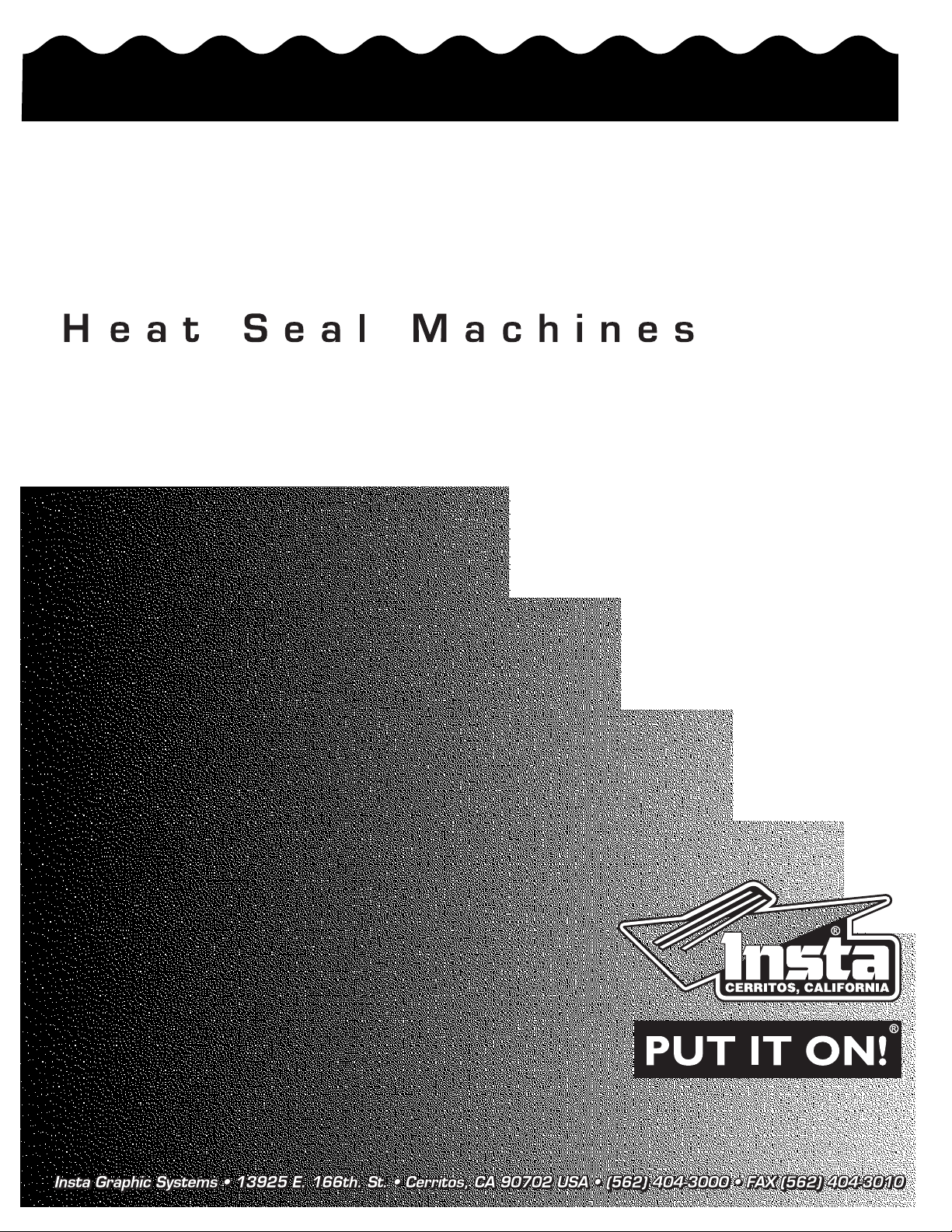

IGS 218A User manual

MODEL 218A/228A

MNL90009

08/31/05Rev. F

Operation and Maintenance Manual

THIS MACHINE IS DESIGNED TO BE OPERATED BY ONE OPERATOR ONLY

- 3 -

Congratulations!

Your selection of the Insta Graphic Systems (IGS)

heat seal machine is a sound business decision.

IGS equipment is the result of the highest quality

engineering and time-tested design. Your new

machine combined with IGS's reputation of

innovation in the heat-sealing field, insures the

continuing capability of delivering the best-

decorated substrates possible.

This manual describes installation, operation, and

maintenance procedures for your new 200 series

machine, as well as easy to use instructions for on-

the- spot maintenance.

Your 200 series machine will have a long, trouble

free life. Read this manual. Keep it with your

machine; it's your key to proper operation and

lasting service.

Installation

DOMESTIC

Use a separate 15 amp AC circuit.

Only industrial extension cords with

proper wire size should be used: size

16/3 wire for distances up to 25 feet,

and size 14/3 for distances up to 50

feet.

