tornos ROBOBAR MSF-522/6 Reference guide

300286 E – 02/01 Chap. /1

ROBOBAR MSF–522/6

ROBOBAR MSF–522/8

ROBOBAR MSF–832/6 300286 E

Printed in Switzerland

Copyright (c)1999–2001

SAFETY REGULATIONS

TORNOS SA

CH–2740 MOUTIER

http://www.tornos.ch

∆ATTENTION !

Before handling the machine, read

first these regulations.

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

300286 E – 02/01 Chap. /2

These instructions are based on the information available at the moment of

their publication. Although the very best has been done to make them as com-

prehensive and precise as possible the instructions do not purport either to

cover all details of the hardware and software or to anticipate every contin-

gency.

TORNOS S.A. neither give any guarantee nor accept any liability for the exac-

titude and the sufficiency of the information contained in this document.

The contents of the instructions remain the property of TORNOS S.A. who

reserve the right to modify, complete or correct them at any time.

Important Safety Indications

These instructions indicate a number of safety measure symbols which

appear also on the machine and are intended to protect the user, his/her

effects and the environment from injuries and damage as applicable.

Below, you will find the safety symbols, their headings and definitions. Please,

read these first before you continue.

∆Danger !

indicates a direct danger of death or serious injury.

∆Warning !

indicates an object or action which may cause death or serious

injury.

∆Attention !

indicates an object or action which may cause injury or serious

damage.

The original language of the instructions to be referred to is French. The haz-

ards of misinterpreting the instructions can be considerably reduced by

following the training courses organized and offered by TORNOS S.A.

The CE-marking indicates conformity with the European standards

of safety, health, environment and protection.

∆Caution !

indicates incorrect actions or such that may cause damage.

⊗Prohibition !

indicates an action or operation prohibited because of evident or

alleged hazards.

⇒Info :

gives information or comment related to safety.

Note that

⇒Note :

gives information unrelated to safety.

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

3300286 E – 02/01

TABLE OF CONTENTS

1. INTRODUCTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. GENERAL RULES FOR ALL USERS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INSTALLATION OF THE BARFEEDER 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. OPERATING INSTRUCTIONS AND NOTICES 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. ORDER – CLEANLINESS – MAINTENANCE 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. SAFETY MEASURES AND DEVICES 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 PROTECTIVE GUARDS FOR PERSONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Inspection of Protective Guards 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 GUARDS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 MAIN SWITCH 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 ELECTRIC CABINET OR LIVE ELEMENT 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

4300286 E – 02/01

6.5 EMERGENCY STOP AND CONTROL PANEL 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 Emergency stop 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. WHAT TO DO BEFORE ANY REPAIR OR SERVICE 7. . . . . . . . . . . . . . . . . . . . . . .

7.1 INTERVENTION IN THE CONVEYING ZONE 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. PRECAUTIONS IN OPERATING MODE 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 WITHDRAWAL OF THE OILPAN 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 BAR LOADING 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 REMNANT RECEPTACLE 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. FIRE PREVENTION 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. SCRAPPING 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

300286 E – 02/01 Chap. 1. /1

SAFETY REGULATIONS

1. INTRODUCTION

All barfeeder users such as

– owners,

– managers, operators, setters, programmers, foremen, mechanics,

– installators, maintenance and service staff or any other person in related

function

must read and strictly follow

–the safety regulations in this document

–the regulations regarding the machine on which the barfeeder is

installed

These regulations also pertain to options, components, installations, attachments and systems related to the barfeeder.

∆Warning ! FAILURE TO COMPLY

WITH THESE REGULATIONS MAY

CAUSE SERIOUS ACCIDENTS.

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

300286 E – 02/01 Chap. 3. /2

2. GENERAL RULES FOR ALL USERS

∆Warning !

In order to avoid accidents, observe the following :

– Read and follow the instructions delivered with the barfeeder and the

machine. The only persons authorized to work with the machine are those

who have mastered the operation and are familiar with the manufacturer’s

instructions.

– Operate the barfeeder in perfect condition only.

Remedy immediately any safety or functioning deficiency.

