igus i.Sense EC.P User manual

Inhaltsverzeichnis

2/14

Manual i.Sense EC.P- V 1.1

Table of contents

1Introduction...................................................................................................... 3

2Safety instructions, protective measures, and guidelines........................... 4

2.1 Important information ........................................................................ 4

2.2 Qualified personnel ........................................................................... 4

2.3 Electromagnetic compability.............................................................. 5

3Product overview............................................................................................. 5

3.1 Product family ................................................................................... 5

3.2 Technical data................................................................................... 6

4Installation........................................................................................................ 7

4.1 Mechanical installation...................................................................... 7

4.2 Electrical installation.......................................................................... 7

4.2.1 Power supply selection...................................................................... 7

4.2.2 Connector assignment and sensor connection ................................. 8

5Sensor installation..........................................................................................10

5.1 Configuration....................................................................................10

5.1.1 Setting force limits............................................................................10

5.1.2 Set date and time.............................................................................11

5.2 Calibration........................................................................................11

6Sensor messages............................................................................................11

6.1 String structure.................................................................................11

7LED conditions................................................................................................12

8Maintenance / change battery........................................................................12

9Troubleshooting..............................................................................................13

10 FAQs ................................................................................................................13

11 Accessories.....................................................................................................13

12 Abbreviations..................................................................................................13

13 Explanation of terms.......................................................................................13

14 Wiring diagrams..............................................................................................13

15 Service .............................................................................................................14

Introduction

3/14

Manual i.Sense EC.P- V 1.1

Thank you,

for deciding for our product i.Sense EC.P!

With i.Sense EC.P it is possible to monitor the push and pull forces of an igus® e-chain®. Following the way, the product works,

and the way it is installed, is described.

If there are any further questions, please don’t hesitate to contact our customer service (p.14).

Have fun with i.Sense EC.P!

The following sign boards will come across sometimes, by reading the manual, they are classified, so that degree and nature of

a hazard are marked.

Safety instructions marked with DANGER indicate an immediate hazardous situation. Disregarding the

notice will inevitably lead to a serious or even fatal accident.

DANGER!

Safety instructions marked WARNING indicate a potential hazardous situation. Disregarding the notice may

lead to a serious or even fatal accident or property damage.

WARNING!

Safety instructions marked with CAUTION indicate possible hazardous situations. Disregarding the notice may

lead to an accident or damage to property.

CAUTION!

Safety instructions marked with NOTE indicate a potential hazardous situation. Disregarding the notice may

lead to property damage.

Moreover, common notes and explanations are marked like that.

NOTE!

1 Introduction

The igus® smart plastics condition monitoring concept prohibits unplanned machine downtime caused by break or blockade of

the igus® e-chainsystem®.

i.Sense EC.P is a microprocessor-based module to mount on a DIN rail, it evaluates connected i.Sense EC.P sensorics

continuously. Through two potential-free contacts there is a quick reaction of the machine possible, if unexpected operating

conditions of igus® e-chain® systems occur.

i.Sense EC.P is no safety-component in terms of the EC machinery directive and is not allowed to use as part of safety-concept.

i.Sense EC.P is no safety-component in terms of the EC machinery directive and contains no protection against body

injury.

Failure to note this can lead to severe damage and injury.

CAUTION!

Character

Description

E

e-Chain®

C

.

-

P

Pull-Force

Safety instructions, protective measures, and guidelines

4/14

Manual i.Sense EC.P- V 1.1

2 Safety instructions, protective measures, and guidelines

2.1 Important information

Read this manual carefully before using the i.Sense EC.P. Familiarize yourself with the safety instructions and ensure that the

required protective measures are followed.

This manual has been prepared to the best of our knowledge and belief. It is used for technical documentation and to support the

user during commissioning. The warning and safety information as well as instructions issuedby igus®regarding the i.Sense EC.P

must always be passed on to the end user if the i.Sense EC.P is used as part of an overall system.

