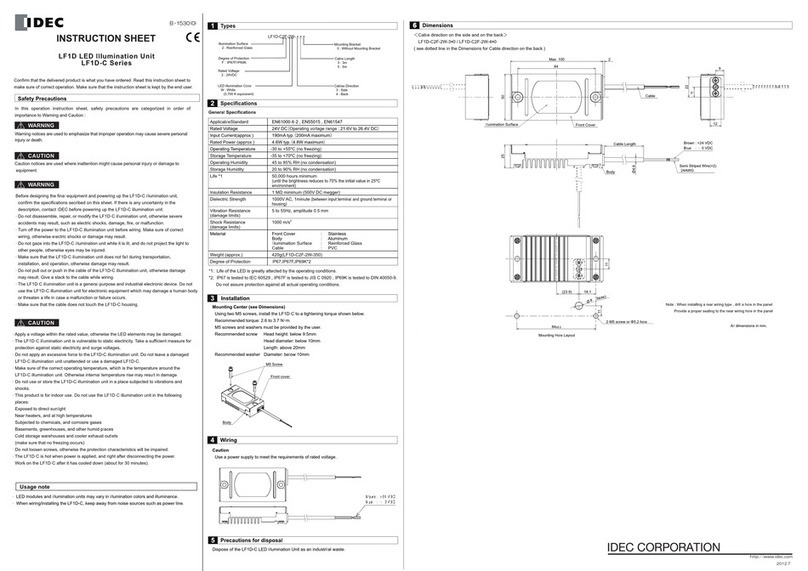

IDEC LUMIFA LF3D User manual

LED Lighting

LF3D/LF1D

Excellent optical performance and robust construction

suitable for use in machine tools

TM

2

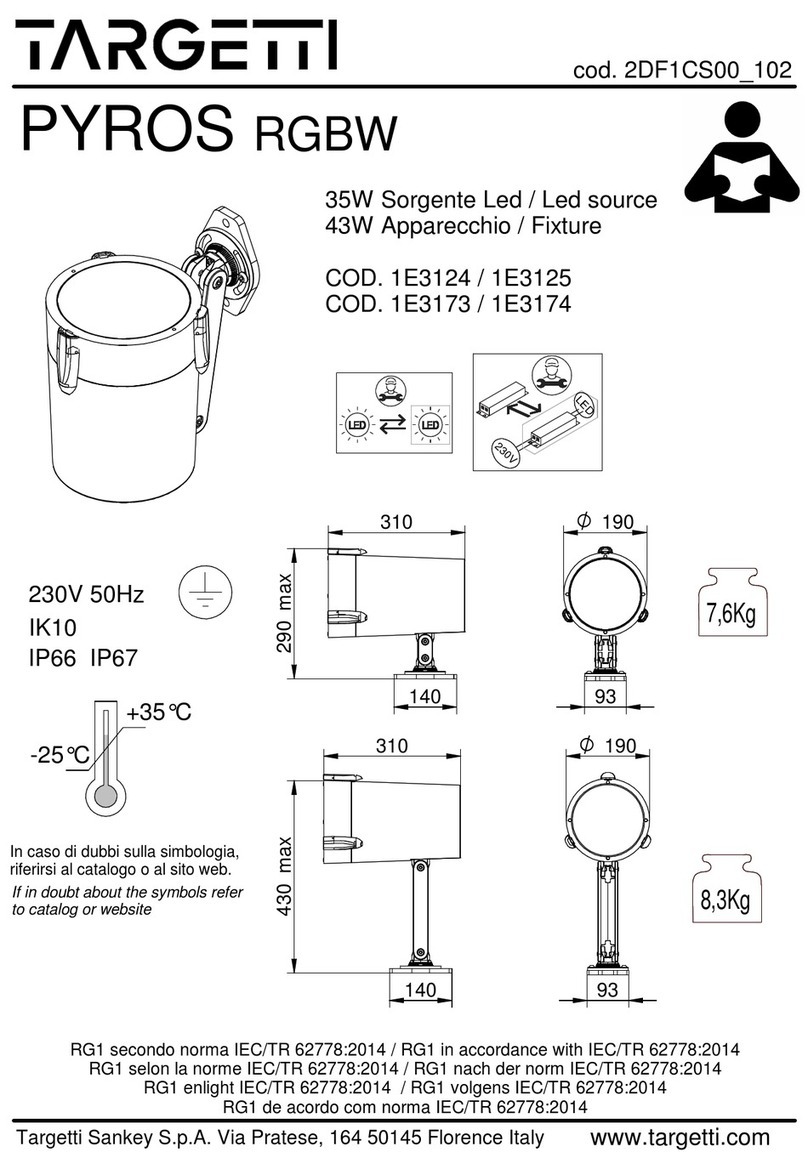

LED lighting inside machine tool allows for clear identification of chatter marks

▲

LED lighting improves machining efciency

IDEC's unique optical technology enables the light to shine evenly on

the surface, suppressing multiple shadows and allowing the operator to

see scratches and unevenness on the workpiece. LF3D lighting makes

it possible to check whether chatter marks have been generated or not

easily, at a glance.

▲

Hard to see chatter marks

Glares from LED lighting inside the machine tool could be mistaken

as chatter marks while visually checking the machine operation. This

often caused chatter marks to be left untreated, delaying maintenance

and worsening the situation.

AFTER

BEFORE

Effective solution for machine tools

3

Eliminates the

multi-shadow effect

▲

Reduced multi-shadow effect enables easy visual inspection of the

machined surface. [Patent pending (LF3D)]

Reduces reflection

from light source

Surface reflection

Surface reflection

LF3D

Conventional Product

LED light source reflects

on the workpiece and

stripes appear.

By combining our optical design

technology gained by

development of LED lighting &

sensors and by optimum LED

alignment, the brightness

contrast difference is improved

by 85%.

The LF3D LED allows the

light to be evenly distrib-

uted to provide natural

lighting, and enables

visual inspection.

