IDROFOGLIA TURBOCAR IG1.1 Instruction Manual

OPERATING INSTRUCTION MANUAL

TURBOCAR Contents

I

0.0

1/3

Name: TURBOCAR

Models: IG1.1-IG1.1S-IG1-IG1S-IG2-IG3-IG4-IG5

IDROFOGLIA S.r.l.

Via Provinciale, 14

61026 Lunano PU - I aly

Tel: +39 0722 700311 - Fax: +39 0722 700309

Websi e:

www.idrofoglia.com

Email:s aff@idrofoglia.com

OPERATING INSTRUCTION MANUAL

TURBOCAR Contents

I

0.0

2/3

I CONTENTS

PAR. DESCRIPTION

- Contents

Parts of the manual Revision

Contents

0.0

Chapter

0

0.0

1

0.0

2

0.0

3

0.0

4

0.0

5

0.

0

6

0.0

7

0.0

8

0.0

9

0.0

Instruction Manual

Revision

0.0

Date 7/03/2017

OPERATING INSTRUCTION MANUAL

TURBOCAR Contents

I

0.0

3/3

0 FOREWORD

1. Purpose of the instruction manual

2. How to read the instruction manual

3. Storage of the instruction manual

4. Update of the Instruction Manual

5. Recipients

6. Glossary and pictorials

1 GENERAL INFORMATION

1. Manufacturer’s identification data

2. Machine identification data and plates

3. Declarations

4. Safety Regulations

5. Information on technical support

2 DESCRIPTION OF THE MACHINE

1. Operating principle

2. Main components

3. Dimensions

4. Environmental conditions

5. Sound emissions

6. Technical specifications

7. Tools

8. Panels and buttons

9. Standard supply

10. Accessories

3 SAFETY

1. General warnings

2. Intended use

3. Contraindications for use

4. Hazardous areas

5. Safety devices

6. Signs

7. Residual risks

4 INSTALLATION

1. Checking the material upon

delivery

2. Storage and unpacking

3. Lifting, handling and unloading

4. Transport

5. Assembly

6. Connecting the battery

7. Topping up and filling the

battery

8. Commissioning

5 USE OF THE MACHINE

1. Checks and preparation prior

to start-up

2. Starting up

3. Adjustment instructions

4. Turning off

6 MAINTENANCE

1. General warnings

2. Maintenance

7 SPARE PARTS AND

ACCESSORIES

1. Support

8 SUPPLEMENTARY INSTRUCTIONS

1. Waste disposal

2. Decommissioning and

disposal

3. Safe work procedures

TURBOCAR Foreword

0

0.0

1/10

FOREWORD

1. PURPOSE OF THE OPERATING AND MAINTENANCE INSTRUCTION MANUAL.

We would like to thank you for the trust you have placed in us by purchasing this new turbocar.

This Instruction Manual is an integral part of the Machine and has the purpose of providing all the

required information for:

•correctly raising operators’ awareness on safety issues;

•handling the packed and unpacked machine in safe conditions;

•correct Machine installation;

•thorough knowledge of its operation and limitations;

•its correct use in safe conditions;

•perform maintenance operations in a correct and safe manner;

•dismantle the Machine in safe conditions and in compliance with the regulations in force

protecting workers’ health and the environment.

The managers of the company where this Machine is to be installed are obliged – in

compliance with regulations in force – to carefully read this document and ensure

operators and maintenance technicians read the parts that concern them.

The time used will be widely made up for by proper machine operation and use in

safe conditions.

This document assumes the regulations in force on occupational health and safety are

complied with in the workplace where the Machine operates.

The instructions, drawings and documentation contained in this Manual are of a confidential technical

nature, strictly owned by the manufacturer and may not be reproduced in any way either wholly or in

part.

0 FOREWORD

PAR. DESCRIPTION

1 Purpose of the instruction manual

TURBOCAR Foreword

0

0.0

2/10

FOREWORD

2. HOW TO READ THE INSTRUCTION MANUAL.

The Manual has been divided into independent chapters, each aimed at a specific operator role

(INSTALLER, OPERATOR AND MAINTENANCE TECHNICIAN), for whom the skills required to

operate safely on the machine have been defined.

