igus robolink User manual

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

robolink

®

Joint kit

Basics..........................................................................................................2

Joint types...................................................................................................3

Articulated arms..........................................................................................4

Angle sensors...........................................................................................11

Actuators...................................................................................................14

Draw wires.................................................................................................15

Mounting instruction cable end bottom..................................................18

Drive pulleys with integrated wire tightening .........................................19

Step motors...............................................................................................20

Drive modules...........................................................................................23

Drive units .................................................................................................24

Accessories...............................................................................................27

Controls.....................................................................................................27

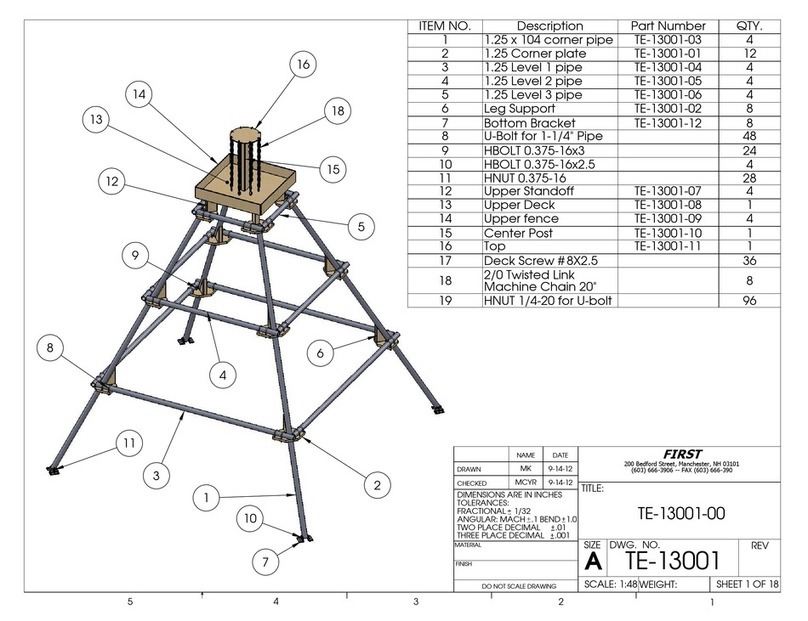

Dimensioned drawings.............................................................................28

Exploded drawings / parts lists................................................................29

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Basics

igus

®

GmbH develops plastic robotics joints, and produces and harnesses these under

the product group robolink

®

Joint kit. At present, 10 different joint types exist, which can

be combined with each other (status 2015-01).

This provides options to configure and design customized articulated arms for a variety of

customer applications.

Articulated arms can be equipped with angle sensors for positioning purposes. The angle

position of the joint is determined and electronically output (incremental magnetic sensor

system).

A variety of products, such as suction cups, blowers, grippers, camera, light source, etc.,

can be used as actuators (at the end of the articulated arm). Generally, the wires for these

actuators can be fed inside the articulated arm.

Articulated arms are moved with draw wires. One pair of wires each is designed to create

motion for one degree of freedom. The wire pair must be driven in an antagonistic

fashion. This provides for a wide selection of drive technologies. A host of drive

technologies are available, such as: pneumatic drives, electro-motors, but also manual

drives.

igus

®

GmbH offers step motors in various configurations as one possible drive

technology.

The step motors are configured into a drive module by means of a planetary gear and a

drive wheel. The drive wheel is a standardized option to attach and move draw wires.

A drive unit has the same number drive modules as the articulated arm has degrees of

freedom (DOF). igus

®

GmbH offers assembled drive units for a variety of articulated arms

on the basis of step motors with planetary gears in an aluminum housing.

A control (in this case: step motor control) is needed to move a robolink

®

articulated arm.

igus

®

GmbH does not offer or supply these controls and other electrical and electronic

components.