[Patent pending (LF3D)]

Conventional Product LF3D

LED

Brightness

contrast

difference

Bright Dark Bright Dark

Brightness

distribution

of illumina-

tion surface

Difference

Difference

Uniform lighting

provides uniform

illumination inside

the work area

LF3D

Conventional Product

LF3D-S (surface mount)

LF3D-F (recessed mount)

4

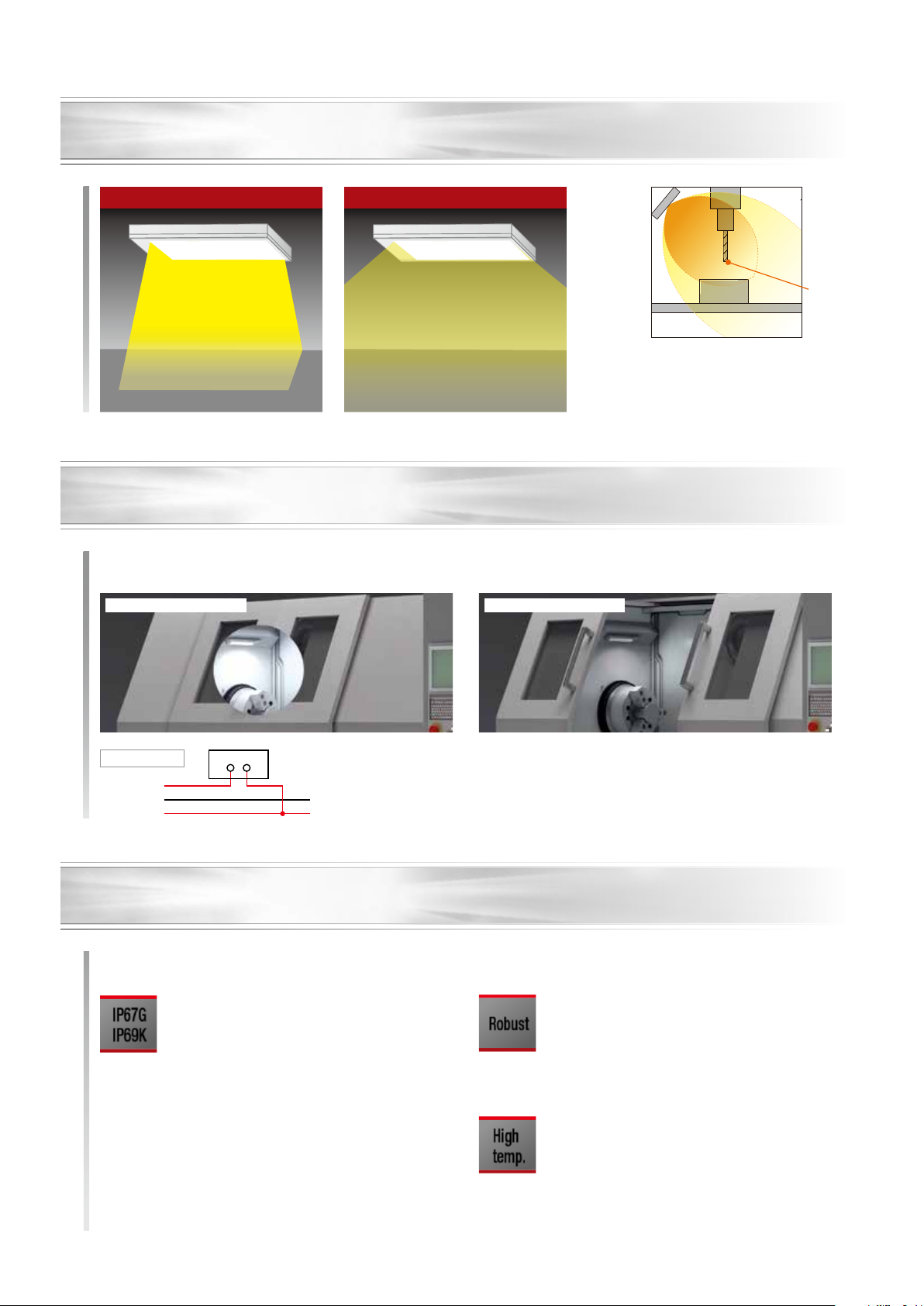

Suitable for use in machine tools

Degree of protection IP67G / IP69K

Robust material

Resistant to high temperature

Oil-resistant gasket and unique structural design achieves

IP67G protection degree. (*1)

Withstands exposure to water and oil. (*2)

IP69K for use in high-pressure, high-temperature washdown.

*1) IP67F (LF1D)

*2) Oil used for testing: Insoluble oil JIS N3-8

Reinforced glass, stainless steel, zinc diecast, extruded

aluminum prevents damage from scraps

Wide operating temperature range (up to 55C).

Robust

High

temp.

IP67G

IP69K

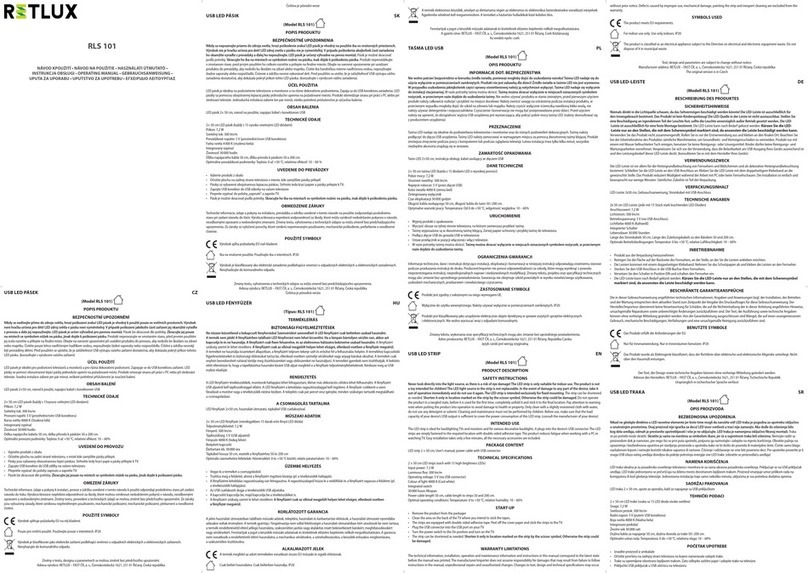

Dim light (*1) (door: closed)

100% illumination (door: closed)

Application example: Functions with opening & closing of doors / switching with control panel

*At least 500 lx shall be provided when arranging lighting for

machines.