The company igus®GmbH only provides a guarantee for products made by igus®in accordance with the standards, norms, and

specifications in this manual. The guarantee only covers the replacement or repair of a defective i.Sense EC.P sensor processing

unit. No liability is accepted for consequential damage and consequential errors. igus® GmbH assumes no responsibility for

integrating i.Sense EC.P into the overall system. The responsibility for this lies with the system designer or the end user. Please

note the information under "Qualified personnel".

igus®GmbH accepts no liability whatsoever for personal injury or damage to property resulting from incorrect use or from

unauthorized technical modifications to the i.Sense EC.P.

The igus®GmbH reserves the right to make changes and optimizations on the product or in the technical documentation at any

time without prior notice.

The i.Sense EC.P may be used only if:

- All instructions and safety instructions for installation given in this manual have been followed.

- The housing has been properly installed according to the valid ESD and EMC regulations.

- No modifications have been made to the i.Sense EC.P and it is in a technically perfect condition.

- The operating limits specified in the Technical data (p. 6) are complied with.

2.2 Qualified personnel

Sebastian Probst

The i.Sense EC.P may be operated by qualified personnel only.

- The personnel must have read and understood this manual and any existing additional documentation.

- The personnel must be familiar with all relevant applicable standards, regulations and accident prevention regulations.

- The training of the personnel must enable them to foresee or identify possible hazards that may occur during the use of

the control system.

- When using the sensor unit in the overall system, personnel must be able to ensure the safety of persons and objects.

- Personnel must be trained in the handling of ESD sensitive equipment and take all necessary precautions.

Product overview

5/14

Manual i.Sense EC.P- V 1.1

2.3 Electromagnetic compability

- Risk of injury due to interference from signals and equipment

Disturbed signals can cause unpredictable actions of the equipment.

Carry out the wiring in accordance with the electromagnetic compatibility (EMC) guidelines. Failure to observe these

precautions may result in death, serious injury or material damage.

WARNING!

EMC measures

Effects

Unit assembly

Use cable clamps for shield support,

connect metallic parts over a large area

Good conductivity through surface (full-area) contact

Supplement switching devices such as

contactors, relays or solenoid valves with

interference suppression combinations or

spark suppression elements (e.g. diodes,

varistors, RC modules).

Reduce mutual interference coupling.

Wiring

Keep cables as short as possible

Avoid capacitive and inductive interference coupling

Do not lay sensor cables and signal cables

together with cables for DC and AC voltage

above 60 V in one cable duct.

Avoiding mutual interference coupling

Earth the shields of digital signal cables on

both sides over a large area or via

conductive connector housings.

Avoid interference with control cables, reduce emissions.

3 Product overview

3.1 Product family

Product

Description

IS.EC.P:00…

- Accessories for EC.P

IS.EC.P.03…

…0

…1

…2

- Monitoring of push-/pull forces, one force limit adjustable, force

and trigger constraints fixed

Load cell

Force sensor big design

Force sensor small design

IS.EC.P.07…

…0

…1

…2

- Monitoring of push-/pull forces, various force limits adjustable,

force and trigger constraints variable through averaging

Wägezelle

Kraftsensor kleine Bauform

Kraftsensor große Bauform

Product overview

6/14

Manual i.Sense EC.P- V 1.1

3.2 Technical data

Mechanical specifications DIN rail module

D x W x H in millimetres incl. connector and fastening elements

17,5 x 99 x114,5 mm

weight in grams

approx. 120 g

mounting/ installation

TS35 support rail in earthed switch cabinet

colour

Light grey, like RAL 7035

material

Polyamid

flamability

UL 94 V0

Mechanical specifications load cell 616

D x W x H in millimetres incl. connector and fastening elements

114,10 x 26 x 80 mm

mounting/ installation

Screw lugs at Obertrunn of e-chain®

material

Stainless steel

Tightening torque

T30

M6

10 Nm

T45

M8

23 Nm

T50

M10

35 Nm

T55

M12

75 Nm

Mechanical specifications load cell 620

D x W x H in millimetres incl. connector and fastening elements

88 x 32 x 90 mm

mounting/ installation

Screw lugs at Obertrunn of e-chain®

material

Stainless steel

Tightening torque

T30

M6

10 Nm

T45

M8

23 Nm

T50

M10

35 Nm

T55

M12

75 Nm

Electrical specifications

- Risk of destruction

An operating voltage that exceeds the voltage specified in the technical data will destroy the i.Sense EC.P. Select an

operating voltage that is within the voltage range specified in the technical data.

