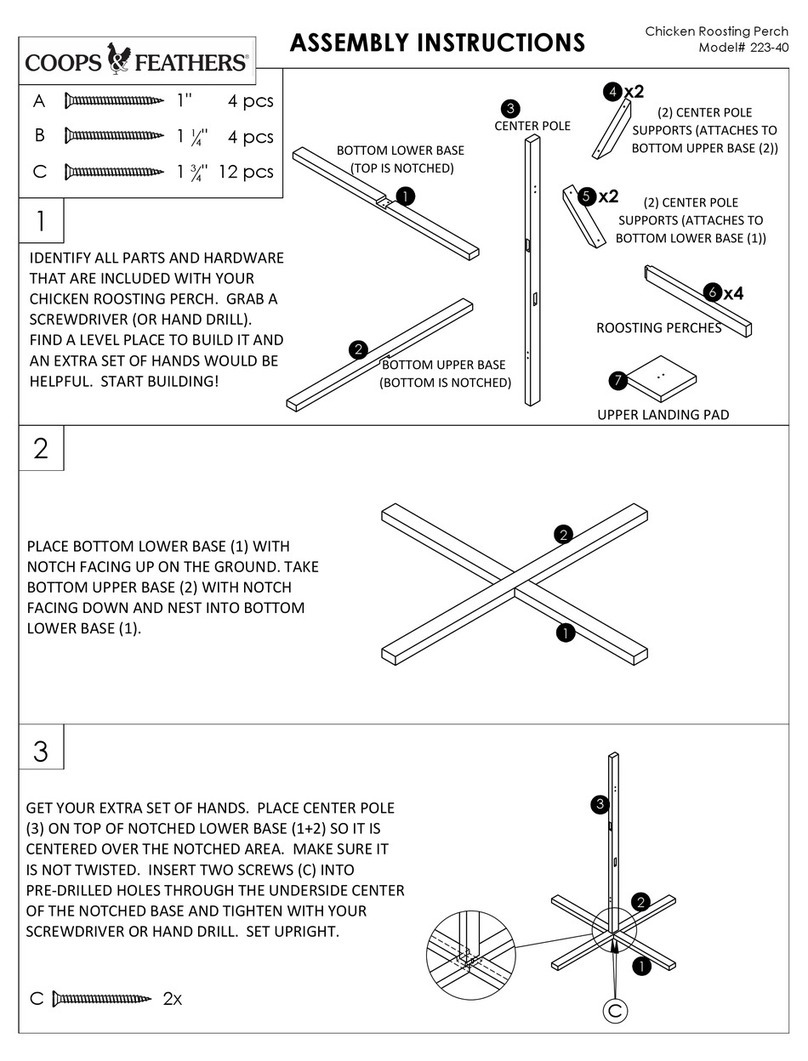

Assembly Instructions

32' Drill

STEP 11 (Refer to Figure 11)

Attach pull bar truss stand to A-frame in

front of fold lug with two (2) 3/4" x

4" x 7 1/2" U-bolts, lock washers, and hex

nuts. Holes in top of stand should be

straight above the front pull bar pivot pins.

Install truss swivel to the top of each hole

in truss stand. These swivels pivot

around a 1 1/4" O.D. x 13/16" I.D. x 9/16"

long spool secured with 3/4" x 2 1/2"

HHCS, flat washer, and lock nut.

Figure 11

STEP 12 (Refer to Figure 12)

Slide tube end of fold arm assembly into

clevis of front pull bar, align holes, insert 1

1/4" x 9 1/2" pin through truss tube down

through front pull bar clevis and fold arm.

Insert 7/8" truss adjusting bolt through

swivel. Install 7/8" hex nut and thread into

truss tube. Install 1 1/4" hex nut on fold

arm pin, tighten and secure set screw.

Follow the same procedure on other side

of drill.

Tighten truss rod bolts so when drill is

folded, pull bars will not catch on A-frame.

Jam 7/8" hex nut to keep truss rod adjust-

ment secure.

Figure 12

STEP 13 Adjust both fold arms to 48 3/4". These

may need minor adjustment when drill is

folded. The adjustable screw ends attach

to the fold slide with 1" x 3 1/2" HHCS and

lock nuts.

STEP 14 Install a 2" x 8" hydraulic cylinder (base

end to frame -- ram end to wheel lug --

ports to inside of drill) to wing wheel

rockershaft. Install 5-bolt rim and tire

assembly to hub. Follow the same proce-

dure on opposite wing rockershaft.

STEP 15 Mount selector valve plate to selector

valve bracket with two (2) 3/8" x 1" HHCS,

nuts, and lock washers. Attach valve to

plate with two (2) 5/16" x 1" HHCS and

lock washers. Valve is mounted with

handle up and two port side forward.

Intall fittings and hoses per Figure 15 on

page 4.

Use hose clamps to attach hoses along

front of frames. These are attached to

walkboard and tooth clamp bolts. Cable

wrap and hose carriers hold hoses which

are routed down top of A-frame. Slack in

hoses going to wing cylinders is needed at

the hinge. Attach a hose clamp on front

bolt of inside wing box standoff to hold

hoses up over hinge area.

STEP 16 WING LEVEL ADJUSTMENTS. Activate

hydraulics to wing and center frame cylin-

ders to raise drill. Level top of 4" x 6"

center frame tube using hitch jack. (Refer

to Figure 16.) Check each wing about

midway out on 4" x 6" tube to make sure

it is level. If wings require leveling, re-

move two (2) 3/8" bolts which hold large

hex plate on top of hinge. Loosen set

screw in side of 1 1/2" hex nut and loosen

nut. Hinges are set at factory at zero

degrees. This is indicated by two small

holes in hex plate pointing outward

toward wing. To tip wing FORWARD,

turn indicator holes to front of drill. To tip

wing BACKWARDS, turn indicator holes

to back of drill. Level both wings and re-

secure 3/8" bolts, 1 1/2" nut, and set

screws.

Figure 16

12