(EN1837:1999+A1:2009 4.2)

LED lighting

500lx min.

Standard distribution Diffused distribution

Switch, etc.

–(0V)

+(24V DC)

White (pin No.2)

Blue (pin No.3)

Brown (pin No.1)

Modes can be changed by just the wiring. Complicated settings such as PWM and dedicated controllers are not required.

[Patent pending (LF3D)]

*1) Approx. 40% illumination

Equipped with glare mode to prevent operators from glare during maintenance

Select from standard or diffused light distribution depending on the machine tool needs

Wiring diagram

Rugged construction and environmentally resistant

5

Wide selection of models to suit a various machine tools

For small to medium machines For large machines

Application Standard lens provides brilliant light on the edges of tools and work pieces.

Diffused lens provides wide light distribution inside work areas.

Wide illumination inside the work

area or replacements for

uorescent lamps

Part no. LF3D-S LF3D-F LF1D-H/J

Shape Surface mount Recessed mount Surface mount

Luminous Flux

(typ.) 1700 lm 2000 lm (LF1D-H)

3000 lm (LF1D-J)

Reference

Illuminance (typ.)

at 1.0m directly

below

1800 lx (standard distribution)

1000 lx (diffused distribution)

560 lx (LF1D-H)

840 lx (LF1D-J)

Dimensions

(W × H × D) 55.8 × 17.5 × 310 mm 80 × 27 × 307 mm

84 × 24.8 × 365 mm

(LF1D-H)

84 × 24.8 × 510 mm

(LF1D-J)

Compact, slim, and light compared to conventional products

Weight

30%

DOWN

Weight

25%

DOWN

Luminous

efciency

37%

UP

Mass

50%

DOWN

Wide variety of connector types available

Easy replacement

with conventional

products

Panel cut-out for older LED lighting

will t the new LF3D LED.

Accessories for surface mount type

replacements available.

Surface mount/Side cable

(LF3D-SB2S05M)

Recessed mount/Back M12

(LF3D-FB1B1)

LF3D-S (surface mount)

LF3D-F (recessed mount)

Luminous

efciency

47%

UP

Mass

40%

DOWN

Surface mount/Side M8

(LF3D-SB2S2)

LF2D-E

LF2D-F

Surface mount/Back M12

(LF3D-SB1B1)

Recessed mount/Back cable

(LF3D-FB1B05M)

Improved design and user-friendly

LF1D-EN (surface mount)

LF2D-FH (recessed mount)

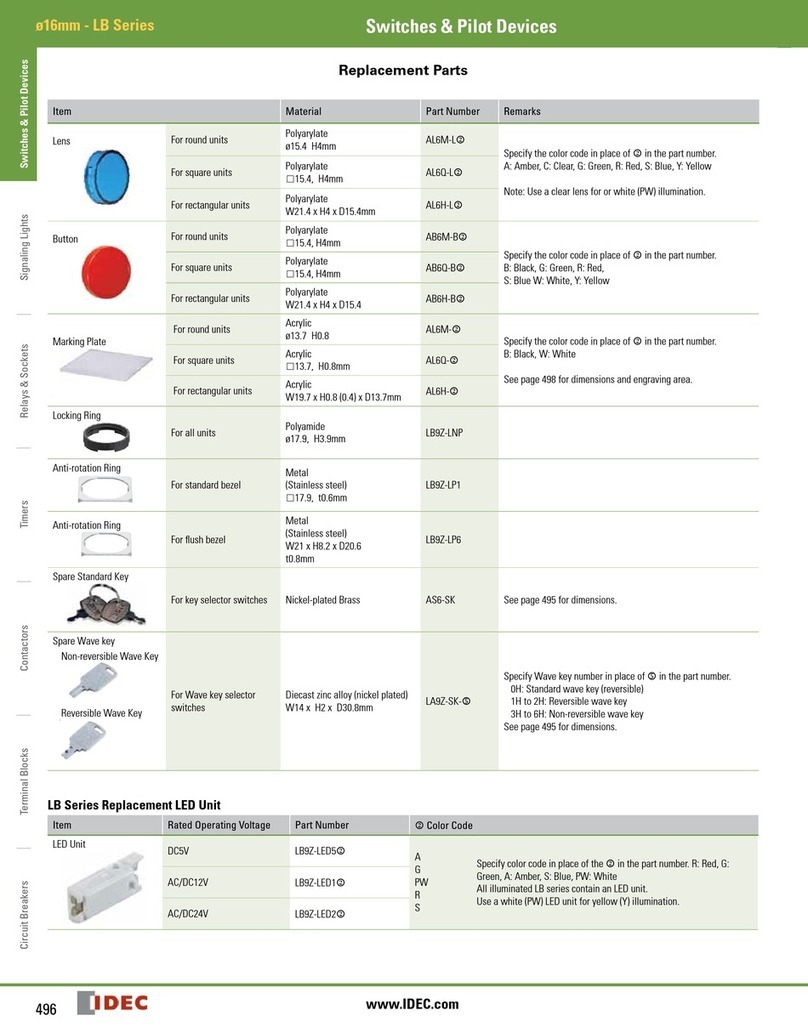

LF3D/LF1D LED Lighting

6

Internal Circuit

LF3D Package Quantity: 1

Model LF3D

Light distribution Standard Diffused

Style Surface mount (*1) Recessed mount Surface mount (*1) Recessed mount

Illumination surface Reinforced glass

Connection

direction

Cable /

Connector Part no. (Ordering no.)

Side 5m cable LF3D-SB2S05M —LF3D-SB1S05M —

M8 connector LF3D-SB2S2 LF3D-SB1S2

Rear

5m cable —

LF3D-FB2B05M

—

LF3D-FB1B05M

LF3D-F1B2B05M (*2)LF3D-F1B1B05M (*2)

LF3D-F2B2B05M (*3)LF3D-F2B1B05M (*3)

M12 connector LF3D-SB2B1

LF3D-FB2B1

LF3D-SB1B1 LF3D-FB1B1

LF3D-F1B2B1 (*2)

LF3D-F2B2B1 (*3)

*1) Contact IDEC for customers using LF1D–E (EH/EN) or LF1D–F (FH).