Note any interference and voltages induced by other consumers and/or motors and plan corresponding safety reserves

and countermeasures. Ensure that your power supply is feedback protected if load and logic voltage come from the

same power supply or the same transformer

CAUTION!

Power supply

24 V DC

Nominal current

Max. 0,16 A

Potential free contact

24 V DC 0,3A max.

Storage

SD-card (micro SDHC-card Class 10) min 8GB

250 CSV files (1x CSV ca. 8h), circular buffer

UART interface

5V & 3,3V compatible, 19200 baud

Accuracy

± 1%

Connectable conductor cross-section

0,14 … 2,5 mm2

Installation

7/14

Manual i.Sense EC.P- V 1.1

Ambient conditions

Temperature range

operation

-20…40 °C

storage

-40…45 °C

Transport

-40…45°C

Protection class

IP20 / DIN EN 60529

Relative humidity

≤ 90%, non-condensing

4 Installation

4.1 Mechanical installation

- Vertical, TS35 DIN rail

- Vibration-free place of installation

- Terminal compartment: 50mm vertical, 35mm

- Avoid hotspot, provide adequate aeration

- Installing EC.P Sensor in e-chain®:

oDetailed mounting manual at this link

4.2 Electrical installation

- Danger of electric shocks

- Danger of electric arcs

- Risk of injury

- Risk of destruction of components

Always switch off the power supply before disconnecting or making electrical connections in the system. Secure the

power supply against being switched on again.

After switching off, wait at least five minutes until the capacitors are discharged. Check that there is no voltage before

working in the system.

Occurrence of electric arcs in case of improperly installed electrical connections. Cables connected to i.Sense EC.P

must not have any exposed and stripped core ends. Also ensure that all connections are securely seated.

WARNING!

The connection terminals are designed for single cores only.

A firm connection cannot be guaranteed due to improper multiple assignment. There is a risk that cores may slip out of

the connection terminals and cause short circuits.

If several signals/cores must be connected to one terminal, these must be brought together via an external terminal and

connected from there with a single core.

CAUTION!

4.2.1 Power supply selection

Information on the correct voltage source can be found in the technical data. Use the pins at X7 (see 4.2.2 ).

Clamp

Name

X7 24V DC, 1A

+24V

X7 GND

GND

X7 Functional Earth(FE)

