Table of Contents SK300 CE V. 1.0

3

Table of Contents

1 About this manual ........................................................................................................5

1.1

How to work with the manual............................................................................................5

1.2

Record of changes............................................................................................................ 5

2 Safety ............................................................................................................................6

2.1

Intended use.....................................................................................................................6

2.2

Liability..............................................................................................................................6

2.2.1

General liability .....................................................................................................6

2.2.2

Machine-specific liability .......................................................................................6

2.3

User qualification for installation.......................................................................................7

2.4

CE certification .................................................................................................................7

2.5

Safety symbols on the machine........................................................................................7

2.6

Safety symbols in the manual...........................................................................................8

2.7

Disposal of the machine ...................................................................................................8

3 Operator manual...........................................................................................................9

3.1

Description........................................................................................................................9

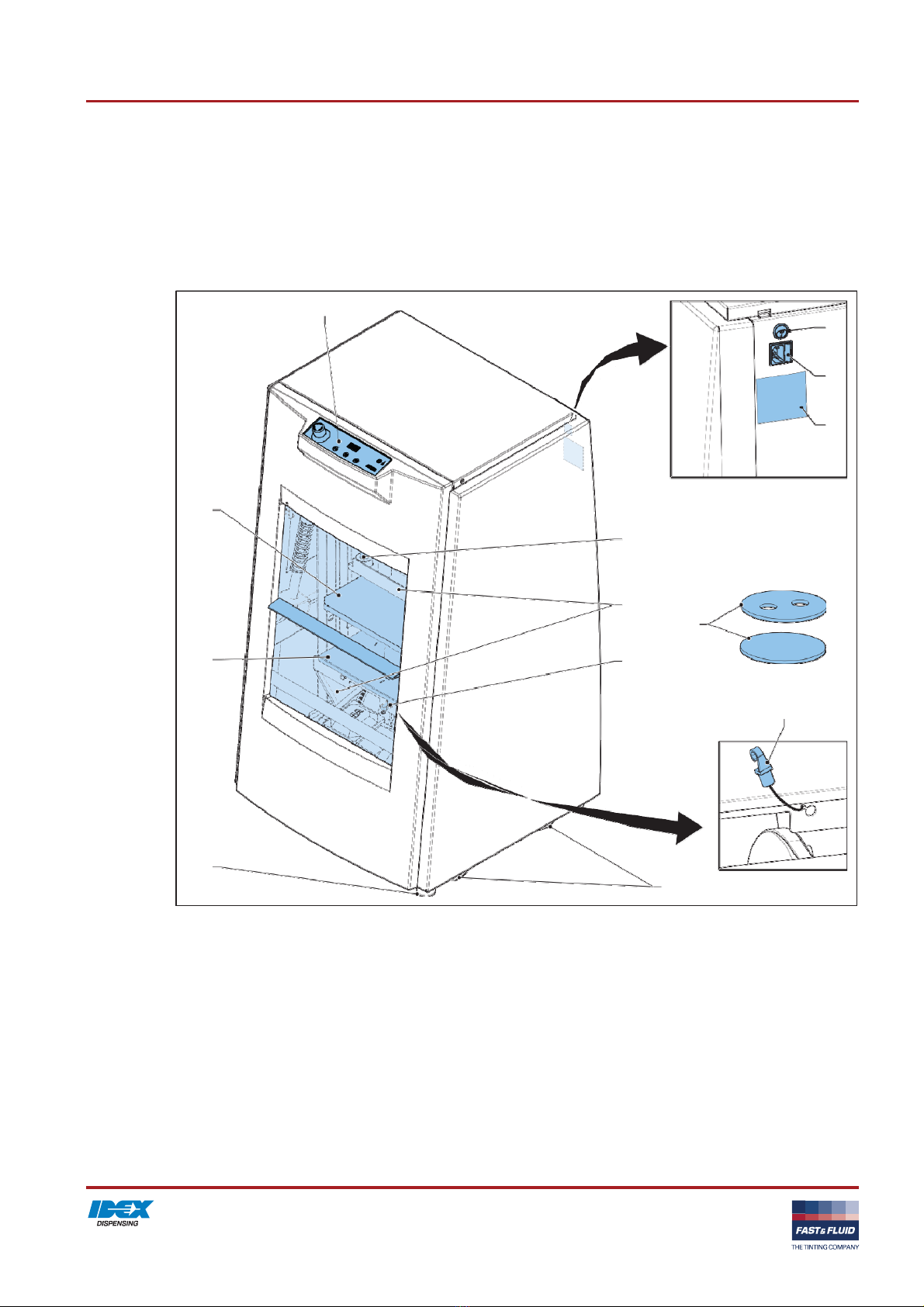

3.1.1

Overview of the machine ......................................................................................9

3.1.2

Overview of the control panel .............................................................................10

3.1.3

Factory default shake times................................................................................10

3.1.4

Type plate: serial number ...................................................................................10

3.1.5

Type plate: details ..............................................................................................11

3.2

Operation........................................................................................................................11

3.2.1

Turning on the machine......................................................................................11

3.2.2

Turning on the machine when the machine is in hibernation..............................11

3.2.3

General shaking procedure ................................................................................11

3.2.4

Placing the can ...................................................................................................12

3.2.5

Start the machine ...............................................................................................13

3.2.6

Remove the can .................................................................................................14

3.2.7

Stop the operation manually...............................................................................14

3.2.8

Using the emergency stop switch.......................................................................14

3.2.9

Restart the machine ...........................................................................................15

3.3

Maintenance ...................................................................................................................15

3.3.1

General safety instructions for maintenance ......................................................15

3.3.2

General cleaning: after every operation .............................................................15

3.3.3

Periodic maintenance: weekly ............................................................................15

3.3.4

Periodic maintenance: monthly ..........................................................................15

4 lnstallation ..................................................................................................................16

4.1

Unpack the machine.......................................................................................................16

4.1.1

Remove the cardboard .......................................................................................16