Idexx Filta-Max xpress Manual

Filta-Max xpress

Pressure Elution Station

Operator’s Guide

2Filta-Max xpress Operator’s Guide

Proprietary rights notice

Information in this document is subject to change without notice. Companies, names, and data used in examples are fictitious unless

otherwise noted. No part of this document may be reproduced or transmitted in any form or by any means, electronic, mechanical, or

otherwise, for any purpose, without the express written permission of IDEXX Laboratories. IDEXX Laboratories may have patents or

pending patent applications, trademarks, copyrights, or other intellectual or industrial property rights covering this document or subject

matter in this document. The furnishing of this document does not give a license to these property rights except as expressly provided

in any written license agreement from IDEXX Laboratories.

© 2019 IDEXX Laboratories, Inc. All rights reserved. • 06-9020469-00

*Filta-Max xpress and Filta-Max are trademarks or registered trademarks of IDEXX Laboratories, Inc. in the United States and/or other

countries. All other product and company names and logos are trademarks of their respective holders.

3Filta-Max xpress Operator’s Guide

Contents

Introduction.............................................................................................................................................5

Safety...........................................................................................................................................................5

Compliance .................................................................................................................................................5

Warnings......................................................................................................................................................6

Components ...........................................................................................................................................7

Pressure Elution Station...............................................................................................................................7

Pressure Elution Station system..................................................................................................................8

Specifications .........................................................................................................................................9

Technical specifications...............................................................................................................................9

Environmental conditions ............................................................................................................................9

Equipment, consumables, and reagents...............................................................................................9

Equipment and consumables not supplied by IDEXX................................................................................9

Equipment and consumables available from IDEXX ..................................................................................9

Setting up the Pressure Elution Station ..............................................................................................10

Location .....................................................................................................................................................10

Power connection ......................................................................................................................................10

Connecting the air supply..........................................................................................................................10

Using your facility’s air supply ...................................................................................................................10

Connecting an air compressor to the hose kit ..........................................................................................10

Checking the pressure regulator setting ...................................................................................................11

Assembling sampling and filtering equipment ...................................................................................12

Sampling....................................................................................................................................................12

Operating pressure....................................................................................................................................12

Assembling the Filter Module and filtering the sample .............................................................................13

Operating the Pressure Elution Station...............................................................................................13

Preparing the buffer solution .....................................................................................................................13

Performing the initial system check...........................................................................................................14

Transferring Filter Modules to an alternative housing................................................................................15

Understanding the control panel...............................................................................................................15

Eluting the sample.....................................................................................................................................16

Concentrating the eluates and resuspending the pellet before IMS ........................................................17

Purging the buffer solution ........................................................................................................................19

4Filta-Max xpress Operator’s Guide

Maintenance and cleaning ...................................................................................................................20

After each elution .............................................................................................................................. 20

On a daily basis................................................................................................................................. 20

On a monthly basis ........................................................................................................................... 20

Servicing the Pressure Elution Station.......................................................................................................21

Storing the Pressure Elution Station ...................................................................................................22

Limited warranty ...................................................................................................................................24

Appendix A: Consumables...................................................................................................................25

Appendix B: Air supply requirements .................................................................................................26

Appendix C: Troubleshooting ..............................................................................................................27

Contacting IDEXX Technical Service ...................................................................................................28

5Filta-Max xpress Operator’s Guide

Introduction

The Filta-Max xpress* Pressure Elution Station is used to automate the elution of

Cryptosporidium spp. oocysts and Giardia spp. cysts from Filta-Max xpress* Filter Modules and

Filta-Max* Filter Modules.

The Pressure Elution Station and elution procedures are designed for use with 10–1,000 L water

samples.

Note: The recovery of Giardia spp. cysts from large-volume finished water samples may be affected

by residual chlorine in the sample.1

Safety

For your safety, read this guide thoroughly before using the Filta-Max xpress Pressure Elution

Station.

IDEXX recommends that you perform your own safety assessments of the Filta-Max xpress

Pressure Elution Station and follow your own in-house health and safety guidelines.

All water samples, spills, splashes, aerosols, filters, and eluates should be handled with at least the

same precautions as the water source with regard to biohazards. The Pressure Elution Station does

not render such samples to be safe and, in fact, concentrates the biological risks into the eluate.

Ensure that the connections between the Filter Housings and any sampling equipment are capable

of withstanding the operating pressure of the elution station.

The Filta-Max xpress Pressure Elution Station weighs approximately 86 lb (38 kg). Be sure to use

a table or bench that can support the weight of the instrument. Two people are required to lift the

instrument. Do not use the pneumatic fittings that extend out of the back panel as a handle for

lifting. This will loosen the fittings and potentially introduce an air leak.

