OPERATING INSTRUCTIONS

TIPS FOR SUCCESSFUL SEALING

REPLACEMENT KIT INSTRUCTIONS

• Always keep the sealing platform clean. Particular care

should be taken to remove any residue from the teflon

tape

• Clean the sealing platform with a dry cloth. Do not use

water or solvents.

• Make sure to change the upper teflon tape (above the

element wire) when they become worn. If this is not

done, the element wire may short out and become

damaged.

• When replacing the heating element, always check the

condition of the bottom teflon tape. We recommend

changing the teflon tape EVERY TIME the element is

changed. If the teflon tape is not changed, you risk the

possibility of short circuit.

• Occasionally check the condition of the top pressure pad

(silicone rubber) for wear and/or burn. A poor rubber pad

will affect the quality of the seal.

Be sure to unplug the power cord before replacing any

parts.

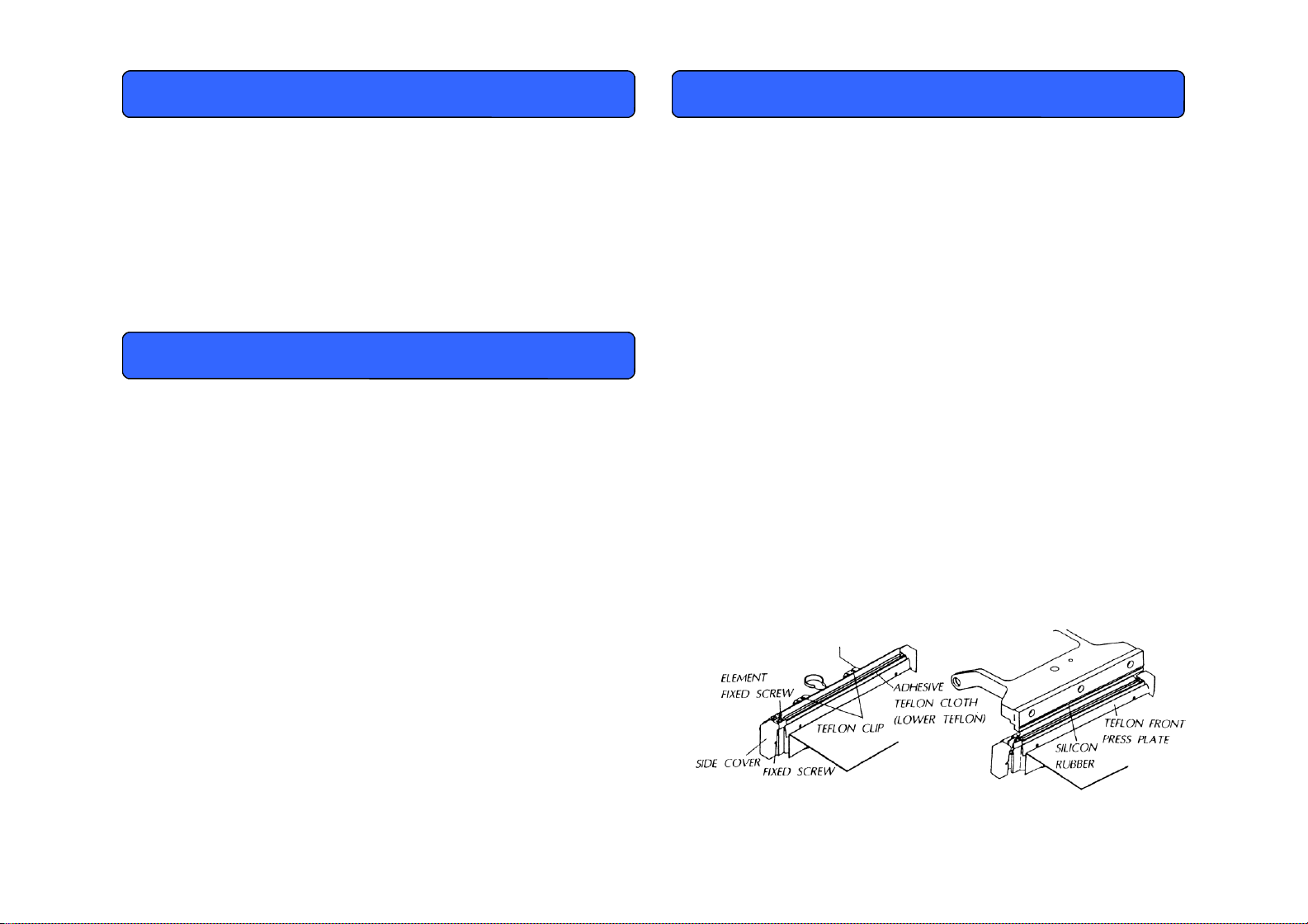

To replace Teflon roll

1. Remove pressing plate and loosen the teflon clips.

2. Pull out the new section of teflon tape and cut off used

portion. Reattach pressing plate.

3. Adjust teflon screw to tighten teflon roll. Tighten teflon

clips.

To replace heating element wire

1. Loosen teflon clips. Remove teflon front pres bar. Lift up

teflon.

2. Loosen side cover fixed screw and element fixed screw.

Remove broken element wire.

3. Put new element wire and tighten element fixed screw.

Also retighten side cover fixed screw. Do not bend or

crimp the wire.

4. Replace the teflon and teflon front press bar. Tighten

teflon with teflon screw. Tighten teflon clips.

1. Plug in unit.

2. Set power switch to “ON”.

3. Adjust the timer to the minimum setting necessary to seal

your poly bag.

4. Insert bag between the jaws of the sealer. Press down on

foot pedal. When the light turns off, sealing is completed.

Wait one to two seconds to allow the seal to cool, then

release the foot pedal.