Ripley Technology

You’ve just purchased the finest softtail ever built. The Ripley has numerous

features which combine to give you an extremely comfortable high performance

ride. The Ripley is in a class of its own: the world’s only aluminum Softtail. Its

1.25” of rear wheel travel equals that of typical titanium softtails, and at 4.4

lbs. it weighs the same, yet it costs a fraction of that of a titanium softtail.

In order to attain long travel, superior front end torsion and excellent lateral

rigidity, the Ripley has a highly evolved and integrated system of components

and features. To maximize the performance and pleasure you experience while

riding your Ripley, we recommend you familiarize yourself with the frame and

its features by reading through this guide, and spending an appropriate amount

of time on setup and tuning.

And don’t forget to activate your warranty!

Table of Contents

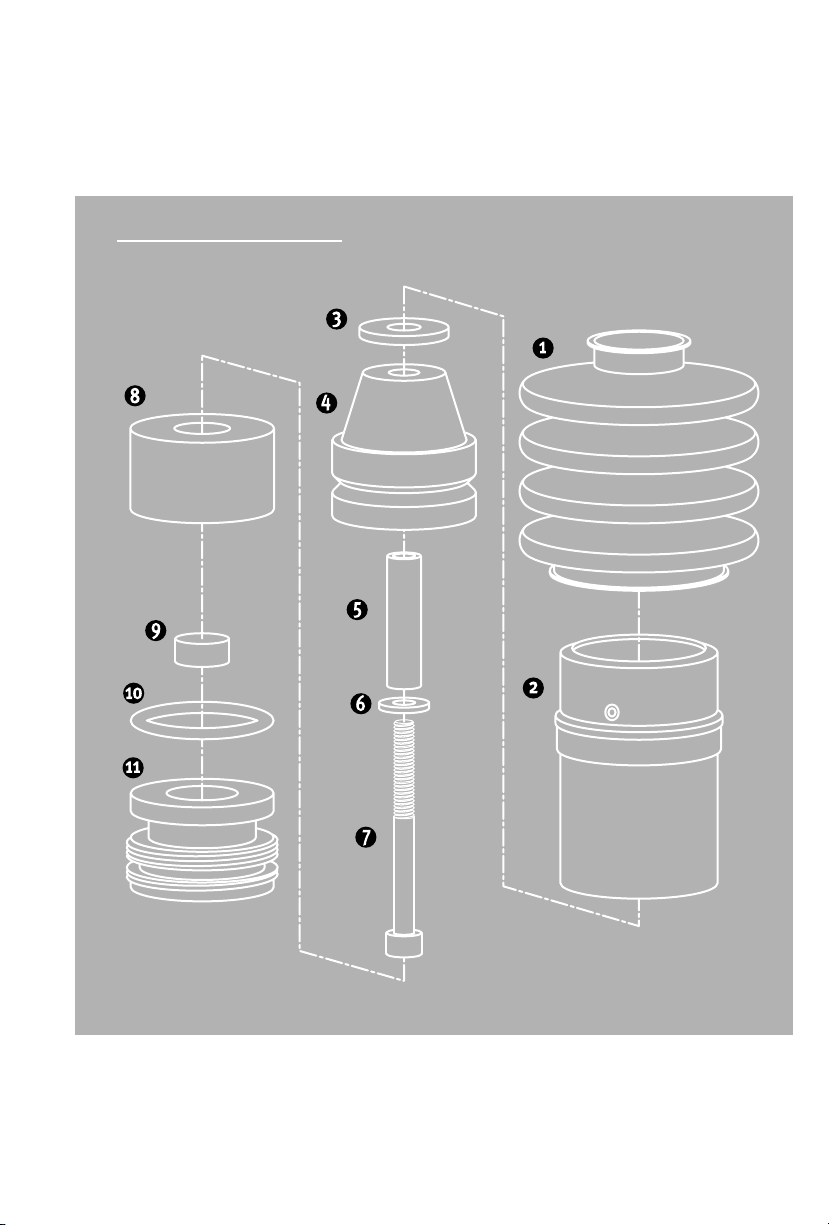

Key Components pg 3 Reassembly pg 8

Shock Tuning Guidelines pg 4-5 Shock Diagram pg 9

Lubrication pg 6 Parts List pg 10

Disassembly pg 7 Warranty pg 11

Quick Guide

Impatient are we? Although we recommend you read this manual in its entirety,

here is the quick and dirty tuning guide:

Step 1—Set the sag of the shock (the amount of travel you see when you sit

on the saddle without moving) to 0.3-0.4 inches. Adjust the sag with a

Shimano (TL-UN74S) or Park (BBT-2) BB tool or with either a 19mm or

3/4” socket by turning the preload adjuster (part # 11 pg. 9) at the

bottom of the shock. Righty tighty increases spring force/decreases sag.

Step 2—Ride the bike for a few hours to allow the spring (part #8 pg. 9) to set.

Step 3—Check sag occasionally, as the springs will continue to find their

groove thang.

