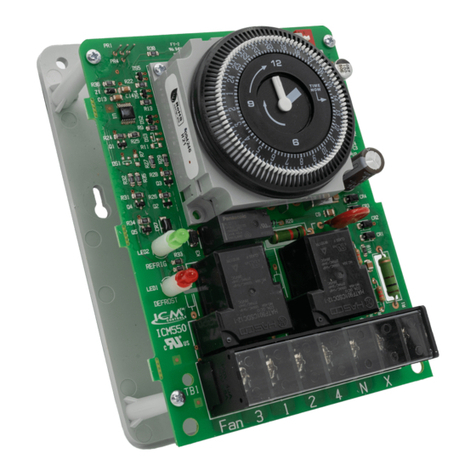

Green • Green • Red (flashing)

• SCCR: 5kA • Uimp = 4kv

• Ue = 240 VAC • Pollution degree 3

• Ui = 240 VAC

(L1, L2) – 100-240 VAC 50/60Hz

• 115 VAC nominal = 140 VAC,

240 VAC nominal = 264 VAC

• 115 VAC nominal = 95 VAC,

240 VAC nominal =195 VAC

•

• Max. nominal = 32A

• ICM870-32A = 40A

•

40°C @ 32 FLA, 8 hour duty

• -40°F to 149°F (-40°C to 65°C)

• 0-95% non-condensing

• IP65

• 7.94” x 4.20” x 2.10”

• 7.36” x 2.97”

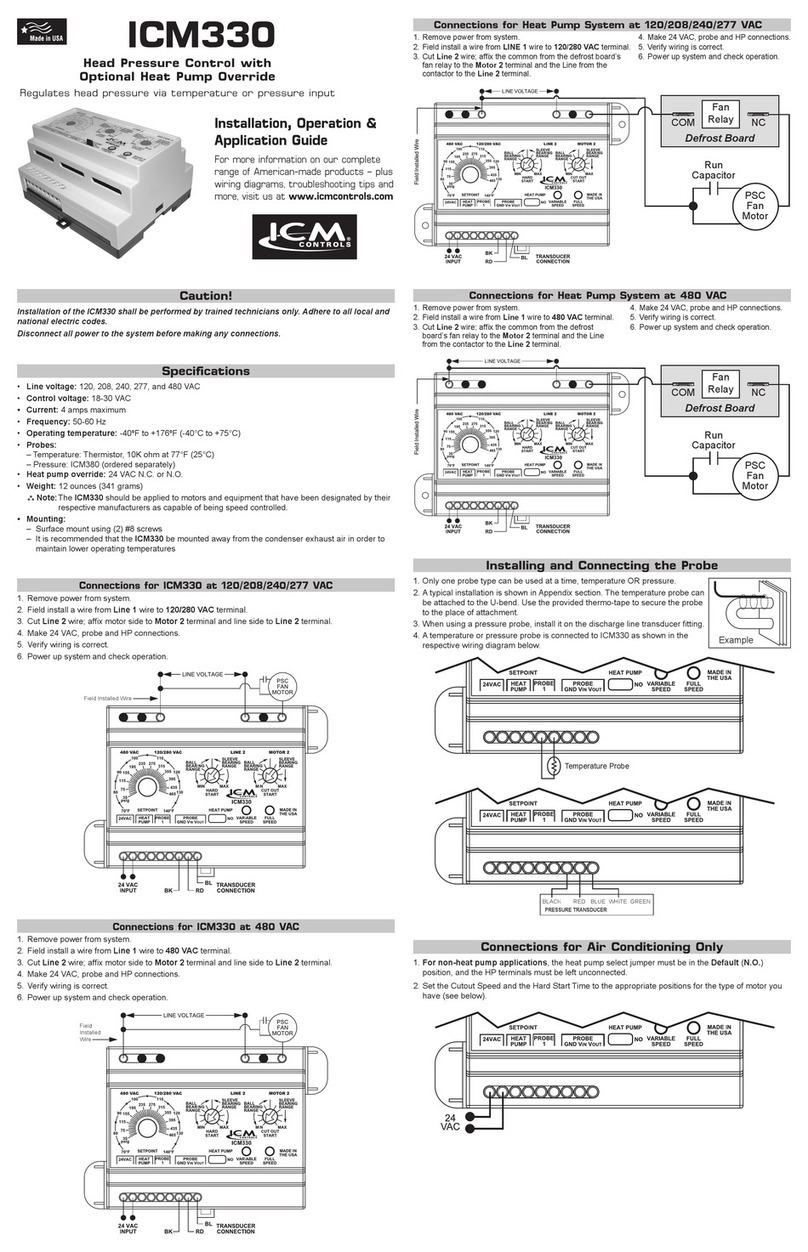

CAUTION:The must be mounted in an area where it will

not be exposed to water or the elements. Exposure of the

The is intended for Marine, Recreational Vehicle, HVAC

and commercial applications. The integrates compressor

in-rush current over startup time, thus reducing peak current demand

on a power supply source (generator or other). The

will monitor system health including voltage, current, compressor

startup and self integrity. Upon a fault condition, the will

halt operation and initiate a 3 minute anti-short cycle routine while

providing diagnostic fault information by means of an LED indicator.

