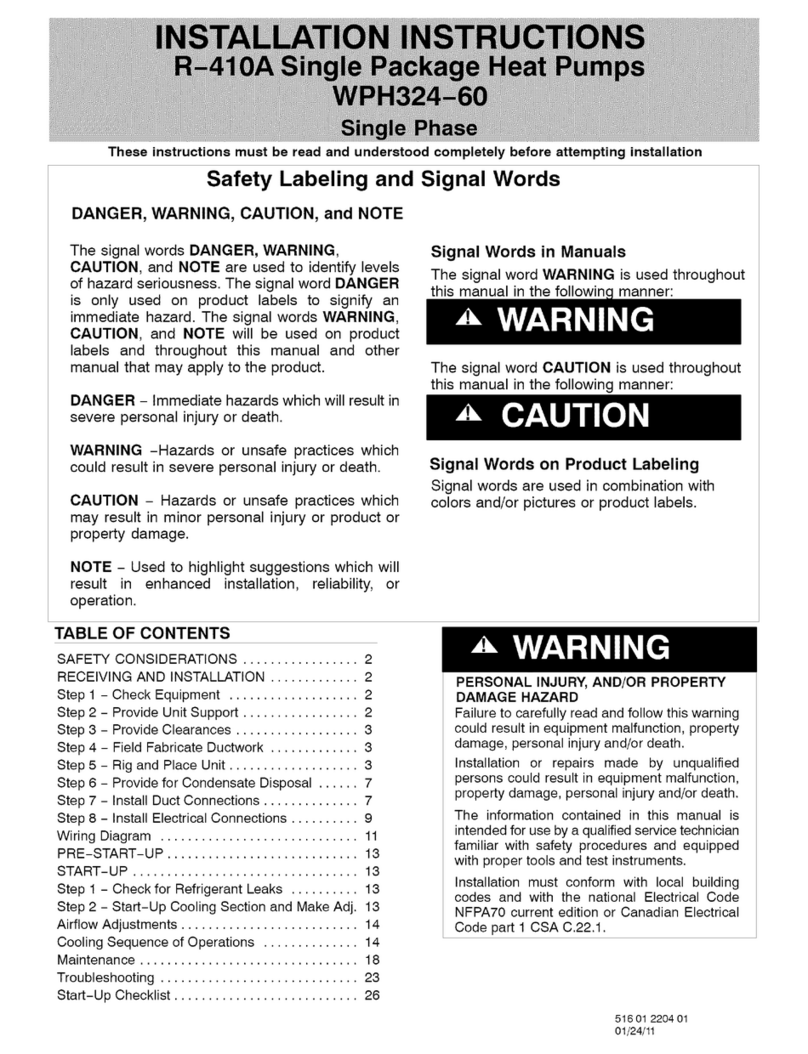

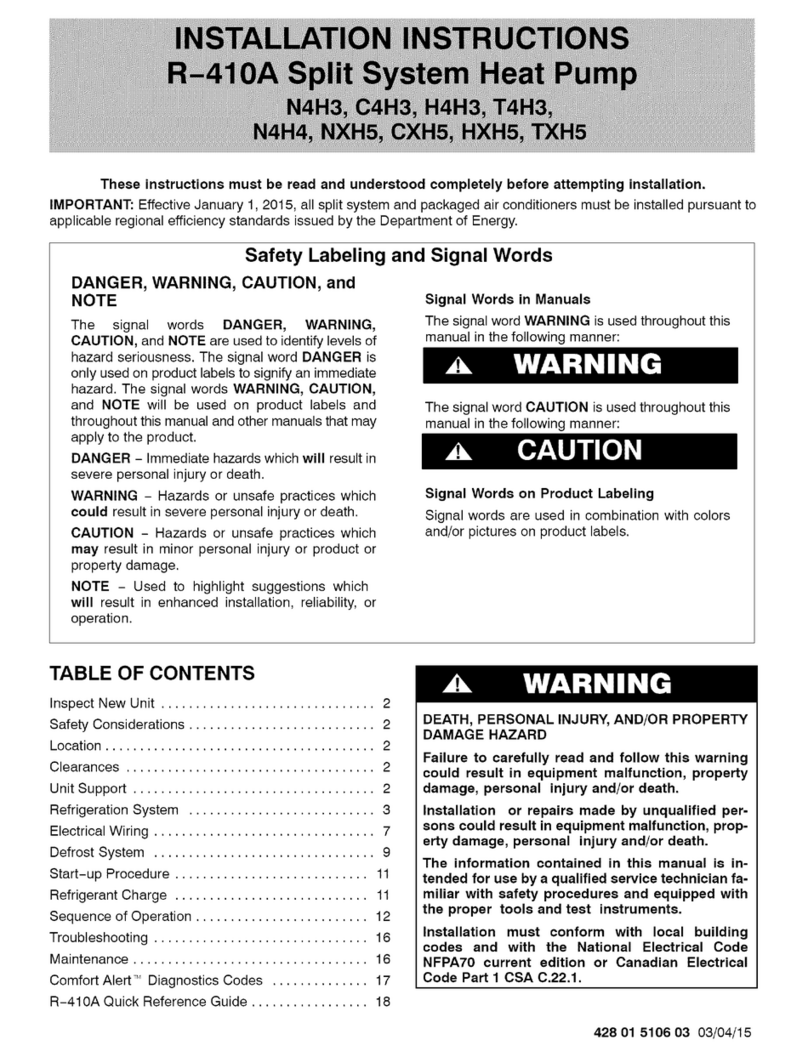

Condensate Drain

The condensate drain outlet is a 3/4" (19.1 mm) threaded female

PVC connection located at the bottom of the unit to the left of the

evaporator access panel.

The circulating blower and the condenser fan create a negative

pressure on the condensate drain line that will prevent the con-

densate from draining properly without a trap. To combat this neg-

ative pressure, a field supplied condensate trap that will allow a

standing column of water of at least 2" (50.8mm) MUST be

installed. The outlet of the trap must be at least 1" below the unit

drain connection. Install the trap as near to the unit as possible

for proper drainage.

A 3/4" (19.1 mm) drain line MUST be installed if required by local

codes or if location of unit requires it. Run the drain line to an open

drain or other suitable disposal point.

4ICondensate Drain Information*

3/4" (19,1mm)

Threaded Female

PVC Fitting

(25.4mm) 3/4" (19,1mm)

Drain Line

(82.! 2" (50.8rnm)

*Condensate trap MUST be installed.

Ground Connections

A ground lug is installed on the control plate (or electric heat

mounting plate) for the ground connection. Use a copper conduc-

tor of the appropriate size from the unit to agrounded connection

in the electrical service panel or to a properly driven and electrical-

ly grounded ground rod. See warning on this page.

Line Voltage Wiring

Do NOT complete line voltage connections until unit is perma-

nently grounded. All line voltage connections and the ground con-

nection MUST be made with copper wire.

Connections for line voltage are made on the unit electrical con-

trol plate (see NO TAG). For access, remove the Blower/Electri-

cal access panel.

Refer to applicable wiring diagram in this Manual. Complete the

line service connections to the contactor 'L1, L2, L3' terminals on

the electrical control plate. Check all screw terminals to ensure

they are tight.

NOTE: If an Electric Heat Accessory is installed, refer to the Elec-

tric Heat Accessory section of this manual to determine line volt-

age connections. The Electric Heat Accessory mounts inside the

unit in the heater box. Field supplied line voltage wires for the

