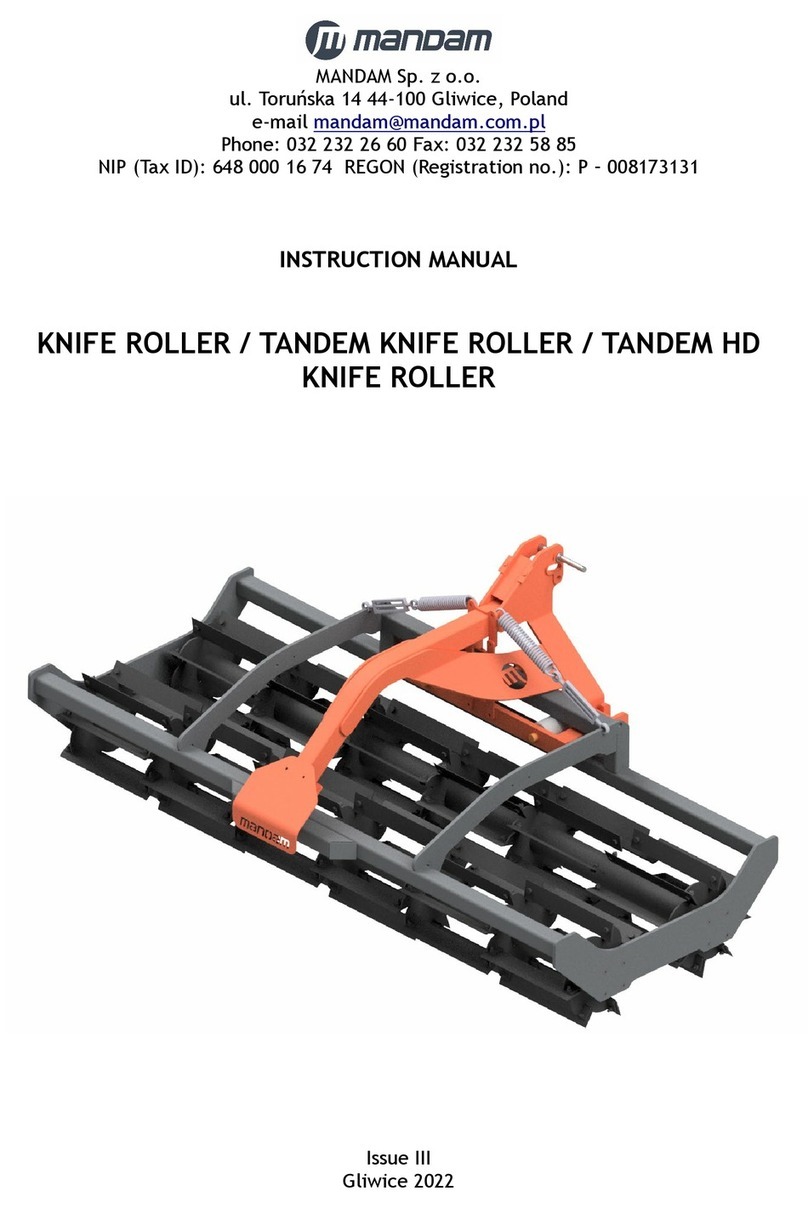

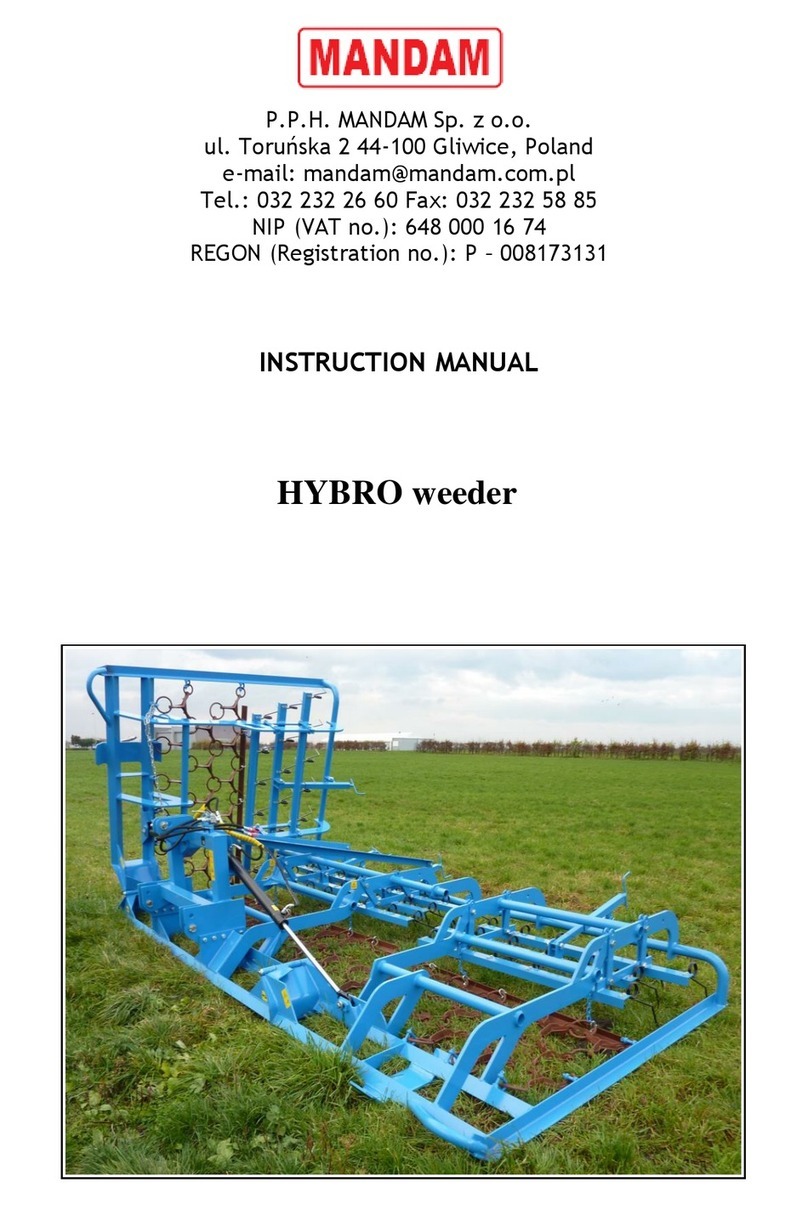

Mandam MGP Series User manual

2

EC DECLARATION OF CONFORMITY

FOR MACHINERY

In accordance with the Ordinance of the Minister of Economy dated 21 October 2008

(Journal of Laws No. 199, item 1228) and European Union Directive 2006/42/EC dated

17 May 2006

Przedsiębiorstwo Produkcyjno-Handlowe „MANDAM” Sp. z o.o. ul.

Toruńska 2

44-100 Gliwice

declares with full responsibility that the following machinery:

to which this declaration refers meets the following requirements:

Ordinance of the Minister of Agriculture dated 21 October 2008 on the essential

requirements for machinery (Journal of Laws No. 199, item 1228)

and European Union Directive 2006/42/EC of 17 May 2006

Persons responsible for the technical documentation of the machinery:

Jarosław Kudlek, Łukasz Jakus

ul. Toruńska 2, 44-100 Gliwice

The following standards were also used for conformity assessment:

PN-EN ISO 13857:2010,

PN-EN ISO 4254-1:2009,

PN-EN ISO 12100-1:2005/A1:2009

PN-EN ISO 12100-2:2005/A1:2009

PN-EN 982+A1:2008

The present EC Declaration of Conformity will no longer be valid if the machine is

modified or rebuilt without the manufacturer's consent.

President of the Board Vice President of the Board

Director Technical and Organizational

Director

inż. Bronisław Jakus mgr inż. Józef Seidel

Gliwice 12.09.2014

Place and date of issue Name, title and signature of the

person authorized

MGP SUBSOILER

Type/model: .........................................

Year of manufacture: ...............................

Serial No.: ………………….

3

Table of Contents

1. Introduction........................................................................................ 4

1.1 Safety signs and inscriptions................................................................ 4

2. Intended purpose of the subsoiler.............................................................. 5

3. Safe operation..................................................................................... 6

4. General information on the subsoiler operation. ............................................ 7

4.1 Adjustment of the subsoiler. ............................................................... 7

4.2 Working with the subsoiler.................................................................. 7

5. Faults and abnormalities in the subsoiler operation......................................... 9

6. Maintenance. ...................................................................................... 9

7. Storage ............................................................................................ 10

8. Transport.......................................................................................... 10

9. Dismantling and scrapping the subsoiler ..................................................... 11

10. Technical characteristics ...................................................................... 11

11.List of spare parts ............................................................................... 12

12. General rules governing the warranty procedure........................................... 14

WARRANTY CARD ...................................................................................... 15

4

1. Introduction

We sincerely congratulate you on your purchase of the MGP subsoiler.

This manual provides information on the hazards that may occur during working with the

subsoiler, technical data and the most important indications and recommendations you need

to know and apply for its proper operation.

Recommendations that are important for safety reasons are marked with:

This machinery has a rating plate located on the main frame. This plate contains the basic

data needed to identify the machine:

Type Number

Weight Year of manufacture

The machinery’s warranty is valid for 24 months from the sale date.

The warranty card is attached hereto as the last page of this manual. The warranty card is

an integral part of the machinery.

Always provide the serial number when requesting spare parts.

