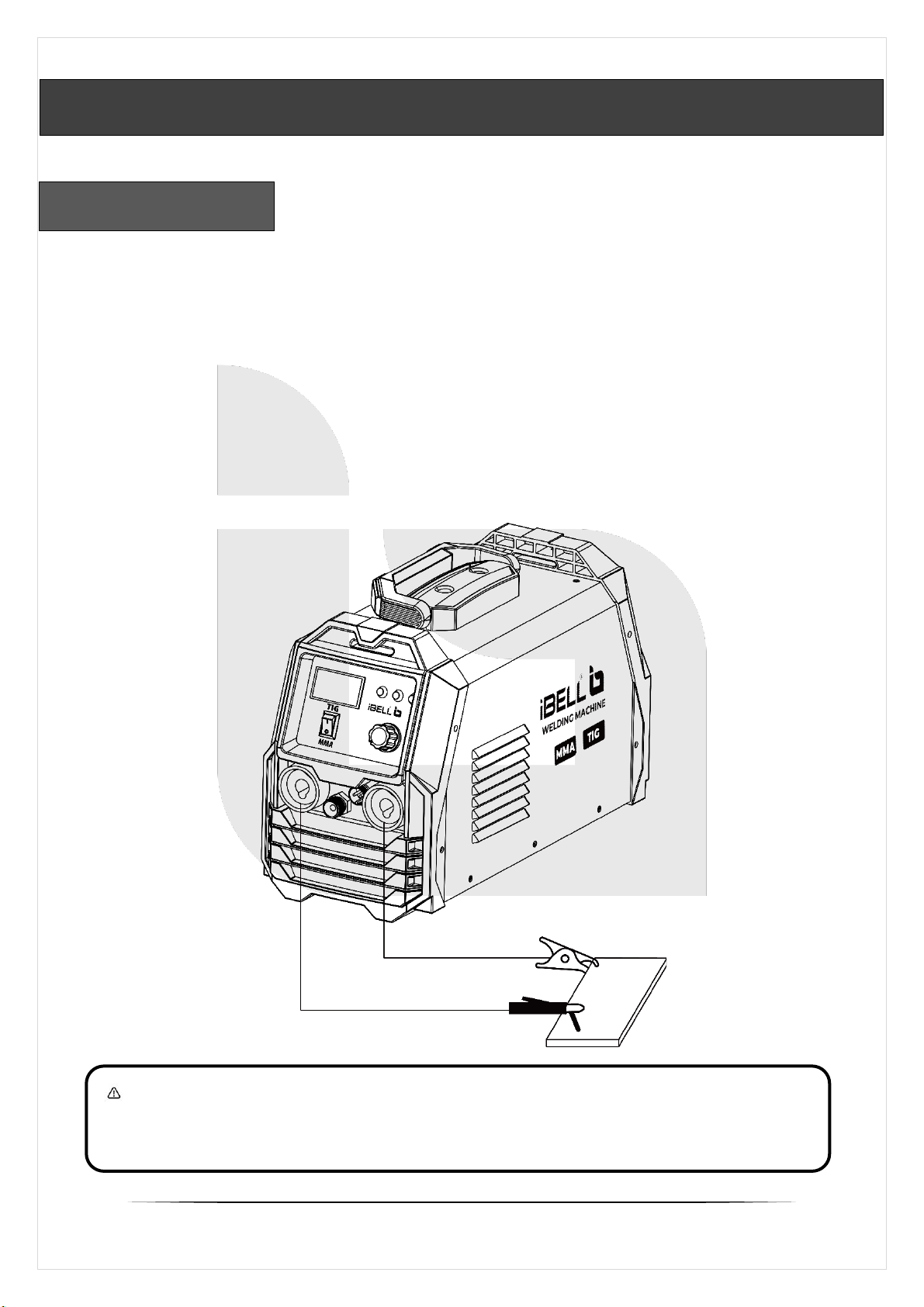

T220-105 and T250-106 Welding machines function both as

Tungsten Inert Gas (TIG) and MMA (Manual Metal Arc) Machine.

▪In Tungsten Inert Gas (TIG) welding, a non-consumable

tungsten electrode is used to produce the weld. The weld area

and electrode are protected by an inert shielding gas (argon)

from oxidation or other atmospheric contamination. A filler

metal is normally used. A constant-current welding power

supply produces electrical energy, which is conducted across the

arc through a column of highly ionized gas and metal vapours.

TIG is most commonly used to weld thin sections of stainless

steel and non-ferrous metals such as aluminium, magnesium,

and copper alloys.

▪In Manual Metal Arc Welding (MMA), with consumable, flux-

covered electrode and a ground clamp, a short-circuit is initially

made on the weld piece. An electric arc forms between electrode

and work-piece, which heats up enough to melt both. As the

electrode melts, the flux coating on the electrode develops gas

and slag, which help protect the weld pool. The gas keeps air and

other pollutants away, while slag forms on top of the weld pool to

protect the weld seam.

▪The machine uses a high performance IGBT Technology, which

is very useful as they give power that can be used for different

welding processes.

Hot Start provides excellent arc ignition without the electrode

sticking and avoiding any metallurgical default in the weld. Its

Anti-sticking feature minimizes the short circuit current in the

event of the electrode sticking to the work piece.

VRD (Voltage Reduction Device) in-built function provides an

additional measure of safety.

Arc force in-built improves the weld performance on the specified

size of electrodes to be used, making the job easier.