2

1.0 Introduction. .............................................................................................................................. 3

1.1 Overview................................................................................................................................ 3

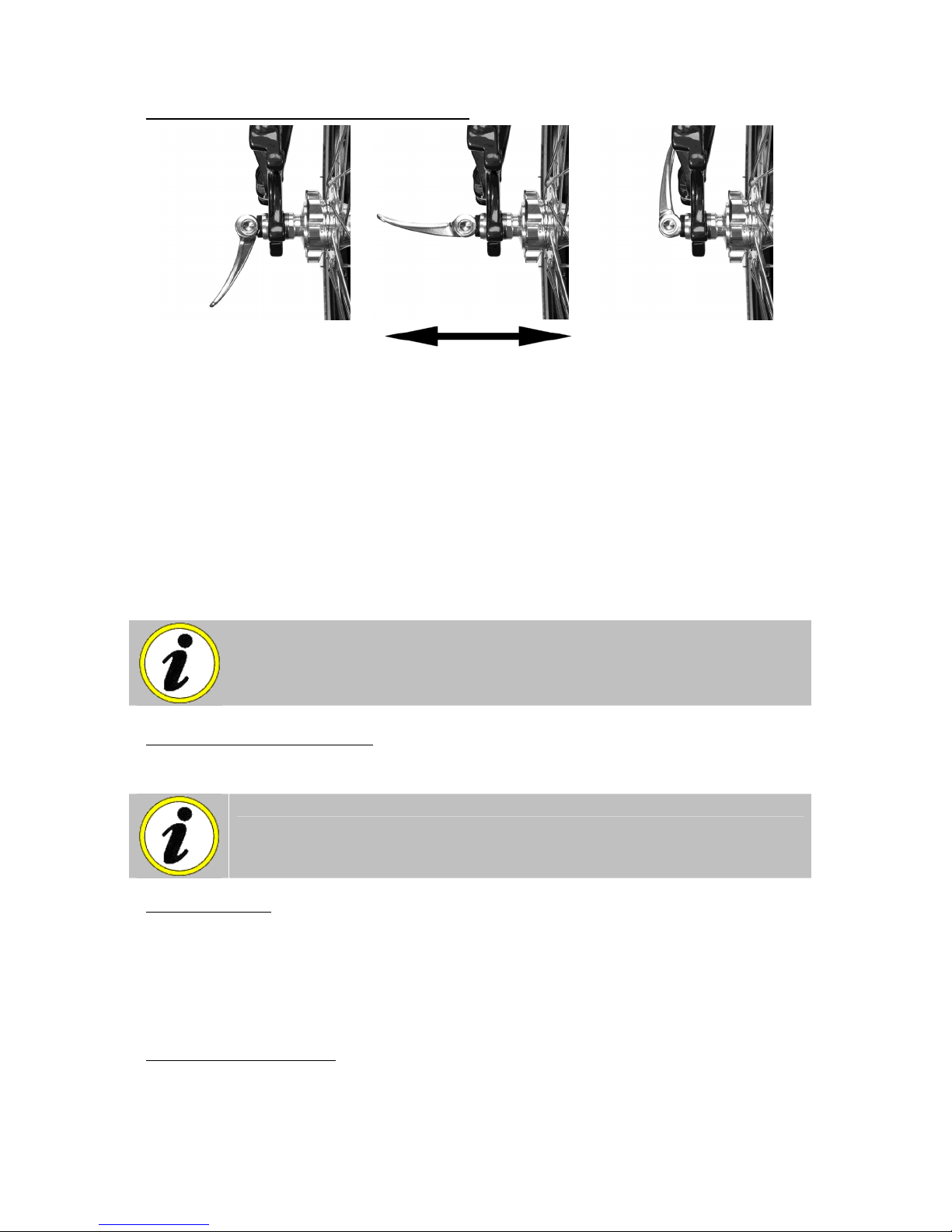

1.2 Adjusting and Closing Quick-releases .................................................................................. 4

2.0 Adjusting your ICE trike ............................................................................................................. 4

2.1 Tyre pressure......................................................................................................................... 4

2.2 Folding and Unfolding........................................................................................................... 4

2.2a Suspension adjustment....................................................................................................... 7

2.2b Front suspension adjustment ............................................................................................. 7

2.3a Mesh seat cover ................................................................................................................ 11

2.3b Fitting the hard-shell seat to you ...................................................................................... 11

2.3c Seat angle adjustment....................................................................................................... 11

2.4 Leg length............................................................................................................................ 11

2.5 Seat brackets ...................................................................................................................... 11

3.0 ICE Optional Accessories........................................................................................................ 13

4.0 Riding your ICE trike................................................................................................................ 13

4.1 Getting on and off the trike. ................................................................................................ 13

