2

SAR460SAG

Contents

Contents ........................................................................ " 2

Ordering spare parts .................................................... " 2

Guarantee ...................................................................... " 2

Machine certification and identification marking ...... " 3

CHAPTER 1

Reference to accident-prevention regulations........... " 4

1.1 - Advice for the operator ..........................................." 4

1.2 - Location of shields against accidental contact with

the tool ...................................................................." 4

1.3 - Electrical equipment according to European

Standard "CENELEC EN 60 204-1"......................." 5

1.4 - Emergencies according to European Standard

"CENELEC EN 60 204-1"......................................." 5

CHAPTER 2

Recommendations and advice for use ....................... " 5

2.1 - Recommendations and advice for using the machine." 5

CHAPTER 3

Technical characteristics ............................................. " 6

3.1 - Table of cutting capacity and technical details

standard model......................................................." 6

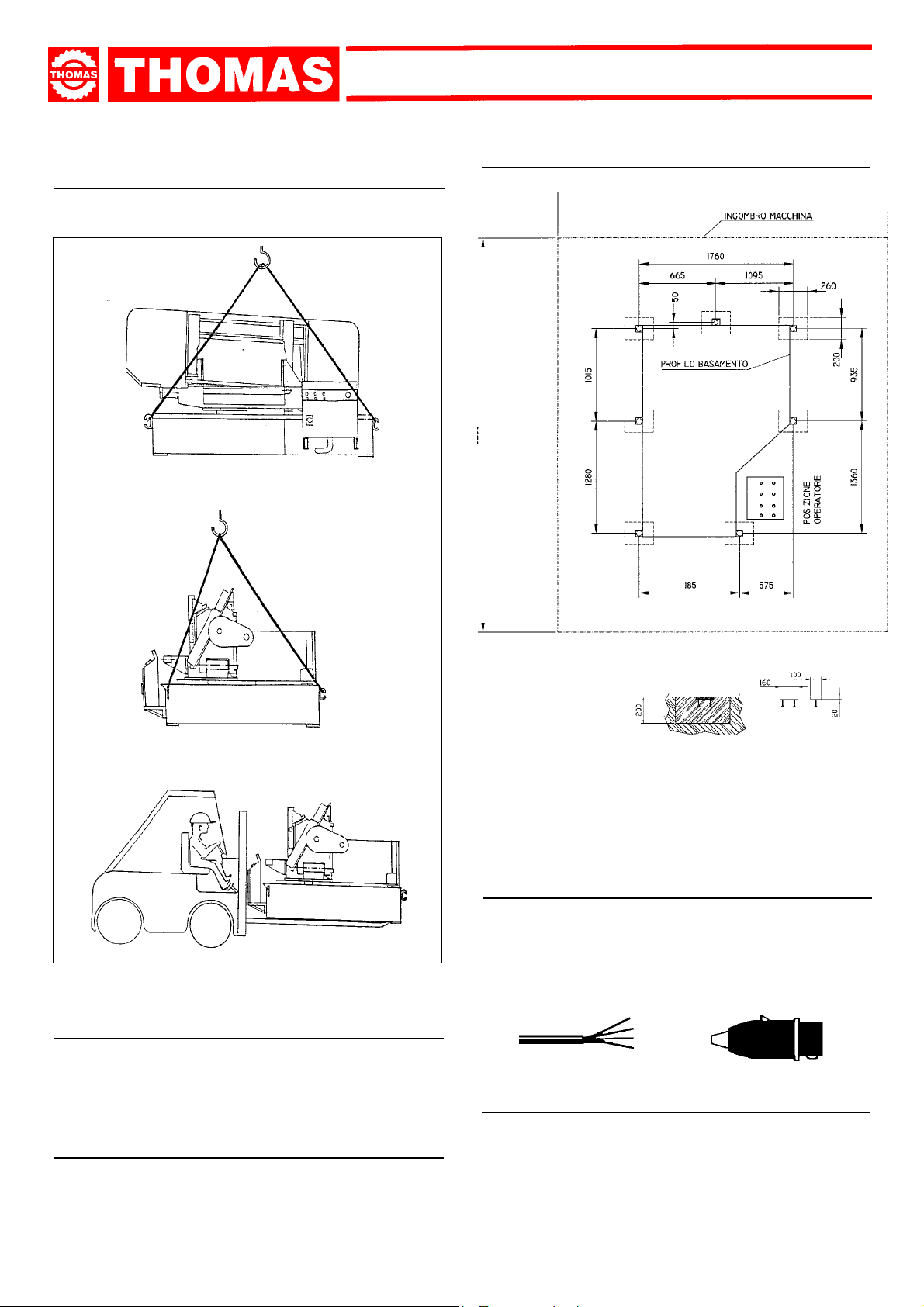

CHAPTER 4

Machine dimensions -Transport - Installation

Dismantling.................................................................... " 6

4.1 - Machine dimensions .............................................." 6

4.2 - Transport and handling of the machine ................." 7

4.3 - Minimum requirements for the premises

housing the machine.............................................. " 7

4.4 - Anchoring the machine .........................................." 7

4.5 - Instructions for electrical connection ......................" 7

4.6 - Disactivating the machine ......................................" 7

4.7 - Dismantling............................................................." 8