INTERNATIONAL

Use a designated 16 amp AC cir-

cuit. Only industrial extension

cords with proper wire size (2.5 sq.

mm) shall be used.

Limited Machine Warranty

Insta Graphic Systems (IGS) warrants this heat seal

machine, when operated under normal conditions,

to be free from manufacturing defects in material

and workmanship for a period of one year on parts

(lifetime on the heating element) and 90 days on

labor from the invoice date.

This warranty will be effective only when IGS

authorizes the original purchaser to return the

product to the factory in Cerritos, California,

freight prepaid, and only when the product upon

examination has proven to be defective.

This warranty does not apply to any machine that

has been subjected to misuse, negligence or

accident.

IGS shall not be liable for the injury, loss or dam-

age, direct or consequential, arising out of the use

or the inability to use the product.

No claim of any kind shall be greater in amount

than the sale price of the product or part to which

claim is made.

This is the sole warranty given by the company, it is in

lieu of any other warranties, expressed or implied, in

law or in fact, including the warranties of merchant-

ability and fitness for a particular use, and is accepted

as such by the purchaser in taking delivery of this

product.

Specifications

Voltage 115/120 Volts AC 50/60 Hertz

Model 218A 12.5 Amps 1500 Watts

Model 228A 14.6 Amps 1750 Watts

Voltage 230/240 Volts AC 50/60 Hertz

Model 218A 6.25 Amps 1500 Watts

Model 228A 9.6 Amps 2200 Watts

Weight Model 218A 75 Pounds (34.1 KG)

Weight Model 228A 94 Pounds (42.7 KG)

THIS MACHINE IS DESIGNED TO BE OPERATED BY ONE OPERATOR ONLY

- 4 -

Operation

1. It is recommended that you review the "How to

Apply Instructions" (on our Product

Information Sheet) before beginning heat

sealing operations.

2. Turn the power on by pressing the POWER

button on the controller.

3. Set desired temperature and time. Swing the

upper platen arm to its fully open position,

away from lower platen.

4. Allow the machine to warm up until the

selected temperature is reached.

5. Set the desired pressure by adjusting the

pressure adjust lever on the top of the

machine. To increase pressure, pull lever

forward.

6. Place the substrate on lower platen, smoothing

out all wrinkles.

7. Position transfer or lettering on substrate.

8. Swing the upper arm into position directly over

the lower platen.

9. Close machine by pulling handle down into

locked position.

10. The timer will start automatically and a buzzer

will beep at the end of the time cycle.

11. Lift safety lock and pull handle up slowly and

move upper platen handle to its full open

position. This technique will avoid transfer

paper (cover) from being pulled off

prematurely due to suction from the separating

platens.

NOTE

For safety purposes, it is necessary to

push the handle into the locked position

after it is lifted. This will eliminate the

accidental lowering of the heat platen

handle.

12. Swing away arm to the extreme right hand

position and remove substrate.

Operation Timer/Temperature Control

Solid State Controller

This controller has three (3) control features:

1. Temperature - Temperature may be set from

225-450°F (107-232°C).

2. Time - Time may be set from 1 second to 10

minutes.

3. Counter - Cycle counter counts the number

of applications from 1 to 9999 (see additional

Notes - Counter).

Controller Operation

1. If the temperature is not being displayed,

press the MODE button until temperature is

displayed.

2. Push and hold SET button and

simultaneously push UP (↑) or DOWN (↓)

arrow buttons to the desired temperature

setting.

3. Press the MODE button until time is

displayed.

4. Push and hold SET button and

simultaneously push UP (↑) or DOWN (↓)

arrow buttons to the desired timer setting.

THIS MACHINE IS DESIGNED TO BE OPERATED BY ONE OPERATOR ONLY

- 5 -

ADDITIONAL NOTES:

Temperature

NOTE

Fahrenheit/Centigrade (Celsius)

Conversion

The temperature controller can be

programmed to display either °F or °C.

To change:

Press the MODE button until the

temperature is displayed, then push and

hold the SET button for 10 seconds.

Timer

• The controller has a count down timer that

automatically activates a buzzer at the

completion of the application.

• Timer display is minutes:seconds. Range is

00:00 to 10:00, Colons (:) flash while timer is

running.

NOTE

The timer or buzzer may be stopped

while the handle is in the down

position by pressing both the DOWN

(

↓

) arrow button and the UP (

↑

)arrow

button simultaneously. The timer will

automatically reset after the handle is

raised.

Counter

The controller has a built in cycle counter.

• Press MODE button until the counter is

displayed.

• Counter display range is 0000 to 9999.

• To reset the cycle counter, display the counter

reading, then push and hold both UP (↑) and

DOWN (↓) arrow buttons for 3 seconds until

the counter resets to zero (0000) on the

display.