*2) Size and mounting centers compatible with LF2D–E (EH/EN). (LF3D-F1)

*3) Size and mounting centers compatible with LF2D–F (FH). (LF3D-F2)

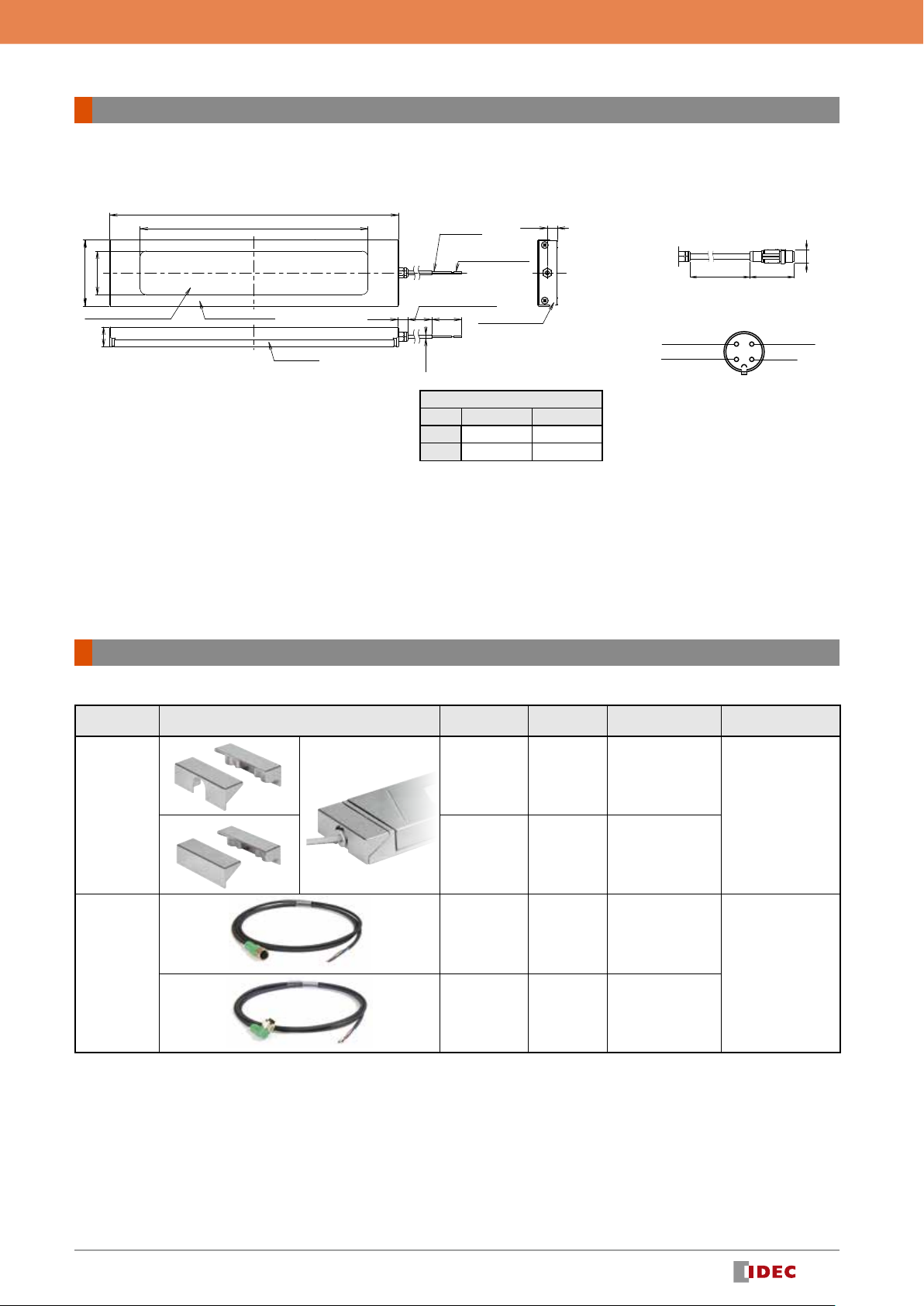

Performance Specifications

Model LF3D

Style Uniform light source / slim type

Light distribution Standard Diffused

Rated voltage 24V DC

Operating voltage range 21.6 to 26.4V DC

Rated Power (typ.)

(at rated voltage) 9.2W

Illumination color Cool white

Color temp. (typ.) 5700K

Luminous Flux (typ.) 1700 lm

Reference Illuminance (typ.)

at 1.0m directly below 1800 lx 1000 lx

Insulation resistance 100M minimum (500V DC megger)

Dielectric strength 1000V AC, 50/60Hz, 1 minute

Vibration resistance

(damage limits) Frequency 5 to 55Hz, amplitude 0.5mm

Shock resistance

(damage limits) 1000m/s2

Operating temperature –30 to +55°C (no freezing)

Operating relative humidity 45 to 85%RH (no condensation)

Storage temperature –35 to +70°C (no freezing)

Operating atmosphere No corrosive gas

Light source life (*1)

50,000 hours (The illumination duration in which the brightness

maintains a minimum of 70%)

(Ta = 25ºC, 45%RH max.)

Degree of protection (*2) Surface mount: IP65, IP67, IP67G, IP69K

Recessed mount: IP65, IP67, IP67G

Glare save mode

(GS-Mode) (*3)

White wire (pin no.1) - open: 100% light on

White wire (pin no.1) and brown wire (pin no. 2) - short-circuit: dim light

Material (Main parts)

Main body: Aluminum

Front cover (surface mount): Stainless steel

Flange (recessed mount): Aluminum

Side cover: Zinc die-cast (plating)

Illumination part surface: Reinforced glass

Gasket: NBR

Weight (approx.) LF3D-S: 680g (*4)

LF3D-F: 770g (*4)

LF3D-F1: 830g (*4)

LF3D-F2: 870g (*4)

Light Distribution Curve

(reference value)

(unit: cd/1000 lm)

200

400

600

800

1000

1200

90°90°

30°

60°60°

0°

30°

90°90°

30°

60°60°

0°

30°

100

200

300

400

500

600

A

C

B

A

B

C

A-A

B-B

C-C

Cross-sectional direction of light distribution

Blue (pin no. 3)

Brown (pin no. 1)

Brown (pin no. 1)

White (pin no. 2)

(–)

(+)

定電流形電源

+ LED

筐体

Housing

Constant-current

power supply

+ LED

Housing

Constant-current

power supply

+ LED

Blue (pin no. 3)

(LF3D only)

LF3D LED Lighting

• Due to variations in LED elements, products may vary in illumina-

tion color and illuminance.

