V15.1 - 4 -

INTRODUCTIONMULTIVAP 118

Items Shipped

Carefully check the contents of all cartons received for damage which may have

occurred in transit. Retain all cartons and packaging materials until all components have been

checked against the packing slip, the component list below, and the equipment has been

assembled and tested. Contact Organomation immediately if any damage or discrepancies are

found.

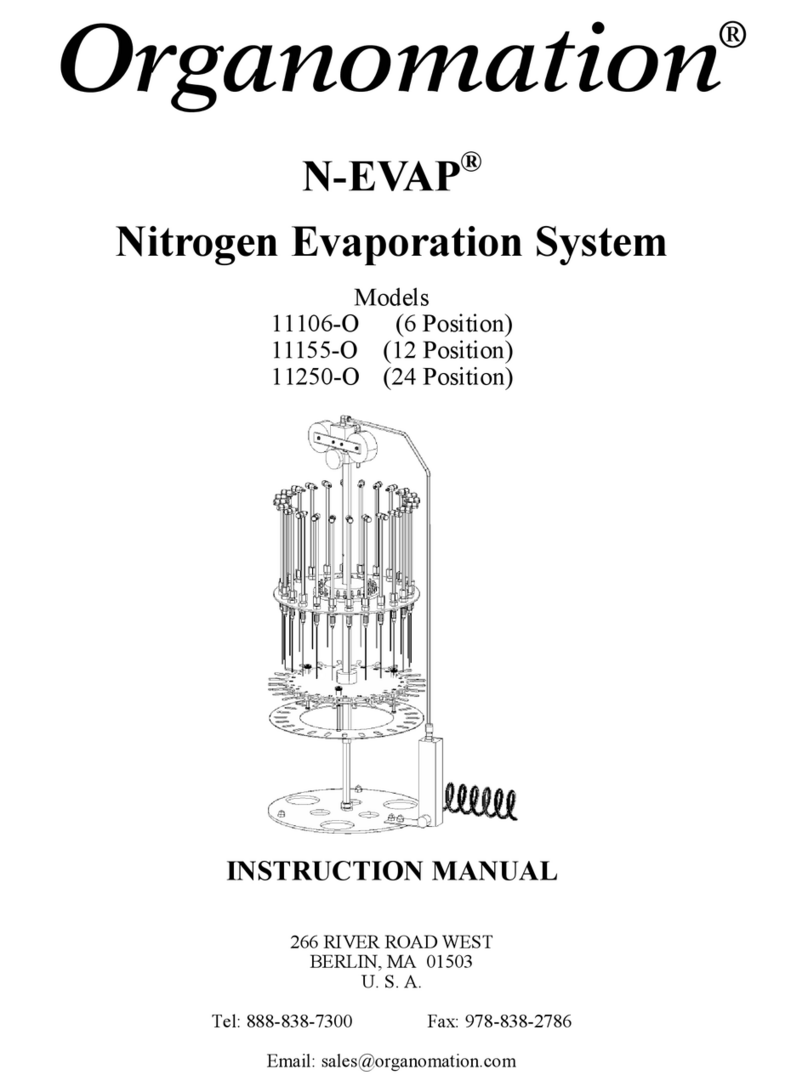

Your shipment should contain one or more of the instruments shown below. Option codes are

listed on the next page.

Instrument Size

9 Position MULTIVAP Nitrogen evaporation system

30 Position MULTIVAP Nitrogen evaporation system

48 Position MULTIVAP Nitrogen evaporation system

80 Position MULTIVAP Nitrogen evaporation system

Flow meter Assembly with Mounting Bracket & Connector Tube

0-30 or 0-100 LPM for all Model 118 MULTIVAP.

1 ea 11809, 11830 & 11848, & 11880

19 ga. x 4” Stainless Steel Needles, blunt end. 9, 30, 48, 80 each for respective

models and positions.

14 ga x 4” Stainless Steel Needles, blunt end. 18 ea for the 11809

Manual for MULTIVAP models 11809-80

Pasteur Pippet Adapter with flow controller, 1 Dozen per set (Optional).

Aluminum Inserts for 11809, size per order. Each

Aluminum Inserts, size per order. Set of 30.

Aluminum Inserts, size per order. Set of 48.

Aluminum Inserts, size per order. Set of 80

Cat #

11809

11830

11848

11880

NA1421

NA0603

NA1105-14

V10124

NA0636

NA1891

NA1832

NA1803

NA1882

MULTIVAP is a Trademark of Organomation