4.2 Initial test ride ...................................................................................................................... 13

4.3 Stopping in a low gear ........................................................................................................ 14

4.4 Relax.................................................................................................................................... 14

4.5 Cornering............................................................................................................................. 14

4.6 Handling .............................................................................................................................. 15

4.7 Brakes ................................................................................................................................. 15

4.8 Hill climbing ......................................................................................................................... 15

4.9 Descending a hill ................................................................................................................. 15

4.10 Ground clearance.............................................................................................................. 16

4.11 Muscles ............................................................................................................................. 16

5.0 Maintenance ............................................................................................................................ 16

5.1 Lubrication........................................................................................................................... 16

5.2 Adjusting cables.................................................................................................................. 16

5.3 Drum Brakes........................................................................................................................ 17

5.4 Disc brakes.......................................................................................................................... 17

5.5 Rear brake ........................................................................................................................... 18

5.6 Drivetrain ............................................................................................................................. 18

5.7 The frame ............................................................................................................................ 19

5.8 Tyres, tubes, & wheels ........................................................................................................ 19

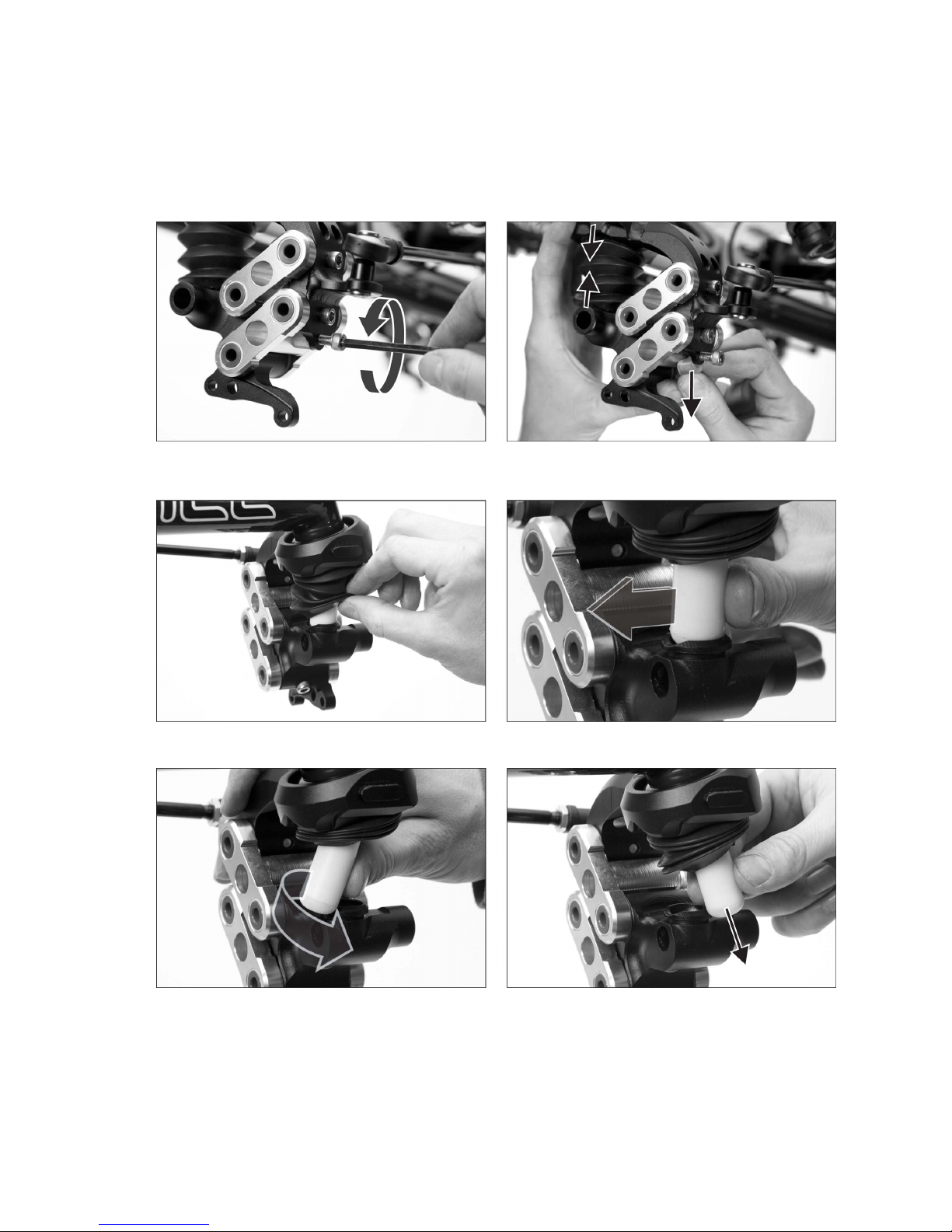

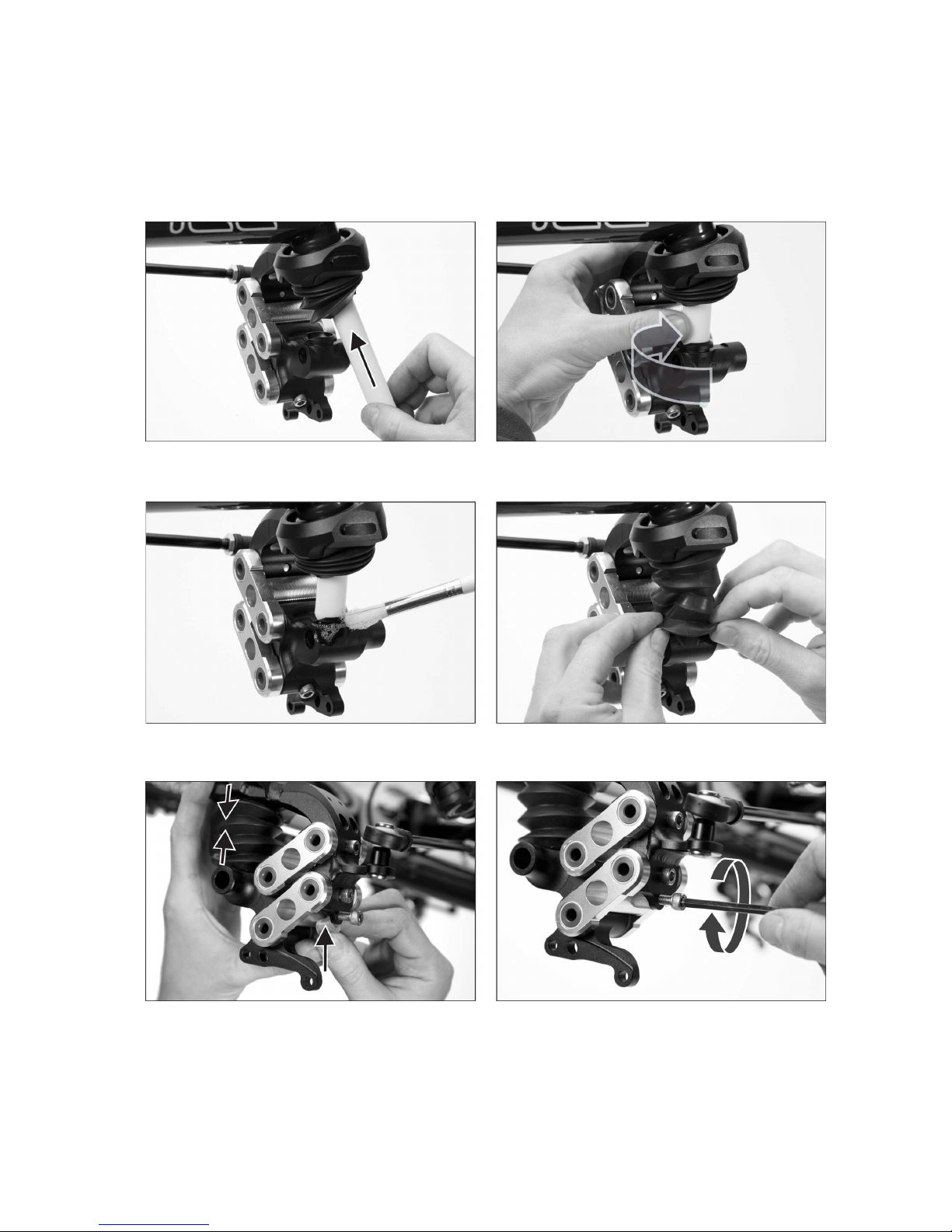

5.9 Suspension.......................................................................................................................... 20

5.10 Adjusting the tracking ....................................................................................................... 20

5.11 Storage.............................................................................................................................. 21

5.12 Serial Number.................................................................................................................... 21

5.13 Recommended minimum tools and spares ...................................................................... 22

5.14 First service ....................................................................................................................... 22

6.0 Safety....................................................................................................................................... 22

7.0 Other Important Information.................................................................................................... 23

7.1 Recumbent/Trike forums on the Internet ............................................................................ 23

7.2 Warranty Information........................................................................................................... 24

7.3 Liability Information ............................................................................................................. 25

7.4 Legal requirements.............................................................................................................. 25

7.5 Contacting us ...................................................................................................................... 25

Appendix A: Tightening torques .................................................................................................... 26

Appendix B: Suspension Elastomer limits .................................................................................... 26

Appendix C: Tyre Pressures.......................................................................................................... 27