2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������3

1�1 Symbols used ������������������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Functions and features ����������������������������������������������������������������������������������������4

3�1 Applications ���������������������������������������������������������������������������������������������������4

4 Functionality���������������������������������������������������������������������������������������������������������5

4�1 Communication, parameter setting, evaluation ���������������������������������������������5

4�2 Operating modes �������������������������������������������������������������������������������������������5

4�3 Monitoring and diagnostic functions ��������������������������������������������������������������6

4�3�1 Drift / fault monitoring ��������������������������������������������������������������������������6

4�3�2 Sensor backup / redundancy switching ������������������������������������������������6

4�4 Analogue function ������������������������������������������������������������������������������������������7

4�4�1 Behaviour in case of exceeding or not reaching the limits of the meas-

uring range �����������������������������������������������������������������������������������������������������7

4�5 Operating mode: 2-wire temperature transmitter�������������������������������������������8

4�5�1 Availability groups in 2-wire operation [drEd]����������������������������������������8

4�5�2 Setting of the analogue value in case of diagnosis [FOU2]������������������8

4�6 Operating mode: 3-wire temperature transmitter with diagnostic switching

output��������������������������������������������������������������������������������������������������������������������9

4�6�1 Availability groups in 3-wire operation [drEd]����������������������������������������9

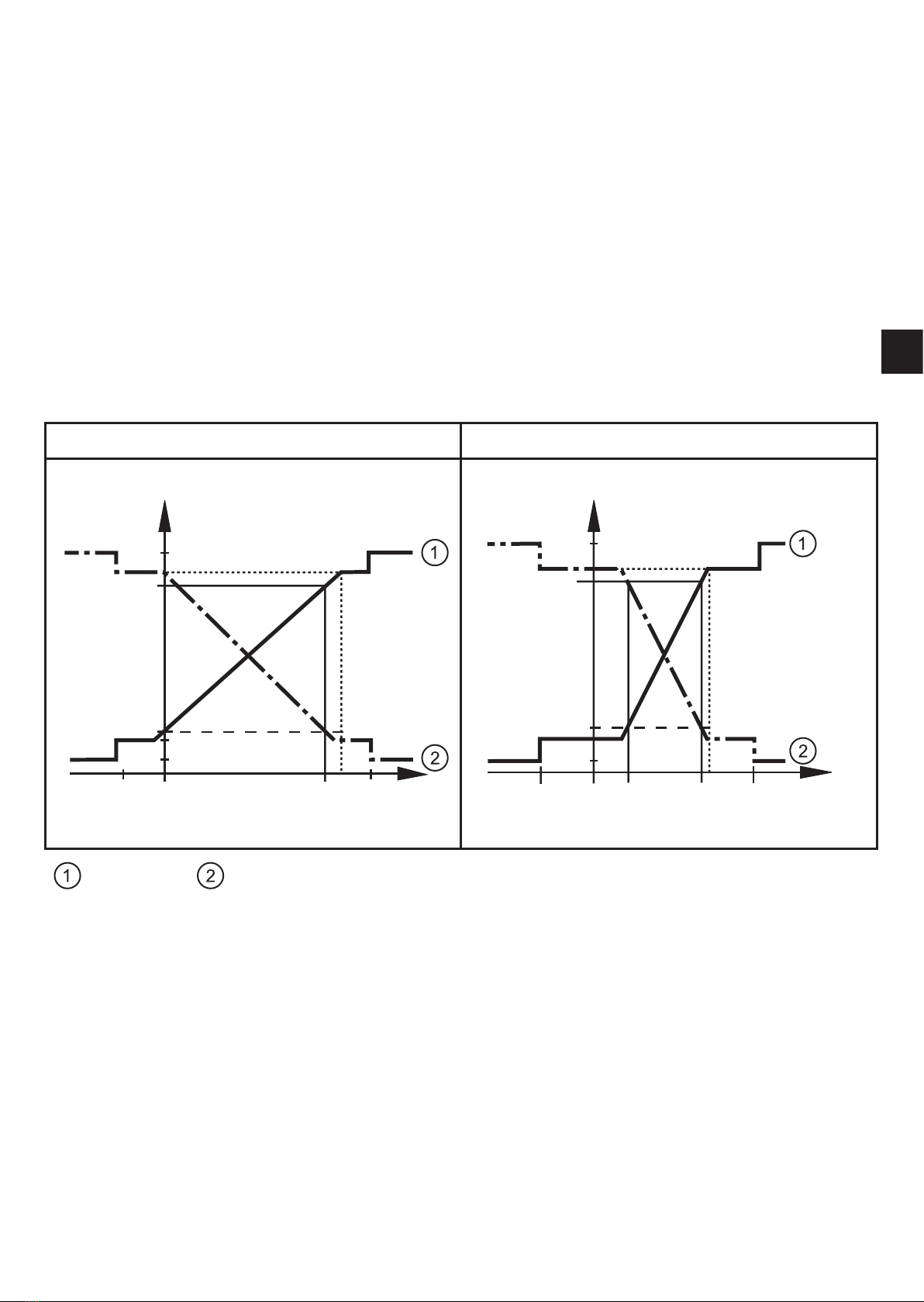

4�6�2 Switching characteristics output 1 in case of diagnosis [dOU1] ��������10

5 Installation ���������������������������������������������������������������������������������������������������������12

