IBM Rear Door Heat eXchanger V2 Product manual

Rear Door Heat eXchanger V2

Ty pe 175 6

Installation and Maintenance Guide

Rear Door Heat eXchanger V2

Ty pe 175 6

Installation and Maintenance Guide

Note: Before using this information and the product it supports, read the general information in Appendix B, “Notices,” on page 81,

the Rack Safety Information and Environmental Notices and User Guide documents on the IBM Documentation CD, and the

Important Notices and Warranty Information documents that comes with the product.

Fourth Edition (September 2013)

© Copyright IBM Corporation 2011, 2013.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Contents

Safety ............................v

Chapter 1. Introduction ......................1

The IBM Documentation CD ....................2

Hardware and software requirements ................2

Using the Documentation Browser .................3

Notices and statements in this document................4

Chapter 2. Heat exchanger planning, specifications, and requirements ...5

Planning considerations ......................5

Heat exchanger specifications ....................6

Heat exchanger performance ....................6

Heat exchanger parts and tools ...................9

Secondary cooling loop parts and services...............10

Miscellaneous parts and services supplier ..............10

Coolant distribution unit supplier .................11

Water specifications for the secondary cooling loop ...........12

Control and conditioning of the secondary cooling loop .........12

Installation and support from IBM Integrated Technology Services .....22

Chapter 3. Special instructions if the heat exchanger comes installed on a

rack ............................23

Chapter 4. Installing the heat exchanger ..............29

Installation guidelines ......................29

Installing the heat exchanger....................30

Routing cables through the upper and lower air baffles ..........42

Front-to-rear cable channels and caps ................43

Routing and securing the hoses ..................44

Raised-floor environment ....................44

Raised-floor and non-raised-floor environments ............47

Filling the heat exchanger with water .................48

Chapter 5. Maintaining the heat exchanger .............55

Draining the heat exchanger ....................56

Refilling after a leak in the system ..................60

Leak in the water-supply circuit ..................60

Leak in the heat exchanger ...................60

Maintenance schedule ......................61

Replaceable components .....................61

Replacing the heat exchanger (trained service technician only) .......62

Removing the heat exchanger ..................62

Installing the replacement heat exchanger ..............69

Replacing the latch on the heat exchanger...............76

Appendix A. Getting help and technical assistance ..........77

Before you call .........................77

Using the documentation .....................78

Getting help and information from the World Wide Web ..........78

How to send Dynamic System Analysis data to IBM ...........78

Creating a personalized support web page...............78

Software service and support ...................78

Hardware service and support ...................79

© Copyright IBM Corp. 2011, 2013 iii

IBM Taiwan product service ....................79

Appendix B. Notices ......................81

Trademarks ..........................81

Important notes.........................82

Particulate contamination .....................83

Documentation format ......................83

Telecommunication regulatory statement ...............84

Electronic emission notices ....................84

Federal Communications Commission (FCC) statement .........84

Industry Canada Class A emission compliance statement ........84

Avis de conformité à la réglementation d'Industrie Canada ........84

Australia and New Zealand Class A statement ............84

European Union EMC Directive conformance statement .........85

Germany Class A statement ...................85

VCCI Class A statement ....................86

Korea Communications Commission (KCC) statement .........86

Russia Electromagnetic Interference (EMI) Class A statement.......86

People's Republic of China Class A electronic emission statement .....87

Taiwan Class A compliance statement ...............87

Index ............................89

iv Rear Door Heat eXchanger V2: Installation and Maintenance Guide

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d'installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

© Copyright IBM Corp. 2011, 2013 v

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Important: Each caution and danger statement in this document is labeled with a

number. This number is used to cross reference an English-language

caution or danger statement with translated versions of the caution or

danger statement in the IBM Rack Safety Information document.

For example, if a caution statement is labeled “Statement 1,”

translations for that caution statement are in the IBM Rack Safety

Information document under “Statement 1.”

Be sure to read all caution and danger statements in this document

before you perform the procedures. Read any additional safety

information that comes with the server or optional device before you

install the device.