The sequence of chapters adheres to the temporal logic of the Machine’s service life.

To promote easy understanding of the text, terms, abbreviations and pictorials are used, the meaning

of which is set out in par. 6.

The Instruction Manual consists of a cover, a table of contents and a series of chapters (sections).

The first page shows the models, revision of the Instruction manual, to help the reader identify the

machine and relevant manual.

PAGE NUMBERING

0 FOREWORD

PAR. DESCRIPTION

2 How to read the instruction manual

TURBOCAR Foreword

Company

Logo

Company Logo Machine name Chapter name Chapter no. Revision no.

Chapter page no.

TURBOCAR Foreword

0

0.0

3/10

FOREWORD

Fig. 0.2.1

Chapter

Picture Abbreviation

Paragraph

Progressive

number

Tab. 0.2.1

Chapter

Paragraph

Progressive

number

Table Abbreviation

PICTURE NUMBERING

Each picture is numbered progressively.

Numbering consists as follows:

TABLE NUMBERING

Each table is numbered progressively.

Numbering restarts from “1” at each new section.

Numbering consists as follows:

ABBREVIATIONS

Sec. = section

Ch. = chapter

Par. = paragraph

Pg. = page

Fig. = figure

Tab. = table

UNIT OF MEASURE

The units of measure used are those set by the international system (IS).

TURBOCAR Foreword

0

0.0

4/10

FOREWORD

3. STORAGE OF THE INSTRUCTION MANUAL.

The Instruction Manual must be stored carefully and must be provided with the Machine through all

changes of ownership it might have throughout its service life.

Preservation must be promoted by handling it with care, with clean hands and by not placing it on

dirty surfaces.

No parts must be removed, torn or arbitrarily modified.

The Manual must be stored in premises away from moisture and heat and close to the Machine it

covers.

On the User’s request, the Manufacturer may provide additional copies of the Machine’s Instruction

Manual.

4. METHOD TO UPDATE THE INSTRUCTION MANUAL.

The Manufacturer reserves the right to modify the project and make improvements to the machine

without informing the Customers, and without updating the Manual already delivered to the user.

Nevertheless, in the event of modifications to the machine installed at the Customer’s premises

agreed with the Manufacturer and entailing modification of one or more chapters of the Instruction

Manual, the manufacturer shall send to the holders of the Instruction Manual concerned the modified

chapters, with its new overall revision model.

It is the User’s responsibility to follow the indications provided with the updated documentation and

replace the old chapters with the new ones, the first page and the table of contents with the new

revision level in all the copies they possess.

The Manufacturer shall be responsible for the description in Italian. Any translations cannot be fully

verified, hence should any inconsistency be found, the Italian version prevails. If required contact our

Sales department which will make the amendment deemed appropriate.

0 FOREWORD

PAR. DESCRIPTION

3 Storage of the instruction manual

0 FOREWORD

PAR. DESCRIPTION

4 Method to update the instruction manual

TURBOCAR Foreword

0

0.0

5/10

FOREWORD

5. RECIPIENTS

The Manual in question should be used by the Installer, the Operator and the Skilled Personnel

authorised to perform machine maintenance.

It is specified that “OPERATOR” refers to the personnel in charge of operating, adjusting, cleaning,

performing routine maintenance on the machine.

“SKILLED PERSONNEL or SKILLED OPERATOR” refer to the people who have attended

specialization, training courses, etc. and have experience in installation, commissioning and

maintenance, repair, handling of the machine.

“HAZARD ZONE” refers to any area within and/or near a machine where the presence of a person

represents a risk for the health or safety of the person.