Ensure that you understand all instructions and safety precautions listed in this manual. If you have

any questions, contact IDEXX Technical Service as follows:

• In the United States call +1 800 321 0207 or email watertechnicalservice@idexx.com.

• In Europe call +44 (0)1638 676800 or email emeatechsupport@idexx.com.

Compliance

• European Union: EN61010-1: 2010 and EN-2-040

• US/MET NRTL Mark: UL 61010-1, 3rd Edition and UL 61010-2-040

• Canada/MET “c” Mark: CSA C22.2 No. 61010-1. 3rd Edition and CSA C22.2 No. 61010-2-040

• EN 61326-1:2013 PART 1: EU EMC Directive: EN 61000-4-3 Radiated Immunity

• 47: CFR Part 15, subpart B, Class A (FCC)

• ICES-003 Issue 4, February 2004, Class A

• CNS13438 (C6357): 2006: Taiwan/BSMI: CISPR32

• CNS13438 (C6357): 2006: Australia/NZ: Market Access

• VCCI V-1/93.11, V-2/97.04, V-3/97, R-1216, and C-1279 Class A ITE

6Filta-Max xpress Operator’s Guide

Warnings

Warnings are designated by an exclamation mark inside a triangle and are highlighted in bold.

Warnings are also displayed as labels on the Filta-Max xpress Pressure Elution Station at strategic

locations.

• Observe all warning labels.

• Never remove warning labels.

• Never operate a damaged or leaking unit.

• Always turn off the power and disconnect the power cord prior to performing any service or

routine maintenance.

• Never operate the Filta-Max xpress Pressure Elution Station with a damaged power cord.

When replacing the power cord, use only power cords with adequate rating.

• The Pressure Elution Station is designed with an electrical ground system. Never defeat any

part of the protective earthing.

• Do not attempt to disassemble the unit. Refer all service and repairs to a qualified service

technician.

7Filta-Max xpress Operator’s Guide

Components

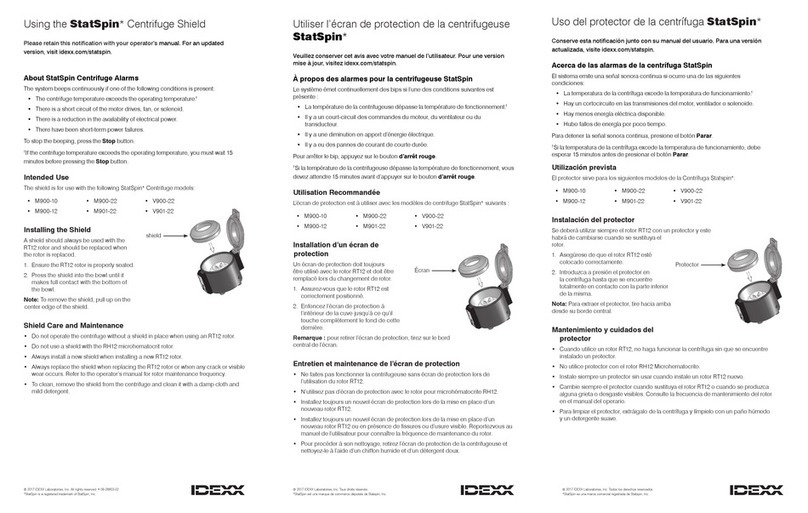

Pressure Elution Station

Emergency

stop button

Green LED: power

supply indicator

Red LED:

• Steady = Machine ready

• Flashing = System fault indicator

Figure 1b. Switches and buttons

Filter Housing/outlet

diverter assembly sensor

Collection vessel

cylinder

Collection

vessel sensor

Collection vessel

holder

Figure 1c. Sensors, fittings, and vessels

Figure 1. Pressure Elution Station

without a Filter Housing and diverter

assembly

Socket head

cap screw

Pressure

chamber lid

Buffer inlet

with flow meter

Pressure

gauge fitting

High-pressure

gauge

Low-pressure

gauge

Pressure

chamber body

Air inlet with

relief valve

Pressure chamber

purge valve

Swagelok quick-

connect (QC) stem

Figure 1a. Pressure chamber and gauges

1a

1b

1c

Green LED: power

supply indicator

Touch-screen

control panel

Four-button

control panel

Control panel

8Filta-Max xpress Operator’s Guide

Pressure Elution Station system

• Filta-Max xpress Pressure Elution Station

• Buffer Reservoir Kit (one 10 L bottle and one 4 L bottle with lids)

• Outlet diverter (5-pack kit)