– Check the functioning and perfect state of safety devices.

– Report any anomaly to your superior or another person in charge.

Warn the other users of the barfeeder.

– Make sure each time you start the machine that nobody hidden from sight

is working on the machine

– Never put your hands or position other parts of your body within or next

to the range of action or movement of the mechanical elements.

– Keep the machine and its environment clean.

– Carry out the maintenance works according to the instructions entitled

INSTALLATION – OPERATION – MAINTENANCE.

⊗Prohibition !

Never deactivate safety devices ! They must be operational at all

times.

– A protective footwear is recommended (bar handling and fall).

– Wear protective gloves for the work on the machine or barfeeder, such as

manual bar loading, cleaning, maintenance, etc.

3. INSTALLATION OF THE BARFEEDER

∆Attention !

The installation of the barfeeder on a machine must be effected by a

qualified and trained person.

∆Warning !

In case of use of a laser centering device, the beam must never be

aimed at the eyes.

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

300286 E – 02/01 Chap. 6.1.1 /3

4. OPERATING INSTRUCTIONS AND NOTICES

– Operating instructions and notices, delivered by the manufacturer with the

machine or at a later date, must be brought to the knowledge of all persons

working on the machine or in whatever manner responsible for it.

– These persons must read the instructions and follow them strictly.

– The instructions must be regularly updated and kept in a clean place.

Anybody likely to work on the machine must have a ready access to the

instructions.

5. ORDER – CLEANLINESS – MAINTENANCE

∆Warning ! Order and cleanliness around the machine are important

measures for the safety. Slipping is dangerous and can entail injuries.

– Clean regularly the floor around the machine.

– Remove stains of grease, oil etc.

– Do not leave tools or other items to lie around on the shop floor or any

workplace.

– Antislip covering of the shop floor is recommended.

– Clean regularly the barfeeder inside.

– Maintain regularly all elements of the machine according to manufactur-

er’s instructions for accident-free operation

6. SAFETY MEASURES AND DEVICES

6.1 PROTECTIVE GUARDS FOR PERSONS

∆Danger ! The barfeeder must not work with doors and protective

guards open. Before each turning on or startup of the machine,

make sure that all doors, access panels and other sliding or

removable guards are properly closed.

⇒Info : Check regularly the safety devices !

A qualified and specially designated person must inspect periodically all

safety measures and devices against the manufacturer’s documenta-

tion.

6.1.1 Inspection of Protective Guards

– The guards must be complete and in good condition.

– The guards and their safety devices must be clean.

– The barfeeder and machine with a sliding guard open must not start.