THIS MACHINE IS DESIGNED TO BE OPERATED BY ONE OPERATOR ONLY

- 6 -

Safety Summary

WARNING

In case of power cord damage, do

not attempt to repair or replace the

power cord. Contact the manufac-

turer or the local distributor.

WARNING

Avoid touching hot surfaces while

operating the machine.

CAUTION

During normal operation, the base

of the machine needs to be installed

or placed above the wall socket.

CAUTION

When servicing or cleaning the

machine, make sure that the power

cord is removed from the wall

socket.

International Symbols

O

Power Off

I

Power On

Hot Surface

Risk of Electrical Shock

Protective Earth Terminal

Ground

Caution - Warning

THIS MACHINE IS DESIGNED TO BE OPERATED BY ONE OPERATOR ONLY

- 7 -

Preventive Maintenance Suggestions

The IGS heat seal machines are relatively

maintenance free. For long trouble-free life, the

following preventive maintenance should be

followed:

1. Do not heat seal items such as buttons, pins,

snaps, or zippers that tend to cut the silicone

rubber pad or scratch the Teflon heat platen.

2. Periodically clean the Teflon-coated heat platen

with a non-abrasive piece of cloth. Stubborn

stains may be cleaned, when platen is cool,

with mineral spirits.

3. When the heat platen is hot and not in use,

keep in open position (away from the silicone

rubber pad).

4. To prevent soiling of substrate, periodic wiping

of the entire exterior machine, including

platens, with a clean rag is recommended. If

necessary, use mineral spirits for cleaning a

cold machine. Since mineral spirits are

flammable, use precautions and keep away

from sparks, flame, or hot heat platen.

5. The Model 218/228 machines require periodic

lubrication with a high-temperature, non-

melting grease (MPPL023).

A. Lubricate the post, handle and cam

assembly depending upon usage.

(Once every month if used

continuously.)

B. There are four (4) points of lubrication:

a) Post

b) Lower Cam

c) Guide Post

d) Upper Pin Area

In addition, occasionally apply a few drops of

heavy machine oil to the upper portion of the cam

assembly. To lubricate the pressure adjustment,

raise cover an inch or two and apply heavy

machine oil to slide mechanism.

General Maintenance

It is recommended that you have the following

items available:

A. Regular screw driver

B. Phillips head screw driver

C. Small adjustable wrench

D. Needle nose pliers with insulated

handle

E. Set of Allen wrenches

F. Grease gun

G. Special high temperature grease

MPPL023

With the above items you should be able to

accomplish most repairs.

WARNING

Power cord replacement should be from

the manufacturer only (because it

requires a specially prepared cord).

Replacement of Silicone Rubber Pads

1. Make sure heat platen is cool.

2. Use tube of MPPC006 adhesive to bond

silicone rubber pad to metal platen.

NOTE: Read instructions on the tube package.

3. Be sure that the surface of the silicone platen is

clean. Use a mild solvent such as mineral

spirits.

4. The pad and metal must be thoroughly dry and

clean, before starting the bonding operation.

5. Apply adhesive sealant to the metal platen.

Spread a thin even coat and apply pad

immediately. Apply pressure and position pad

making sure that there is no air entrapment.

NOTE: A serrated blade such as used for laying down

rubber floor tiles would be helpful.

6. Allow to cure overnight under low pressure at

normal room temperature.