• Hose kit

• Accessory kit:

– Power pack

–Filta-Max xpress Operator’s Guide

– Pressure chamber O-ring

– Tool kit (2 hex wrenches, quick-connect fitting, screwdriver)

Figure 2. Pressure Elution Station with a

Filter Housing and diverter assembly attached

Figure 2a. Filta-Max xpress Filter Housing and

diverter assembly

Swagelok quick-

connect (QC) body

Filta-Max xpress

Filter Housing

Swagelok

quick-flow (QF) body

Swagelok quick-flow

(QF) stem

Outlet diverter

assembly

Sensor ring

9Filta-Max xpress Operator’s Guide

Specifications

Technical specifications

• Dimensions: 28" H x 14" D x 20.5" W (711 mm H x 356 mm D x 521 mm W)

• Weight: 86 lb (37.7 kg)

• Minimum input pressure: 65 psig (4.5 bar)

• Maximum input pressure: 150 psig (10.3 bar)

• Working pressure: 72.5 to 116 psig (5.0 to 8.0 bar)

• Supply voltage (through an external power source):

100–240 V AC @ 47–63 Hz, output 4.2–5.0 A @ 24 V DC (limited power source only)

• Pressure Elution Station current rating: 4.2–5.0 A @ 24 V DC

Environmental conditions

• Intended for indoor use only

• Temperature range: ambient temperature of 16°C–24°C

• Humidity range: 0%–80% relative humidity

• Maximum altitude: 2,000 m (6,562 feet)

• Pollution degree: 2

• Overvoltage protection: category 2

Equipment, consumables, and reagents

The following additional equipment, consumables, and reagents are necessary for filter elution.

Equipment and consumables not supplied by IDEXX

• Sampling pump that is suitable for use with the sampling fittings or a suitable sampling rig for

use with a pressurized water supply

• Platinum cured tubing (13–15 mm internal diameter) suitable for use with the sampling pump

or pressurized water supply

• 500 mL centrifuge tubes and/or 50 mL conical centrifuge tubes (for double centrifugation)

• Centrifuge with capacity for 500 mL centrifuge tubes and/or 50 mL conical centrifuge tubes

that is capable of reaching 2,000 × g (g-force or relative centrifugal force)

• Alcohol-soaked wipes, laboratory grade ethanol, or sodium hypochlorite solution

• Reagents:

– Phosphate buffered saline (PBS)

– Polyoxyethylene sorbitan monolaurate (TWEEN* 20)

For additional information on the reagents, see "Preparing the buffer solution" on page 13.

Equipment and consumables available from IDEXX

These items may be purchased from IDEXX. For more information, see Appendix A.

• Filta-Max xpress Filter Housing

• Filta-Max xpress Filter Module or Filta-Max Filter Module

• Filta-Max xpress Sampling Kit

• Filta-Max xpress Housing Conversion Kit

10 Filta-Max xpress Operator’s Guide

Setting up the Pressure Elution Station

Location

The Filta-Max xpress Pressure Elution Station and buffer reservoir bottle should be placed on a

sturdy bench or laboratory surface capable of supporting both their weight and the force required to

install and remove the Pressure Elution Station housing and fittings.

Power connection

• Connect the low-voltage cable to the inlet power socket on the back panel of the Pressure

Elution Station.

• Connect the provided power supply to a suitable electrical outlet using a power cord with

the appropriate rating (18 AWG/.75 mm2). The external power supply will function normally

between 100 and 240 V AC at 47–63 Hz.

Connecting the air supply

Compressed air is required for the Pressure Elution Station to function properly because it supplies

the air pressure needed to elute the Filter Modules. IDEXX supplies a hose kit that lets you connect

either your facility’s air supply or a compressor to the Pressure Elution Station. The hose kit consists

of a 12-foot self-retracting hose and connector.

Compressed air must be oil and moisture free. IDEXX can supply an external air filter that attaches

to the rear of the Pressure Elution Station to remove oil and moisture from the air.

Using your facility’s air supply

If you use your own facility’s air supply, check to ensure that the outlet pressure is between 5.0 bar

and 8.0 bar (72.5 and 116 psig). The air supply must have a sufficient capacity to perform elution

cycles whilst remaining above 5.0 bar (72.5 psig). Your facility’s air supply may require filters to

remove oil and moisture.

Use the quick-connect fittings supplied with the Pressure Elution Station or other appropriate fittings

to connect the air supply. The connection is made at the back of the Pressure Elution Station at the

air line inlet connector.

Before connecting and applying air pressure to the Pressure Elution Station, ensure that the

lockable air inlet valve is in the OFF (EXH) position by turning it clockwise. When the connection

has been made and there is pressure to the Pressure Elution Station, turn the lockable air inlet valve

counterclockwise to the ON (SUP) position.