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

300286 E – 02/01 Chap. 6.2 /4

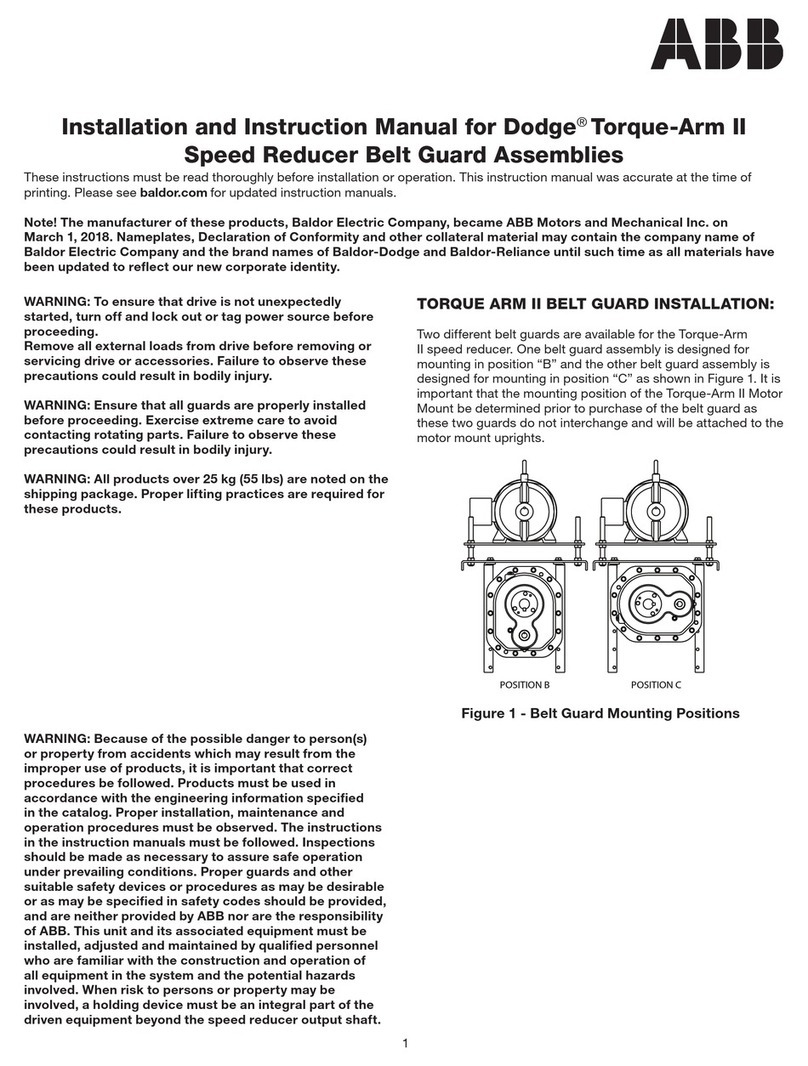

6.2 GUARDS

Description

– Fixed guards in steel sheet

– Upward opening guards with see–through parts before the conveying

zone

∆Attention !

The opening of the doors entails the immediate stop of the machine

and the barfeeder

Components

1010 Guard of stacker drive

1020 Rear guard

1030 Rear door

1040 Front door

1050 See–through guards for the conveying zone

1060 Electric cabinet

1070 Operator control panel

1080 Remnant receptacle

1090 Handle for the withdrawal of the oilpan and of the stock reel

1100 Zone of bar loading

1020

1010 1030 1050 1040

1060

1070

1090

1080 fig. 1

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

300286 E – 02/01 Chap. 6.4 /5

6.3 MAIN SWITCH

∆Danger !

Before repairs, maintenance works or any other activity on the barfe-

eder, turn Main Switch QS0 off and lock it with padlock(s) 1(see Fig. 2).

TURNING OFF AND LOCKING THE MAIN SWITCH

What to do ? How & Notes

Turn the button of the main switch

of the machine on 0:

(see fig. 2)

Position the arrow of the button on

0.

Fit Padlock(s) Cin the opening(s)

provided for this purpose: ... ... according to local regulations.

6.4 ELECTRIC CABINET OR LIVE ELEMENT

∆Danger !

Only a qualified person is authorized to intervene inside the electric

cabinets or on an electric element.

– Turn off and lock the main switch of the machine

– Follow the electric regulations in force with all interventions.

Should the electric regulations be disregarded, TORNOS declines any

liability for the damages.