Statement 5:

≥18 kg (39.7 lb) ≥32 kg (70.5 lb) ≥55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

CAUTION:

or

>32 kg (70.5 lb)

or 32-55 kg (70.5-121.2 lb)

The weight of this part or unit is between 32 and 55 kg (70.5 and 121.2 lb). It

takes three persons to safely lift this part or unit. (C010)

vi Rear Door Heat eXchanger V2: Installation and Maintenance Guide

Statement 6:

CAUTION:

Do not place any object on top of a rack-mounted device unless that

rack-mounted device is intended for use as a shelf.

Statement 7:

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current

from the device, ensure that all power cords are disconnected from the power

source.

1

2

Statement 8:

DANGER

vPlug power cords from devices in the rack cabinet into electrical outlets

that are located near the rack cabinet and are easily accessible.

vEach rack cabinet might have more than one power cord. Be sure to

disconnect all power cords in the rack cabinet before servicing any

device in the rack cabinet.

vInstall an emergency-power-off switch if more than one power device

(power distribution unit or uninterruptible power supply) is installed in

the same rack cabinet.

vConnect all devices installed in a rack cabinet to power devices installed

in the same rack cabinet. Do not plug a power cord from a device

installed in one rack cabinet into a power device installed in a different

rack cabinet.

Safety vii

Statement 12:

CAUTION:

See the instructions in the rack documentation before you install devices,

remove devices, or relocate the rack.

Statement 14:

CAUTION:

Goggles are needed for the procedure.

(L011)

viii Rear Door Heat eXchanger V2: Installation and Maintenance Guide

Chapter 1. Introduction

This Installation and Maintenance Guide contains instructions for installing, setting

up, and maintaining the IBM®Rear Door Heat eXchanger V2 Type 1756.

Note: Installation of the IBM Rear Door Heat eXchanger V2 Type 1756 is your

responsibility and is not provided as part of the product purchase.

The heat exchanger is a water-cooled door that is mounted on the rear of an IBM

42U 1100 mm Deep Dynamic Rack Type 9363 to cool the air that is heated and

exhausted by devices inside the rack. A supply hose delivers chilled, conditioned

water to the heat exchanger. A return hose delivers warmed water back to the water

pump or chiller. In this document, this is referred to as a secondary cooling loop.

The primary cooling loop supplies the building chilled water to secondary cooling

loops and air conditioning units. The hoses for the secondary cooling loop are not

included with this product. The rack on which you install the heat exchanger can be

on a raised floor or a non-raised floor. Each heat exchanger can remove 100,000

Btu per hour (or approximately 30,000 watts) of heat from your data center.

See “Secondary cooling loop parts and services” on page 10 for information about

hoses, water treatment, and coolant distribution units for supplying conditioned

water.

If you would like to procure IBM installation planning services regarding what is

needed to plan for supplying conditioned water and installing the heat exchanger,

see “Installation and support from IBM Integrated Technology Services” on page 22.

If documentation updates are available, you can download them from the IBM

website. The heat exchanger might have features that are not described in the

documentation that comes with the product, and the documentation might be

updated occasionally to include information about those features, or technical

updates might be available to provide additional information that is not included in

the heat exchanger documentation. To check for updates, go to

http://www.ibm.com/supportportal/.