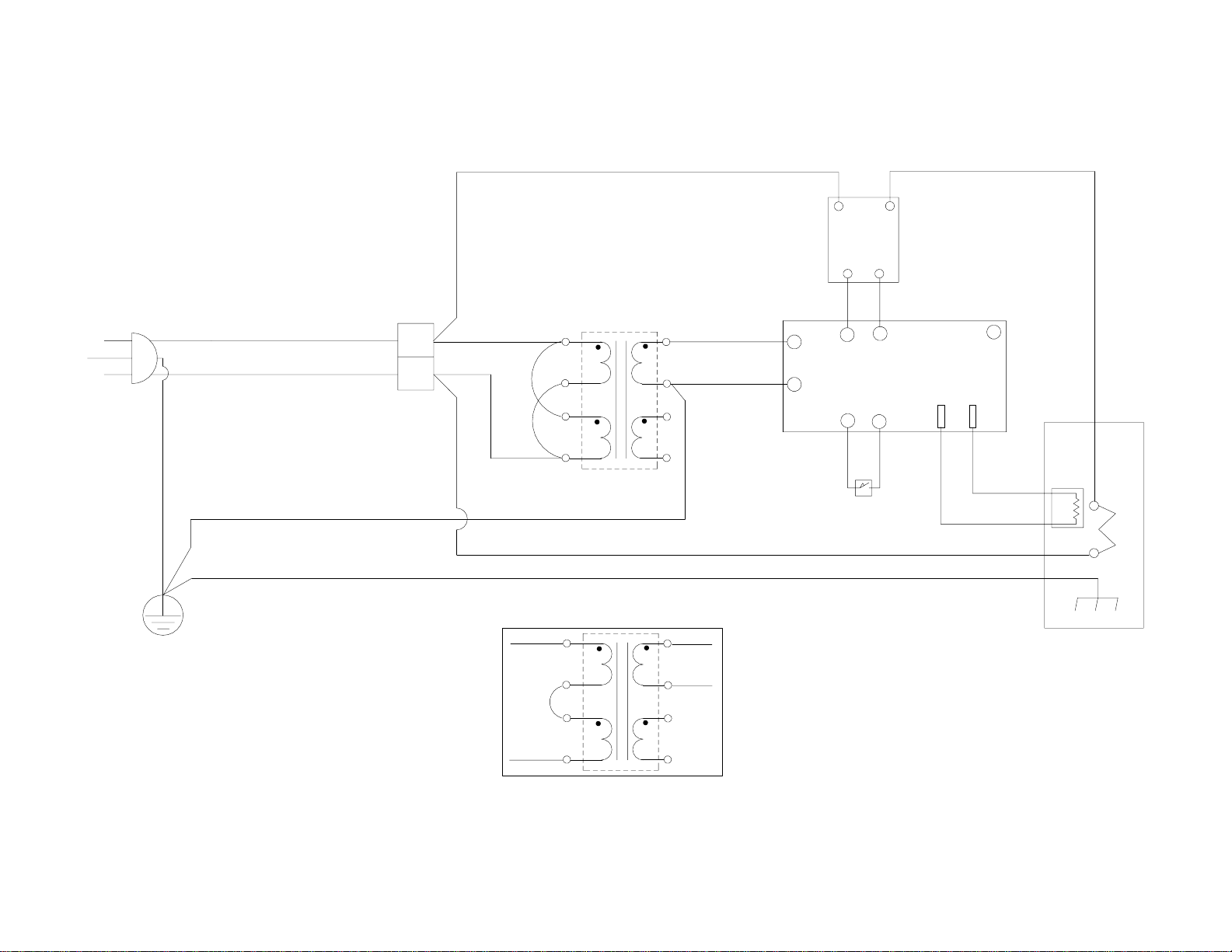

HEAT PLATEN

TEMPERATURE

CONTROL

RELAY

BLUE

12 Vac

INPUT

OP-1

SENSOR

OP-2

N/C

TIMER

START

CNO

MICRO

SW\ITCH

7

3

5

6

4

2

1

+12V

GN/YEL

BROWN

RED

GRAY

YELLOW

WHITE

PURPLE

WHITE

COIL

NO

C

12 Vac

5

2

6

8

7

11

12

1

TRANSFORMER

WHITE WHITE

GN/YEL

TRANSFORMER

BLUE

12 Vac

230 Vac

5

2

6

8

7

11

12

1

BROWN

BLUE

BROWN

GREEN/YELLOW

TERMINAL

BLOCK

218A 228A Wiring Diagram - 10/08/04

WHITE

(BLUE-EUROPE)

BLACK

(BROWN-EUROPE)

RTD

BLACK

TAN

GREEN

(GN/YEL-EUROPE)

