The speed is set using the front knob(A). The scale from 1 to 10

corresponds to a speed range for the output shaft of 40 to 1200

rpm under nominal load. With no load the speed at maximum set-

ting of the knob (right position) is 1600 rpm, at minimum setting

of the knob (left position) 0 rpm. If viscosity increases due to the

process, the speed reduces gradually. If, however, the viscosity is

reduced by eg the addition of thinning agents, the speed increa-

ses somewhat. This can be balanced out in both cases by re-set-

ting the knob accordingly, provided torque does not exceed maxi-

mum torque. Please note that fluctuations in mains voltage wit-

hin the permitted tolerances may also cause minor fluctuations in

speed.

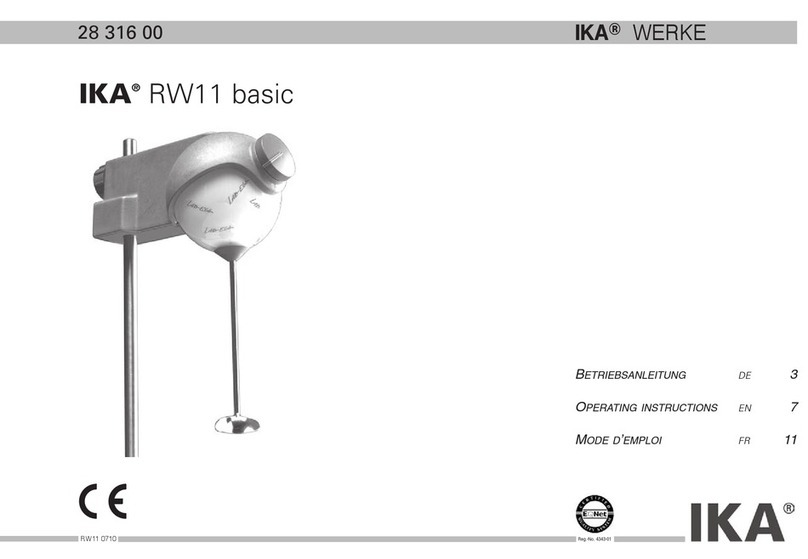

For correct use, the stirrer must be secured to a stable object

(eg R1822) with a cross-sleeve (eg R181). For safety reasons the

stirrer container should always be fixed with a tension-holder

(eg RH1).

For diagram see (Fig. 2)

The extension arm (X) has a step at its end with a cross hole. This

end is used to insert the extension arm into the hole on the back

of the machine. To do this, the cross hole in the extension arm

must point upwards. It must be brought into alignment with the

hole in the fixing rib on the back of the machine. To do this, press

the extension arm until it catches in the hole. Please do not use

force to do this. If it proves difficult to insert the extension arm,

light oiling may help. The hexagonal socket screw (Y) used for

fixing is inserted in the hole in the housing from above. The screw

is tightened using the hexagon socket offset screw key (Z).

Check that the extension arm is firmly seated. The screw may

loosen with vibration. Therefore as a precaution check from time

to time that the extension arm is still securely attached.

If necessary tighten the hexagonal socket screw.

You can also secure the hexagonal socket screw with adhesive,

but you are then unable to release the connection later

.

Check whether the voltage given on the type plate corresponds

to the available mains voltage. The socket used must be earthed

(fitted with earth contact). If these conditions have been met, the

machine is ready to operate when the mains plug is plugged in.

If these conditions are not met, safe operation is not guaranteed

and the machine could be damaged.

The machine is started by pressing the mains switch (B) into

position “l”. A green control light (C) signals the operating

condition “ON”.

During commissioning of the machine the output shaft starts to

run at the last speed set. Therefore check the setting of the con-

trol knob. Also ensure that the speed set is suitable for the test

texture selected. If in doubt, set the speed knob (A) to the lowest

speed (left-hand position).

12 RW160995EU

Commissioning

Mounting the extension arm

Speed

Switching on the machine

RW160995EU 12.11.2001 13:39 Uhr Seite 12