© Copyright IBM Corp. 2011, 2013 1

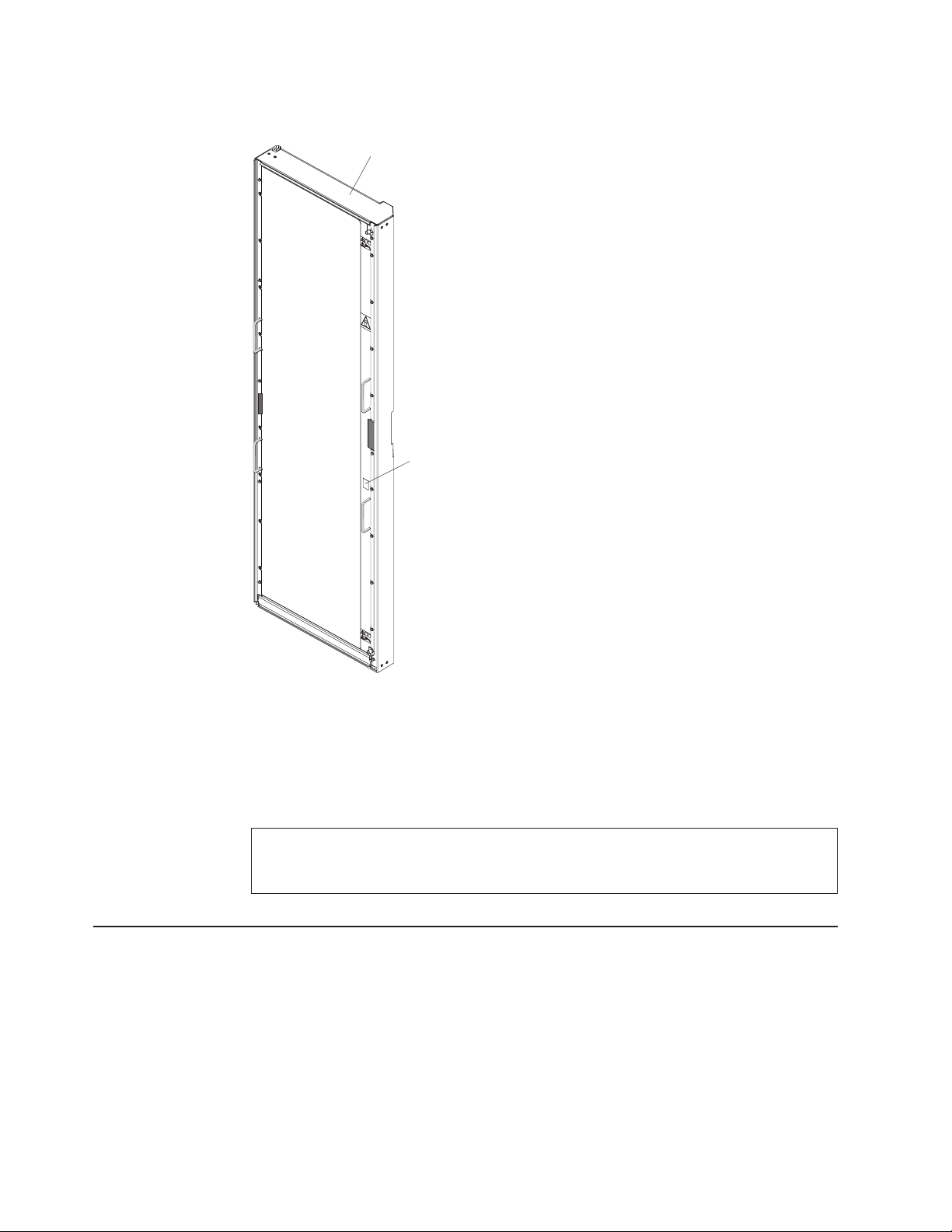

Record information about the IBM Rear Door Heat eXchanger V2 Type 1756 in the

following table. You will need this information if you need to call for service.

The serial number is on the side rail of the heat exchanger, between the two lift

handles.

Product name IBM Rear Door Heat eXchanger V2 Type 1756

Serial number _____________________________________________

The IBM Documentation CD

The IBM Documentation CD contains documentation for your rack product in

Portable Document Format (PDF) and includes the IBM Documentation Browser to

help you find information quickly.

Hardware and software requirements

The IBM Documentation CD requires the following minimum hardware and

software:

vMicrosoft Windows XP, Windows 2000, or Red Hat Linux

Rear door heat

exchanger asembly

Serial

number

Figure 1. Serial number location on the IBM Rear Door Heat eXchanger V2 Type 1756

2Rear Door Heat eXchanger V2: Installation and Maintenance Guide

v100 MHz microprocessor

v32 MB of RAM

vAdobe Acrobat Reader 3.0 (or later) or xpdf, which comes with Linux operating

systems

Using the Documentation Browser

Use the Documentation Browser to browse the contents of the CD, read brief

descriptions of the documents, and view documents, using Adobe Acrobat Reader

or xpdf. The Documentation Browser automatically detects the regional settings in

your computer and displays the documents in the language for that region (if

available). If a document is not available in the language for that region, the

English-language version is displayed.

Use one of the following procedures to start the Documentation Browser:

vIf Autostart is enabled, insert the CD into the CD or DVD drive. The

Documentation Browser starts automatically.

vIf Autostart is disabled or is not enabled for all users, use one of the following

procedures:

– If you are using a Windows operating system, insert the CD into the CD or

DVD drive and click Start --> Run.IntheOpen field, type

e:\win32.bat

where eis the drive letter of the CD or DVD drive, and click OK.