The model crosses to the comparable amperage models

from the following manufacturer’s:

(Easy Start) • (So Start)

• (Smart Start) • (Sure Start)

Starting current reduction and

self-learning algorithm

Built-in start capacitor

Over-current protection

Over/under voltage

monitoring

Diagnostic indicators

Sealed enclosure

• UL 60947-1

• UL 60947-4-2

• Altitude: 2000 m

• IP65

• CSA C22.2 NO. 60947-1

• CSA C22.2 NO. 60947-4-2

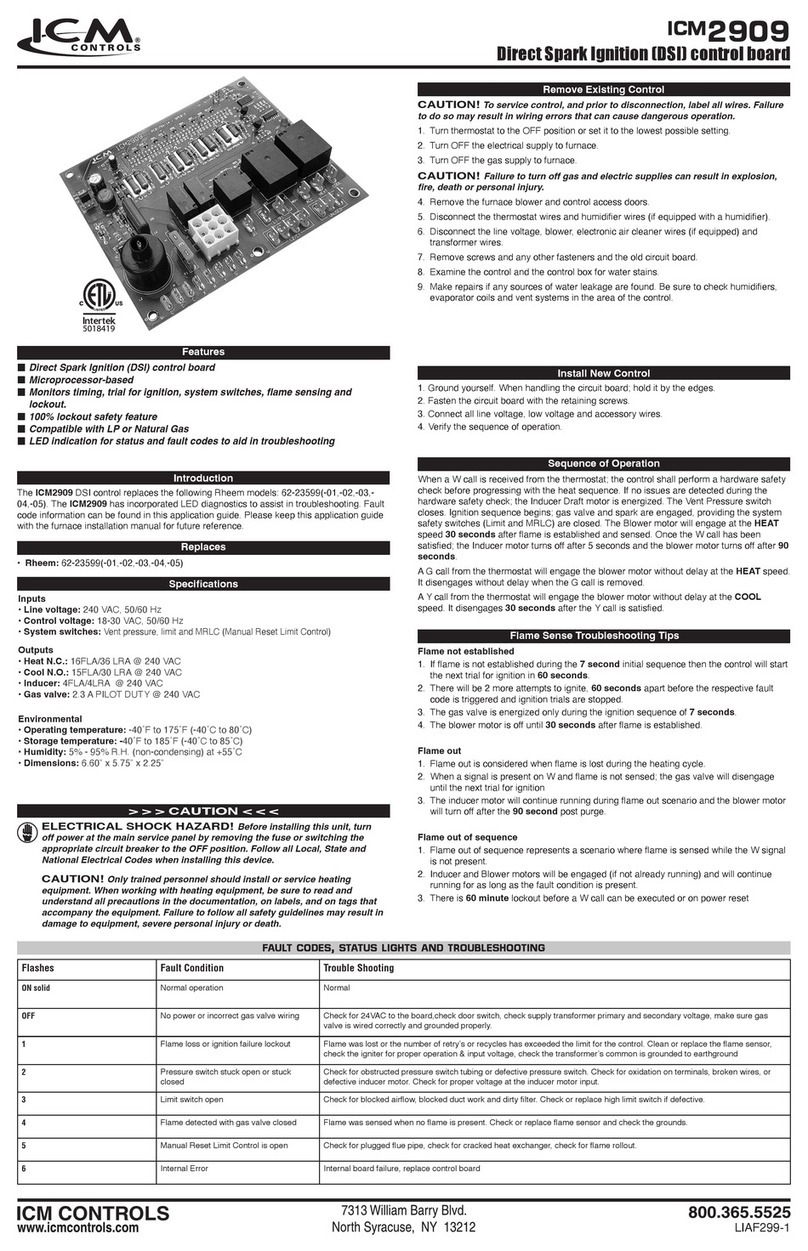

1High or low voltage