Connecting an air compressor to the hose kit

Note: The compressor must be oil free.

1. Prepare the air compressor for use according to its operating instructions.

Note: The components and their respective locations on the air compressor may vary with

the model. Polytetrafluroethylene (PTFE) tape, plumbing tape, or other appropriate sealant is

recommended at all threaded connections.

2. Connect the swivel end of the 12-foot self-retracting hose (found in the Filta-Max xpress

Hose Kit) to the air compressor’s filter, which is attached to the regulator.

3. Ensure that the lockable air inlet valve on the Pressure Elution Station is in the OFF (EXH)

position by turning it clockwise.

4. Connect the other end of the hose to the air line inlet connector on the Pressure Elution

Station.

11 Filta-Max xpress Operator’s Guide

5. Follow the compressor’s instruction manual to modulate the outlet pressure between 5.0 and

8.0 bar (72.5 and 116 psig).

6. Connect the air compressor’s power cord to a suitable electrical outlet.

7. Turn the air compressor’s ON/OFF switch to ON or AUTO.

8. Allow the air pressure in the receiver to build to at least 5.0 bar (72.5 psig).

Note: With the air compressor in auto mode, the motor will automatically stop when the

pressure reaches a preset maximum and will restart when the pressure drops below a preset

minimum. You can monitor the pressure in the receiver via the receiver pressure gauge.

The minimum pressure required for use with the Pressure Elution Station is 5.0 bar. The air

compressor should have a sufficient flow rate to maintain pressure above 5.0 bar during use.

9. To increase or decrease the outlet pressure, turn the pressure regulator’s adjustment

according to the manufacturer’s instructions.

10. When you have attached the quick-connect fittings to the Pressure Elution Station and there is

pressure, turn the lockable air inlet valve counterclockwise to the ON (SUP) position. The air

supply is now ready for use with the Pressure Elution Station.

Note: If the pressure from the air supply falls below 5.0 bar (72.5 psig), there will be

insufficient pressure to complete an elution cycle and a Low Pressure error message will be

displayed. When processing multiple samples, be sure to monitor the pressure.

Checking the pressure regulator setting

With pressure supplied to the Pressure Elution Station and the lockable air inlet valve in the ON

position, the high-pressure gauge should read approximately 5.0 bar (72.5 psig), while the

low-pressure gauge should read approximately 0.38 bar (5.5 psig).

If the gauge readings are not correct, contact IDEXX Technical Service for assistance.

Note: The low-pressure regulator, a precision-regulator located within the Pressure Elution Station,

will always release a small amount of air; a slight hissing sound is normal.

12 Filta-Max xpress Operator’s Guide

Assembling sampling and filtering equipment

Sampling

You can collect samples at the point of source or in the laboratory. IDEXX provides the equipment

necessary to perform sample filtration using the Filta-Max xpress Filter Modules or

Filta-Max Filter Modules, Filter Housings, and sampling and elution fittings (see Appendix A).

To set up the sampling equipment:

1. Connect the Swagelok* quick-flow (QF) body

to the Swagelok hose-tail fitting to create the

sampling inlet. Use PTFE tape to help form a

seal.

2. Attach the sampling inlet to a hose that is

connected to the water supply or a pump.

If a pump (diaphragm, peristaltic, etc.) is used

to sample water, it must be installed upstream of

the Filter Housing.

Note: A hose clip is required to ensure that the

seal between the hose and the sampling inlet is

watertight.

3. Connect the Swagelok quick-connect (QC)

stem to a Swagelok hose-tail fitting to create the

sampling outlet. Use PTFE tape to help form a

seal.

4. Attach the sampling outlet to a hose that is connected to a suitable waste outlet.

Note: A hose clip is required to ensure that the seal between the hose and the sampling outlet

is watertight.

Operating pressure

A head pressure of 0.5 bar (7.5 psig) is required to generate flow through the Filter Module. The

recommended operating pressure is 5.0 bar (72.5 psig), which should generate a flow of 1–2 liters

per minute (LPM). The operating pressure should not exceed 8.0 bar (116 psig). Pressure spikes

should be avoided where possible.

Hose Hose-tail

fitting QF body

Sampling inlet

Hose

Hose-tail

fitting

QC stem

Sampling outlet

13 Filta-Max xpress Operator’s Guide

Assembling the Filter Module and filtering the sample

1. Place the Filter Module bolt-head down into a

Filter Housing.

2. Tighten the lid until the two serial-numbered tag

holes are aligned and a gap of approximately

0.5 mm is left between the lid and the base.