Qualification of recipients (see PAR. 0.6)

The Machine is intended for agricultural use, therefore professional and not general, hence skilled

personnel should be entrusted with its use, specifically they should:

•have reached the age of majority;

•be physically and mentally fit to perform jobs having special technical difficulty;

•have been adequately instructed on machine use and maintenance;

•have been deemed fit and trained by the employer to perform the task entrusted to them;

•are able to understand and interpret the operator manual and safety requirements;

•know the emergency procedures and their implementation;

•have the skills required to operate the specific type of equipment;

•are familiar with the specific applicable regulations;

•have understood the operative procedures set by the machine’s Manufacturer.

0 FOREWORD

PAR. DESCRIPTION

5 Recipients

TURBOCAR Foreword

0

0.0

6/10

FOREWORD

6. GLOSSARY AND PICTORIALS

This paragraph lists uncommon terms or however having a meaning other than common.

The paragraph below explains the abbreviations and the meaning of the pictorials used to indicate the

qualification of the operator and Machine status. They are used to provide quickly and unequivocally

the information required for proper use of the Machine in safe conditions.

GLOSSARY

HAZARD ZONE: Area within and/or near a machine where the presence of an exposed person

represents a risk for the health or safety of that person;

EXPOSED PERSON: Any person who is entirely or in part in a hazard zone;

OPERATOR: Person in charge of installing, operating, adjusting, performing maintenance, cleaning,

repairing and handling the machine.

MAN-MACHINE INTERACTION: Any situation in which an operator interacts with the machine in any

operative stage at any time of its service life;

OPERATOR QUALIFICATION: Minimum level of the skills the operator must have to perform the

operation described;

NUMBER OF OPERATORS: Adequate number of operators to perform in an optimal manner the

operation described and arising from careful analysis performed by the manufacturer, hence using a

different number of workers might prevent the expected result from being achieved or jeopardise the

safety of the personnel involved;

MACHINE STATUS, refers to:

- the operating mode;

- the condition of the safety devices installed on the Machine.

RESIDUAL HAZARD: Danger that could not be eliminated or reduced sufficiently through design,

against which the guards are not (or are not wholly) effective. The manual provides information on its

existence and instructions and warnings to address it (see respectively, 5.5 and 5.5.1 of European

standards EN 292/1 and EN 292/2);

SAFETY COMPONENT: Refers to a component used to assure a safety function and whose fault or

bad operation undermines the safety or health of the exposed persons (e.g. lifting equipment; fixed,

movable, adjustable guard, etc., electrical, electronic, optical, pneumatic, hydraulic device that feeds

or interlocks a guard etc.);