At the end of this manual you will find a list of spare parts that will help you to place an

order and help you become acquainted with the subsoiler’s construction.

1.1 Safety signs and inscriptions

REMEMBER! During use of the subsoiler, special caution should be exercised in

areas marked with special information and warning signs (yellow stickers).

Listed below are the signs and inscriptions placed on the machine. Signs and inscriptions

should be protected from falling off or becoming illegible. Missing and illegible signs and

inscriptions should be replaced by new ones.

5

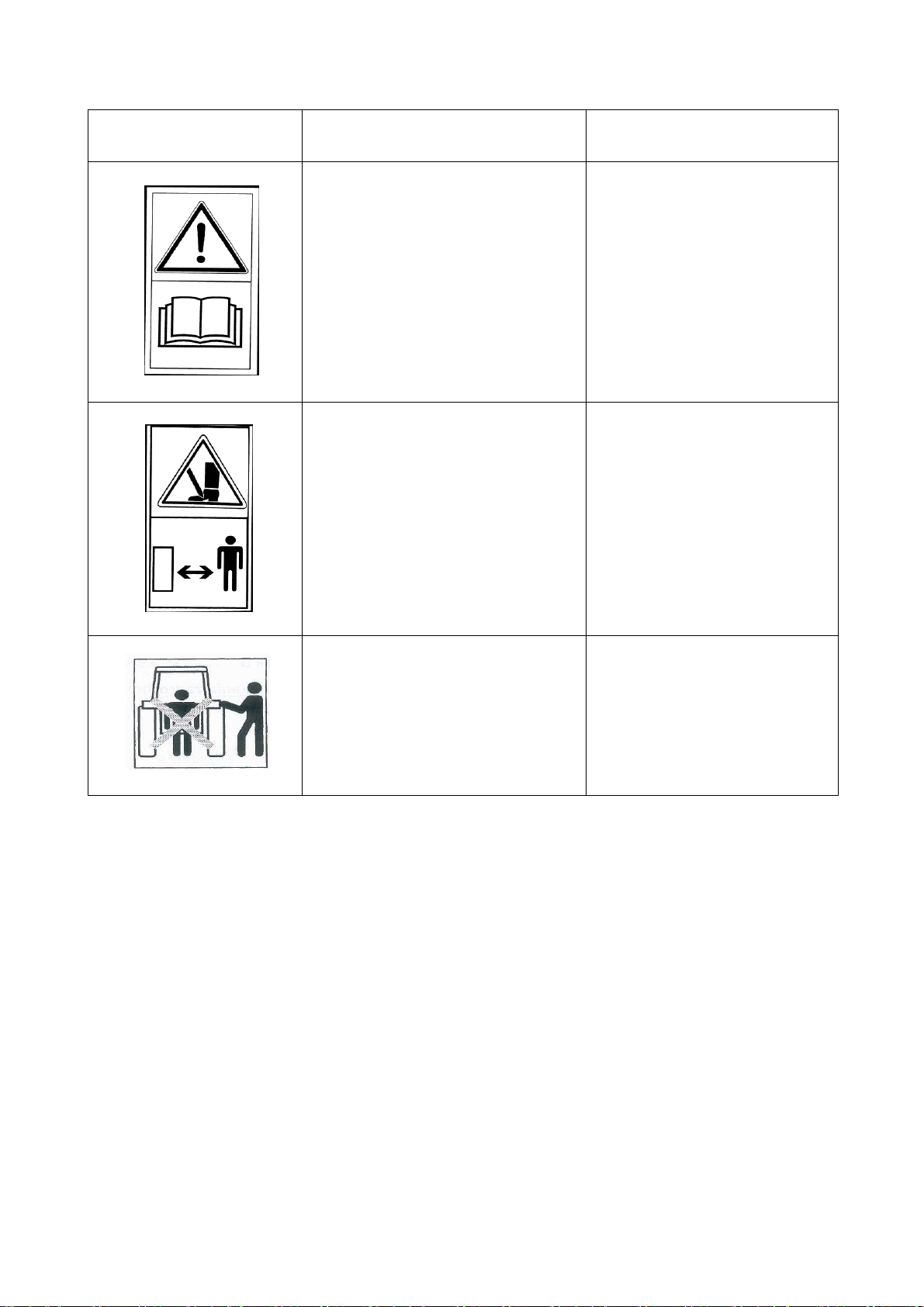

Table 1. Information and warning signs

Safety sign

Meaning of the safety mark

Place the sign is located on

the machine

Read the operating instructions

before using this machinery

The subsoiler frame near the

top connection fixing point

Risk of toes or feet being crushed

The subsoiler frame near the

top connection fixing point

Do not stand too close to hoists

while the lift is being operated

The subsoiler frame near the

top connection fixing point

2. Intended purpose of the subsoiler

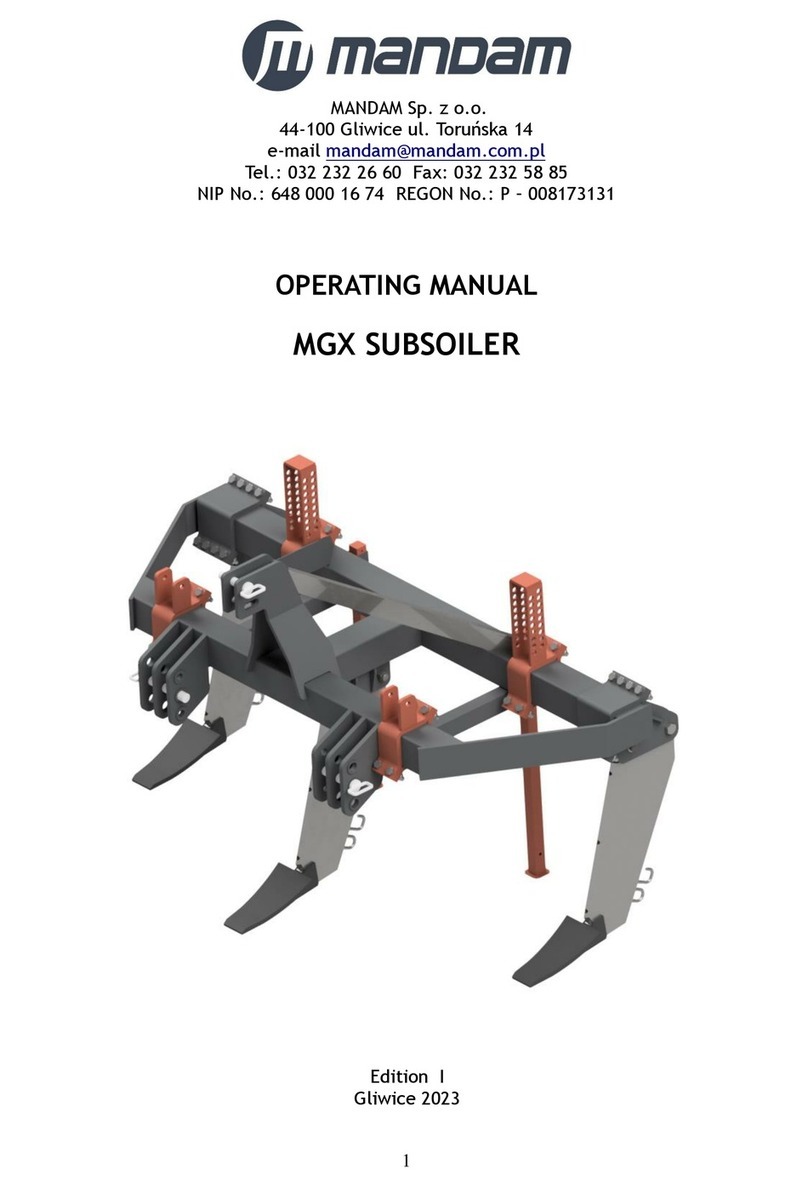

The MGP subsoiler is an agricultural machine intended for loosening the soil,

especially the destruction of the plough sole, and airing of the soil (at the depth from 20 to

60 cm) without disturbing its layered structure. As a result, its physical and biological

properties are improved, especially in case of heavy, catchment soils. Aeration and

improvement of the water and air circulation in the soil profile obtained through the use of a

subsoiler ensures an excellent agrotechnical effect. The MGP subsoiler is designed to work

with active machinery. It is equipped with a three-point suspension system and a frame

structure that does not interfere with the WOM shaft, allowing a two-layer cultivation of the

soil. This also ensures comprehensive cultivation for plants that have particular soil

structure requirements (potatoes, sugar beet).

6

WARNING! The subsoiler is intended exclusively for agricultural work. Use for other purposes will

be construed as improper use and will result in loss of warranty. Failure to comply with these

operating instructions will also be construed as misuse.

WARNING! The manufacturer is not responsible for damage caused by misuse of the machine.