– If you are using Red Hat Linux, insert the CD into the CD or DVD drive; then,

run the following command from the /mnt/cdrom directory:

sh runlinux.sh

Select your rack product from the Product menu. The Available Topics list

displays all the documents for your rack product. Some documents might be in

folders. A plus sign (+) indicates each folder or document that has additional

documents under it. Click the plus sign to display the additional documents.

When you select a document, a description of the document is displayed under

Topic Description. To select more than one document, press and hold the Ctrl key

while you select the documents. Click View Book to view the selected document or

documents in Acrobat Reader or xpdf. If you selected more than one document, all

the selected documents are opened in Acrobat Reader or xpdf.

To search all the documents, type a word or word string in the Search field and

click Search. The documents in which the word or word string appears are listed in

order of the most occurrences. Click a document to view it, and press Crtl+F to use

the Acrobat search function, or press Alt+F to use the xpdf search function within

the document.

Click Help for detailed information about using the Documentation Browser.

Chapter 1. Introduction 3

Notices and statements in this document

The caution and danger statements in this document are also in the multilingual

Rack Safety Information document, which is on the IBM Documentation CD. Each

statement is numbered for reference to the corresponding statement in the Rack

Safety Information document.

The following notices and statements are used in this document:

vNote: These notices provide important tips, guidance, or advice

vImportant: These notices provide information or advice that might help you avoid

inconvenient or problem situations.

vAttention: These notices indicate potential damage to programs, devices, or

data. An attention notice is placed just before the instruction or situation in which

damage might occur.

vCaution: These statements indicate situations that can be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

vDanger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or

situation.

4Rear Door Heat eXchanger V2: Installation and Maintenance Guide

Chapter 2. Heat exchanger planning, specifications, and

requirements

This chapter provides information about planning the installation, and heat

exchanger specifications, parts, tools, and suppliers.

Planning considerations

As you plan the installation of the heat exchanger, include the following

considerations.

vProviding chilled, conditioned water that meets the specifications that are outlined

in “Control and conditioning of the secondary cooling loop” on page 12.

vProcuring and installing the water supply system that is suitable for your data

center. Details are provided in “Water delivery specifications for secondary loops”

on page 14.

vProviding a redundant secondary cooling loop water supply or enough room air

conditioning to handle a tolerable heat load if the function of one or more of the

heat exchangers is compromised. For example, if the rear door is opened for

rack maintenance or conditioned water supply to the door is stopped, the rack

heat load is sent out into the room and must be handled by room air conditioning

until the conditioned water supply is restored.

vProviding floor or ceiling tile cutouts or protective coverings to avoid tripping

hazards on non-raised floors as part of hose management.

CAUTION:

or

>32 kg (70.5 lb)

or 32-55 kg (70.5-121.2 lb)

The weight of this part or unit is between 32 and 55 kg (70.5 and 121.2 lb). It

takes three persons to safely lift this part or unit. (C010)

© Copyright IBM Corp. 2011, 2013 5

Attention:

1. Because of the size and weight of the heat exchanger, three trained persons

are required to install or remove the heat exchanger.

2. You must remove the power from the rack and all components before you

connect or disconnect the water supply lines and drain or fill the heat

exchanger.

Heat exchanger specifications

The following information is a summary of the specifications of the IBM Rear Door

Heat eXchanger V2, Type 1756.

Table 1. Heat exchanger specifications

Door size:

vDepth: 129 mm (5.0 in.)

vHeight: 1950 mm (76.8 in.)

vWidth: 600 mm (23.6 in.)