0 FOREWORD

PAR. DESCRIPTION

6 Glossary and pictorials

TURBOCAR Foreword

0

0.0

7/10

FOREWORD

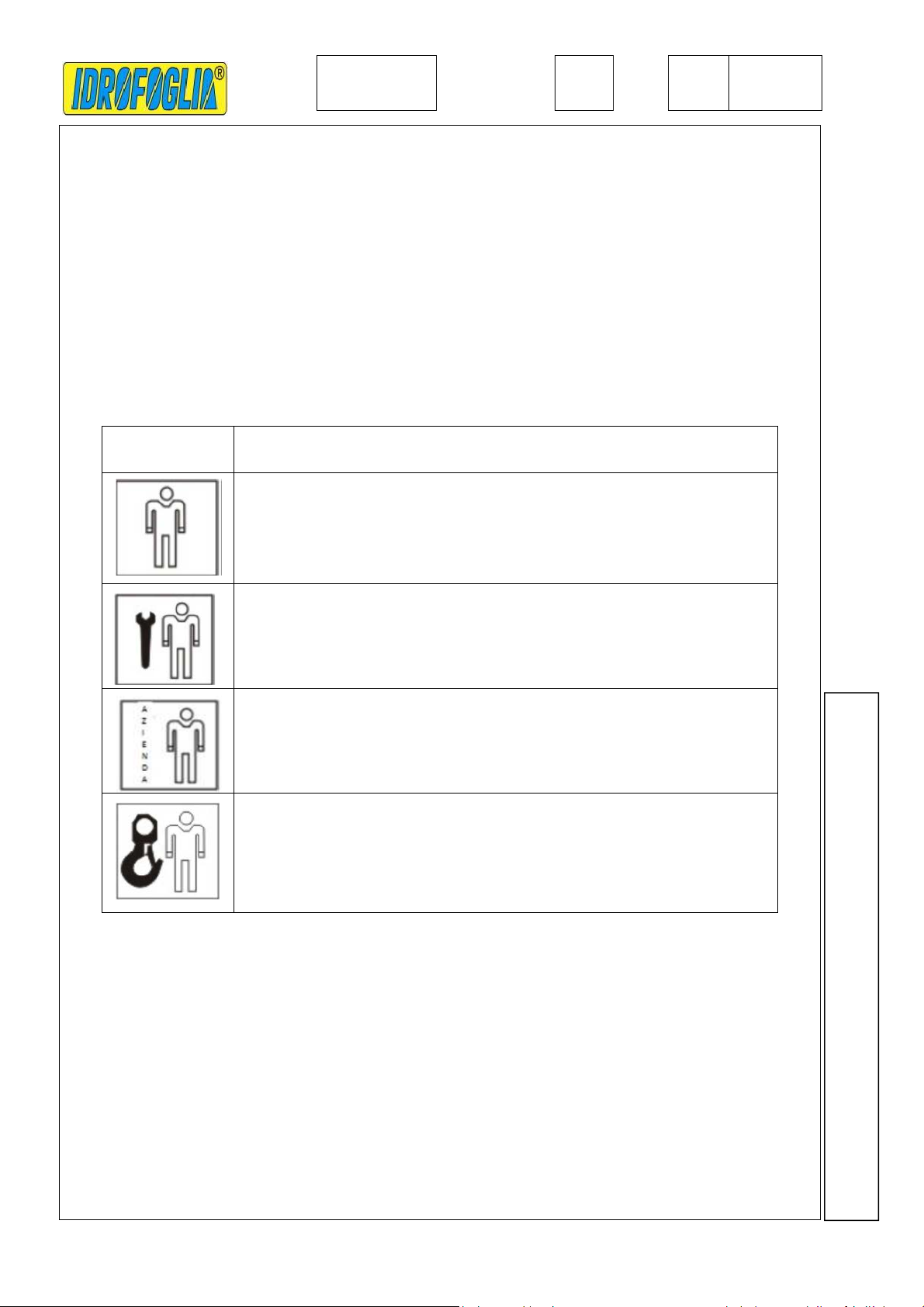

PICTORIALS

The descriptions preceded by this symbol contain

Very important information/requirements, especially as regards safety.

Failure to comply may entail:

•dangers for the safety of operators;

•loss of the contractual warranty;

•disclaimer of manufacturer’s liabilities.

SYMBOL DESCRIPTION

Machine operator: operator authorised to use the machine (strictly following

the manufacturer’s instructions), in compliance with the laws in force in the

machine user’s country.

Mechanical maintenance technician: skilled technician, able to operate

the machine in normal conditions, to act on mechanical parts to perform the

required adjustments, maintenance and repairs. Typically, they are not

authorised to perform operations on live electrical systems.

Manufacturer’s technician: skilled technician, provided by the

manufacturer to perform operations of a complex nature in special situations

or however agreed with the user. As the case may be, their skills are

mechanical, electrical or electronic.

Driver of lifting and handling equipment: operator authorised to use lifting

and handling equipment for materials and machines (strictly complying with

the manufacturer’s instructions) in compliance with the laws in force in the

machine user’s country.

Tab. 0.6.1

TURBOCAR Foreword

0

0.0

8/10

FOREWORD

SAFETY PICTORIALS

In the event they should be deteriorated or removed, the buyer is obliged to restore with

identical signs. Operators are expressly forbidden to remove or tamper with the signs.