QS0

C

fig. 2

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

300286 E – 02/01 Chap. 6.5.1 /6

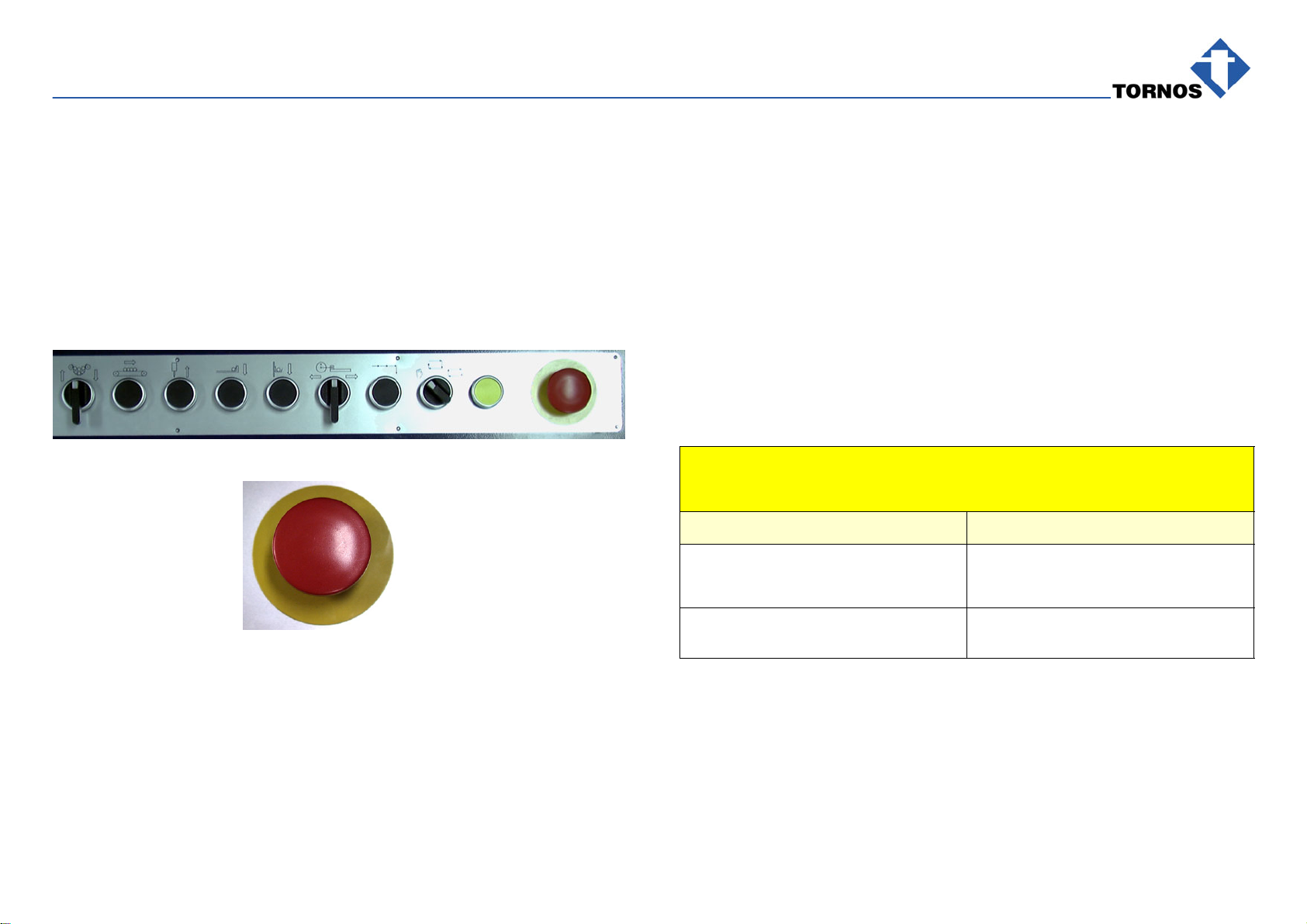

6.5 EMERGENCY STOP AND CONTROL PANEL

Components

SB1 Emergency stop pushbutton

1070 Operator control panel

SA9 SB6 SB9 SB8 SB7 SA8 SB3 SA2 SB5 SB1

fig. 3

SB1

6.5.1 Emergency stop

Emergency stop pushbutton SB1 is a mushroom-like pushbutton with a lock.

It is located on operator control panel according fig. 3.

⇒Information :

The emergency stop of the barfeeder is directly connected to the emer-

gency stop of the machine. They ensure both the same function.

Emergency stop operation

When you press the emergency stop, all elements of the machine and of the

barfeeder will instantaneously come to a halt except for the air conditioning

of the electric cabinet.

Once pressed, the emergency stop sets all controls out of operation.

Emergency stop inspection

⇒Information :

Check regularly the emergency stop operation.

Restarting after emergency stop

RESTARTING MACHINE AND BARFEEDER

To start with: after having activated the emergency stop pushbutton

What to do ? How & Notes

Remedy the cause of the stop. See also overleaf.

Unlock the activated pushbutton. Turn the pushbutton clockwise.