TAN

GREEN

GN/YEL

1

2

GND

BLACK

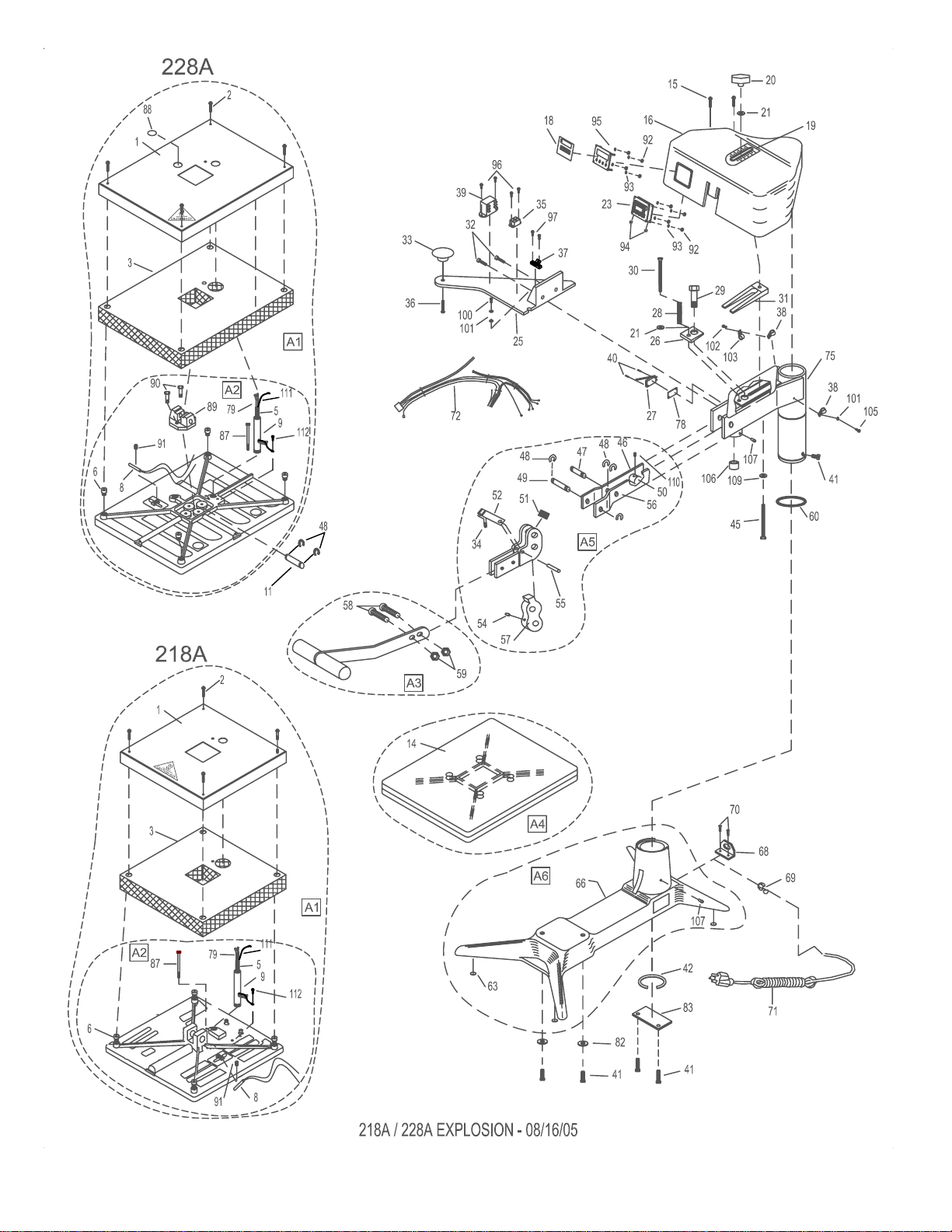

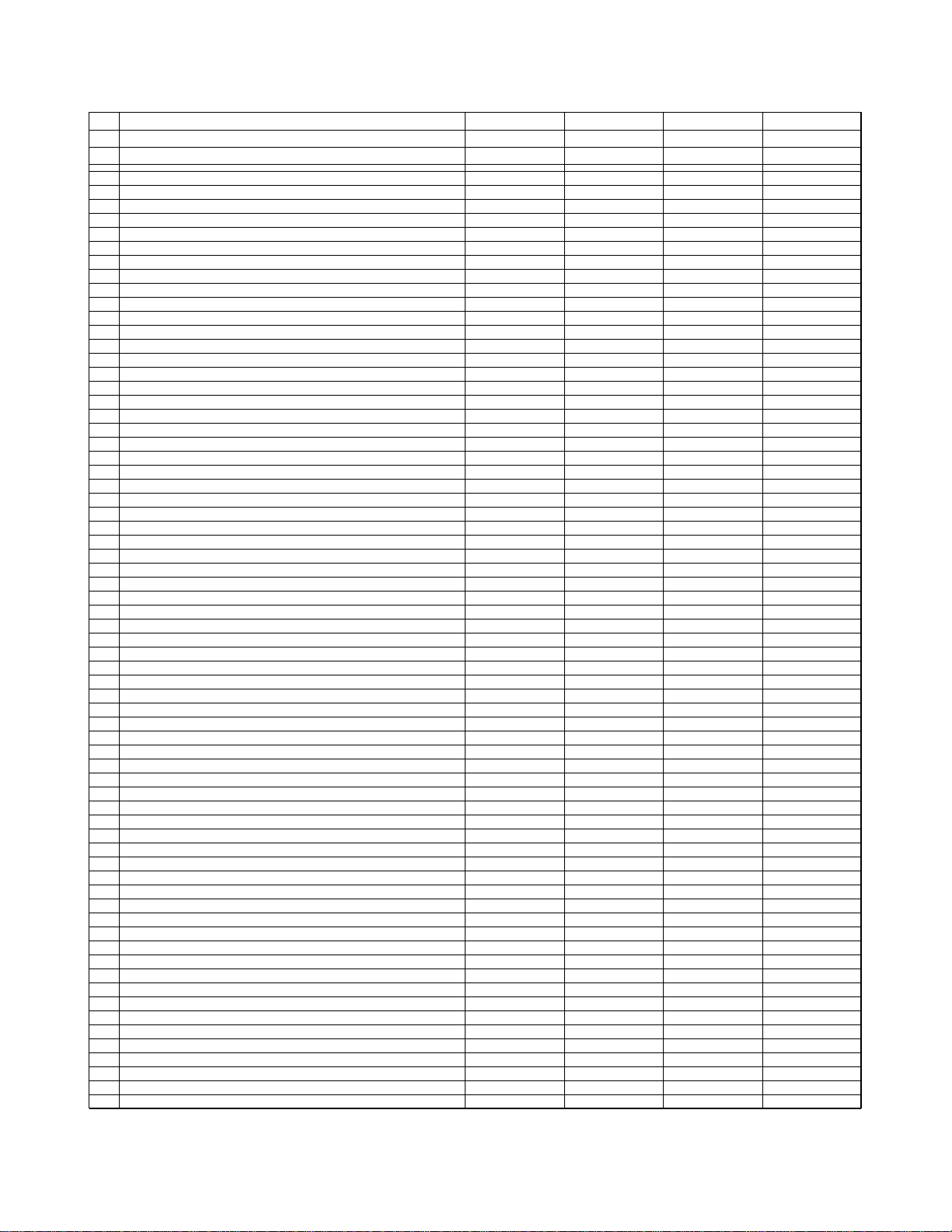

MODEL MODEL MODEL MODEL

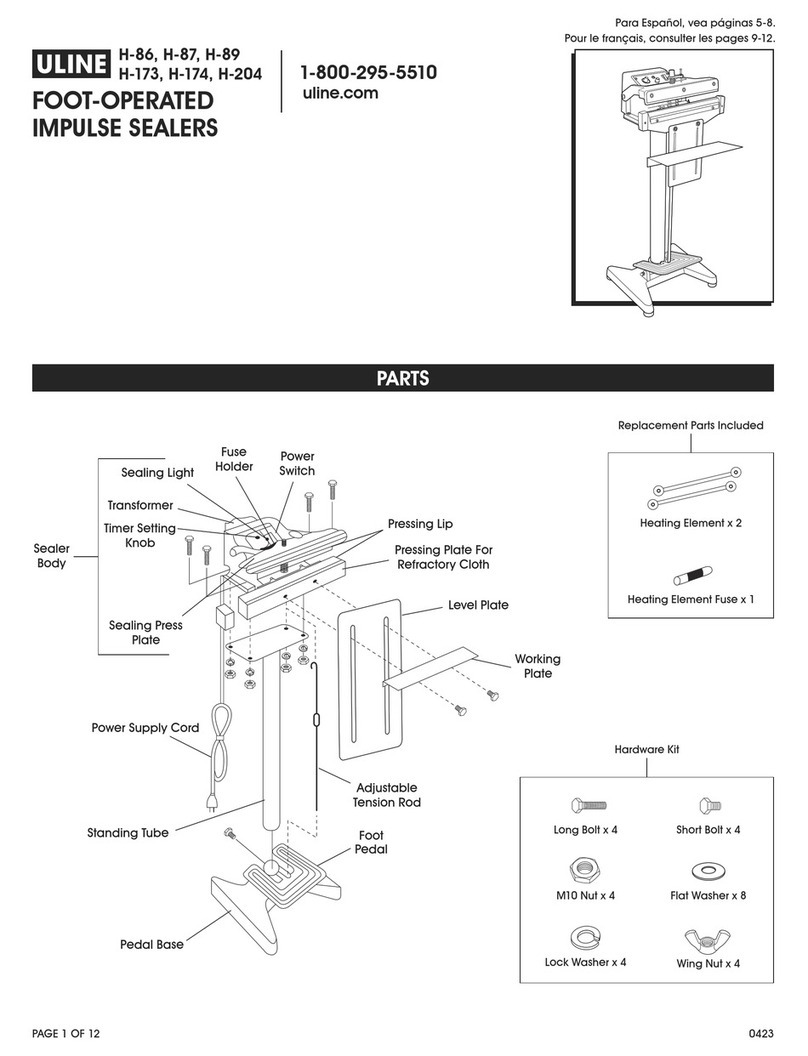

218A 218A 228A 228A

NO PART NAME 120V AC 240V AC 120V AC 230V AC

1SHROUD, HEAT MPSS218 MPSS218 MPSS228 MPSS228

2SCREW, PAN HD #10 x 1.00 LG MPSS143 MPSS143 MPSS143 MPSS143

3INSULATION, FIBERGLASS MPSP251 MPSP251 MPSP254 MPSP254

5TUBING, SHRINK TFE AWG7 MPPS131 MPPS131 MPPS131 MPPS131

6INSULATORS, SPACER (4/SET) MPSI089 MPSI089 MPSI089 MPSI089

8SENSOR, TEMPERATURE REPLACEMENT KIT MPPS210 MPPS210 MPPS210 MPPS210

9POST, GUIDE MPSP085 MPSP085 MPSP085 MPSP085

11 PIN, PIVOT PLATEN MPP0139 MPP0139 MPP0139 MPP0139

14 PAD, SILICONE RUBBER MPPP030 MPPP030 MPPP031 MPPP031

15 SCREW, PHILLIP PAN HEAD 10-24 x 0.5 LONG MHSP102412 MHSP102412 MHSP102412 MHSP102412

16 HOUSING, INSTRUMENT MBAH90000 MBAH90000 MBAH90000 MBAH90000

18 LABEL, CONTROLLER OVERLAY MPSL128 MPSL128 MPSL128 MPSL128

19 LABEL, SCALE OVERLAY (PRESSURE ADJ.) MPPL012 MPPL012 MPPL012 MPPL012

20 KNOB, PRESSURE ADJUST MPPK019 MPPK019 MPPK019 MPPK019

21 WASHER, SAE 5/16" I.D. MHWSAE516 MHWSAE516 MHWSAE516 MHWSAE516

23 CONTROLLER, DIGITAL MPC90003 MPC90003 MPC90003 MPC90003

25 HANDLE, SWING AWAY MPH90002 MPH90002 MPH90002 MPH90002

26 WASHER, WEDGE MPSP010 MPSP010 MPSP010 MPSP010

27 SWITCH, MICRO MPPS043 MPPS043 MPPS043 MPPS043

28 SPRING, TENSION MPSS200 MPSS200 MPSS200 MPSS200

29 SCREW, BOLT HEX 1/2-13 x 3.00 LONG MHBH12133 MHBH12133 MHBH12133 MHBH12133

30 SCREW, FLAT HD 5/16-18 x 2.00 LONG MHSF516182 MHSF516182 MHSF516182 MHSF516182