3. Tighten the lid an additional 1/8 of a turn past

this point and then back again to align the tag

holes. This step correctly seats the O-ring.

4. Connect the Filter Housing to the sampling

setup by connecting the QF stem to the

sampling inlet and the QC body to the sampling

outlet.

Note: The QC body on the Filter Housing is self-

sealing and does not require an additional seal.

5. Turn on the water supply and restrict the flow

to 1–2 liters per minute using a suitable flow

restrictor located downstream of the Filter Housing.

6. When sampling is complete, turn off the water supply.

7. Disconnect the Filter Housing from the sampling setup, and seal the QF stem using the

stopper provided.

Note: You can perform sample filtration in suitable Filter Housings fitted with connectors other

than those required for use with the Pressure Elution Station. In this case, the Filter Module must

be transferred to a Filter Housing suitable for use with the Pressure Elution Station. For more

information, refer to “Eluting the Sample.”

Operating the Pressure Elution Station

Preparing the buffer solution

Before you begin mixing the buffer solution, determine the amount of solution required for the

number of samples you are going to elute. In addition, 400 mL of buffer solution is required for the

initial system check of the Pressure Elution Station and for each subsequent elution.

Phosphate buffered saline solution may be purchased in a ready-made solution or may be

prepared using individual ingredients as follows:

• Sodium chloride 8.0 g/L

• Potassium chloride 0.2 g/L

• Disodium hydrogen phosphate 1.15 g/L

• Potassium dihydrogen phosphate 0.2 g/L

To prepare 1 L of the buffer solution:

1. In a suitable container, add the individual ingredients for PBS to 1 L of reagent-grade water.

2. Place the container on a magnetic stirrer plate.

3. Add 0.1 mL of TWEEN 20, and mix for at least 10 minutes or until dissolved.

Note: TWEEN 20 is very viscous and requires careful pipetting. Wipe the outside of the pipette

with a paper towel/tissue to ensure the correct amount is dispensed.

Sample flow

through Filter

Housing

QC body

Filter Module

Bolt end

Filter Housing lid

Filter Housing

base

QF stem

14 Filta-Max xpress Operator’s Guide

To fill the buffer reservoir:

The Buffer Reservoir Kit includes one 10 L bottle and one 4 L bottle. Because of the performance of

the initial system check and buffer purge, two reservoirs are required. IDEXX suggests that the 10 L

reservoir be used for the buffer solution and the 4 L reservoir be used for reagent-grade water.

The buffer reservoirs provided by IDEXX are manufactured from heavy-duty high density

polyethylene (HDPE). Only heavy-duty reservoirs should be used in this application.

1. After mixing the buffer solution, decant it into a buffer reservoir bottle.

2. The closure cap is attached to the Pressure Elution Station by an air and liquid feed line.

Attach the buffer reservoir to the cap.

3. Ensure there is a tight seal between the reservoir body and the closure cap.

Note: When the closure cap is new, the integral seal is quite stiff and may be difficult to

tighten. After several uses, tightening the closure cap will become easier. Vacuum grease can

be used to help make tightening easier.

Performing the initial system check

Before performing sample elution, you must perform an initial system and integrity check to ensure

that no error messages are generated during sample elution. This initial step also serves to purge

reagent-grade water from the lines and replace it with buffer solution.

1. Place a blank Filter Module into a Filta-Max xpress Filter Housing. (See "Assembling the

Filter Module and filtering the sample" on page 13 for instructions.)

2. This blank Filter Module can be reused for 1 month when performing the initial system check

or when purging buffer solution from the system (see "Purging the buffer solution" on page

19 for more information).

3. Complete steps 1–8 of "Eluting the sample" on page 16.

4. The Pressure Elution Station will run through a complete elution cycle. If no errors are

generated, continue with steps 3–6 below. If a pressure or flow error occurs, refer to

Appendix C.

5. At the end of the elution cycle, discard the liquid from the centrifuge tube.

6. You can reuse the centrifuge tube when performing the initial system check or when purging

buffer solution from the system.

7. Disconnect the Filter Housing from the Pressure Elution Station, and then disconnect the

outlet diverter fitting from the Filter Housing.

8. Clean the Swagelok QC stem on the elution station with alcohol-soaked wipes.

9. Because the system uses positive pressure to elute filters, there is limited to no risk of sample-

to-sample cross-contamination.2

10. Proceed to “Transferring Filter Modules to an alternative housing” and/or “Eluting the sample.”

15 Filta-Max xpress Operator’s Guide

Transferring Filter Modules to an alternative housing

If sample filtration was performed in a housing other than one suitable for use with the Pressure

Elution Station, you must transfer the Filter Module to an appropriate housing before elution.