CHAPTER 5

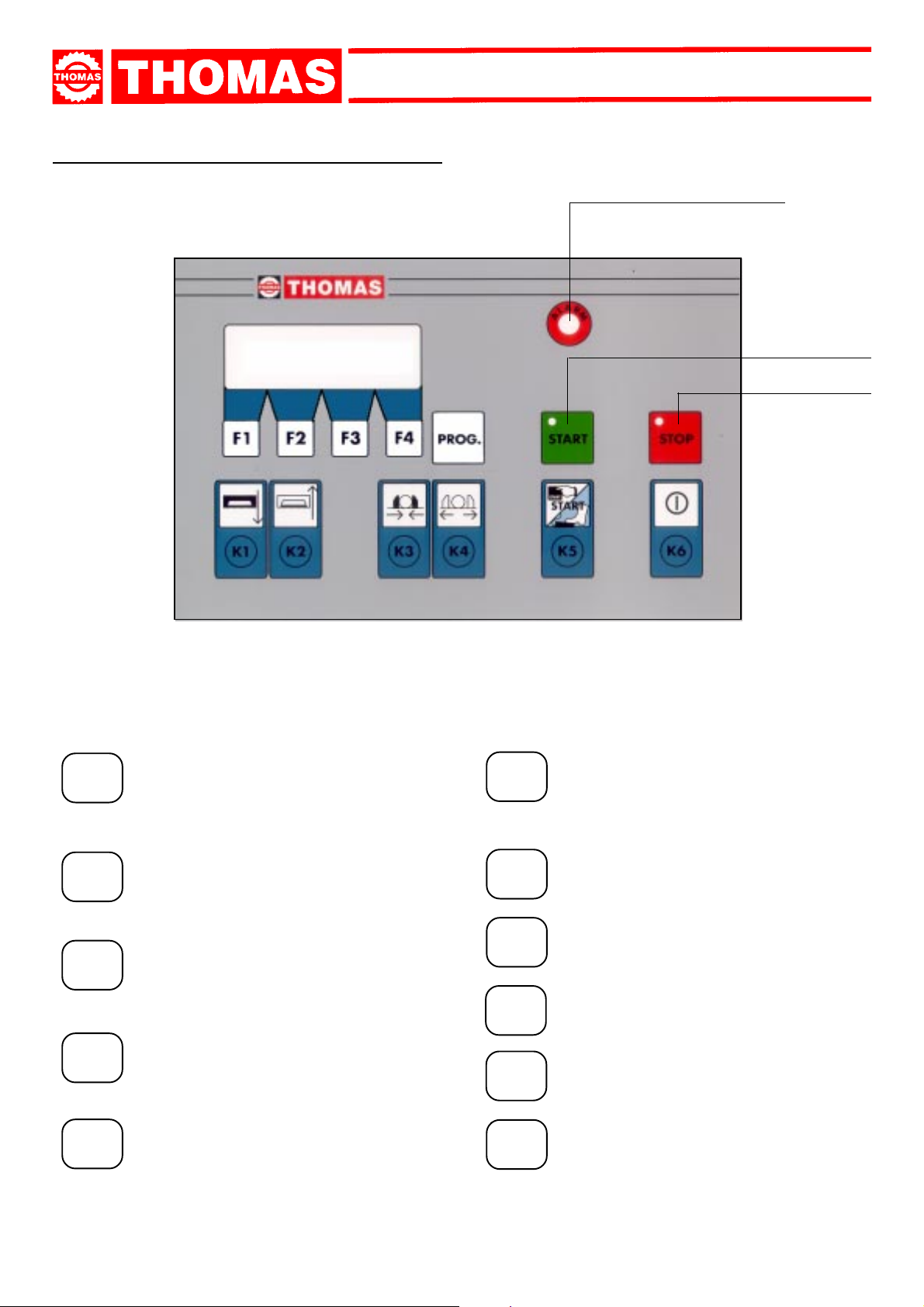

Machine functional parts .............................................. " 8

5.1 - Operating head or sawframe.................................." 8

5.2 - Vice........................................................................." 8

5.3 - Bed ........................................................................." 8

CHAPTER 6

Description of the operating cycle .............................. " 9

6.1 - Starting up .............................................................." 9

6.2 - Cutting speed INVERTER ......................................" 9

6.3 - Piece-counter ........................................................." 10

6.4 - Cutting cycle ..........................................................." 10

6.5 - Sawframe return stroke limit (option) ....................." 10

6.6 - Alarm ......................................................................" 12

Orderingspareparts

- Whenorderingsparepartsyoumuststate:

MACHINE MODEL

SERIAL NUMBER

PART REFERENCE NUMBER

WithoutthesereferencesWEWILLNOTSUPPLYthespares.Seepoint10.1-listofspareparts-

Guarantee

- TheCompanyguaranteesthatthemachine,describedinthismanual,hasbeendesignedtomeetsafetyrequirements.Asformachinefunctionality,inspectionhasbeen

successful.

- Themachineisguaranteedfor12months:theguaranteedoesnotcovertheelectricmotors,electriccomponents,pneumaticcomponentsoranydamageduetodropping

ortobadmachinemanagement,thefailuretoobservemaintenancestandardsorbadhandlingbytheoperator.

- Thebuyerhasonlytherighttoreplacementofthefaultyparts,whiletransportandpackingcostsareathisexpense.

- Theserialnumberonthemachineisaprimaryreferencefortheguarantee,forafter-salesassistanceandforidentifyingthemachineforanynecessity.

CHAPTER 7

Regulating the machine ................................................ " 12

7.1 - Blade tension assembly ........................................." 12

7.2 - Blade-guides .........................................................." 13

7.3 - Vice........................................................................." 14

7.4 - Cutting angle adjustment ......................................." 14

7.5 - Vice pressure regulation ........................................" 14

7.6 - Blade cleaning brush ............................................." 14