3. Safe operation

The subsoiler can only be handled and operated by adults who are familiar with the

operating instructions and take all necessary precautions and in particular:

when transporting the subsoiler on public roads, the following must absolutely be

mounted on the machinery’s frame:

◦a distinctive plate for slow-moving vehicles according to PN-93/R-36154

◦a portable warning light device that includes two / forward-facing and backward

facing warning signs / with white driving lights facing forward and rear light

clusters and backward facing reflective discs.

special care is to be taken when overtaking and passing other vehicles,

while the subsoiler is in operation do not use the tractor independent brakes,

all operations on the machine must be performed only when the tractor’s engine is

switched off and the machine is lowered to the ground,

do not approach the subsoiler when it is being lifted or lowered,

do not come between the tractor and the attached subsoiler while the engine is

running,

do not reverse the subsoiler or make turns when the machine is lowered into its

operating position,

do not stand on the machine or add any extra loads during operation or while it is

standing idle,

use only factory supplied bolts and cotter pins for safe connection of the subsoiler

with the tractor,

all repairs, inspections, maintenance or cleaning of working parts shall be carried out

only when the tractor engine is switched off and after having lowered the subsoiler to

the ground,

turn off the engine before leaving the tractor,

the subsoiler may only be disconnected from the tractor on a level surface ensuring

a stable stop,

7

the subsoiler should be parked in an area out of the reach of the farm animals,

use and operation of the machine by children or persons unfamiliar with the

instructions or under the influence of alcohol is prohibited.

WARNING! Failure to follow the above rules may present a risk to the operator and any third

parties, as well as damage to the machine. The user is responsible for any damage resulting from

non-compliance.

4. General information on the subsoiler operation

The main frame of the subsoiler constitutes the basic support element for the entire

machine. Six tines are attached to the subsoiler frame (6 pieces). Subsoilers can be

equipped with support wheels, which serve to adjust and maintain the depth of the

subsoiler’s operation.

4.1 Subsoiler adjustment

The subsoiler is delivered for sale in ready-to-use condition. Due to the limitations of

transportation, it may also be delivered in a partially disassembled condition - most often

this involves disengaging the support wheels from the MGP subsoiler.

The subsoiler should be protected against overturning by properly adjusted support legs

(these are standard equipment of the subsoiler).

During operation the machine is subject to adjustment of the following:

