IGM BR300 User manual

Distributor:

IGM nástroje a stroje s.r.o.

Ke Kopanině 560, 252 67, Tuchoměřice

Czech Republic, EU

Phone: +420 220 950 910

E-mail: [email protected]

Website: www.igmtools.com

Portable edgebander for ABS

Operationg instructions

2022-07-12

142-BR300 IGM Portable Edgebander for ABS Manual EN v2.5.00 A4ob

142-BR300

www.igmtools.info

PDF ONLINE

-2-www.igmtools.com

Operating instructions EN

Please read this manual thoroughly and follow the safety instructions in it! Technical changes

and printing errors reserved!

Dear customer,

This manual contains important instructions and information for the installation and proper use of the BR300

edgebander.

This manual is part of the machine and therefore it should not be kept elsewhere than in the vicinity of the machine

so that you can be consulted at any time by you or other persons operating the machine.

Please read and follow the safety instructions!

Carefully read these instructions before using the machine. Operation of the machine will be simpler

and you will also lower the risk of injury while eliminating the probability of incorrect operation and

possible damage to the machine.

Because of our policy of constant improvement, the design, construction or pictures may differ slightly.

1. DECLARATION OF CONFORMITY

The undersigned: IGM nástroje a stroje s.r.o.

Address: Ke Kopanině 560

Tuchoměřice, Praha-západ, PSČ 252 67

Czech Republic, EU

Phone no: +420 220 950 910

Certifies the

Product: Manual Edgebander for ABS

Type: BR300

Manufacturer: CO-MATIC Machinery Co.,

Ltd.,No. 473-16,

San Feng Road, Houli District, Taichung

City,Taiwan, R.O.C. 42156

We declare under our sole responsibility that the

productdescribed in this manual is in conformity

with the followingstandards: EN ISO 12100, EN ISO

13857, EN 349, EN 953,EN 60204-1, EN ISO 11202, EN

55014-1, EN 55014-2 withthe provisions of Directives

2006/42 / EC, 2004/108 / EC,2006/95 / EC, 2002/95 /

EC

Signed: Ivo Mlej

Managing Director

TABLE OF CONTENTS

PAGE

1. DECLARATION OF CONFORMITY 2

2. WARRANTY SERVICE 3

3. SAFETY INSTRUCTIONS 3

3.1 Advice 3

3.2 General safety instructions 3

3.3 Risks 4

3.4 Important notice 4

4. SPECIFICATIONS OF THE MACHINE 4

4.1 Machine description 4

4.2 Technical data 5

4.3 Contents 5

5.

TRANSPORT, UNPACKING AND ASSEMBLY

5

5.1 Transport and unpacking 5

5.2 Assembly 5

5.2.1 Mounting the corner guide 5

6. SETUP AND ADJUSTMENT 5

6.1 Preparing for work 5

6.1.1

How to measure and set up the width of the tape

5

6.1.2

Control and gauge set up on the supporting table

6

6.1.3 Adjusting the amount of glue 6

6.1.4 Adjusting tape thickness 6

6.1.5 Setting length of tape 6

6.1.6

Fastening the workpiece before edgebanding

7

6.1.7 Refilling glue 7

6.2 Before turning on 7

6.3 Functions of control panel 7

7. OPERATING THE MACHINE 8

7.1 Edgebanding 8

7.2 Stationary use 8

8. MAINTENANCE AND CONTROL 8

8.1 Maintenance after work 8

8.2 Preventive check 8

9. MALFUNCTION ASSISTANCE 9

9.1 Problem solving 9

10. ENVIRONMENTAL PROTECTION 9

11. ACCESSORIES spare parts 9

-3-www.igmtools.com

Operating instructions EN

2. WARRANTY SERVICE

The warranty is subject to Terms and Conditions and

Warranty Conditions of IGM nástroje a stroje s.r.o.,

the current version of which are available at www.

igmtools.com.

3. SAFETY INSTRUCTIONS

3.1 Notice

This machine is designed for work with wood and

wooden materials.

Proper use also includes compliance with the regular

operational and maintenance work described in this

manual.

The machine can be operated only by persons familiar

with the operation procedures, maintenance and are

aware of potential risks.

