Tape

Transport

Read

Back

Checking

Full-Width

Erasure

File

Protection

Rewinding

3420

Models

4,

6,

and

8

A single, direct-drive capstan moves tape forward

or

backward. Air bearings

reduce friction and tape wear since the oxide (recording) tape surface contacts

only the

read/

write head, the erase head, and the tape cleaner. Short, tapered

vacuum columns greatly reduce tape inertia when starting and stopping tape. The

tapered columns and single-drive capstan start and stop tape quickly and

smoothly.

A two-gap

read/

write head allows read back checking during a write operation.

Moving forward tape passes first the write gap, then the read gap.

An erase head applies a strong magnetic field that erases the entire width

of

tape

during write operations. Full-width erasure prevents interchangeability problems

when tape

is

written on one tape unit and read

on

another; it also reduces the

chances of leaving extraneous bits in interblock gaps or skip areas.

During a write, write tape mark, or erase operation, the tape unit monitors the

erase head operation. On a 3420 Model 4, 6, or 8 an erase head failure drops

tape unit ready status and halts tape motion.

On

a 3420 Model 3, 5, or 7 an

erase head failure sets

UNIT

CHECK, but does not drop ready status.

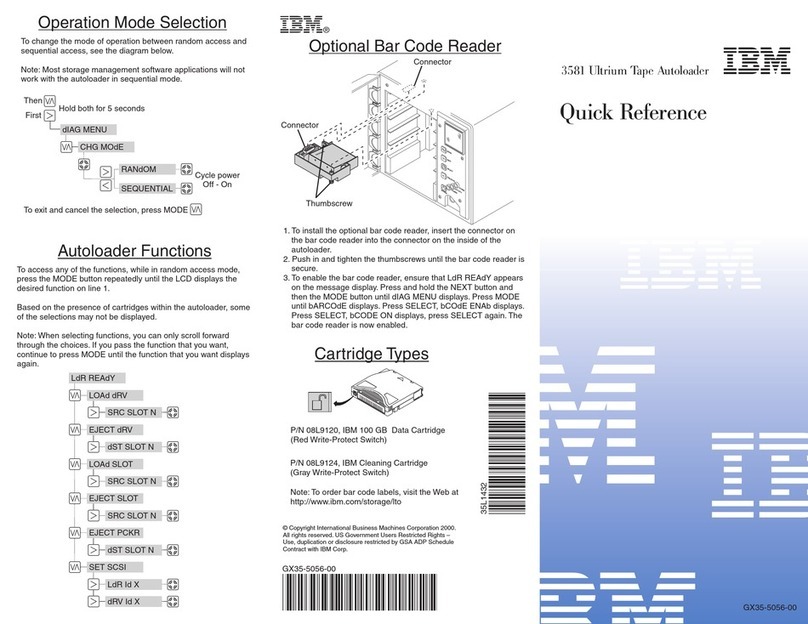

A write enable ring must be present in the

file

reel when writing. To avoid

destroying information on tape, remove the write enable ring. A reel without the

ring

is

"file-protected." The FILE PROTECT indicator remains on when a reel

without a file protect ring

is

mounted and no writing can occur.

Tape remains in the vacuum columns during rewind operations. Rewind ends

when a photocell senses a beginning-of-tape (load point) reflective marker on

tape.

During a rewind/unload operation, tape

is

rewound completely onto the file reel.

The tape unit

is

left in unloaded status, with the tape reel latch unlocked and the

window open, allowing the operator to remove the file reel.

The 3420 Models 4, 6, and 8 have the following added capabilities and features:

• 6250 BPI capability.

• 0.3-inch IBG.

Nominal data rates of 1250, 780, or 470

Kb/sec

at 6250 BPI.

• Improved access times.

• Prec:1e motion control

of

the media to achieve faster data access times.

6250 BPI or

6250/1600

BPI density features.

• Automatic read amplification.

New tape cleaning mechanism.

3420 Models 3, 5, and 7 can be converted to 3420 Models 4, 6,

and

8.

10 3803-2/3420 Subsystem Description