1. Remove the lid of the housing used for sampling or the transport container, and carefully

transfer the Filter Module, bolt-head down, to a Filta-Max xpress Filter Housing, which will be

used in the Pressure Elution Station.

2. Pour any remaining liquid from the Filter Housing or container into the centrifuge tube.

3. Rinse the Filter Housing or container with reagent-grade water, and transfer this rinse to the

centrifuge tube. The total volume transferred to the centrifuge tube should not exceed

50 mL.

4. Seal the second housing as described in "Assembling the Filter Module and filtering the

sample" on page 13.

Understanding the control panel

Instruments with a four-button control panel:

The menu screen displays the following:

• F1 starts the elution cycle.

• F2 checks the pressure.

With the buffer reservoir cap sealed, press and hold the F2 button for 3 or more seconds.

Listen for any air leaks, and monitor the low-pressure gauge for pressure changes.

• F3 resets the cycle counter.

Press and hold the F3 button for 3 seconds to display the number of cycles completed (i.e.,

the number of samples eluted).

Press and hold the F3 button for 5 seconds to reset the counter to zero.

• F3 and F4 display total cycles run (this counter is not resettable).

Press and hold the F4 button, and then press and hold the F3 button to display the total

number of cycles run on the Pressure Elution Station.

Instruments with a touch-screen control panel:

The menu screen displays the following:

• Start starts the elution cycle.

• Pressure Test displays the Buffer Reservoir Pressure Test screen.

From the Buffer Reservoir Pressure Test screen:

– Exit returns to the start screen.

– Start Test starts the buffer reservoir pressure test.

– With the buffer reservoir cap sealed, press and hold the Start Test button for 3 or more

seconds. Listen for any air leaks, and monitor the low-pressure gauge for pressure

changes.

– Line Purge starts the line purge process

Note:

A Filter Housing without a Filter Module must be in place.

A centrifuge tube must be in the centrifuge tube holder.

The buffer reservoir must be empty.

The buffer reservoir cap must be securely sealed.

16 Filta-Max xpress Operator’s Guide

Press and hold the Line Purge button. This will lift the centrifuge tube and purge the

fluid from the lines. Continue to hold the Line Purge button until all the fluid is purged,

which usually takes about 10 seconds. Release the Line Purge button, press the Exit

button to return to the start screen, and then remove the centrifuge tube.

• User Cycles resets the cycle counter.

Press the User Cycles button to display the Tests Count screen. This screen shows the

number of cycles completed (i.e., the number of samples eluted).

From the Tests Count screen:

– Exit returns to the start screen.

– Reset resets the cycle counter to zero. Press and hold the Reset button for 5 seconds

to reset the counter.

• Total Cycles displays the total cycles run (this counter is not resettable).

Press the Total Cycles button to display the total number of cycles run on the Pressure

Elution Station.

From the Cycle Count screen:

– Exit returns to the main start screen.

– Wash Time shows the most recent wash cycle time in minutes.

Eluting the sample

1. Turn on the Pressure Elution Station by depressing the on/off switch to the I position. The

green LED (power) and the red LED (machine ready) are lit.

The on/off switch is located on the back of the Pressure Elution Station.

2. Remove the lid from a 500 mL centrifuge tube, and place it into the collection vessel holder.

3. With the Filter Housing QF stem facing upward, attach the outlet diverter fitting to the QF stem

by pulling back the collar and pushing the fittings together.

4. Turn the Filter Housing over, and place the outlet diverter over the centrifuge tube to catch any

sample that may leak.

5. Connect the Filter Housing QC body to the QC stem on the Pressure Elution Station by

pushing the fittings together.

Note: If you have already performed a system check, you can skip steps 6–7 and proceed

directly to step 8.

6. Check that the air supply is set up correctly, the air line is connected to the Pressure Elution

Station, and the air inlet valve is open.

Note: Compressed air must be used with the Pressure Elution Station.

7. Ensure that there is sufficient buffer solution in the buffer reservoir bottle and that the seal

between the closure cap and the reservoir bottle is airtight.

8. To start the filter elution cycle:

On the four-button control panel press F1.

On the touch-screen control panel press Start.

IMPORTANT: During the elution cycle, the collection vessel holder and centrifuge tube are

lifted into position. Do not override the door sensors as they protect you from pinch points

produced by this movement. If the door sensors fail to function, do not place your hands or

any objects in this area. Contact IDEXX Technical Service for assistance.