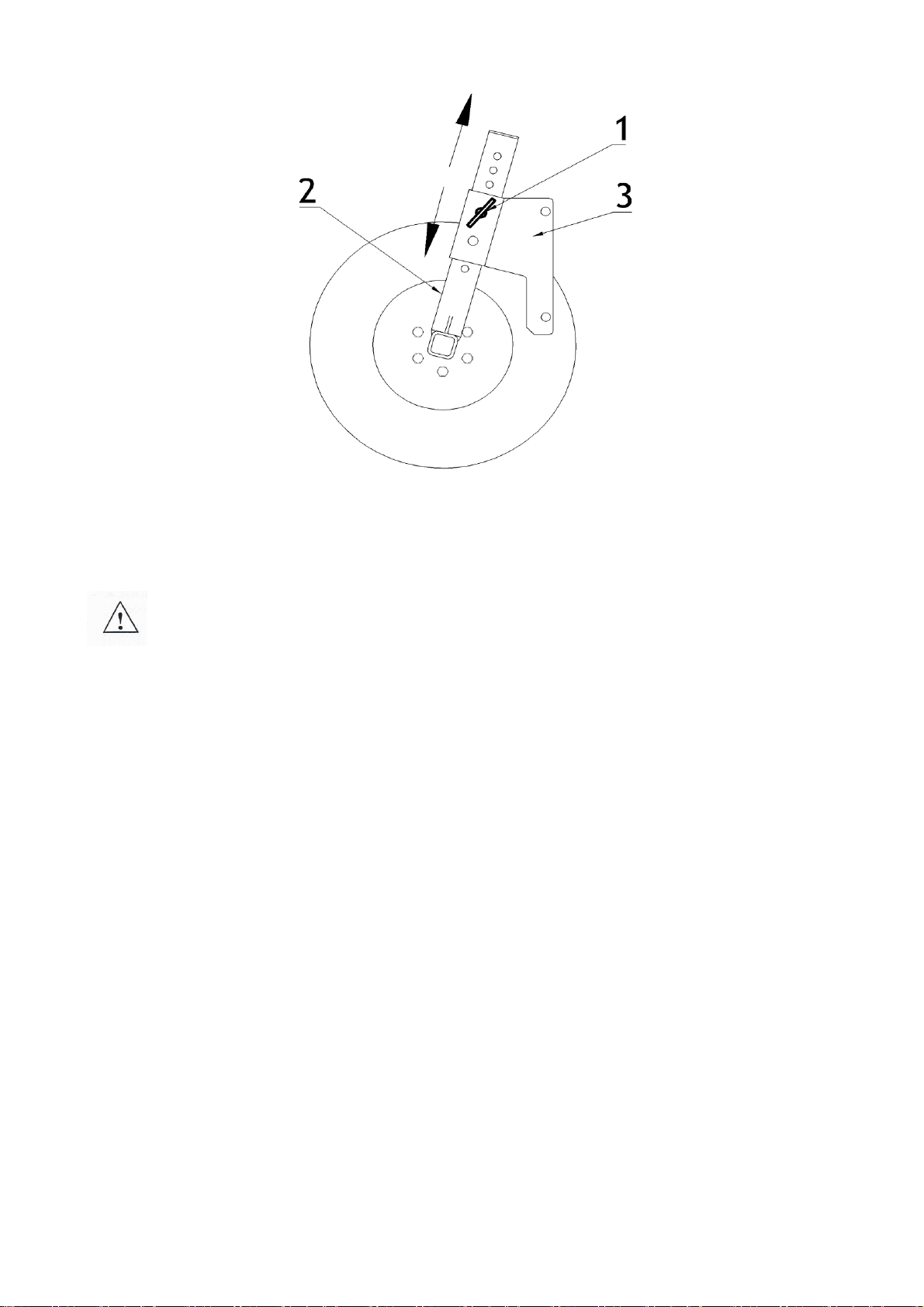

depth of the tines’ operation - by adjusting the position of the support wheels in the

adjustment brackets (fig. 1),

depth of the tines’ operation relative to the machine used with it - by setting the

three-point hitch depth with the appropriate adjustment opening.

8

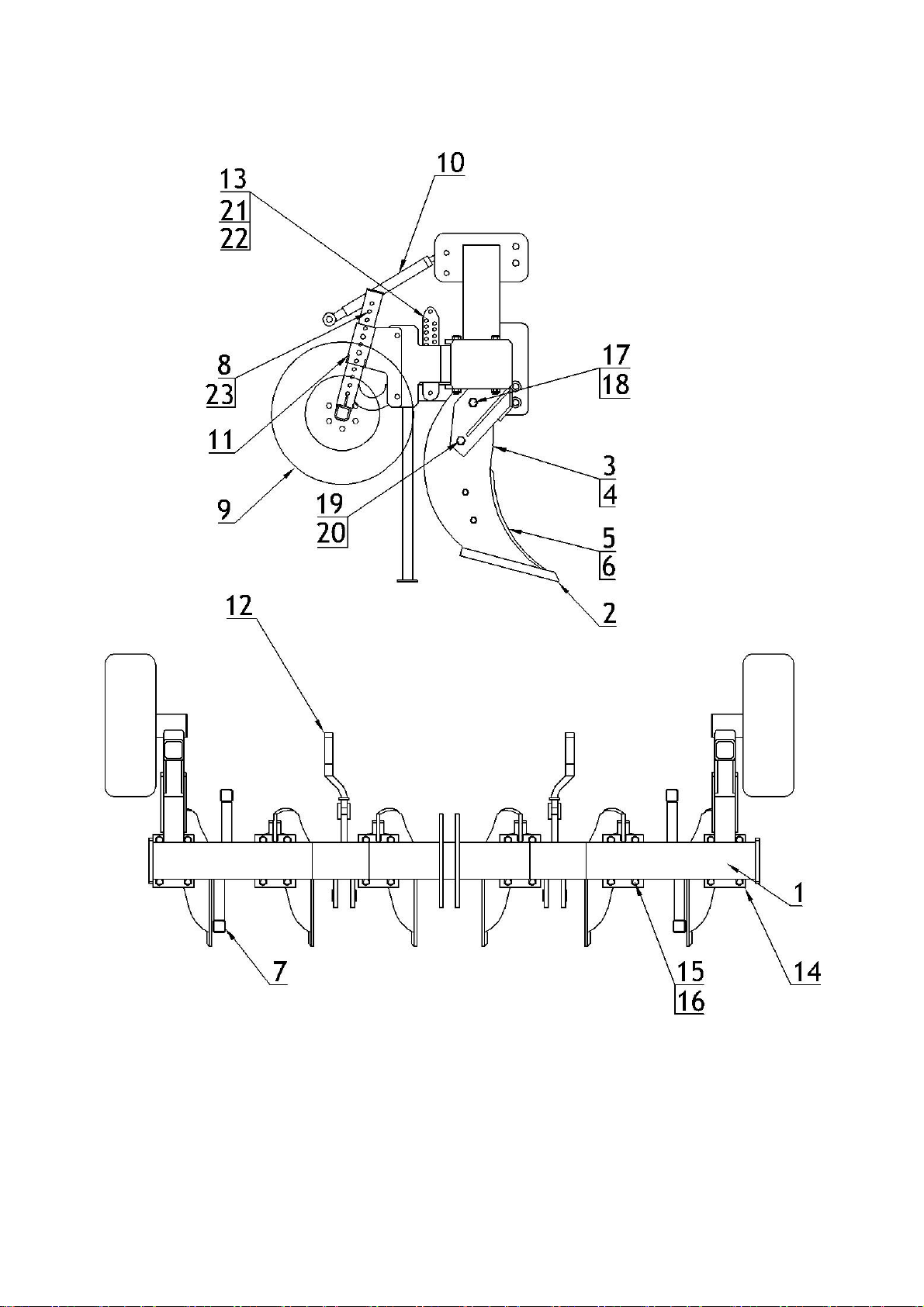

Figure 1. Adjustment of operation depth by means of the wheel on the subsoiler: 1 - depth

adjustment bolt; 2 - bar with openings in the support wheel; 3 - support wheel bar handle.