Comply with the minimum age limits specified by

law. The machine may only be used when in perfect

technical condition.

All safety and protective components must be

installed when operating the machine.

Besides these instructions, also adhere to the safety

instructions of your country and to the generally

recognized technical practices concerning the

operation of woodworking machinery.

The manufacturer or the supplier is not responsible

for any damage resulting from improper use.

Every user is responsible for their own actions.

Warranty cannot be claimed if any of the following

principles are broken:

- Unsuitable work environment: high humidity,

contamination.

- Damage caused by an improper assembly and/or

improper storage.

- Use of damaged machinery.

- Failure to follow the operating instructions:

transport, storage, assembly, putting into operation,

cleaning and maintenance of the machine.

- Use of unauthorized spare parts.

- Unauthorized assembly of the machine.

- Do not use worn out spare parts.

3.2 General safety instructions

The machine can pose danger when improperly

operated.

Thoroughly read the operating instructions and make

sure that you understand everything before doing

anything with the machine.

Keep this user manual clean and protect it from dirt

and moisture; in case of re-selling, pass the manual

onto the new owner.

Any alterations or changes to the machine are

prohibited. Daily try out if the machine runs smoothly

and check the function of protective covers before

operating the machine. Remove any malfunctions or

deficiencies found on the machine as well as

damaged protective cover. The machine may only be

used when in perfect technical condition.

Use a hairnet or a hat to protect long hair. Wear tight-

fitting clothes, remove all bracelets, rings, necklaces

or ties. Wear work shoes only. In any case, do not wear

casual shoes or sandals during work. Abide by the

regulations for personal protection.

Always wear safety eyewear. Always use hearing

protection.

Abide by the„safety“ instructions in this manual.

Make sure you have enough space for your work.

Do not perform any operations that

are not suitable for this machine.

Make sure you have good lighting.

Make sure the power cord is not in your way when

working. Keep your work area clean. Never touch the

machine when it‘s running.

Make sure you are concentrating and paying

attention. Use caution. Never work under the

influence of drugs and/or alcohol.

Make sure there are no children around when

working with the machine. Never leave the machine

unattended. Always switch the machine off when

leaving the workspace.

Do not place anything on the machine.

The repair of electrical components can be only

carried out by a professional. Damaged electric cord

must be replaced immediately.

Before banding, remove nails and any other foreign

objects that could be in the way of your work.

The switch must be in the„OFF“ position before you

connect the machine to the power supply.

Do not use the machine if the ON-OFF switch does

not work correctly.

The use of any other accessories than recommended

by this manual be hazardous.

Make sure the cable is long enough and there is no

excessive tension or bend over the table.

Keep away from flammable or explosive materials.

-4-www.igmtools.com

Operating instructions EN

3.3 Risks

Risk exists even when using the machine according to

the manual.

WATCH OUT! Heated glue may reach the

temperatures of 200°C. Do not touch any hot

parts.

The glue may contain harmful chemicals. Therefore,

ensure sufficient ventilation of your workplace.

3.4 Important notice

Make sure the machine has been off for at least 60

minutes before storing it in the portable case. That

way, the glue in the container will cool down to 60°C.

Use a piece of cloth to wipe any adhesive residues on

the machine.

The Edgebander is designed for interior work. Do NOT

use the machine outdoors!

If you want to prevent debris falling into the glue pot.

Put on the lid. If debris is already in the pot, remove

the glue, turn on the machine for approximately 3

minutes, the glue should come out easily now. Re-fill

with glue again.