2Compressor not sensed or open fuse

3High current

4Compressor start error

5Invalid operating frequency

For more information on our complete range of American-made products – plus

wiring diagrams, troubleshooting tips and more, visit us at

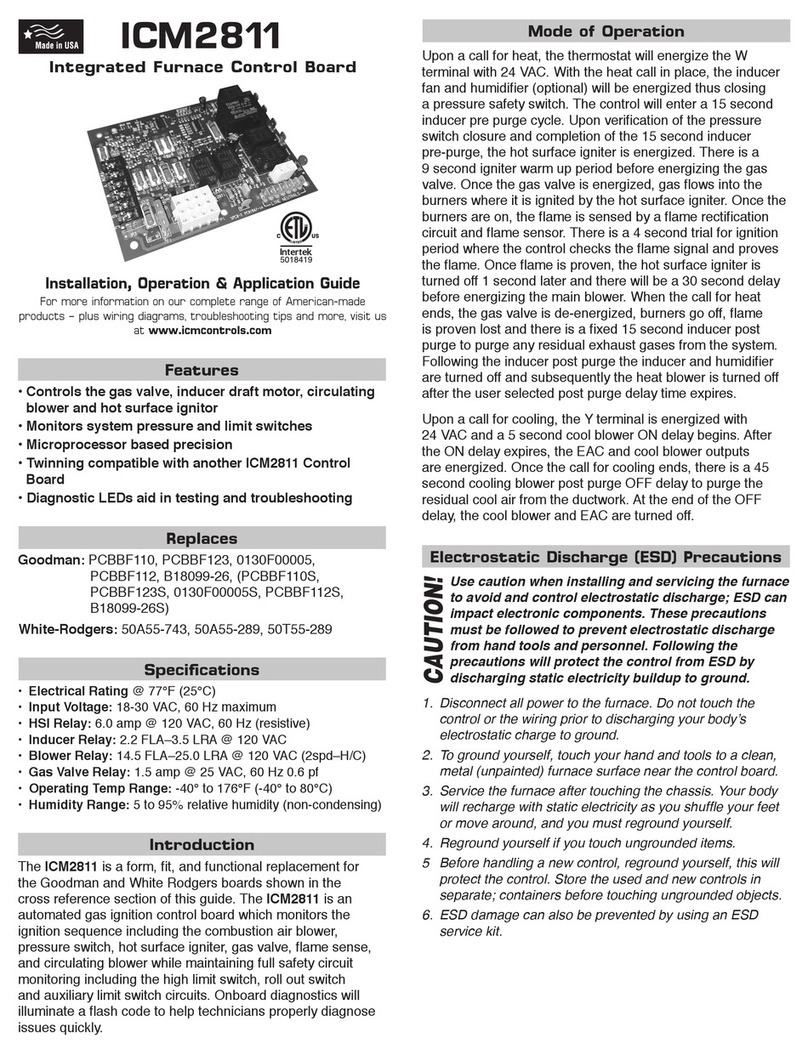

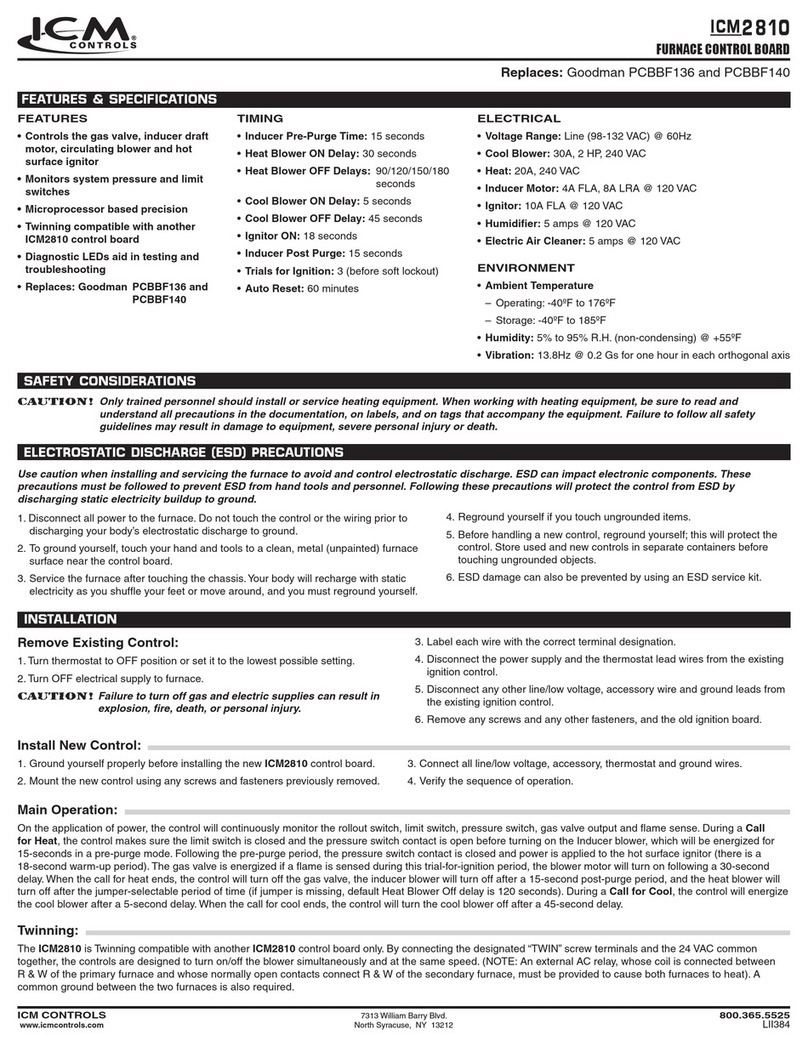

IMPORTANT SAFETY INFORMATION

SPECIFICATIONS

STANDARD AND TEST RESULTS

FAULT CODES

ICM870-32A COMPARABLE AMPERAGE CROSSES

FEATURES

APPLICATION

LED INDICATORS