Electric Heat Accessory (separate from the field supplied line

voltage wires to the unit) connect to the appropriate circuit break-

er (if used) in the Electric Heat Accessory.

Converting 230V Units to 208V

To convert 230V units to 208V:

1. Turn electric power OFF

5. Unit Electrical Wiring 2. Remove the blower/electrical access panel.

3. Locate the 24V control transformer.

Electrical shock hazard.

Disconnect power at fuse box or service panel before

making any electrical connections.

Unit MUST be grounded to electrical service panel.

Failure to follow this warning can result in property

damage, personal injury, and/or death.

NOTE: All electrical work MUST conform with the requirements of

local codes and ordinances and in the United States with National

Electrical Code ANSI/NFPA 70-1990 (or current edition). Provide

line voltage power supply from a separate fused circuit with a dis-

connect switch (when required) located within sight of the unit.

Supply voltage, amperage, fuse and disconnect switch sizes

MUST conform with local codes and ordinances.

Wiring MUST be protected from possible mechanical damage

and MUST NOT interfere with removal of access panels, filters,

etc.

All exposed line voltage connections MUST be made through liq-

uid tight conduit to prevent water from entering the unit through

the electrical access..

4. Remove wire from the terminal labeled "240V" on the 24V

control transformer and reconnect it to the 208V terminal of

the 24V control transformer.

5. Replace the blower /electrical access panel.

Low Voltage Wiring

For access, remove the electrical blower /electrical access panel.

Refer to the connection wiring diagram for the applicable model

and to the instructions included with the thermostat.

Route low voltage wires through the port located on the rear panel

and up to the control box.

NOTE: If an Electric Heat Accessory is installed, see the Electric

Heat Accessory Installation Section of this manual for low voltage

connections.

Thermostat Connections

The location of the thermostat has an important effect on the op-

eration of the unit. See the thermostat instructions for proper con-

nection. See NO TAG for Low Voltage Wire Harness

Connections

427 01 1005 00

4