9. At the end of the elution cycle, disconnect the Filter Housing from the Pressure Elution Station

by pushing the collar on the QC body upwards while pulling the Filter Housing down; then

disconnect the outlet diverter fitting from the Filter Housing.

17 Filta-Max xpress Operator’s Guide

10. Open the Filter Housing, remove the Filter Module, and discard the Filter Module according to

appropriate disposal regulations.

IMPORTANT: All Filter Modules should be autoclaved according to your standard autoclave

waste disposal cycle.

11. Cap the centrifuge tube, and remove it from the collection vessel holder.

Note: The Pressure Elution Station contains several sensors. The Pressure Elution Station will

not start an elution cycle if the centrifuge tube, the Filter Housing, or the outlet diverter are not

in place. At the end of an elution cycle, the Pressure Elution Station will not start the next cycle

unless the centrifuge tube is removed from the collection vessel holder and replaced with a

fresh tube.

12. Clean the QC stem on the Pressure Elution Station with alcohol-soaked wipes.

13. Proceed with subsequent sample elutions.

Concentrating the eluates and resuspending the pellet before IMS

After eluting the samples, you must concentrate the eluates further by centrifugation before

purifying them by immunomagnetic separation (IMS).

Centrifuge requirements (e.g., Hettich* Rotanta 460)

• Swing-out rotor

• Inserts and support cushions for 500 mL centrifuge tubes

• In good working order, with bucket supports lightly greased

Centrifuge setup

• Locate centrifuge to minimise vibration.

• Set RCF to 2000 × g.

• Set acceleration to maximum and deceleration to minimum, with the minimum amount of

braking possible.

• Set time to 15 minutes, excluding ramp-up time.

To concentrate the eluates:

1. Balance the centrifuge tubes (collected in step 11 of "Eluting the sample" on page 16),

the cushions, and the centrifuge buckets to within 0.5 g of each other.

Note: Failure to balance the tubes correctly can result in centrifuge imbalance and can affect

the target sedimentation efficiency due to excessive vibration.

2. Centrifuge the samples at 2,000 × g for 15 minutes (not including the time taken to reach

2000 × g), allowing the centrifuge to coast to a stop at the end of centrifugation. DO NOT

USE THE BRAKE.

Note: The deceleration profiles of different centrifuge models can vary. For optimal

performance, the centrifuge should not be braked during deceleration. Check the operator’s

guide provided with the centrifuge or the centrifuge vendor’s technical service department for

the centrifuge deceleration profile. Deceleration via braking can reduce method performance

during this procedure.

The sample separates into supernatant and concentrated eluates, which often form a pellet at

the bottom of the tube.

18 Filta-Max xpress Operator’s Guide

3. First aspiration:

a. Aspirate the supernatant immediately following centrifugation, leaving 25 mL of the

supernatant in the tube.

b. Once aspiration is complete, vortex the sample at full speed for 20 seconds to disperse

the pellet (extend vortexing time if needed).

c. Swirl and pour into a 50 mL centrifuge tube.

d. Add 10 mL reagent-grade water to the 500 mL centrifuge tube (this acts as a rinse).

e. Vortex the sample at full speed for 20 seconds.

f. Swirl and pour into the 50 mL centrifuge tube.

g. Add a second 10 mL reagent-grade water rinse to the 500 mL centrifuge tube.

h. Vortex the sample at full speed for 20 seconds.

i. Swirl and pour into the 50 mL centrifuge tube.

4. Second centrifugation:

Perform a second centrifugation of the 50 mL centrifuge tube containing your sample, using

the following centrifuge setup:

Centrifuge requirements (e.g., Hettich Rotanta 460)

• Swing-out rotor

• Inserts and support cushions for 50 mL centrifuge tubes

• In good working order, with bucket supports lightly greased

Centrifuge setup

• Locate centrifuge to minimize vibration.

• Set RCF to 1500 × g.

• Set acceleration to maximum and deceleration to minimum, with the minimum amount of

braking possible

• Set time to 15 minutes, excluding ramp-up time.

5. Second aspiration of supernatant:

• Carefully remove the 50 mL tube from the centrifuge.

• Aspirate to the 3 mL mark on the 50 mL tube.

• Perform IMS on the sample as soon as possible.

To resuspend the pellets:

1. From the centrifuge tube, aspirate the sample supernatant leaving approximately 7–8 mL in

the tube.

Notes:

• Hold the pipette in the center of the tube, and aspirate the sample from the surface of the

liquid. Avoid disturbing the pellet.

• Use a wide bore pipette (such as a 5 mL serological pipette) or equivalent attached to a

vacuum source.

• Do not exceed a vacuum of -0.5 psig. The flow rate during this procedure should be

approximately 200 mL per minute (+/- 20 mL).