SYMBOL DESCRIPTION

MAXIMUM PERMITTED TOWING SPEED: placed on the

back of the turbocar trolley (if the machine is approved the

limit specified on the registration paper/technical annex

applies)

UNAUTHORISED PERSONS MUST NOT STAND NEAR

THE MACHINE

DO NOT CLEAN, GREASE, LUBRICATE, REPAIR OR

ADJUST MOVING PARTS BY HAND

DO NOT REMOVE THE SAFETY DEVICES

MANDATORY USE OF PROTECTIVE GLOVES

MANDATORY USE OF SAFETY SHOES

MANDATORY USE OF PROTECTIVE HELMET IN

ACTIVITIES ENTAILING A POSSIBLE RISK OF

FALLING MATERIALS

MANDATORY USE OF PROTECTIVE OVERALLS

MANDATORY USE OF PROTECTIVE GOGGLES IN

ACTIVITIES ENTAILING A POSSIBLE RISK OF LIQUID

SPRAYS OR JETS

TURBOCAR Foreword

0

0.0

9/10

FOREWORD

OPERATORS MUST ADHERE TO THE INSTRUCTIONS

OF THE MACHINE’S OPERATING MANUAL

GENERIC HAZARD: placed on the machine

LIFTING HOOK CONNECTION: placed near each

connection on the machine’s top frame

CAUTION HOT SURFACES HAZARD : placed on the

compressor, if any

UPPER LIMBS CRUSHING HAZARD: placed near the

abutments of the bar joint

UPPER LIMBS ENTRAINMENT AND DRAGGING

HAZARD: placed near moving mechanical parts (roller

crown gear-gearbox pinion, roller crown gear-sliding bar

pinion drive)

LOWER LIMBS CRUSHING HAZARD: placed near the

drawbar lifting and parking feet

LEVER CONTROLS: placed near the distributor and

identifies the types of possible controls

GEARBOX ENGAGE/DISENGAGE: placed near the

gearbox release lever

GEAR INDICATOR: placed on the gearbox gear lever

(there are gearbox models with 4 gears and models with 2

gears)

SUMMARY OF INSTRUCTIONS AND WARNINGS:

placed near the roller crown gear (grease before use)

TURBOCAR Foreword

0

0.0

10/10

FOREWORD

ENTRAINMENT AND DRAGGING HAZARD placed near

the PTO shaft

PRESSURISED DUCTS HAZARD place near ducts that

may be released

DIGITAL METRE COUNTER GRAPH: placed near the

digital metre counter (only found on machines with VDO

metre counter)

SUMMARY OF INSTRUCTIONS AND WARNINGS:

placed near the turbine, it sums up the basic instructions

for turbocar operation (read carefully)

DANGER DURING USE : placed near the trolley loader

TURBOCAR

General

Information

1

0.0

1/6

GENERAL INFORMATION

1. MANUFACTURER’S IDENTIFICATION DATA

MANUFACTURER

IDROFOGLIA S.r.l.

REGISTERED OFFICE – ACCOUNTS

Via Provinciale, 14

61026 Lunano (PU) - Italy

SWITCHBOARD

Tel.: +39 0722/700311

Fax: +39 0722/700309

CONTACTS

Email: staff@idrofoglia.com

Website: www.idrofoglia.com

1 GENERAL INFORMATION

PAR. DESCRIPTION

1 Manufacturer’s identification data

TURBOCAR

General

Information

1

0.0

2/6

GENERAL INFORMATION

2. MACHINE IDENTIFICATION DATA

Each machine is identified by a CE plate indelibly marked with the machine’s reference data.

This plate must never be removed and must always be kept legible. In the event of damage a

duplicate must be requested.

1 GENERAL INFORMATION

PAR. DESCRIPTION

2 Machine identification data and plates

TURBOCAR

General

Information

1

0.0

3/6

GENERAL INFORMATION

3. COPY OF DECLARATION OF CONFORMITY

1 GENERAL INFORMATION

PAR. DESCRIPTION

3 Copy of declaration of conformity

TURBOCAR

General

Information

1

0.0

4/6

GENERAL INFORMATION

4. SAFETY REGULATIONS

The machine has been constructed in compliance with the safety regulations listed below:

UNI EN ISO 12100

Safety of machinery – Risk assessment and risk reduction

UNI EN ISO 14121-1

Safety of machinery – Risk assessment – Part 1: Principles.