PE

Installation

8/14

Manual i.Sense EC.P- V 1.1

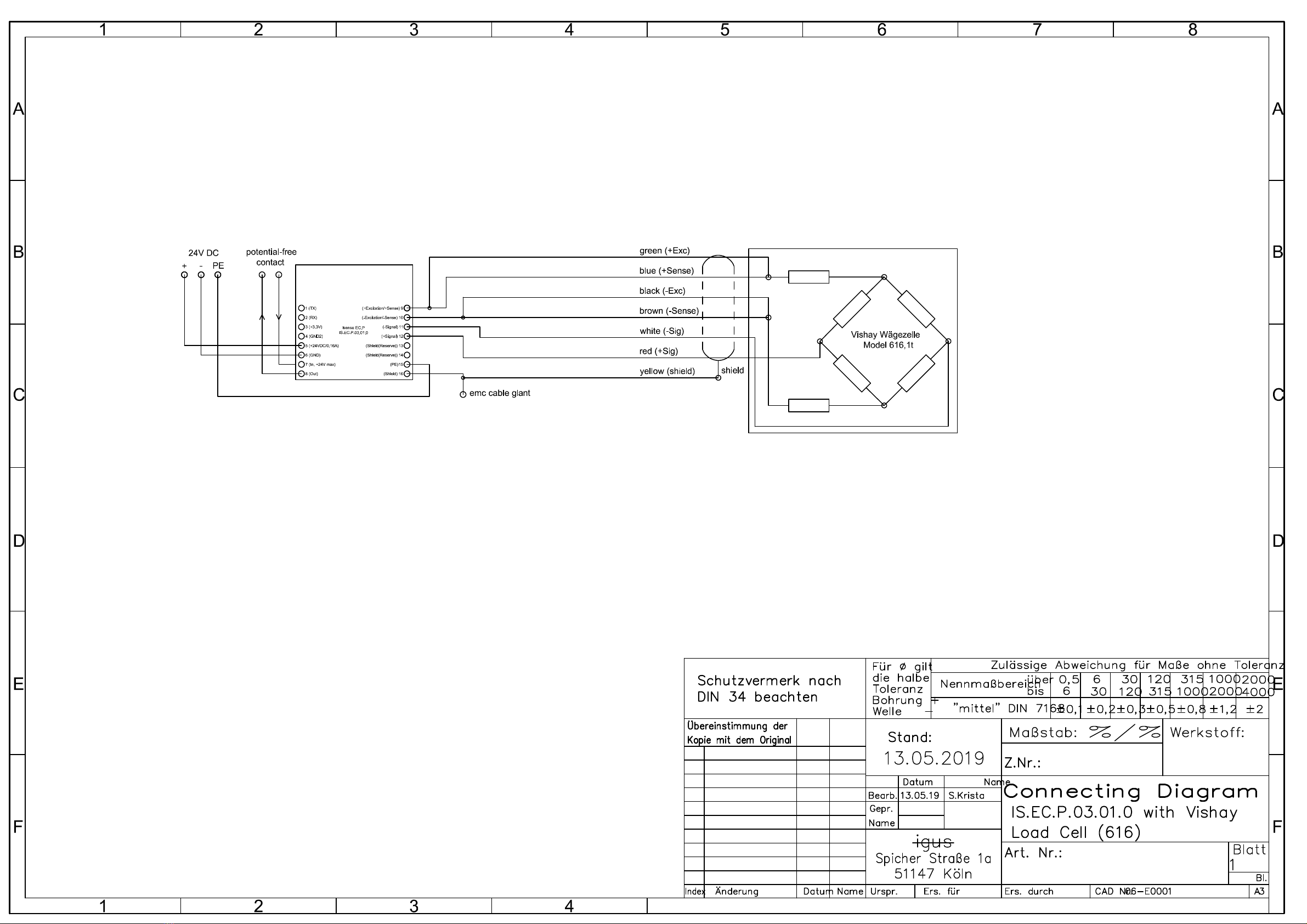

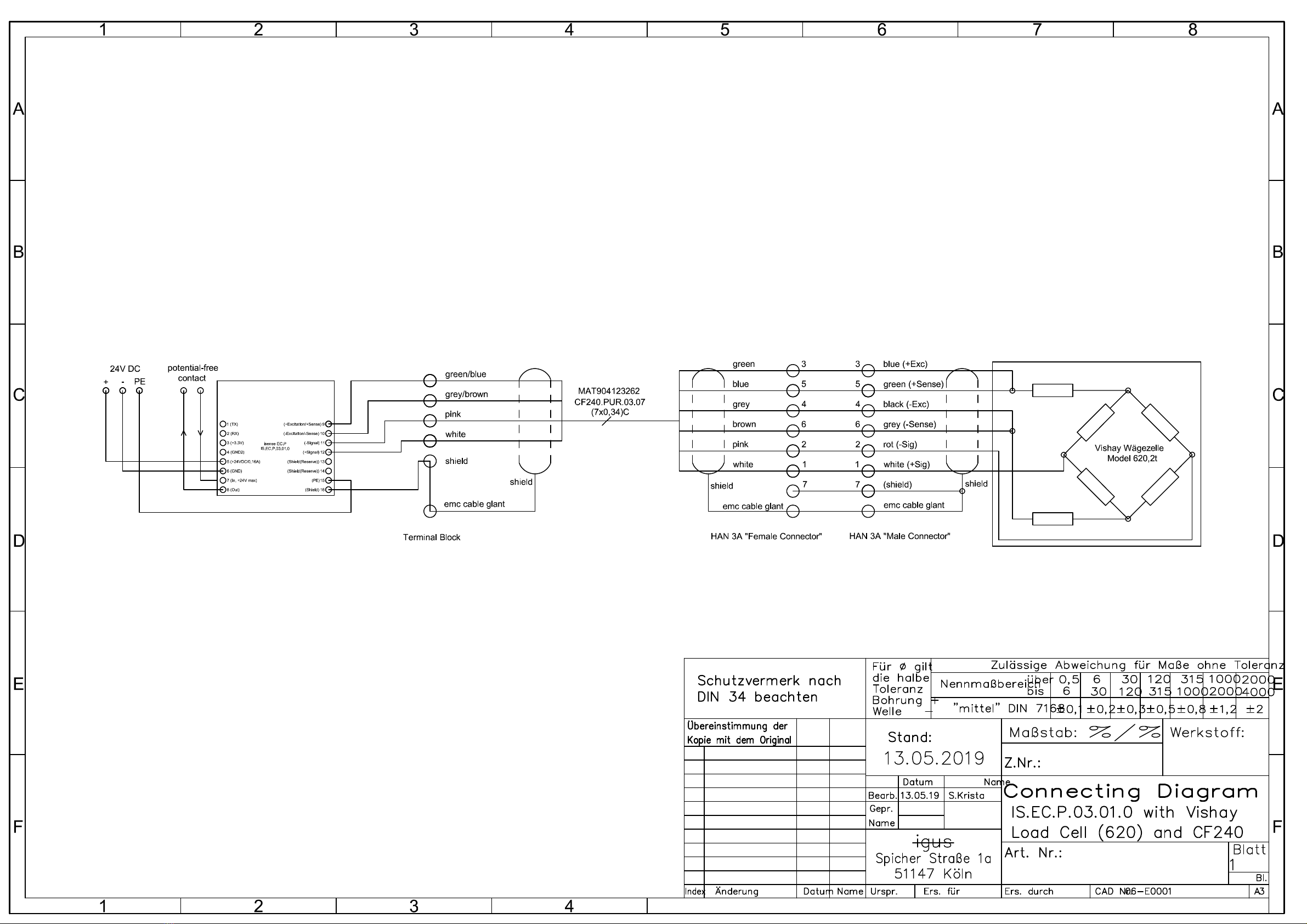

4.2.2 Connector assignment and sensor connection

- Wires with cross sections of 0,15 - 2,5 mm2connectable with screws

- Recommended to use terminal blocks for connecting sensorics, structured wiring is given easier

Connectors of i.Sense EC.P

Housing

i.Sense EC.P housing

1 | 2 | 3 | 4

Installation

9/14

Manual i.Sense EC.P- V 1.1

module’s connecting diagram

5

24 V DC/ 0,16 A

1

TX

6

GND

2

RX

7

In (24 V max.)

3

+3,3 V

8

out

4

GND 2

Power Supply & Potential-free contacts

UART- Interface

↑ DIN rail ↑

i.Sense EC.P

Shield & PE

Sensor

13

Shield (Reserve)

9

+ Excitation/+ Sense

14

Shield (Reserve)

10

- Excitation/- Sense

15

PE

11

- Signal

16

Shield

12

+ Signal

Sensor connection

Vishay load cell model 616,1t

Clamp

Name

Colour

9

+Excitation/+Sense

Green/blue

10

-Excitation/-Sense

black/brown

11

-Signal

white

12

+Signal

red

16

Shield

Shield

Vishay load cell model 620,2t

Clamp

Name

Colour

9

+Excitation/+Sense

Green/blue

10

-Excitation/-Sense

Black/grey

11

-Signal

Red

12

+Signal

White

16

Shield

Shield

igus force sensors ( all models with CF10.Ini-cable)