*1) Not a guaranteed value. The actual life may differ depending on

the operating environment and conditions. Specications are

subject to change without notice.

Ta is the ambient temperature of this product.

*2) Testing conditions specied by IEC60529 (IP67), JIS C 0920

(IP67F/IP67G), and DIN40050-9 (IP69K)

Not guaranteed for every operating condition (the rated value of

the protective structure is when the product is mounted.)

*3) Dimming differs according to the operating environment.

Not a xed value. (Ta=25ºC typ.)

*4) Weight of cable type.

7

LF3D/LF1D LED Lighting

LF1D

LF1D-H/LF1D-J Long type Package Quantity:

Model LF1D-H LF1D-J

Mount style Surface mount

Illumination surface Reinforced glass

Cable direction Cable length Part no. (Ordering no.)

Side 5m LF1D-H2F-2N-350 LF1D-J2F-2N-350

1.5m + M12 connector LF1D-H2F-2N-3B0 LF1D-J2F-2N-3B0

Rear 5m LF1D-H2F-2N-450 LF1D-J2F-2N-450

1.5m + M12 connector LF1D-H2F-2N-4B0 LF1D-J2F-2N-4B0

Performance Specifications

Model LF1D-H LF1D-J

Style Long type

L=365mm

Long type

L=510mm

Light distribution Diffused

Rated voltage 24V DC

Operating voltage range 21.6 to 26.4V DC

Rated Power (typ.)

(at rated voltage) 18.4W 27.6W

Illumination color Neutral white

Color temp. (typ.) 4700K

Luminous Flux (typ.) 2000 lm 3000 lm

Reference Illuminance

(typ.)

at 1.0m directly below

560 lx 840 lx

Insulation resistance 100M minimum (500V DC megger)

Dielectric strength 1000V AC, 50/60Hz, 1 minute

Vibration resistance

(damage limits) Frequency 5 to 55Hz, amplitude 0.5mm

Shock resistance

(damage limits) 1000m/s2

Operating temperature –30 to +55°C (no freezing)

Operating relative

humidity 45 to 85%RH (no condensation)

Storage temperature –35 to +70°C (no freezing)

Operating atmosphere No corrosive gas

Light source life (*1)

50,000 hours (The illumination duration in which the

brightness maintains a minimum of 70%)

(Ta=25ºC, 45%RH max.)

Degree of protection (*2) IP67, IP67F, IP69K

Material (Main parts)

Main body: Aluminum

Front cover (surface mount): Stainless steel

Illumination part surface: Reinforced glass

Gasket: NBR

Weight (approx.) LF1D-H2F-2N-350: 1200g LF1D-J2F-2N-350: 1600g

Light Distribution Curve

(reference value)

(unit: cd/1000 lm)

90

°

90

°

60

°

0°

30

°

60

°

100

30 °

200

90

°

90 °

60 °

0°

30

°

60

°

100

30 °

200

Internal Circuit

Blue (pin no. 3)

Brown (pin no. 1)

Brown (pin no. 1)

White (pin no. 2)

(–)

(+)

定電流形電源

+ LED

筐体

Housing

Constant-current

power supply

+ LED

Housing

Constant-current

power supply

+ LED

Blue (pin no. 3)

A

C

B

A

B

C

A-A

B-B

C-C

Cross-sectional direction of light distribution

LF1D LED Lighting

• Due to variations in LED elements, products may vary in illumination

color and illuminance.

*1) Not a guaranteed value. The actual life may differ depending on the

operating environment and conditions. Specications are subject to

change without notice.

Ta is the ambient temperature of this product.

*2) Testing conditions specied by IEC60529 (IP67), JIS C 0920 (IP67F/

IP67G), and DIN40050-9 (IP69K)

Not guaranteed for every operating condition (the rated value of the

protective structure is when the product is mounted.)

8

LF3D/LF1D LED Lighting

Connector Wiring

M12 connector type (A coding)

Pin no. Wiring color Function Connection

➀Brown +DC Power Supply +24V

➁White GS Mode Open or +DC

➂Blue -DC Power Supply 0V(GND)

➃– N.C.