WARNING! Prior to working with the subsoiler, check all bolted connections and ensure the

machine is properly connected to the tractor.

4.2 Working with the subsoiler

Prior to working with the subsoiler, it should be hooked up to the tractor's three-point hitch,

and for this purpose the operator must:

remove the lower coupling bolts,

carefully reverse the tractor and attach the coupling bolts to the tractor's lower rod,

and then secure them with their cotter pins,

connect the tractor’s upper rod,

check the lifting and lowering of the subsoiler.

In order to attach the machine cooperating with the MGP subsoiler the operator must:

adjust the distance between the rod hooks and the ground so that they are located

below the rod pins of the co-operating machine, by means of the pins, placing these

above the depth-setting bar (Figure 2)

carefully reverse the tractor along with the subsoiler to meet up with the co-operating

machine,

raise the coupling hooks so that they engage with the pins,

lock the coupling hooks on the bolts,

connect the upper rod to the co-operating machine.

9

Upper connector

Depth adjustment

Bolt

Setting bar

Three-point hitch tension rod

Figure 2. MGP subsoiler three-point hitch components

WARNING! Coupling of the tractor with the subsoiler must be carried out carefully, at the tractor’s

minimum speed! When hooking up the machine, make sure there are no bystanders too close.

Before leaving for the field via a public road, a warning sign must be attached to the

subsoiler or the co-operating machine, for transport on public roads.

The subsoiler can be operated at the speed of 8 km/h.

WARNING! Failure to keep to the above speed may result in a malfunction or accident.

When properly hooked up, the subsoiler should, while working, move evenly behind the

tractor and uniformly loosen the soil over its entire working width. The subsoiler’s frame

should be horizontal to the field’s surface (by adjusting the upper rod of the tractor).

The hydraulics of the tractor should be set for position adjustment, but under unfavourable

conditions one may use powered adjustment or mixed adjustment.

10

The subsoiler’s proper operating depth is determined by adjusting the position of the bolts

in the openings of the adjustable support wheels (Figure 1). The depth relative to the co-

operating machine is determined by means of the depth adjustment bolts by inserting them

into the appropriate opening below the depth-setting bar (Figure 2).

WARNING! Maximum operating depth of the subsoiler is 600mm. Exceeding this parameter may

cause a malfunction or accident.

WARNING! The subsoiler must not be used on extremely stony soil, as this may cause damage to

the working parts of the machine or an accident.

5. Faults and abnormalities in the subsoiler operation

In order to extend the machine’s working life, all instructions in this manual must be

observed as regards the operation, adjustment, lubrication, transport and storage of the

machine.

WARNING! Any adjustments, repairs, or removal of blockages should only be carried out with the

subsoiler lowered onto the ground. The tractor’s engine must be switched off.

WARNING! The subsoiler must not be used on soil that is too damp, as this results in degradation

of the soil structure, or on stony ground with rocks of any considerable size!

6. Maintenance

On finishing each job (following at least every 10 hours), the subsoiler should be

cleaned of all soil and all connections and assemblies should be checked. Loosened bolted

joints are to be tightened. Damaged or worn parts should be replaced with new or

regenerated parts.

WARNING! During any maintenance work the shaft must rest on the ground and the tractor’s

engine must be turned off.

7. Storage

After the season has ended, you should check all parts and assemblies. In the event

of damage or significant wear, replace appropriate parts with the new ones. Clean the

painted surfaces of all dirt and paint any rusted areas with anti-corrosion paint and then add

a topcoat. Protect the working surfaces of the tines and the tubular shaft from corrosion.

11

WARNING! Store the subsoiler on a level, horizontal surface, preferably indoor or in a roofed area

protected from unauthorized access by outsiders or animals.

8. Transport

9.

WARNING! Particular caution should be exercised when transporting the subsoiler. It is forbidden

to travel on public roads without an appropriate additional warning sign.

Prior to travel on a public road, a portable warning light device and a distinctive sign for

slow-moving vehicles should be fitted to the ends of the subsoiler’s frame.

The portable warning light device should consist of two panels in red and white stripes,

equipped with:

at the front - white driving lights, and a reflective white circle,

at the rear - red driving lights, brake lights, indicators and a reflective red triangle.

A distinctive plate (a triangle) should be affixed in the middle of the frame.

During transport, the subsoiler should be raised to such a height that the minimum

clearance under the machine is at least 25 cm.