UNI EN 908:2001 Trolley hose reel irrigators - Safety

UNI EN ISO 4254-1

Agricultural machines – Safety – Part 1: General safety requirements

ISO 11684:1995 Tractors, machinery for agriculture and forestry, powered lawn and

garden equipment –

Safety signs and hazard pictorials – General principles

UNI EN ISO 5674 Tractors and machinery for agriculture and forestry – Guards for

PTO drive shafts

UNI EN ISO 13732-1

Ergonomics of the thermal environment – Methods for the

assessment of human responses to contact with surfaces – Part 1:

Hot surfaces

UNI EN ISO 13849 – 1

Safety of machinery – Safety-related parts of control systems – Part

1: General principles for design.

UNI EN ISO 13857

Safety distances to prevent hazard zones being reached

by upper and lower limbs.

UNI EN ISO 4413

Hydraulic fluid power – General rules and safety requirements for

systems and their components.

1 GENERAL INFORMATION

PAR. DESCRIPTION

4 Safety regulations

TURBOCAR

General

Information

1

0.0

5/6

GENERAL INFORMATION

5. INFORMATION ON TECHNICAL SUPPORT AND WARRANTY

The machines are covered by warranty as set forth in the general sales conditions.

IDROFOGLIA S.r.l. WARRANTY CONDITIONS

1. The Seller guarantees to the Buyer their final products against faults or malfunctions due to

defects in constructions or materials. Any damage, impact or tampering with the material

received shall be notified to the Seller within 8 days from receipt of the goods by the Buyer (or

recipient) (either in case of Free Port or Freight Collect shipment).

2. The Seller guarantees the final product to the Buyer and for a period of 12 months from the

delivery date. Said warranty shall cover all components except motor and pump, for which the

warranty stated by the relevant Manufacturers shall apply.

The warranty claim on any component must be submitted directly to the Seller.

3. It is understood that said warranty includes and supersedes the warranties or liabilities set by

the Law and excludes any other Seller liability, except the case of the latter’s wilful misconduct

or gross negligence, either contractual or extra-contractual, however originating from the final

product supplied. Therefore, without prejudice to the event of wilful misconduct or gross

negligence, the Buyer may not demand compensation for damage, price decrease or

termination of the contract. After the term of the warranty has expired, no claim may be put

forth against the Seller.

Any defects or malfunctions of the final product shall not entitle the Buyer to discontinue or

delay payments thereof, nor of other supplies.

4. The Seller’s warranty is excluded hence not applicable in the following cases:

a. Should the buyer make modifications or have repairs made on the final product without

prior written authorisation by the Seller.

b. Should the final product be misused by the Buyer or used otherwise than specified on the

Use and Maintenance Manuals (including in the delivery of the final product). Should the

Manuals not be provided the Buyer shall be obliged to report it. In this connection, it is

pointed out, as specified in the use and maintenance manuals, that prior to using the

product the customer or dealer must ensure the finished product is complete with all its

parts or components, that all screws are properly tightened and that all gear parts are

appropriately lubricated. As a matter of fact, no complaints arising from said failings shall

be accepted. Any missing parts shall be reported to the company which, after the due

checks, shall send the material.

c. In the event the defects or malfunction should be caused by carelessness or negligence in

using the final product by the Buyer or wear caused by prolonged use.

d. In the event the final product has not undergone maintenance or lubrication servicing

solely by authorised personnel or other personnel recognised by the Seller.

e. In the event the Buyer has used non original spare parts or made repairs or made

modifications with personnel not authorised by the Seller.

f. In the event the breakdown or wear of the product arise from inadequate liquids or

affecting its duration, such as when irrigating using water that contains traces of sand,

1 GENERAL INFORMATION

PAR. DESCRIPTION

5 Information on technical support and warranty

TURBOCAR

General

Information

1

0.0

6/6

GENERAL INFORMATION

algae or other types of foreign matter, or if using fuels or oils that are not appropriate for

the motor or pumps they are used for.

g. In the event the final product is used in places other than agreed, in places that are dusty,

brackish, with presence of corrosive substances, high moisture, difficult environmental

conditions, low temperature (lower than 0°C) or high temperature (higher than +30°C).

