6

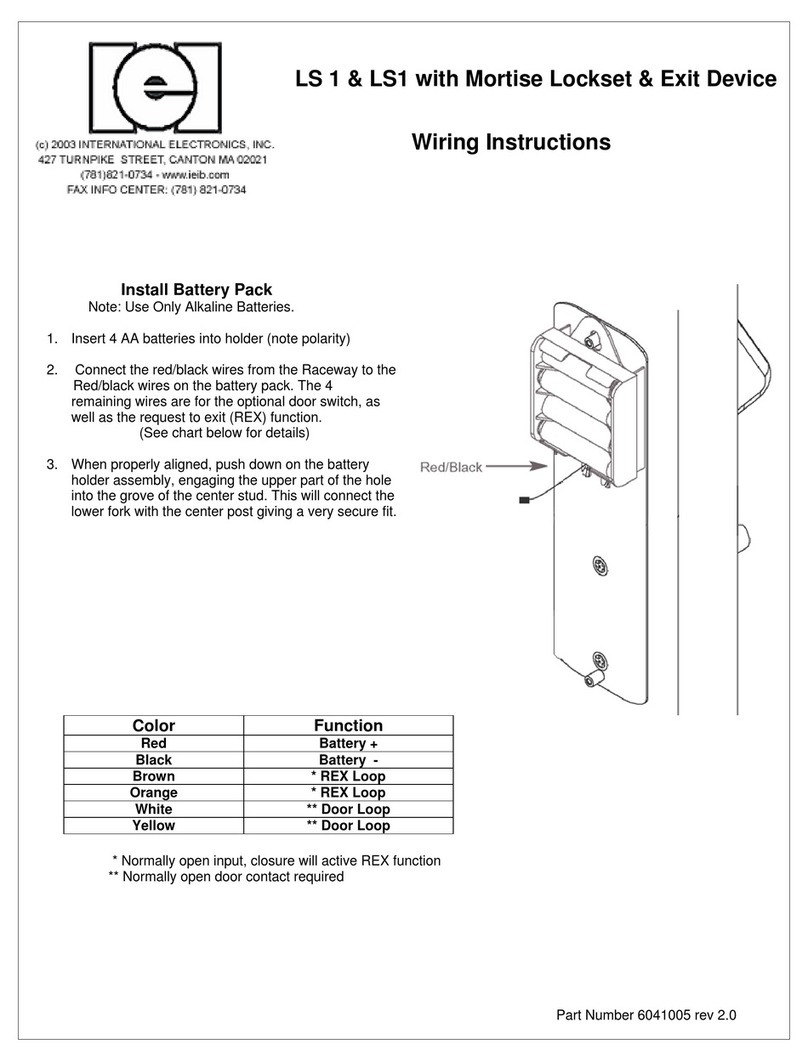

1. S lide the inside lower housing over the lever tube until it has

passed over the lever catch. Make sure no wires are

pinched by the lower housing.

2. Fasten with two brass #8 screws. Once secure, fasten the

finished #8 screw at the bottom.

3. R emove red strip form battery pack to power the unit before

continuing.

Brass #8 S crews

Finished #8 Inside Lower Housing

Lever C atch

B attery C over

#8 S crews

Inside Lower

Housing

C enter

Grooved S tud

1. Attach the battery cover with two finished #8 screws.

Battery cover has a lip which engages the lower inside

housing, it is important that this lip be seated properly to

insure correct alignment.

1. Insert cylinder retainer into lever until flush with base of lever.

2. P ush lever on door in horizontal position until secure.

R emove red strip

to engage battery pack

Ins talling Interior As s embly

(part 2)

Figure 9 Figure 10

AA

Lower Housing

B

Battery Cover

C

Interior Lever

Interior Lever

C ylinder

R etainer

Electrical

Symptom Probable Cause Correction

1. Beeping after assemby is completed

(4 long beeps) Low Voltage R eplace B atteries

2. S olid green LE D, no motor action C ontrol Module not sending lock/unlock pulse Verify continuity of wire harness and

replace if necessary

3. Yellow LE D flashes and sounder chirps

after install Unit not intialized C onta ct IE I

4. Motor locks but will not unlock

5. Unable to change system default

R E X loop is shorted

(Brown and Orange on P 4 wire harness ) Inspect connection and remove short

V arious C onta ct IE I

Mechanical

Symptom Probable Cause Correction

1. Lever S ticks or is sluggish Hand is too close to front escutcheon Tighten motor spacer ring

2. Handle rests in down position Bushing is not set correctly R emove handle and set bushing in escutcheon

3. C annot s nap on handle A. C has sis not adjus ted correctly

B. Chassis lever locking tab is damaged or missing

A. Adjust to correct setting

B . C ontact IE I

4. C annot tighten the raceway by hand

5. Latch works in only one direction

R ace threads are damaged Use thread chaser to clean threads or contact IE I

The backset is not centered on the latch retractor C enter the backset on the latch retractor

TROUBLESHOOTING

4 of 6

F C C Label

7

6. Does not read proximity cards Unit may not be an LS -2P C heck the FC C Label (see F igure 10). If the label does not refer

to model LS -2P then it is an LS -2 and not an LS -2P .