Door assembly weight:

vEmpty: 39 kg (85 lb)

vFilled: 48 kg (105 lb)

Air movement:

vProvided by servers and other devices in

the rack

Air Temperature drop:

vWith high-heat-load devices, up to 25°C

(45°F) between the air exiting the rack

devices and the air exiting the heat

exchanger

Water:

vSource:

– User-supplied, compliant with

specifications in this document

vPressure:

– Normal operation: <137.93 kPa (20 psi)

– Maximum: 689.66 kPa (100 psi)

vVolume:

– Approximately 9 liters (2.4 gallons)

vTemperature:

– Above dew point

– 18°C ±1°C (64.4°F ±1.8°F) for

ASHRAE Class 1 Environment

– 22°C ±1°C (71.6°F ±1.8°F) for

ASHRAE Class 2 Environment

Note: See “Heat exchanger

performance” for more information.

vRequired water flow rate (as measured

at the supply entrance to the heat

exchanger)

– Minimum: 22.7 liters (6 gallons) per

minute

– Maximum: 56.8 liters (15 gallons) per

minute

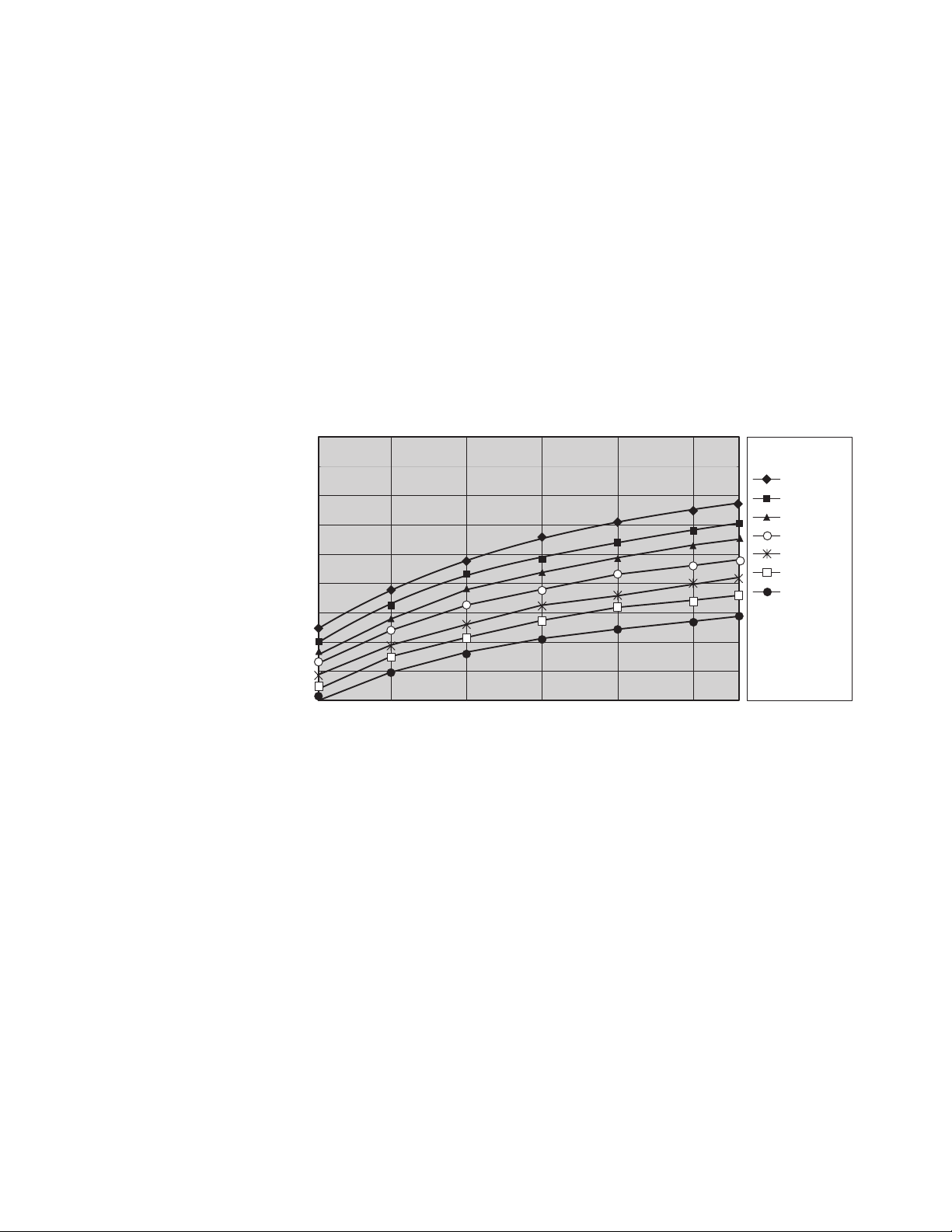

Heat exchanger performance

Expected performance of the heat exchanger is illustrated in Figure 2 on page 7 for

a typical inlet air temperature of 27°C (80.6°F), with a fully populated rack, near

uniform power dissipation, and a 30 kW heat load. By selecting the correct water

inlet temperature and water flow rate, you can achieve the necessary heat removal.