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Joint types

The following joint types are on offer and can be combined into articulated arms:

Swivel joint RL-50-PL1 +/-90° swivel range

Rotating joints RL-50-TL1 +/-90° rotating range

RL-50-TL2 +/-90° rotating range

Symmetric RL-50-001 +/-90° swivel range

2 axes joint +/-170° rotating range

Asymmetric RL-50-002 +130°/-50° swivel range

2 axes joint +/-170° rotating range

Version without rotation RL-50-PL2 +130°/-50° swivel range

Fully swing in RL-50-003 +180°/0° swivel range

2 axes joint +/-170° rotating range

Version without rotation RL-50-PL3 +180°/0° swivel range

Big base joint RL-90-BL1 +/-90° swivel range

(for 6 DOF arms) +/-90° rotating range

Small base joint RL-50-BL2 +/-90° swivel range

(as “shoulder”) +/-90° rotating range

The swivel ranges are limited by mechanical stop dogs. These can be removed, thus

expanding the swivel range. This is only possible if the wire feed-through is not designed

to be inside the joint (=> Section - Wire feed-through) This option can only be used after

a technical review. Each joint can be optionally equipped with angle sensors.

Nur in Kombination mit RL-90-BL1

only in combination with RL-90-BL1

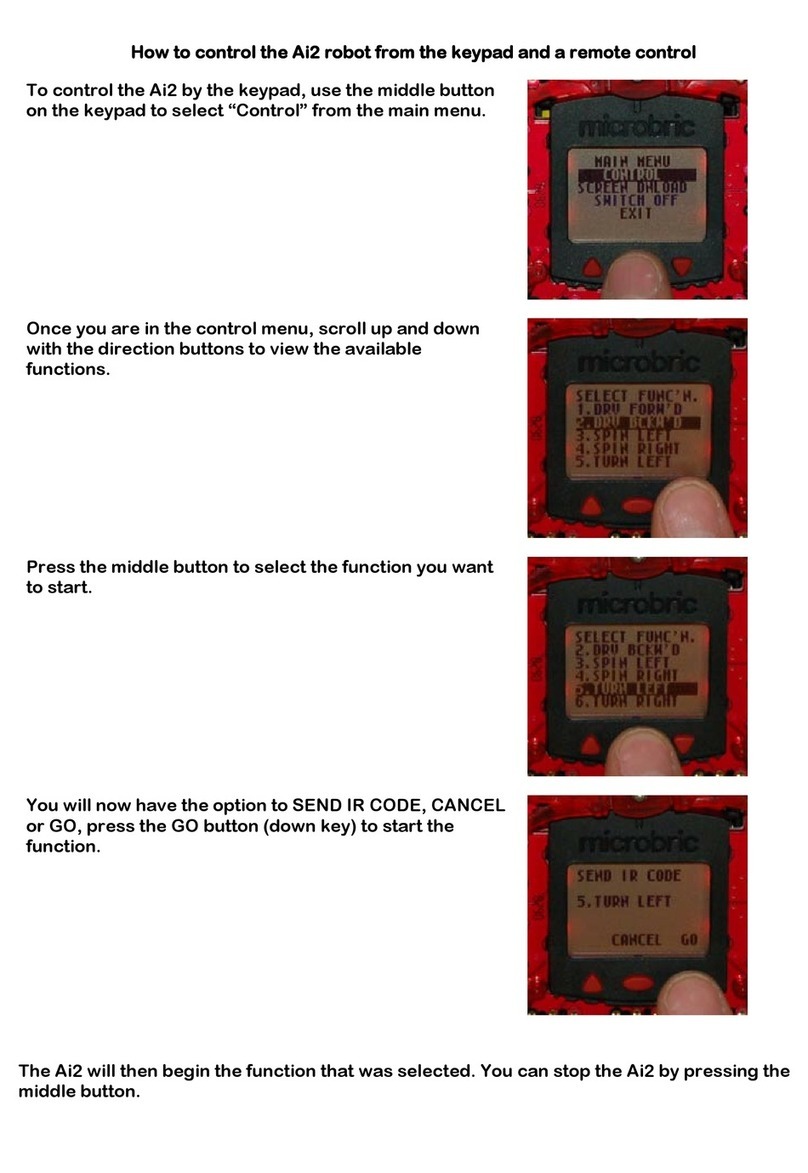

Fig.1: pivot joint

RL-50-PL1 Fig.2: rotating joint

RL-50-TL1 Fig.3: rotating joint

RL-50-TL1

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Fig.4: symmetric 2 axes

joint RL-50-001

Fig.5: asymmetric 2 axes

joint RL-50-002

Fig.6: fully swing in 2 axes

joint RL-50-003

Fig.7: Big base joint

RL-90-BL1 (2 axes)

Fig.8: Small base joint

RL-50-BL2 (2 axes)

Articulated arms

The 10 joint types can be used to configure customized articulated arms. Please consider

the following characteristics:

•Rotating joint RL-50-TL1 and base joints RL-90-BL1 and RL-50-BL2 can only be

used as first joints in a multi axes joint arm.