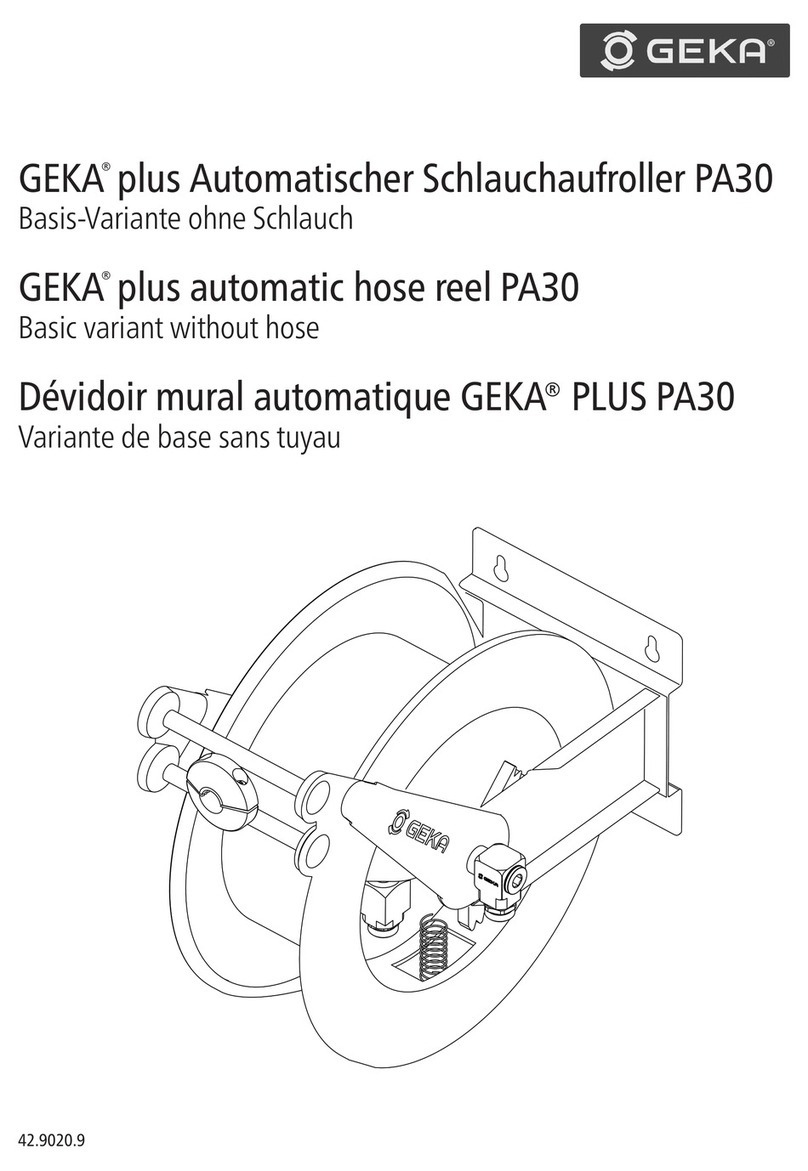

1Infeed tape guide

2 Temperature control

3

Set upof pressure of tape on application roller the

4 Main switch

5 Feed switch

6 Fuse

7 Outfeed roller

8 Support table locking lever

9Support table with a handle

10 Glue pot cover

11 Regulation of amount of glue

12 Infeed roller pressure plate

4. SPECIFICATIONS OF THE MACHINE

4.1 Machine description

4

5

3

1

2

6

8

12

11

10

9

7

-5-www.igmtools.com

Operating instructions EN

4.2 Technical data

Input power 855W / 230V

Tape thickness 0,4 - 3mm

Tape thickness 10 - 65mm

Temperature range 120° - 200°C

Feed speed 4m/min

Shipping size 33,5x29,8x36,7cm

Weight 8,7kg

Shipping weight 11kg

Warm-up time(120 °C) 4min

Fuse F 6A (230V)

Cable length 5m

Glue pot capacity 400ml

4.3 ContentsIGM

BR300 Portable

Edgebander for ABS

IGM Worktable Light

transport case

Sample tape from calibration procedures

5. TRANSPORT, UNPACKING AND ASSEMBLY

5.1 Transport and unpacking

The machine is not assembled due to transport.

Assemble before operating. Remove the edgebander

from the packaging and place on a flat surface. Check

for any apparent transport damages, these could

damage the machine or your health.

5.2 Assembly

5.2.1 Mounting the corner guide

- Equip the corner guide only when banding inner

corners or a radius smaller than 50 mm. It would be

getting in your way during other operations.

- Place the corner guide on your edgebander

according to pic.5 and tighten the screw.

Obr. 8

pic.1

6. SETUP AND ADJUSTMENT

6.1 Preparing for work

6.1.1 How to measure and set up tape width

- Loosen the screw on the tape stop (pic.2)

- Place the tape under the stop and measure the

height (pic.3), tighten the screw.