7.7 - Changing the blade................................................" 15

CHAPTER 8

Routine and special maintenance ............................... " 15

8.1 - Daily maintenance ................................................." 15

8.2 - Weekly maintenance.............................................." 15

8.3 - Monthly maintenance ............................................." 15

8.4 - Six-monthly maintenance......................................." 15

8.5 - Oils for lubricating coolant......................................" 15

8.6 - Oil disposal ............................................................." 15

8.7 - Special maintenance.............................................." 15

CHAPTER 9

Material classification and choice of tool.................... " 16

9.1 - Definition of materials............................................." 16

9.2 - Selecting blade......................................................." 16

9.3 - Teeth pitch .............................................................." 16

9.4 - Cutting and advance speed ..................................." 17

9.5 - Blade running-in....................................................." 17

9.6 - Blade structure ......................................................." 17

9.7 - Blade type..............................................................." 17

Shape and angle of tooth ......................................." 17

Set..........................................................................." 18

9.7.1 - Table of recommended cutting parameters .............. " 18

CHAPTER 10

Machine components ................................................... " 19

10.1- List of spare parts ................................................... " 19

CHAPTER 11

Three-phase electric diagram...................................... " 30

Hydraulic electric diagram........................................... " 35

CHAPTER 12

Troubleshooting ............................................................. " 37

12.1-Blade and cut diagnosis........................................." 37

CHAPTER 13

Noise tests..................................................................... " 41

Plates and labels ........................................................... " 42