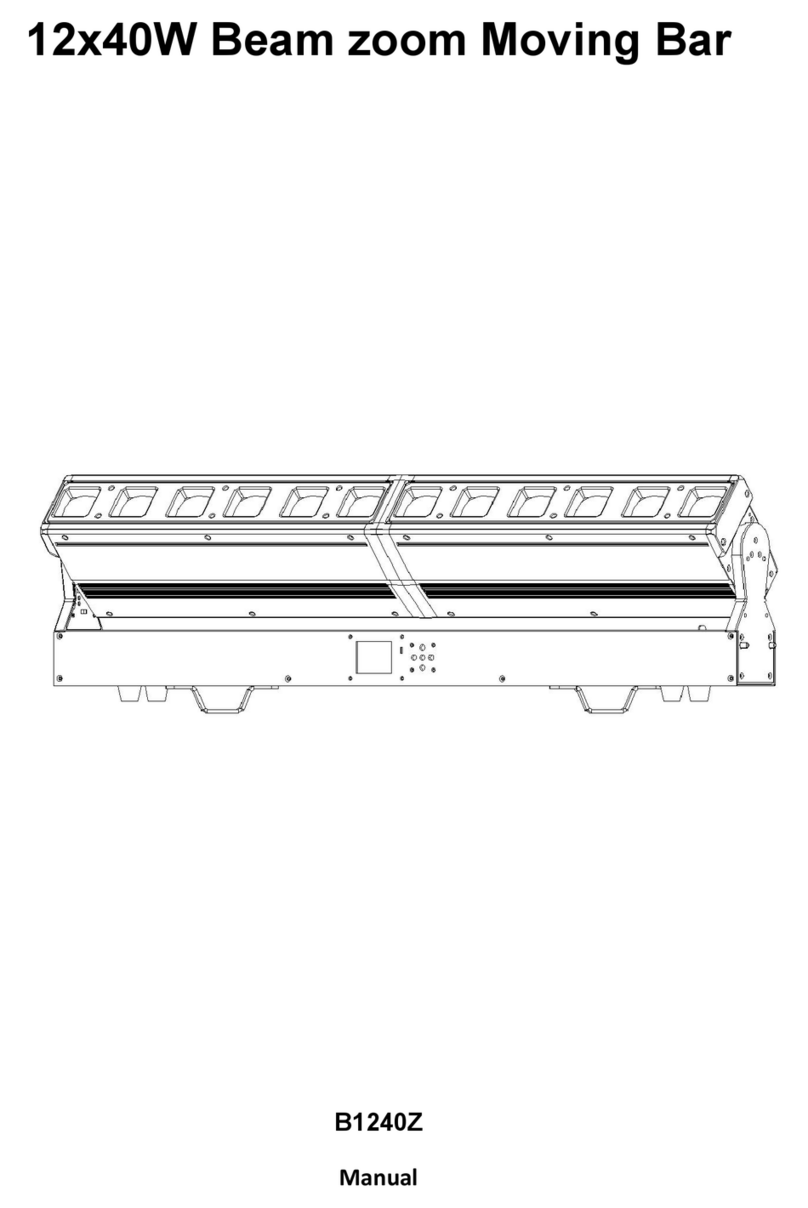

Dimensions (mm)

Model LF3D-F LF3D-F1 LF3D-F2

A 307 389 308

B 292 374 293

C 80 80 105

D 65 65 90

E 292 374 293

F 284 366 286

G 65 65 90

H 55 55 80

Use a connector on a power

supply side that satisfies the

required degree of protection.

Phoenix Contact (M12 con-

nector)

Mounting hole layout

Illumination

surface

Main body

Side cover

Flange

6-M5×10 Hexagon socket

+ Gasket (supplied with LF3D)

Cable length: 5m

6-M5 screw hole

or tapped hole

184.8

D

C

31

A

B

3

27

124.5

F

E

H

G

ø4

①

④

②

③

5m cable type

(33)

(34.5)

M12 connector type

Connector Wiring

LF3D (surface mount)

M8 connector

Pin No. Wiring color Function Connection

➀Brown +DC Power Supply +24V

➁White GS Mode Open or +DC

➂Blue -DC Power Supply 0V(GND)

➃– N.C.

Use a connector on a power supply side that satisfies the

required degree of protection.

Recommended connector: Harting (M8 connector)

Phoenix Contact (M12 connector)

Illumination

surface

Front cover

Side cover

Body

*1) When M12 connector is used

*1) When M12 connector is used

Mounting hole layout (M5 screw)

Mounting hole layout (M6 screw)

When LF9Z-B2 is used

Cable length: 5m

4-M4

26

4-M5 screw hole

or tapped hole

4-M6 screw hole

or tapped hole

310

184.8

55.8

17. 5

ø4

40±0.2

38±0.2

292 ±1.0

296 ±1.0

315.2

305

124.5

124.5

40

ø20 (*1)

ø20 (*1)

P0.7

④

③

②

①

①

④

②

③

5m cable

17. 5

M8 connector

17. 5

(30.5)

M12 connector

M12 connector

(A coding)

LF3D (recessed mount)

Dimensions (LF3D)

Dimensions in mm

9

LF3D/LF1D LED Lighting

Item Shape Type Part no.

(Ordering no.) Package quantity Remarks

Mounting

Bracket

Example(LF9Z-B21)

Side connection LF9Z-B21

2

(for right and left,

supplied with mounting

screws)

Bracket used for

mounting LF1D-E (EN/

EH) from the back with

the same mounting

centers.

Back connection LF9Z-B22

2

(for right and left,

supplied with mounting

screws)

M12 connector

cable

Straight LF9Z-CM13 1

Length: 3m

Right angle LF9Z-CM23 1

• Accessories are not supplied with the product.

Accessories exclusive for LF3D

Note: For mounting hole layout and the size of mounting screws on the back of the LED unit, see the specication sheet and dimensions supplied with the product.

Connector Wiring

LF1D-H/J2F-2*-*B*

(M12 connector)

(+)

(–) (+)

(–)

1470 46.8

ø14.8

➀+24V DC

➂-0V DC

➃NC

➁NC

Plug 4-pin assignment

M12 connector: SAC-4P-MS SCO/150/1.5

Use a connector on the power sup-

ply side that satises the degree of

protection.

Recommended connector:

Phoenix Contact

SAC-4P-1.5-PUR/FS SCO

LF1D-H [long type] L=365mm] / LF1D-J [long type L=510mm]

Dimensions (mm)

Model LF1D-H LF1D-J

A 365 510

B 288 432

A

55

B

84

24.8

ø4.6

12.5 (35)

Cable length 5 m

12.7

Side cover

Semi-stripped × (2)

24AWG

Front cover

Illumination surface

Main body

Brown: (+)

Blue: (–)

Dimensions (LF1D)

Accessories (LF3D)

Dimensions in mm

10

LF3D/LF1D LED Lighting

• Do not disassemble, repair, or modify the product. Otherwise electric

shock, re, or malfunction may occur.

• Turn off power before wiring. Make sure that the temperature has

lowered sufciently before wiring.

• To prevent electric shock or damage, ensure that the wiring is

correct.

• Do not stare directly into the LED while it is lit, and do not project the

light towards other people, otherwise eyes may be injured.

• The product is a general-purpose industrial electric device.

• Ensure correct operating temperature. Operating temperature is the

ambient temperature where the product will be used. Temperature

exceeding the specied value may cause rise in internal temperature

and cause damage to the unit.