- Measure the thickness of the banded piece and

set up the support table accordingly, make sure to

tighten the locking lever properly (pic.4)

Fig1

pic. 2

Fig3

333

pic. 4

Fig2

pic. 3

-6-www.igmtools.com

Operating instructions EN

6.1.2 Control and gauge set up of the support table

The pre-set support table is perpendicular to the pressure

plate. Place the support table on a mitre gauge (pic.2,

gauge not supplied) to check proper alignment. If the

table is not perpendicular, loosen the screw (1). Align

the table according to the mitre gauge, tighten screw

(1). Release screw (3) and set up the gauge (4) to„0“, then

tighten again.

6.1.3 Adjusting the amount of applied glue The

amount of glue is pre-set and should suit the

majority of operations.

- If the amount of glue is not convenient. Prepare a test

tape, warp up your machine and load the tape. Use the

amount of glue adjustment knob to set the demanded

quantity. Turning left adds and turning right decreases

the amount of applied glue (pic.6) The scale displays the

amount of glue.

- Caution: Do not turn the adjustment knob until the glue

has reached operating temperature.

Too much glue overows on the visible side of the tape. Not

enough glue is not evenly applied along the whole width of

the tape.

pic. 5a

pic. 5b

2

pic. 5c

Obr. 5

pic. 6

6.1.4 Thickness of tape

Set up thickness only when you have a softer or thinner

tape than 1 mm. Otherwise, the pressure automatically

adjusts to the tape. The thickness can be simply set by a

turn of the knob (pic.7).

pic. 7

6.1.5 Setting up tape length

- Measure the length of the banded edge and leave a

bit more of the tape for final trimming.

- Apply enough pressure when trimming the edge,

this will improve the finish.

-7-www.igmtools.com

Operating instructions EN

6.1.6 Proper fastening before edgebanding

Fasten the workpiece to a worktop using clamps.

Make sure the edge of the workpiece you will

edgeband extends beyond the edge of your worktop.

It may be more comfortable to use a vacuum suction

cup. You can order one from IGM as an optional

accessory. Use of the vacuum cup (pic.8)

6.1.7 Refilling the adhesive

- Regularly check the amount of glue in the glue pot.

We recommend refilling the glue when there is only

half of the pot left.

- Loosen the screw on the cover so that it can be

lifted. DO NOT TOUCH THE COVER - it‘s hot.

pic. 8

6.3 Functions of control panel

1

2

pic.10

2

pic. 10a

Power feed switch: The feed (4m/

min) will start after turning on.

Temperature control. Turning

left turns of the heating (I/o ),

turning right sets up the desired

temperature.

Heating indicator: If the light is on,

the glue is being heated.

Operating indicator light: lights

up when the temperature is over

120 °C (250 F), you can speed up

the heating by turning on the tape

feeder.

Safe storage light:

When you turn off the heating, this

light will light up. And will go out

when the temperature in the glue pot

goes below 60 °C (140 F). Now you can

safely store your machine in

1

2

6.2 Before turning on

- Keep the machine clean throughout the whole

operation.

- Store the workpiece and the tape at room temperature.

- Cold tape or workpiece can affect the quality of

adhesion.

- Always maintain enough pressure on the tape when

working. Insufficient pressure may result in a weak

connection between the tape and the workpiece.

- Store your glue in a cool and dry place.

- A pot full of glue is enough for approximately

(depending on the type of glue) 50 m of tape (width 25

mm) or 25 m of tape (width 65 mm).

- Make sure the glue has completely melted before

working.

- Use glue supplied by IGM which has an operating

temperature of 120-150 °C.

pic. 9

-8-www.igmtools.com

Operating instructions EN

7. OPERATING THE MACHINE

7.1 Edgebanding

Check for debris or dust in the glue pot, turn on

the main switch and trigger the heating next to the

display. On/off switch

The button (1) on the handle (2) will light up when

the temperature reaches 120°C, press the button

(1) to accelerate the melting process. Make sure

the glue is properly stirred up before working. Turn

the feed off and place the tape on the infeed roller.