A heat removal of 100% indicates that an amount of heat equivalent to that

generated by the devices has been removed by the heat exchanger and the

average air temperature leaving the heat exchanger is identical to that entering the

rack (27°C [80.6°F] in this example). Heat removal in excess of 100% indicates that

the heat exchanger not only removed all of the heat generated by the devices but

further cooled the air so that the average air temperature leaving the rack is actually

lower than that entering the rack.

6Rear Door Heat eXchanger V2: Installation and Maintenance Guide

Attention: To help maintain optimum performance of the Rear Door Heat

eXchanger and provide proper cooling for all rack components, you must always

take the following precautions:

vInstall filler panels over all unoccupied bays.

vRoute signal cables at the rear of the rack so that they enter or exit the cabinet

through the top and bottom air baffles.

vBundle signal cables together in a rectangle so that the upper and lower

air-baffle sliders are closed as far as possible. Do not bundle signal cables

together in a circular formation. For more information, see “Routing cables

through the upper and lower air baffles” on page 42.

The following illustration shows the typical performance of the heat exchanger, 30

kW heat load.

* As described in “Water-supply requirements for secondary loops” on page 13, a

given water temperature may be used only if the system that is supplying the water

is able to measure the room dew point and automatically adjust the water

temperature accordingly. Otherwise, the water temperature must be above the

maximum dew point that is allowed at that data center installation.

140

130

120

110

100

90

80

70

60

50

% heat removal as function of water temperature and flow rate for

given rack power, rack inlet temperature, and rack air flow rate

4101214

% heat removal

Water flow rate (gpm)

