7

Dongguan Ortur Intelligent Technologies Co., Ltd.

https://ortur.tech/olm2pro

No.1 Building, Ruijin Science and Technology Industrial Park, Changping, Dongguan 523558, Guandong Province, China

Laser Generated Air Contaminants

Laser engraving or cutting will generate fumes, vapours and

particulates from the substrate material that can be highly toxic.

Is recommended to select a room to operate the Ortur Laser

Master 2 Pro where access to good ventilation is available and

proper ventilation is maintained at all times when the Ortur Laser Master 2 Pro is

in operation.

Although most of the recommended materials for engraving on the Ortur Laser

Master 2 Pro are safe, the user should seek information each time a new material

is used.

Some materials, specially plastic based, will generate highly toxic

fumes that are - not only - very health hazardous but can also

damage and corrode your Ortur Laser Master 2 Pro metal frame.

Below a list of some of the most known hazardous materials that the user

SHOULD NOT attempt to engrave or cut on. If a material is not in this list, do

not consider it to be safe to use. Obtain the Safety Data Sheet (SDS) from the

material’s manufacturer when handling unknown materials.

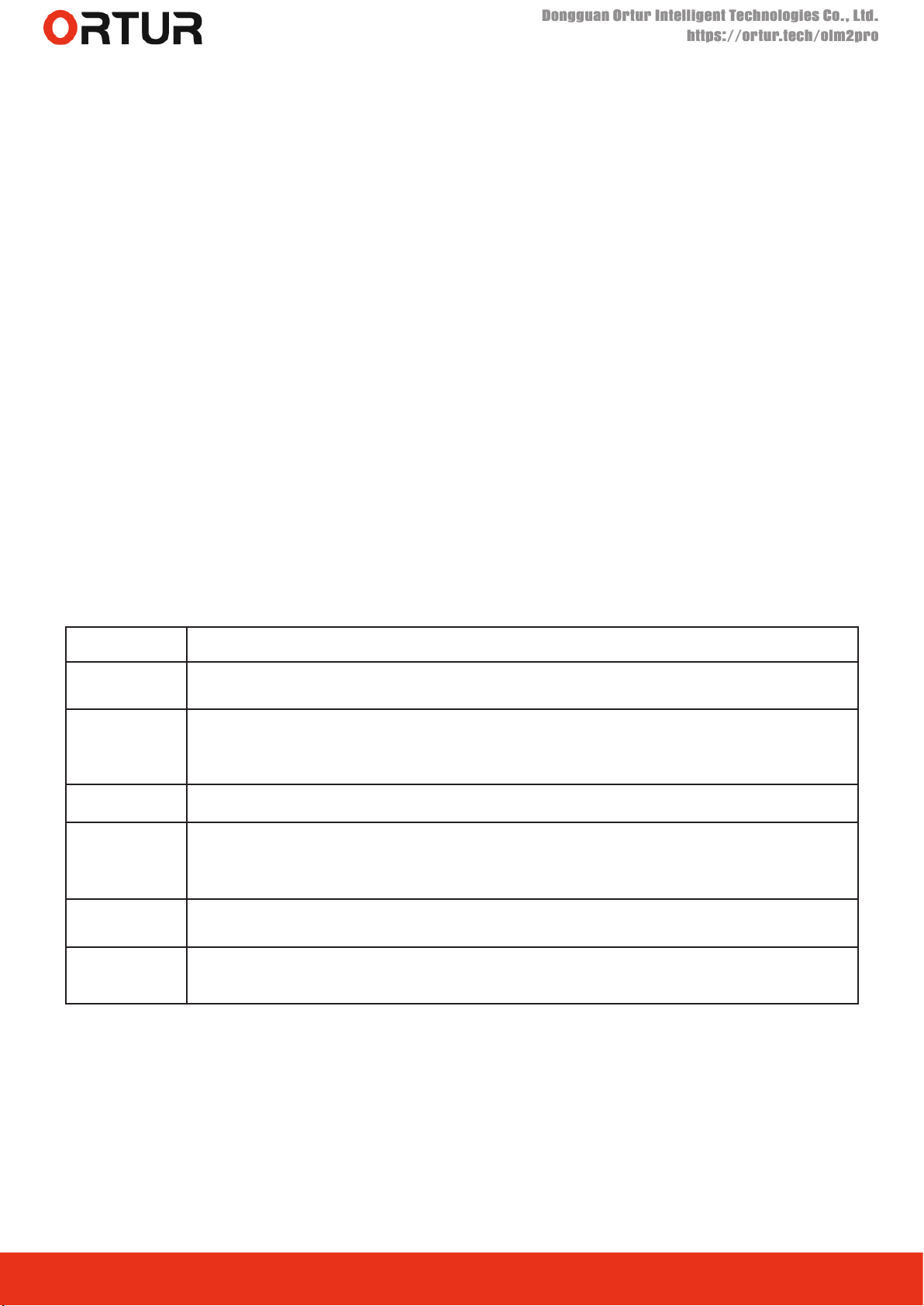

Material Reason to avoid engraving / cutting it

PVC (Poly Vinyl

Chloride)

PVC will emit Chlorine gas when laser cut or laser engraved. This toxic gas can

ruin the optics and motion control system of the laser engraver, In fact, engraving

or cutting PVC is a sure way of voiding the warranty of your laser engraver

Lexan / Thick Poly-

carbonate

Lexan not only cuts poorly but it also catches on re very easily. The window of

the laser engraving machine is usually made from polycarbonate because it does

a very good job of attracting infrared radiation., which is the frequency of light the

engraver uses when cutting and engraving materials. This makes the laser cutter

quite ineective in cutting polycarbonate materials

ABS ABS melts upon exposure to a laser beam as opposed to vaporizing which would

be the ideal reaction needed for laser engraving. Instead of leaving a crisp image,

ABS will melt and leave a gooey deposit on the surface.

HDPE HDPE melts and catches on re pretty easily upon exposure to a laser beam.

Polystyrene Foam Only very thin pieces can be laser cut but for the most part, polystyrene catches

on re and melts when exposed to a laser beam

Fiberglass Fiberglass is made from two materials; glass and epoxy resin. The best method

of marking glass is etching while epoxy resin can emit toxic fumes upon laser

engraving. These two reasons make berglass a bad choice for a laser engraving

material

Polypropylene polypropylene melts and catches on re easily and then the melted material con-

tinues to burn thereby forming pebble-like drips that harden on the surface

Coated Carbon

Fiber

Coated carbon ber emits noxious fumes. Additionally, carbon ber can be cut

albeit with some fraying but this is not the case when it is coated.