Place the support table on the workpiece and hold

the machine firmly with both hands (2), (3). Place

the pressure roller approximately 5 cm from the

workpiece. Turn the feed on (1), and wait for the tape

to reach the pressure roller. Press the tape to the

workpiece using the pressure roller. Then allow the

machine to run at its feed speed and only check the

proper feed of the tape.

7.2 Stationary use

It‘s better to use the machine with a worktable when

banding smaller pieces, the worktable is available at

IGMtools.com as an optional accessory. That way, you

can band edges like on a stationary edgebander.

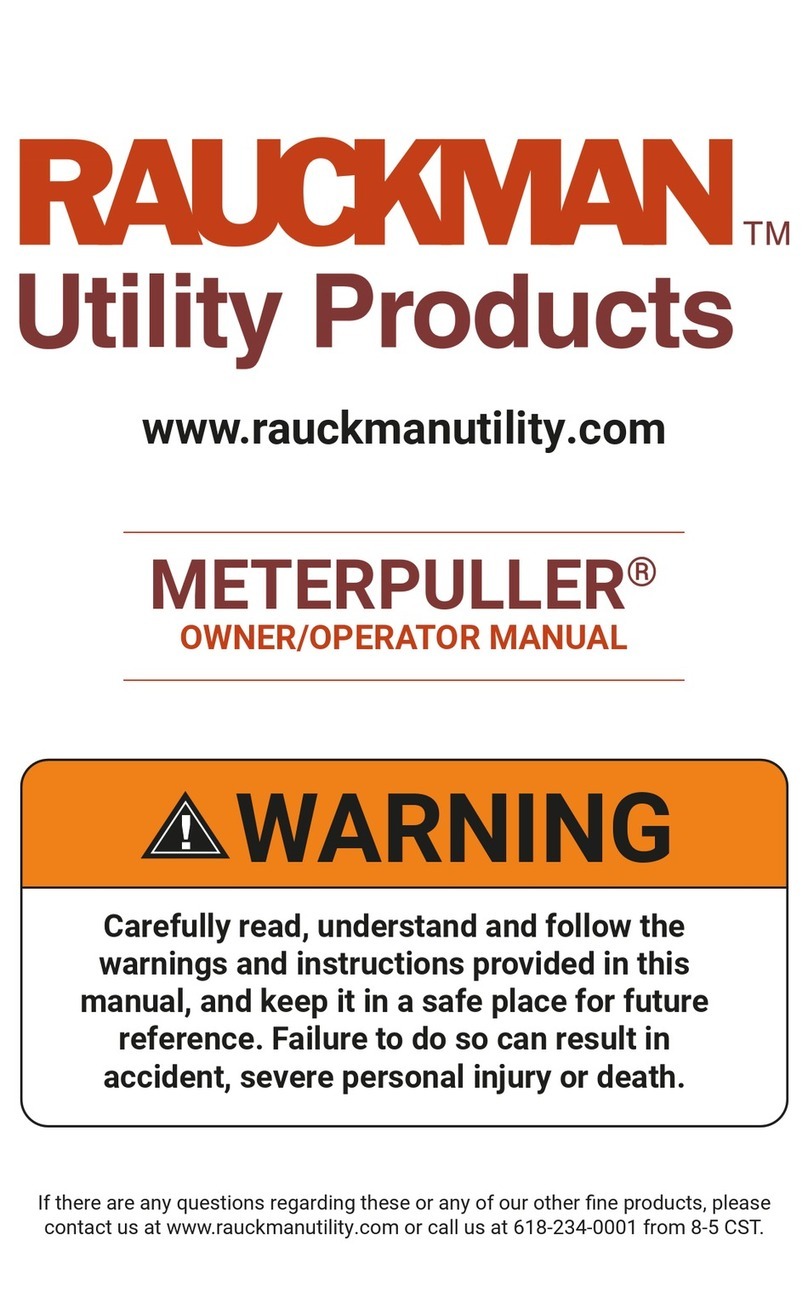

8. MAINTENANCE AND CONTROL

8.1 Maintenance after work

Clean the machine properly after every operation

and get rid of any glue on the edgebander with a

proper tool or a dissolvent to prevent glue build-up.