Clamp

Name

Colour

9

+Excitation/+Sense

White

10

-Excitation/-Sense

Black

11

-Signal

Blue

12

+Signal

Brown

16

Shield

Shield

Connecting UART interfaces

Clamp

Name

Colour

1

TX

Yellow

2

RX

Orange

3

+3,3 V

Red

4

GND 2

black

Sensor installation

10/14

Manual i.Sense EC.P- V 1.1

5 Sensor installation

5.1 Configuration

5.1.1 Setting force limits

The configuration of the microprocessor unit is done by adjusting the text files, saved on the SD-card.

There are two files saved:

Config.txt: Is not allowed to be changed.

config.txt

Values.txt:

Here parameters can be assigned to the needed limits, the sequence of numbers is described below. It is recommended to set

the force limits to nominal force of the load cell, can be changed afterwards.

For finishing the configuration, the RESET button must be pushed for five seconds while the device turns on. After that the limits

have been set from values.txt.

For finishing the configuration, the RESET button must be pushed for five seconds while the device turns on. After that

the limits have been set from values.txt.

NOTE!

EC.P.03… load cell capacity, one force limit (only one value for upper and lower limit) and a forcefactor to multiplictae the

measured force has to be set.

values.txt (EC.P.03…)

EC.P.07… additionally there is the possibility to set various outer force limits (under and over zero-point), where alerting takes

place if the value is passed only once. Moreover, an inner force limit can be set in each direction, it is monitored the pass of an

average out of an number of values (adjustable).

values.txt (EC.P.07…)

After that a calibration has to take place.

Without calibration, there are wrong trigger limits. The correct operation is no longer guaranteed and there can be

malfunctions, so that there can be danger for machine and human.

NOTE!

Sensor messages

11/14

Manual i.Sense EC.P- V 1.1

5.1.2 Set date and time

Date and time can be set in values.txt.

5.2 Calibration

- Push and hold RESET button

- Turn offset-potentiometer until yellow LED flashs

- Red LED flashs: force limit too high

- Green LED flashs: force limit too low

- Push RESET button again, calibration finished

Visual shown on p.11 of Assembly instruction.

Offset can also bechanged by terminalprogram, OFFSET potentiometer has to be turned until force is 0 .

6 Sensor messages

The metrics are stored 18 times per minute as CSV-file on SD-card. A new file is generated after eight hours and when turning

on the module. A maximum of 250 files can be stored, before the circular buffer begins again at file, that file will be overwritten.

6.1 String structure

The sensor messages are given in that form:

IS.EC.P.03…

IS.EC.P.07…

If force is out of adjusted limits, no LED blinks. For calibration it is recommended to use load cells nominal force as force

limits. This can be changed afterwards. (see 5.1.1)

NOTE!

Name

Format

Date

DD.MM.JJJJ;

Time

HH:MM:SS;

Upper Force Limit [N]

XXXXXX;

Actual Force [N]

XXXXXX;

Lower Force Limit [N]

XXXXXX;

Name

Format

Date

DD.MM.JJJJ;

Time

HH:MM:SS;

Absolute Upper Force Limit [N]

XXXXXX;

Upper Force Limit [N]

XXXXXX;

Actual Force [N]

XXXXXX;

Lower Force Limit [N]

XXXXXX;

Absolute Lower Force Limit [N]

XXXXXX;

Number of Upper Force Tolerance Oversteppings

XXXXXX;

Number of Lower Force Tolerance Oversteppings

XXXXXX;

Number of Force Sampling until Averaging

XXXXXX;\ r\n

Maintenance / change battery

12/14

Manual i.Sense EC.P- V 1.1

7 LED conditions

LED

(flash)

Description

Condition floating

contact

Green

(Active)

Modul connected to 24V DC and tension in limits

high

Yellow

(replace

battery)

LED turns on if buffer battery is empty. Please change battery, it is described how

to change on page 12 (8 maintenance/ change battery).