Water

temperature

12°C *

14°C *

16°C *

18°C *

20°C *

68

22°C *

24°C *

Airflow

(cfm) = 2500

Rack Power

(W) = 30000

Tinlet, air

(C) = 27

Figure 2. Typical performance of the heat exchanger, 30 kW heat load

Chapter 2. Heat exchanger planning, specifications, and requirements 7

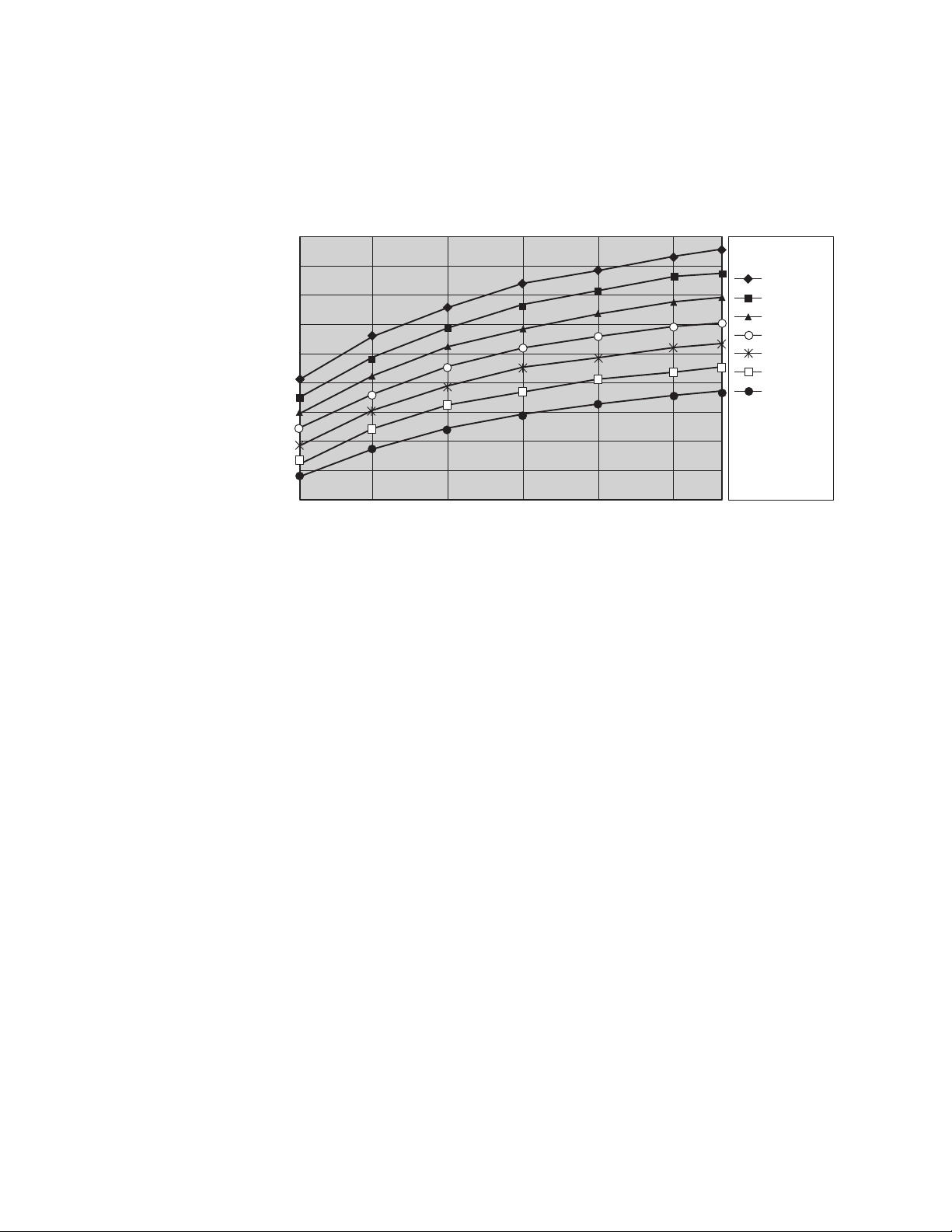

Performance data is shown in Figure 3 for a 20 kW heat load. Because of the lower

heat load, a specific level of cooling can be achieved with warmer water, a lower

flow rate, or both.

* As described in “Water-supply requirements for secondary loops” on page 13, a

given water temperature may be used only if the system that is supplying the water

is able to measure the room dew point and automatically adjust the water

temperature accordingly. Otherwise, the water temperature must be above the

maximum dew point allowed at that datacenter installation.

140

130

120

110

100

90

80

70

60

50

% heat removal as function of water temperature and flow rate for

given rack power, rack inlet temperature, and rack air flow rate

4101214

% heat removal

Water flow rate (gpm)