31 CAM WEDGE MPSP001 MPSP001 MPSP001 MPSP001

32 SCREW, SOCKET HD 1/4-20 x 0.5 LONG MHSSH142012 MHSSH142012 MHSSH142012 MHSSH142012

33 KNOB, HANDLE (MUSHROOM) MPPK017 MPPK017 MPPK017 MPPK017

34 CAP, VINYL BLACK 5/16" x .281 LONG MPC90006 MPC90006 MPC90006 MPC90006

35 RELAY MPPR200 MPPR200 MPPR200 MPPR200

36 SCREW, BUTTON HD 1/4-20 x 0.875 LONG MHSB142078 MHSB142078 MHSB142078 MHSB142078

37 BLOCK, TERMINAL MH11096914 MH11096914 MH11096914 MH11096914

38 CLAMP, CABLE 5/16 IN MHCC516 MHCC516 MHCC516 MHCC516

39 TRANSFORMER MPPT700 MPPT700 MPPT700 MPPT700

40 SCREW, ROUND HEAD 4-40 x 0.75 LONG MHSR44034 MHSR44034 MHSR44034 MHSR44034

41 SCREW, SOCKET HD 5/16-18 x 0.75 LONG MHSSH5161834 MHSSH5161834 MHSSH5161834 MHSSH5161834

42 RING, SNAP MPSR268 MPSR268 MPSR268 MPSR268

45 SCREW, CARRIAGE BOLT 5/16-18 x 2.750 LONG MHBC51618234 MHBC51618234 MHBC51618234 MHBC51618234

46 PRESSURE ADJUST LEVER (LH) MPSP2201 MPSP2201 MPSP2201 MPSP2201

47 PIN, PIVOT (LOWER) MPSP2211 MPSP2211 MPSP2211 MPSP2211

48 CLIPS, "E" MPSC240 MPSC240 MPSC240 MPSC240

49 PIN, CAM PIVOT (UPPER) MPSP262 MPSP262 MPSP262 MPSP262

50 NUT, PRESSURE ADJUSTMENT MPSP2209 MPSP2209 MPSP2209 MPSP2209

51 SPRING, CAM MPSS201 MPSS201 MPSS201 MPSS201

52 SAFETY LOCK MPSL241 MPSL241 MPSL241 MPSL241

54 FITTING, GREASE (SHORT) MPSF145 MPSF145 MPSF145 MPSF145

55 PIN, ROLL (SAFETY LOCK) MPSR141 MPSR141 MPSR141 MPSR141

56 PRESSURE ADJUST LEVER (RH) MPSP2200 MPSP2200 MPSP2200 MPSP2200

57 CAM MPSC218 MPSC218 MPSC218 MPSC218

58 SCREW, BUTTON HD 5/16-18 x 1.00 LONG MHSB516181 MHSB516181 MHSB516181 MHSB516181