Before replacing thebatteries, it is imperative that the device be shutdown

and that you ensure that it has been disconnected from all power.

Otherwise, there is danger of injuries and device malfunction. Use only

batteries with exactly the same characteristic values.

These values are:

Lithium button cell Type CR 1225 3V 50 mAh

CAUTION!

If the battery is to be replaced, the housing must be opened. It is imperative

that you coordinate this effort ahead of time with the responsible igus®

branch to avoid invalidating your guarantee.

Any other procedure voids the guarantee.

NOTE!

Date and time must be reset after changing the battery.

NOTE!

high

Red

(Force

Error)

The maximum movement range is passed.

The pass can be acknowledged by pushing the RESET button, the

measurement will continue.

NOTE!

low

none

The device is separated from power supply.

low

8 Maintenance / change battery

Battery must be changed if yellow LED flashs. Disconnect the device from all power and prove if there is no power anymore. Open

the housing carefully and change the battery by keeping the ESD guidelines.

The specifications of the old and the new battery must be equal.

If hardware problems occur, please contact customer service (p. 14).

It is imperative that the device be completely disconnected from power. Failure to ensure disconnection and follow ESD

measures can result in shock and the destruction of the device.

CAUTION!

After battery replacement, date and time must be reset in setup area.

NOTE!

Wiring diagrams

13/14

Manual i.Sense EC.P- V 1.1

9 Troubleshooting

- The unit does not detect all sensor data. What now?

oCheck all plug-in connections and restart the system.

oIf this does not help, contact the Customer service (p.14)

10 FAQs

- How are the sensor limits set?

oIn file values.txt (SD-card)

oSee chapter 5.1.1 setting force limits (p.10)

- How do you retrieve the sensor data?

oThe determined data are stored on SD-card

11 Accessories

Article

amount

Cable length [m]

Nominal force[N]

Article number

supplier

Force sensor (little)

1

5

X

ISENSE

Igus®

Force sensor (big)

5

X

ISENSE

Igus®

Vishay load cell 616, 1t

3

10.000

MAT01722742

Igus®

Vishay load cell 620, 2t

5

20.000

MAT01722743

Igus®

Beam for mounting carrying run

1

/

/

/

customer

Chainflex-cable with assembled

M12 connector

1

Customer’s

specification

/

/

Igus®

screws (sorted by e-chain®):

E4.32: M5x20

E4.42: M6x20

E4.56: M8x20

P4: M10x20

8

/

/

/

customer

12 Abbreviations

Abbreviation

Description

EMC

Elektromagnetic compatibility

ESD

Electrostatic discharge

PLC

Programmable Logic Controller

13 Explanation of terms

Term

Description

Force Factor

Factor, the measured force is multiplied with (lever)

Force limit

Limit, that a a measured force should not pass

Outer force limit

Passing this limit once triggers the sensor

Inner force limit

Passing this limit several times in a litthle while triggers the sensor (parameters are defined in values.txt)

14 Wiring diagrams

Inserted after page 14.

Service

14/14

Manual i.Sense EC.P- V 1.1

15 Service

Customer service

de-smartplastics-serv[email protected]

+49 (0) 2203 9649 9806

Technical support for igus®smart plastics

Documentation/FW

https://www.igus.de/info/zustandsueberwachung-ec-p

Download of manuals, FW updates and certificates

Website smart Plastics

https://www.igus.de/info/vorausschauende-wartung-smart-plastics

Possibility to order sensors, processing units and other accessories

Contact

www.igus.com

+49 (0) 2203-9649-0F

Legal Notice

© 2021

All rights reserved by

igus®GmbH

Spicher Str. 1a

D-51147 Cologne

Table of contents

Other igus Industrial Equipment manuals