• When using this product as part of or in connection with electrical

equipment for general use (*), use a DC power supply unit with a PSE

mark that conforms to the technical standards of the Product Safety

Electrical Appliance & Material (PSE). For installation, follow the laws

and regulations such as technical standards for electrical equipment

and construction equipment standards.

*) Electrical facilities mainly for general residences and stores, receiving AC

600V or less, and small power generation facilities.

• The product is for indoor use only. Do not use outdoors, otherwise

insulation failure, electric shock, or failure may result.

• Do not use for applications which may cause harm or injury in case a

malfunction or failure occurs.

• Due to variations in LED elements, products may vary in illumination

color and illuminance.

• Before designing equipment and powering up the product, conrm

the specications described in the instruction sheet.

• Apply voltage within the rated value, otherwise the LED elements

maybe damaged.

• Do not use or store in a location subject to vibration and shock,

otherwise electric shock or failure will result.

• Do not loosen screws, otherwise the protection characteristics will be

impaired.

• To clean the cover, use a soft cloth with water or neutral detergent.

Do not use solvents such as thinners, benzene, or alkaline, otherwise,

discoloration, deterioration, or decrease in strength may occur.

• When using this product in environments subject to dust and water,

make sure that the wiring part of cable or wire are dustproof/water-

proof. Otherwise leakage, electric shock, or failure may occur.

• Do not use in the following locations:

➀Locations subject to high water pressure (environments exceeding protec-

tion degree IPX5, IPX7X or IPX9K in accordance with IEC 60529.)

➁Locations subject to dust (environments exceeding protection degree IP6X

in accordance with IEC 60529.

➂Environment subject to corrosive gases, volatile gases, ammable gases, or

chemicals that could affect the safety and reliability of the product.

➃Locations subject to electric or magnetic elds.

➄Subject to ammable substances.

➅Exposed to direct sunlight, near heaters, high temperatures.

➆Exposed to salt water.

➇Subject to condensation or freezing, such as cold storage warehouse or air

cooler outlet (make sure that condensation or freezing do not occur).

➈Exposed to ozone, radiation, UV or other locations where safety and reli-

ability of the product.

• When using the product as a UL/c-UL listed product, use a Class 2

power supply.

• Some metal parts are surface treated and the appearance may vary

depending on each part. Also, some scratches may appear on the

surface but does not affect product performance.

• The warranty does not apply if the product is used outside of the

conditions described in the instruction manual and specications.

• The warranty period is one year after delivery to the specied

location.

*Exceptions to warranty coverage

The warranty period is reduced to six (6) months if the product is run

continuously over 20 hours.

• In the event of a failure caused by our responsibility within the above period,

we will replace the product free of charge at the place where the product was

purchased or delivered.

*Does not include expenses required for mounting, replacing, or installation

work.

• LED lighting have a product life.

• Because internal elements deteriorate after 8 to 10 years of installation even if they have no defects in appearance, inspection and/or replacement

are recommended. Operation condition: temperature 30°C, 3,000-hour operation per year (10 hours per day). (JIS C 8105-1)

• Product life is shortened under high operating temperature or when it is lit for long hours.

• Inspection and/or cleaning by user every 6 months is recommended.

• Inspection by contractors is recommended every 3 years.

• Do not use the product for a long time without inspection, otherwise smoke, re, or electric shock may occur.

Safety Precautions

Instructions

Warranty

For details on mounting, wiring, and circuit examples, see the instruction manual from the

below URL.

URL LF3D-S/F https://product.idec.com/?product=LF3D

LF3D-F1 https://product.idec.com/?product=LF3D-F1

LF3D-F2 https://product.idec.com/?product=LF3D-F2 LF3D-S/F LF3D-F1 LF3D-F2

11

LF3D/LF1D LED Lighting

1. Notes on contents of Catalogs

(1) Rated values, performance values, and specification values of IDEC products

listed in this Catalog are values acquired under respective conditions in

independent testing, and do not guarantee values gained in combined

conditions.

Also, durability varies depending on the usage environment and usage

conditions.

(2) Reference data and reference values listed in Catalogs are for reference

purposes only, and do not guarantee that the product will always operate

appropriately in that range.

(3) The specifications / appearance and accessories of IDEC products listed in

Catalogs are subject to change or termination of sales without notice, for

improvement or other reasons.

(4) The content of Catalogs is subject to change without notice.

2. Note on applications

(1) If using IDEC products in combination with other products, confirm the

applicable laws / regulations and standards.

Also, confirm that IDEC products are compatible with your systems, machines,

devices, and the like by using under the actual conditions. IDEC shall bear no

liability whatsoever regarding the compatibility with IDEC products.

(2) The usage examples and application examples listed in Catalogs are for

reference purposes only. Therefore, when introducing a product, confirm the

performance and safety of the instruments, devices, and the like before use.

Furthermore, regarding these examples, IDEC does not grant license to use

IDEC products to you, and IDEC offers no warranties regarding the ownership

of intellectual property rights or non-infringement upon the intellectual

property rights of third parties.

(3) When using IDEC products, be cautious when implementing the following.

i. Use of IDEC products with sufficient allowance for rating and

performance

ii. Safety design, including redundant design and malfunction prevention

design that prevents other danger and damage even in the event that an

IDEC product fails

iii. Wiring and installation that ensures the IDEC product used in your

system, machine, device, or the like can perform and function according

to its specifications

(4) Continuing to use an IDEC product even after the performance has

deteriorated can result in abnormal heat, smoke, fires, and the like due to

insulation deterioration or the like. Perform periodic maintenance for IDEC

products and the systems, machines, devices, and the like in which they are

used.

(5) IDEC products are developed and manufactured as general-purpose products

for general industrial products. They are not intended for use in the following

applications, and in the event that you use an IDEC product for these

applications, unless otherwise agreed upon between you and IDEC, IDEC shall

provide no guarantees whatsoever regarding IDEC products.

i. Use in applications that require a high degree of safety, including nuclear

power control equipment, transportation equipment (railroads / airplanes

/ ships / vehicles / vehicle instruments, etc.), equipment for use in outer

space, elevating equipment, medical instruments, safety devices, or

any other equipment, instruments, or the like that could endanger life or

human health

ii. Use in applications that require a high degree of reliability, such as

provision systems for gas / waterworks / electricity, etc., systems that

operate continuously for 24 hours, and settlement systems

iii. Use in applications where the product may be handled or used deviating

from the specifications or conditions / environment listed in the Catalogs,

such as equipment used outdoors or applications in environments

subject to chemical pollution or electromagnetic interference

If you would like to use IDEC products in the above applications, be sure

to consult with an IDEC sales representative.