• IDEXX suggests using a peristaltic pump attached to a waste trap for this procedure.

2. Resuspend the pellet by vortexing the sample for 20 seconds; extend the vortex time if

required.

19 Filta-Max xpress Operator’s Guide

3. Transfer the sample to an L10 tube using a suitable pipette primed with buffer solution.

Note: Priming, by drawing up buffer into the pipette and subsequently expelling it, prevents

any target organisms from sticking to the wall of the pipette.

4. Rinse the sides of the centrifuge tube twice with half the remaining volume of reagent-grade

water, transferring each of these wash volumes to the same L10 tube. For example, if the

volume remaining in the centrifuge tube is 7 mL, perform two rinses each with 1.5 mL of

reagent water.

5. Perform IMS according to appropriate procedures, for example, U.S. EPA Method 1622/1623,

Microbiology of drinking water (2010)-Part 14-Methods for the isolation, identification and

enumeration of Cryptosporidium oocysts and Giardia cysts or other appropriate guidelines or

manufacturer’s instructions.

Purging the buffer solution

When all the Filter Modules have been eluted, you must remove any remaining buffer solution from

the lines of the Pressure Elution Station by purging the system with reagent-grade water.

Note: If sample elution is performed infrequently during a day—for example, early morning and late

afternoon—it is advisable to perform a buffer purge between elution events. This will increase the

volume of buffer solution required.

1. Load a blank Filter Module into a Filta-Max xpress Filter Housing. (See "Assembling the Filter

Module and filtering the sample" on page 13 for instructions.)

This blank Filter Module can be reused for one month to perform the initial system check or to

purge buffer solution from the system.

2. Complete steps 1–8 of "Eluting the sample" on page 16.

3. When performing a buffer solution purge, replace the buffer solution with reagent-grade water.

At the end of the elution cycle, discard the liquid from the centrifuge tube.

The centrifuge tube can be reused to perform the initial system check or to purge buffer

solution from the system.

4. Disconnect the Filter Housing from the Pressure Elution Station, and then disconnect the

outlet diverter fitting from the Filter Housing. The lines are now filled with reagent-grade water.

5. Clean the Swagelok QC stem on the Pressure Elution Station with alcohol-soaked wipes.

Because the system uses positive pressure to elute filters, there is limited to no risk of

sample-to-sample cross-contamination.2

20 Filta-Max xpress Operator’s Guide

Maintenance and cleaning

Follow the guidelines below when decontaminating the Filta-Max xpress system.

After each elution

• Clean the QC stem on the Filta-Max xpress Elution Station using an alcohol-soaked wipe or

equivalent.

• Decontaminate the sampling kit, outlet diverter fittings, and the Filter Housing by soaking

them in warm (40°C–60°C) water containing laboratory-grade detergent for 15–30 minutes.

Then manually clean the equipment using a bottle brush or similar device, and rinse with (oo)

cyst-free finished water and then with reagent-grade water.

• Should more stringent decontamination be required, equipment may be soaked for 30

minutes in a 6% solution of sodium hypochlorite (60 mL of household bleach in 1 L of water).

Then manually clean the equipment using a bottle brush or similar device, and rinse with (oo)

cyst-free finished water and then with reagent-grade water.

• Relubricate and/or replace all O-rings, as required.

On a daily basis

• Clean the surfaces of the Filta-Max xpress Pressure Elution Station with laboratory disinfectant

or alcohol-soaked wipes.

• Clean the metal base plate and back plate (inside the door) using laboratory disinfectant or

alcohol-soaked wipes. Keep the inside of the machine as clean and dry as possible; remove

any spills between samples.

Note: With the air supply turned off, you can raise the collection vessel holder to improve

access to the base plate.

On a monthly basis

If the Pressure Elution Station is not used for 2 weeks, then you should also clean the pressure

chamber, following the steps below. The following tools are required and are supplied with each

Filta-Max xpress Pressure Elution Station as part of the accessory kit:

Angled screwdriver

Large 5/16" hex wrench

Small 5/64" hex wrench

1. Remove the four screws from the burgundy lid/cover using the small hex wrench provided,

and then remove the lid/cover of the Pressure Elution Station.

Table of contents

Other Idexx Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

BIO RAD

BIO RAD PowerPac Universal Power Supply instruction manual

Christ

Christ Epsilon 2-6D LSCplus operating manual

cytiva

cytiva AxiChrom Master 300 unpacking instructions

NPI

NPI ISO-STIM 01B Operating instructions and system description

Hettich

Hettich rotina 380 operating instructions

VWR International

VWR International DUO SAS 360 Contact instruction manual