59 NUT, HEX JAM 5/16-18 MHNHJ51618 MHNHJ51618 MHNHJ51618 MHNHJ51618

60 RING, "O' POST MPSS273 MPSS273 MPSS273 MPSS273

63 FEET, RUBBER (6/SET) MPF90004 MPF90004 MPF90004 MPF90004

68 BRACKET, POWER CORD MPSS163 MPSS163 MPSS163 MPSS163

69 STRAIN, RELIEF MPSS168 MPSS168 MPSS168 MPSS168

70 SCREW, PHILLIP PAN HEAD 10-24 x 0.375 LONG MHSP102438 MHSP102438 MHSP102438 MHSP102438

71 POWER CORD (USA MODEL) MPPW141 MPPW142 MPPW141 MPPW142

71A POWER CORD (EUROPEAN MODEL) N/A MPPW202 N/A MPPW202

71B POWER CORD (UK MODEL) N/A MPPW203 N/A MPPW203

72 WIRE HARNESS MPW90011 MPW90011 MPW90011 MPW90011

75 POST, ARM ASSEMBLY MPSP235A MPSP235A MPSP235A MPSP235A

78 INSULATION, MICRO SWITCH MH700214 MH700214 MH700214 MH700214

79 WIRE, HEATER MPPW700 MPPW700 MPPW700 MPPW700

82 WASHER, SAE 5/16 I.D. MHWSAE516 MHWSAE516 MHWSAE516 MHWSAE516

83 PLATE, REAR POST MPSP2303 MPSP2303 MPSP2303 MPSP2303

87 SCREW, SOCKET HD 1/4-20 x 4.0 LONG MHSSH14204 MHSSH14204 MHSSH14204 MHSSH14204

88 PLUG, BUTTON 7/8 IN MHPB78 MHPB78 MHPB78 MHPB78

89 CLEVIS, UPPER PLATEN N/A N/A MPSP221 MPSP221

90 BOLT, HEX 5/16-18 x 1 IN LG STAINLESS N/A N/A MH51618S MH51618S

91 SCREW, SET 3/8-16 x 0.5 IN MHSST381612 MHSST381612 MHSST381612 MHSST381612

MODEL MODEL MODEL MODEL

218A 218A 228A 228A

NO PART NAME 120V AC 240V AC 120V AC 230V AC

92 NUT, HEX 6-32 MHNH632 MHNH632 MHNH632 MHNH632

93 WASHER, SHIM #6 (.031) MH311150019 MH311150019 MH311150019 MH311150019

94 SPACER, LG NYLON 0.166 ID x 1/4 IN MH110969111 MH110969111 MH110969111 MH110969111

95 PLATE, CONTROLLER MPP90011 MPP90011 MPP90011 MPP90011