We recommend having the machine checked after

500 hours of work or every 6 months of use. During

regular weekly maintenance, you should lubricate

the timing chain and the pressure plate (pic.13) with

silicone oil. Loosen screws, see (pic.12), and remove

the plastic cover. Now you can lubricate the chain and

the plate. After maintenance, place the cover back

and tighten the screws.

Obr. 7

3

4

1

2

pic. 11

every two months or every 50 hours of operation

of the edgebander. Remove the rest of the glue and

refill with a new one

The machine has to be turned off and

disconnected from the power source during

maintenance.

8.2 Preventive check

pic. 12

pic. 13

Regularly check the glue status in the glue pot. Refill

the glue when the glue pot is half empty. The heater

should be always submerged in the glue.

-9-www.igmtools.com

Operating instructions EN

9. MALFUNCTION ASSISTANCE

9.1 Solution to problems

Malfunction Cause Repair

Cannot turn on

the machine

Damaged fuse Replace the fuse (use a fuse with the same value)

The tape is not

completely covered

with the glue

The glue is not properly melted Open the glue pot and check if the glue has

dissolved properly.

The amount of glue in relation

to the width of the tape is

improperly set

Increase the amount of glue with the control

knob. (see chapter 6.1.3)

Deformed tape Use a tape of better quality.

The glue was applied poorly to

the banding roller

Turn on the feed and let the glue circle between

the applicator and the glue pot

The tape doesn‘t

hold on the

workpiece

The pressure roller isn‘t

perpendicular to the edge of the

workpiece

Adjust the angle of the support table so that it‘s

perpendicular to the edge (see chapter 6.1.2)

Overheating can degrade the

properties of the glue Replace the old glue in the pot with the new one

The glue hasn‘t been heated to

the right temperature

Check the label on the glue and set the

temperature accordingly

The tape has twisted

while banding

The feed speed is slower than

the feed of the tape Increase pressure on the workpiece

The tape is slipping

on the infeed roller

Dust or debris on the infeed

roller Clean the infeed roller

The feed won‘t turn

on

The glue isn‘t melted enough,

the operating temperature

hasn‘t been reached so far

The motor can be turned on after reaching 12 °C

to ensure proper temperature for work.

Overheating Malfunctioning temperature

control

Let a qualified electrician replace the

temperature detector

10. PROTECTION OF THE ENVIRONMENT

Protect the environment.

Your machine contains materials that can be recycled.

Please, let specialized institutions handle the machine.

11. ACCESSORIES SPARE PARTS

IGM Tape Holder for Edgebander DR500-BR300

142-BC25

IGM PD80 Edgeband Trimmer

142-PD80

IGM End Trimmer for Shaped and Straight Panels

M951-V

IGM Fachmann Edge Banding Hand Trimmer

M950-00001

IGM Worktable for Edgebander and Trimmer for

DR500-BR300 142-ST95A

IGM Straightline Edgebanding and Trimming Kit for

Worktable ST95A 142-ST97

Glue Technomelt KS224 for IGM Manual Edgebanders

- 5kg pack M967-5

Glue Technomelt KS224 for IGM Manual Edgebanders

- 25kg pack M967-25

IGM Vacuum Clamp One-sided, set M964

IGM Lever Valve for Vacuum Clamp M964 M966-01

IGM Plastic T-splitter for Vacuum Clamp M964

M966-02

IGM nástroje a stroje s.r.o., Ke kopanině 560,

Tuchoměřice, 252 67, Czech Republic, E.U.

+420 220 950 910,www.igmtools.com

© 2022 IGM nástroje a stroje s.r.o.

This manual suits for next models

1

Table of contents

Other IGM Tools manuals

Popular Tools manuals by other brands

Sioux Tools

Sioux Tools SC41011A instructions

Rauckman Utility Products

Rauckman Utility Products METERPULLER M-001 Owner's/operator's manual

D'Amore engine'ring

D'Amore engine'ring SMD IM-SG owner's manual

TRI tool

TRI tool 604SB manual

SUHNER

SUHNER WB 4 Technical document

Lux Tools

Lux Tools A-FMR-20 Set Original instructions