5. By virtue of this warranty, only shipment to the Buyer’s premises of components having

construction or material defects shall be understood as borne by the Seller. Therefore, should

the Buyer require the repair or replacement under warranty at the place where the final

product is installed, the transport expenses of the component, the expenses for the authorised

personnel (including travel/board and lodging expenses) shall be borne by the Buyer.

Furthermore, in the event it should be required to return the components of the final product to

the Seller’s premises, the costs and expenses for said operation shall be borne by the Buyer.

6. Any servicing under warranty, replacement or repair of components by the Seller do not entail

renewal of this warranty.

TURBOCAR Description

Machine

2

0.0

1/22

DESCRIPTION OF THE MACHINE

1. OPERATING PRINCIPLE

Hose reel irrigators mainly consists of a long range irrigator, placed on a rubber wheel trolley

connected to a polyethylene hose.

1 Winder roller or drum or reel

2 Superstructure or upper frame

3 Hose guide system

4 Long range irrigator

During machine preparation the polyethylene hose is paid out. After that, during irrigator operation,

hose reeling in is controlled by the machine onto a horizontal axis drum (roller) placed on a

wheeled galvanised steel frame.

In most cases reeling in is hydraulic with turbine.

A motor pump unit may convey pressurised water into the hose.

Adjustment of the winding or reeling in speed (which must be constant for the whole duration of the

position) is indispensable in order to assure even water height on the irrigated surface.

Almost all models are fitted with a mechanical type speed regulator: the most widespread

regulators are the reel probes (bar joint) that act on bypass.

The Machines have been solely designed and constructed for irrigation of agricultural plots with

any kind of crop, parks, sport facilities and hothouses.

They essentially consist of:

2.1 turbine;

2.2 gearbox with gears in oil bath;

2.3 safety devices for PTO and reeling in out of stowed position;

2.4 motion drive to the roller via crown gear (double crown for large machines);

2.5 hose guide moved by worm screw;

2.6 bypass to adjust speed;

2.7 glycerine pressure gauge;

2.8 digital metre counter;

2.9 turntable and holder;

2.10 base rotation and lifting/lowering of the trolley loader, of the drawbar lifting foot and of the

right and left wheels, actuated by hydraulic system;

2.11 trolley loader and parking feet;

2.12 2-wheel frame (4 for larger machines) with water system with double inlet;

2.13 2-wheel irrigator traveller;

2.14 irrigator with set of nozzles;

2.15 Polyethylene (PE) hose.

2 DESCRIPTION OF THE MACHINE

PAR. DESCRIPTION

1 Operating principle

This manual suits for next models

7

Table of contents

Other IDROFOGLIA Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Krone

Krone Big Pack 890 Original operating instructions

PBZ

PBZ CropCare LGX25-1 owner's manual

LeeBoy

LeeBoy L600 Operation, service and parts manual

CrustBuster

CrustBuster 3200 owner's manual

KMC Controls

KMC Controls 33 Series Operator's manual

sitrex

sitrex SR 320/8 H Use and Maintenance Spare Parts List

ProAG

ProAG HD4SR Operator's manual

Mandam

Mandam MGP Series instruction manual

Anderson

Anderson 680HS Operator's manual

REIST INDUSTRIES

REIST INDUSTRIES Roto-Rake RR60 Operator and parts manual

Redexim

Redexim RINK DS 3800 Operating Instructions and Spare Parts Book

MacDon

MacDon M155 installation instructions