Step 4—Lube the shock every 20 hours of riding (or as needed) by pulling

up the shock boot and injecting each of the two chamfered holes with

SRAM Jonnisnot®. You’re finished when you see lube coming out of the

non chamfered holes. DO NOT USE ANY OTHER LUBES

Step 5—Ride

2

Ibis Lifetime Warranty

IMPORTANT – PLEASE READ:YOU MUST ACTIVATE YOUR NEW PRODUCT WARRANTY WITHIN 14 DAYS OF

PURCHASE BY CALLING IBIS AT 800-283-0943 OR BY VISITING OUR WEBSITE: www.ibiscycles.com/warranty

11

Subject to the limitations, terms and conditions set forth below, Ibis LLC (“IBIS”) warrants to the original

owner of each IBIS frame (“Frame”) that when new, such Frame is free of defects. This Lifetime Limited

Warranty (“Frame Warranty”) covers IBIS Frame for the lifetime of the Frame1. This Warranty does not

apply to paint/finish or third party components attached to the Frame such as front forks, wheels, drive

train, brakes, seatpost, handlebar and stem or any third party suspension-related parts or components.

Subject to the limitations, terms and conditions set forth below, ibis LLC (“IBIS”) warrants to the original

owner of each IBIS rear shock that is provided with an Ibis soft tail Frame (“Rear Shock”), that when new,

such Rear Shock is free of defects. This Three Year Limited Warranty (“Rear Shock Warranty”) covers

factory installed IBIS Rear Shocks for three years from the date of purchase.

In order to initiate coverage under the Frame Warranty or Rear Shock Warranty, the original owner must

register the Frame2with IBIS within 14 days of purchase. In order to exercise a claim under this

Warranty, the Frame and/or Rear Shock must be presented to IBIS or an authorized IBIS dealer, together

with a receipt, or other proof of purchase, which identifies the Frame by serial number. Should the Frame

and/or Rear Shock be determined by IBIS to be covered by this Warranty, it will be repaired or replaced,

at the sole option of IBIS, which will be conclusive and binding. If repaired or replaced, the original

owner will receive a credit towards the cost of such repair or replacement based on the number of years

since original purchase of the Frame and IBIS’ standard warranty schedule. This Warranty does not include

the cost of travel or shipment to and from an authorized IBIS dealer or IBIS factory. Such costs, if any,

shall be born by the original owner.

This Warranty does not apply to normal wear and tear, nor to claimed defects, malfunctions or failures

that result from abuse, neglect, improper assembly, improper maintenance, alteration, collision, crash or

misuse. This Frame and/or Rear Shock have not been designed, engineered, distributed, manufactured, or

sold for uses in trick riding, ramp riding, jumping, aggressive riding, riding on severe terrain, riding in

severe climates, riding with heavy loads, commercial activities, or any similar activities. Such uses may

damage the Frame and/or Rear Shock, can cause serious injury to the rider, and in all cases will void this

Warranty. This Warranty is made only to the original owner of a new IBIS Frame and/or Rear Shock

purchased from an authorized IBIS dealer and is not transferable.

An authorized IBIS dealer should periodically check IBIS Frame for indicators of stress and/or potential

failure, including cracks, deformations, corrosion, paint peeling, dents, and any other indicators of

potential problems, inappropriate use, or abuse. These are important safety checks that can prevent

accidents, bodily injury and shortened Frame life. This Warranty does not cover malfunctions or failures

caused by delay in bringing a problem or potential problem to the attention of IBIS or an authorized IBIS

dealer.

This is an integrated and final statement of the IBIS Warranty. IBIS does not authorize anyone, including

its dealers, to extend any other warranties, express or implied, for IBIS. No other representation, and no

statement of anyone but IBIS, including a demonstration of any kind by anyone, shall create any warranty

regarding IBIS Frame or Rear Shock. IBIS’s liability under this Warranty shall be no greater than the

amount of the original purchase price of the Frame or Rear Shock and in no event shall IBIS be liable for

incidental or consequential damages.

All other remedies, obligations, liabilities, rights, warranties, express or implied, arising from law or

otherwise, including but not limited to any claimed implied warranty of merchantability, any claimed

implied warranty arising from course of performance, course of dealing or usage of trade, and any claimed

implied warranty of fitness, are disclaimed by IBIS and waived by the original owner of the Frame.

1 Titanium, steel, and aluminum frames are warranted for life to the original owner. Aluminum frames are subject

to a valuation schedule, which governs the value of the repair and/or replacement.

The Ripley chainstay carries a lifetime warranty. Should any other portion of the Ripley frame fail, its repair or

replacement will be based on the terms and conditions above, and this Aluminum Frame Valuation Schedule:

First 5 years from original purchase: Frame replacement or repair at no charge.

Years 6-7: Frame replacement or repair at current prices, with 75% of original frame price credited to original buyer.

Years 8-10: Frame replacement or repair at current prices, with 50% of original frame price credited to original buyer

After Year 10: Frame replacement or repair at current prices, with 25% of original frame price credited to original

buyer.

2 Product must be registered by completing an official Ibis Registration Form (accompanied with Frame, or available

on the Ibis Website or at an Authorized Ibis Dealer).