The transport speed must not exceed:

20 km/h –on asphalt roads

5 km/h –on roads with any other surface

When towing the subsoiler, drive the tractor as close to the right edge of the road as

possible. Use caution when overtaking and passing other road users.

REMEMBER! Travel on public roads without the required traffic signs, warning signs and lighting

may cause an accident!

REMEMBER! Warning light devices are not factory fitted to the subsoiler. They can be purchased

at any agricultural machinery sales outlet.

10. Dismantling and scrapping the subsoiler

Dismantling and scrapping of a used subsoiler does not pose any great threat to the

environment. Dismantling the subsoiler should start with the removal of the small parts

(bolts, screws, etc.) then going on to the larger ones. The dismantled subsoiler should be

sent to a scrap metal recycling centre as a recyclable material.

12

11. Technical characteristics

Table 2. Technical data for the MGP subsoiler

Type

Working width

[m]

Secured by

Number of

tines

[pcs]

Min. power

[KM]

Weight

[kg]

MGP 6 3000

3.00

Cotter pin

6

190

995

13

12.Spare parts list

Figure 2 Subsoiler MGP 6 3000 - spare parts

14

Table 3. List of spare parts for the MGP subsoiler

Item

N

ame

MGP 6 3000

1

Frame

1

2

Double sided coulter

6

3

Right-hand tine

3

4

Left-hand tine

3

5

Right-hand moldboard

3

6

Left-hand moldboard

3

7

Support leg

4

8

Frame with front axle (optional)

2

9

Support wheel (optional)

2

10

Turnbuckle

1

11

Handle of the arm with front axle

2

12

Band with three-point hitch hook

2

13

Height adjuster

2

14

Tine holder

6

15

M24x270-10.9

)

bolt

24

16

M24

(self-locking) nut

24

17

M30x90-10.9 bolt

6

18

M30

(self-locking) nut

6

19

M16x90-10.9 bolt

6

20

M16

(self-locking) nut

6

21

M20x80-8.8 bolt

4

22

M20

(self-locking) nut

4

23

Pin

2

15

4 General rules governing the warranty procedure

•Only original spare parts intended for Mandam machinery provide long-lasting

and efficient operation. Parts for all Mandam machinery are available through

our dealer network or directly from the manufacturer.

•The warranty covers defects and damage attributable to the Manufacturer as a result

of material defect, inappropriate treatment or assembly. By granting a warranty, the

Manufacturer agrees (the scope and total costs of repairs must be agreed between

the Manufacturer and the other party) to the following:

a) free repair of equipment found to be faulty,

b) provide the User with new properly manufactured replacement parts free of

charge,

c) cover labour and transport costs.

•Complete replacement of the equipment with another unit free of defects, should the

operations listed in a) and b) fail to ensure proper operation of the equipment.

•Warranty services are to be provided by the Manufacturer, or by the warranty

services contractor appointed by the Manufacturer.

•The User should report a complaint promptly and within 14 days of the occurrence of

the fault or damage.

•The warranty is automatically to be extended for the period during which the

equipment is repaired.

•The Manufacturer shall not accept any warranty claim if the equipment has

undergone any technological modifications or repair without the Manufacturer’s prior

knowledge, has been improperly stored, maintained or improperly used.

•If the User considers that the complaint they have made has not been properly

handled, they have the right to demand that the Seller has the case examined by an

expert appointed by both parties to the dispute.

16

P.P.H. MANDAM Sp. z o.o.

44-100 Gliwice ul.Toruńska 2

e-mail mandam@mandam.com.pl

Tel.: 032 232 26 60 Fax: 032 232 58 85

NIP: 648 000 16 74 REGON: P –008173131

WARRANTY CARD

ORKAN VARIO plough

Type ......................................

Serial number ......................................

Year of manufacture ......................................

Sale date ......................................

The guarantee is valid for 12 months from the date of sale.

Warranty services on behalf of the equipment’s manufacturer is to be performed by

............................................................................................................

(to be filled in by the seller)

.......................................

........................................

(Manufacturer's stamp) (Seller’s stamp)

The warranty card must be shown when submitting a claim

This manual suits for next models

1

Table of contents

Other Mandam Farm Equipment manuals

Mandam

Mandam GAL-K User manual

Mandam

Mandam KNIFE ROLLER 3.0 User manual

Mandam

Mandam Hybro 3,0 User manual

Mandam

Mandam MBS User manual

Mandam

Mandam RHINO User manual

Mandam

Mandam SPEC HD 2,5 User manual

Mandam

Mandam ORKAN VARIO Series User manual

Mandam

Mandam MGX 2200 User manual

Mandam

Mandam ORKAN 3+ User manual

Mandam

Mandam MWC Series User manual