5�1 Installation of units with G1 process connection������������������������������������������12

5�2 Installation of units with G½ process connection�����������������������������������������14

6 Electrical connection������������������������������������������������������������������������������������������15

7 Parameter setting ����������������������������������������������������������������������������������������������16

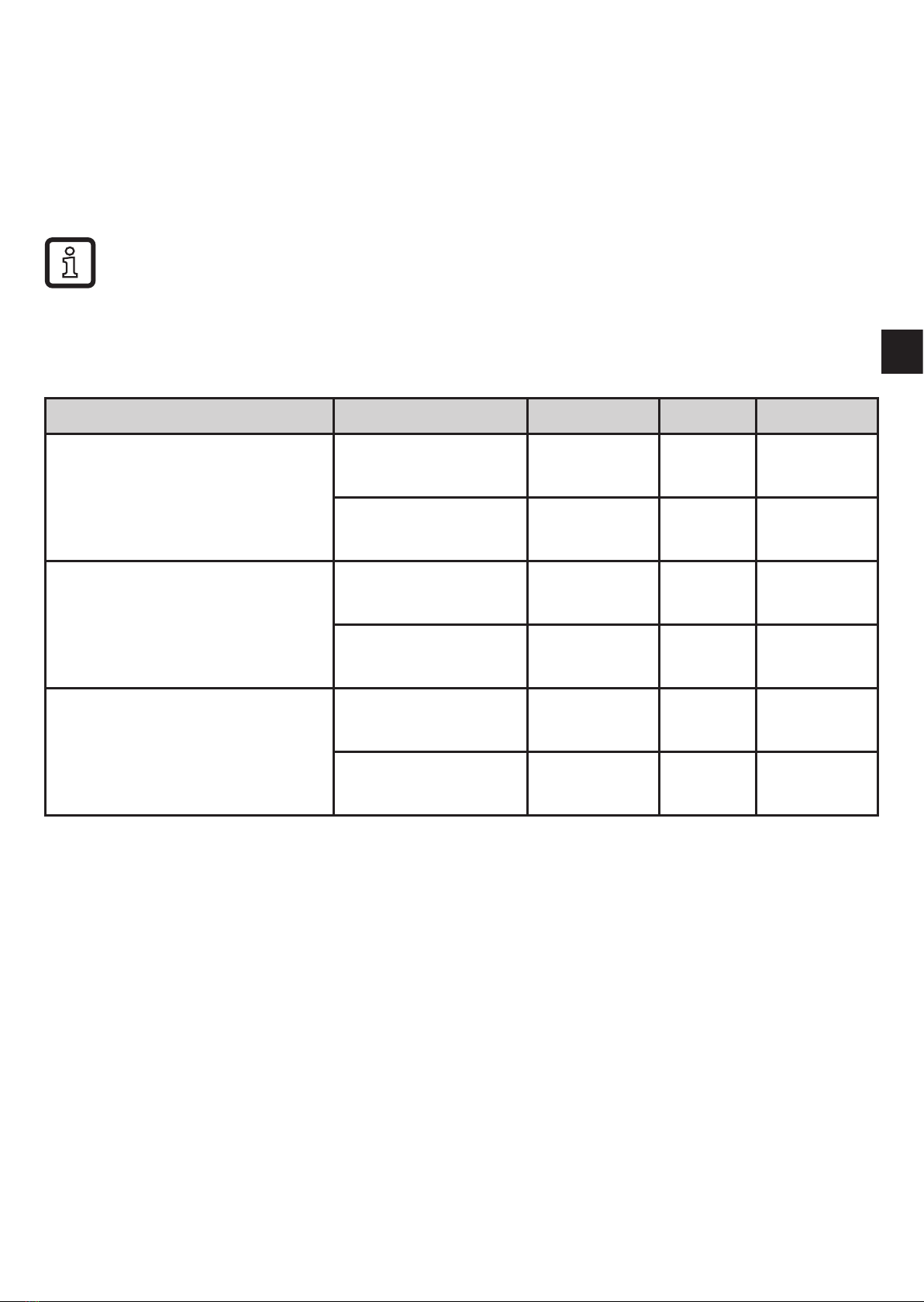

7�1 Adjustable parameters���������������������������������������������������������������������������������17

7�2 General parameter setting���������������������������������������������������������������������������17

7�2�1 Define the analogue signal �����������������������������������������������������������������17

7�2�2 Scaling of the analogue value ������������������������������������������������������������18

7�2�3 Min� / max� values for the system temperature�����������������������������������18

7�2�4 Define drift warning threshold�������������������������������������������������������������18

7�2�5 Define drift alarm threshold ����������������������������������������������������������������18