3. Inspections

We ask that you implement inspections for IDEC products you purchase without

delay, as well as thoroughly keep in mind management/maintenance regarding

handling of the product before and during the inspection.

4. Warranty

(1) Warranty period

The warranty period for IDEC products shall be one (1) year after purchase or

delivery to the specified location. However, this shall not apply in cases where

there is a different specification in the Catalogs or there is another agreement

in place between you and IDEC.

(2) Warranty scope

Should a failure occur in an IDEC product during the above warranty period

for reasons attributable to IDEC, then IDEC shall replace or repair that

product, free of charge, at the purchase location / delivery location of the

product, or an IDEC service base. However, failures caused by the following

reasons shall be deemed outside the scope of this warranty.

i. The product was handled or used deviating from the conditions /

environment listed in the Catalogs

ii. The failure was caused by reasons other than an IDEC product

iii. Modification or repair was performed by a party other than IDEC

iv. The failure was caused by a software program of a party other than

IDEC

v. The product was used outside of its original purpose

vi. Replacement of maintenance parts, installation of accessories, or the like

was not performed properly in accordance with the user’s manual and

Catalogs

vii. The failure could not have been predicted with the scientific and

technical standards at the time when the product was shipped from

IDEC

viii. The failure was due to other causes not attributable to IDEC (including

cases of force majeure such as natural disasters and other disasters)

Furthermore, the warranty described here refers to a warranty on the IDEC

product as a unit, and damages induced by the failure of an IDEC product are

excluded from this warranty.

5. Limitation of liability

The warranty listed in this Agreement is the full and complete warranty for IDEC

products, and IDEC shall bear no liability whatsoever regarding special damages,

indirect damages, incidental damages, or passive damages that occurred due to an

IDEC product.

6. Service scope

The prices of IDEC products do not include the cost of services, such as dispatching

technicians. Therefore, separate fees are required in the following cases.

(1) Instructions for installation / adjustment and accompaniment at test operation

(including creating application software and testing operation, etc.)

(2) Maintenance inspections, adjustments, and repairs

(3) Technical instructions and technical training

(4) Product tests or inspections specified by you

The above content assumes transactions and usage within your region. Please

consult with an IDEC sales representative regarding transactions and usage outside

of your region. Also, IDEC provides no guarantees whatsoever regarding IDEC

products sold outside your region.

Ordering Terms and Conditions

Thank you for using IDEC Products.

By purchasing products listed in our catalogs, datasheets, and the like (hereinafter referred to as “Catalogs”) you agree to be bound by these terms and conditions. Please read

and agree to the terms and conditions before placing your order.

www.idec.com

USA IDEC Corporation Tel:

+1-408-747-0550

Germany

APEM GmbH

Singapore IDEC Izumi Asia Pte. Ltd. Tel: +65-6746-1155

Thailand

IDEC Asia (Thailand) Co., Ltd

Australia IDEC Australia Pty. Ltd. Tel:

+61-3-8523-5900

India

IDEC Controls India Private Limited

Taiwan IDEC Taiwan Corporation Tel: +886-2-2577-6938 [email protected]

Hong Kong IDEC Izumi (H.K.) Co., Ltd. Tel: +852-2803-8989

China

IDEC (Shanghai) Corporation Tel:

+

86-21-6135-1515

Beijing Branch

Guangzhou Branch Tel: +86-20-8362-2394 [email protected]

Japan IDEC Corporation Tel:

+81-6-6398-2527

Head Office

6-64, Nishi-Miyahara-2-Chome, Yodogawa-ku, Osaka 532-0004, Japan

Specications and other descriptions in this brochure are subject to change without notice.

Information in this brochure is current as of May, 2021.

2021 IDEC Corporation, All Rights Reserved.

EP1752-1

Related products

Durable and compact slim power relays with high contact

allowable current.

High performance DIN rail power supplies with low profile, space

saving 6

-

direction mounting, and spring

-

up terminals for wiring

efficiency and safety. Mounting brackets are also available for

direct mounting. Compliant with SEMI

-

F47 standards. (Certified

for 208V AC input voltage.)

Reduce the cost of relay replacement

Prevent momentary stops that cause machine failures

RJ PS5R

-

V

Slim power relays Switching power supplies

Safey relay module to monitor and diagnose safety systems.

Improves productivity by predictive maintenance of safety

systems.

Diagnose and monitor safety systems

HR6S

Safety relay modules

The compact RFID reader mounts on ø22 panel cut

-

out.

Water

-

and oil

-

proof with verification functions. Suitable for

controlling and tracking access to production sites.

Smart RFID reader to manage user authority/log control

KW2D

Smart RFID reader

HS5L: 4

-

contact switches suitable for small doors. 2

-

contact switches

suitable for food machinery and injection molding machines.

HS1T: 5000N locking strength is suitable for large machines and

equipment, ensuring operator safety.

HS5L HS1T

Interlock switches with solenoid

Conforms to ISO 13856

-

2 (pressure

-

sensitive protective devices).

Ensures safety without reducing the opening/closing speed of

automatic doors. The rubber part is made of oil

-

resistant NBR

material, suitable for environments where oil mist is dispersed.

E30BK1

Safety edge switches

Available August, 2021

Compact safety pressure sensitive switch

conforming to ISO13856-2

A wide variety of safety switches covers small

to large-size machine tools

Machine tools industry solutions

Find out how IDEC has solved customers' problems in the

machine tools industry.

This manual suits for next models

1

Table of contents

Other IDEC Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

V-Show

V-Show B1240Z manual

wofi

wofi 226 Series installation instructions

German Light Products

German Light Products impression X4S instruction manual

Ibiza

Ibiza HYPNO40-LED user manual

Home Accents Holiday

Home Accents Holiday TY315-1314 Use and care guide

Osram

Osram PermaLED® Area Light Medium installation guide