Restart the machine and the bar–

feeder Consult the instruction entitled

USER INTERFACE OPERATION

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

300286 E – 02/01 Chap. 8.3 /7

7. WHAT TO DO BEFORE ANY REPAIR OR SERVICE

∆Danger !

Stop and switch off the machine before any intervention on the

bar–feeder!

Do not turn off Main Switch QS0 if the maintenance works require elec-

tric power. Only qualified and trained staff is authorized to take action

on the machine with the main switch QS0 engaged ! (See Fig. 1 and 2,

main switch)

CONDITION BEFORE ANY INTERVENTION

What to do ? How & Notes

Stop the machine

Follow the usual procedure accord-

ing to instruction “USER INTER-

FACE OPERATION” of the

machine

CUT OFF ALL POWER

SOURCES when the machine is completely

stopped

Turn off Main Switch QS0 of the

machine and lock it with Padlock(s)

C.

On the side of the machine, see

fig. 2

7.1 INTERVENTION IN THE CONVEYING ZONE

∆Warning !

When intervening in the conveying zone, after a breakdown and/or just

after the stop of the barfeeder (and of the machine) take care to the

possible heating of certain elements.

8. PRECAUTIONS IN OPERATING MODE

8.1 WITHDRAWAL OF THE OILPAN

In order to effect certain operations of maintenance and starting on the

spindles of the machine, it is necessary to be able to withdraw the oilpan of

the barfeeder

What to do ? How & Notes

Stop the machine

Follow the usual procedure accord-

ing to instruction “USER INTER-

FACE OPERATION” of the

machine

CUT OFF ALL POWER

SOURCES when the machine is completely

stopped

Turn off Main Switch QS0 of the

machine and lock it with Padlock(s)

C.

On the side of the machine, see

fig. 2

Withdraw the oilpan by hand ∆Warning ! Wear gloves and

make sure that the floor is not

slippery.

8.2 BAR LOADING

∆Warning !

The loading of the bars into the barfeeder requires the wearing of

gloves and if necessary the use of an adequate lifting means.

8.3 REMNANT RECEPTACLE

∆Warning ! The remnant receptacle must be emptied regularly in order

to avoid that remnants accumulate and fall on the floor.

Wear gloves and safety shoes.

SAFETY REGULATIONS – ROBOBAR MSF–522/6 & ROBOBAR MSF–832/6

300286 E – 02/01 Chap. 10. /8

9. FIRE PREVENTION

– Keep any form of fire at least 1 meter from the machine and the barfeeder

(including sparks and cigarettes).

– Carry out daily maintenance according to instructions.

– The machine and the barfeeder must work within the scope for which they

have been conceived.

– It is advisable to use a room of the workshop to equip it with a fire alarm

system.

RISKS DUE TO INFLAMMABLE OR EXPLOSIVE MATERIAL

∆Warning !

If the machine works with pyrophoric elements, it must be fitted with a

fire monitoring device and a fire control equipment.

When in doubt, please contact TORNOS.

Daily fire prevention

∆Caution !

Carry out the following daily fire prevention measures :

– Pay attention to excessive noise and vibrations.

– Make sure that coolant is distributed correctly and sufficiently and that dis-

tribution openings are not obstructed.

– Make sure that the guards are correctly closed and that no oil leaks out.

Recommandations in case of smoke or mist emission

∆Caution !

Respond rapidly and stop machine and barfeeder if you state any of

the following :

– Vapor and mist spread in your workshop.

– Cutting action or an electric element produces sparks.

10. SCRAPPING

The scrapping of the barfeeder must comply with environmental standards in

force in the respective country.

Particular heed must be paid to:

– lubrication oils

– batteries

– electronic elements

which will be recycled.

This manual suits for next models

2

Table of contents

Other tornos Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Siemens

Siemens VPM 120 operating instructions

Regulus

Regulus PS 400 K+ Installation and operation manual

ABB

ABB Dodge Torque-Arm II Installation and instruction manual

Horizon Fitness

Horizon Fitness SQ3TS Operational manual

SCHUNK

SCHUNK iTENDO 2 Original operating instructions

Enerpac

Enerpac V17 Operation and maintenance manual