Water

temperature

12°C *

14°C *

16°C *

18°C *

20°C *

68

22°C *

24°C *

Airflow

(cfm) = 2000

Rack Power

(W) = 20000

Tinlet, air

(C) = 27

Figure 3. Typical performance of the heat exchanger, 20 kW heat load

8Rear Door Heat eXchanger V2: Installation and Maintenance Guide

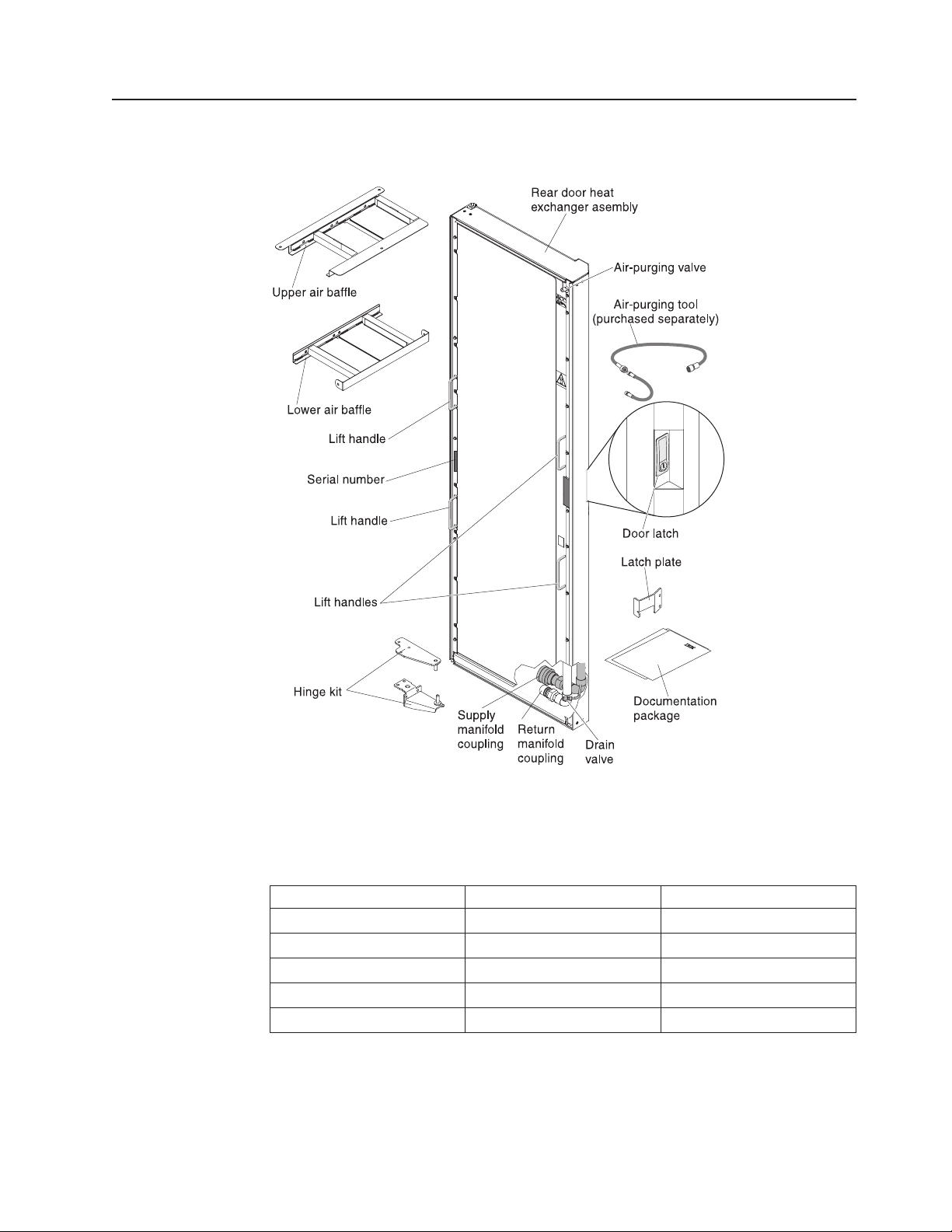

Heat exchanger parts and tools

The following illustration shows the heat exchanger and the parts that come with it.

Use the tools in the following table to install or remove a part or to attach the rear

door heat exchanger.

Table 2. Installation and removal tools

Tool Part to install or remove FRU part number

Phillips screwdriver Hinge bracket; air baffle 73G5363

8 mm socket Air baffle 73G1458

10 mm socket Hinge bracket 73G1463

Ratchet-head wrench Hinge brackets; air baffle 1650840

Platform ladder Hinge bracket (top) 45E0998

Figure 4. The IBM Rear Door Heat eXchanger V2 Type 1756

Chapter 2. Heat exchanger planning, specifications, and requirements 9

Secondary cooling loop parts and services

This section provides lists of suppliers that can provide coolant distribution unit

solutions, flexible hose assemblies, and water treatment that meets the suggested

water quality requirements.

Miscellaneous parts and services supplier

Coolcentric supplies the following secondary loop parts and services to customers

in North America, Europe, Middle East, Africa, and Asia Pacific:

vParts

– Rear door heat exchangers (designed for non-IBM Enterprise racks)

– Coolant distribution units

– 3/4-inch inside diameter hose kits

– Water treatment

– Chillers

– Raised-floor grommets

vServices

– Installation of door and secondary loop items

– Preventive maintenance

You can contact Coolcentric for all or some of the listed items, depending on your

needs.

Coolcentric

a Division of Wakefield-Vette

33 Bridge Street

Pelham, NH 03076

Telephone: 1-603-635-5199

http://www.coolcentric.com

Sales: [email protected]

10 Rear Door Heat eXchanger V2: Installation and Maintenance Guide

This manual suits for next models

1

Table of contents

Other IBM Industrial Equipment manuals