96 SCREW, PAN HEAD 8-32 x 0.25 IN MHSP83214 MHSP83214 MHSP83214 MHSP83214

97 SCREW, PAN HEAD 8-32 x 0.5 IN MHSP83212 MHSP83212 MHSP83212 MHSP83212

100 SCREW, PAN HD 8-32 x 0.375 IN MHSP83238 MHSP83238 MHSP83238 MHSP83238

101 WASHER, #8 SAE MHWSAE8 MHWSAE8 MHWSAE8 MHWSAE8

102 SCREW, SOCKET HD 1/4-20 x 0.5 IN LONG MHSSH142012 MHSSH142012 MHSSH142012 MHSSH142012

103 CLAMP, CABLE METAL 3/8 IN MHCC38 MHCC38 MHCC38 MHCC38

105 SCREW, PAN HEAD 8-32 x 0.375 IN MHSP83238 MHSP83238 MHSP83238 MHSP83238

106 BUSHING, GUIDE POST MPSB070 MPSB070 MPSB070 MPSB070

107 FITTING, GREASE (LONG) MPSF144 MPSF144 MPSF144 MPSF144

109 WASHER, WAVE 0.5 IN MH5806282 MH5806282 MH5806282 MH5806282

110 SCREW, SET 8-32 x 0.1875 IN LG MHSST832316 MHSST832316 MHSST832316 MHSST832316

111 WIRE, GROUND MPW90125 MPW90125 MPW90125 MPW90125

112 SCREW, PAN HD 6-23 x 0.25 LG MHSP63214 MHSP63214 MHSP63214 MHSP63214

A1 PLATEN, HEAT ASS'

Y

MPP218A1

A

MPP218A2

A

MPP228A1

A

MPP228A2

A

A2 PLATEN, HEAT (WIRING ONLY

)

MPP218A1

W

MPP218A2

W

MPP228A1

W

MPP228A2

W

A

3

HANDLE, PRESSURE ASS'

Y

MPSH515 MPSH515 MPSH515 MPSH515

A

4

PLATEN, LOWER ASS'

Y

MASP010 MASP010 MASP007 MASP007

A

5

CAM / PRESSURE LEVER ASS'

Y

MPSC201 MPSC201 MPSC201 MPSC201

A

6

BASE ASS'

Y

MPSB204

A

MPSB204

A

MPSB204

A

MPSB204

A

®

Service: (800) 426-3609 • (562) 861-2566 • Sales: (800) 421-6971 (562) 404-3000 • Fax: (562) 404-3010 • http://www.instagraph.com

13925 E. 166th Street • Cerritos CA USA 90702-7900

This manual suits for next models

1

Table of contents