•Rotating joint RL-50-TL2 can only be used in annexation to base joint RL-90-BL1

(“shoulder” kinematics: rotation – pivot – rotation).

•A 6 DOF configuration needs a big base joint RL-90-BL1 as first joint.

•The small base joint RL-50-BL2 is designed for easy humanoid applications with

low additional loads (max. 5 DOF: shoulder and elbow).

•Further joint variants or higher angle range on request.

Standard aluminum tubes (dia = 26 mm) are used as connecting elements between the

joints. The tubes have an inside contour to prevent rotation on the joint interface. The big

base joint RL-90-BL1 is connected by a plain aluminum tube (da = 40 mm), the distorsion

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

lock is given by 4 pcs. M4 screws in this case. Fiberglass (FGC) or carbon-fiber (CFC)

tubes can be selected as alternatives. The tube length is user selectable between l(min)

and l(max) = 1,000mm The minimum length l(min) differs depending on the location in the

system and is defined in Fig. 12 and Fig. 13. The standard length is 100 in each case.

Fig. 9: Interior contour of a connecting tube Fig. 10: Material versions - connecting

tube: FGC, aluminum, CFC

The specifications for the tube lengths, visible tube lengths and rotating point distances

are shown in Figures 7 and 8, along with information for minimum lengths:

X distance of the rotating points to each other, and from the end of the arms,

Y visible tube length,

L true tube length,

1…4 the first figure is always at the beginning of the articulated arm, increasing to a

max. of 4

2 axes joints and swivel joints are designed so that a maximum of 4 wires for each joint

located above can be fed through the joint (=> Section - Draw wires). In addition, each

joint can also feed 3 more cables or hoses with a maximum diameter of 4mm.

The rotating joint can only be the first joint of a series connection, but it can feed up to 8

additional wires, and directly distribute these to the drives in wire pairs.

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Fig. 11: Tube length information for 1 joint

Fig. 12: Tube length information for combinations of 2 joints

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

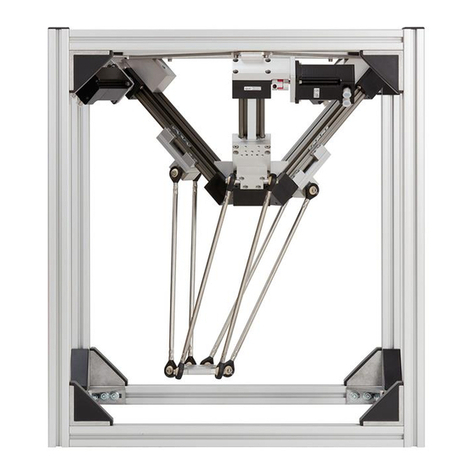

This results in certain configuration options of the joints to each other. Articulated arm

versions can be configured with 1 to 6 degrees of freedom (DOF). The following figures

show some possibilities as an example.

RL-P1 RL-T1

RL-01 RL-T1P1 RL-P1P1

Fig. 13: Articulated arms with 1 DOF Fig. 14: Articulated arms with 2 DOF

RL-01P1 RL-P1P1P1 RL-T1P1P1 RL-B1P1

Fig. 15: Articulated arms with 3 DOF

RL-0101 RL-B103 RL-T1P101 RL-T1P1P1P1

Fig. 16: Articulated arms with 4 DOF

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

RL-T10101 RL-T101P1P1 RL-B101P1

Fig. 17: Articulated arms with 5 DOF

RL-B10101 RL-B10301

Fig. 18: Articulated arms with 6 DOF, ordering key

The following technical data corresponds to the system examples shown (at 100 mm tube

length each):

DOF

Fig.

Version

LT

[mm]

(Stand.)

x1*)

[mm] x2*)

[mm] x3*)

[mm] x4*)

[mm]

x

tot

.

[mm]

*)

weight

[gr]

*)

max. stat.

load [N]

*)

max. dyn.

load [N]

*)**)

1

13

RL-T1(-E)

100 173

134

-

-

307

290

89 62

13

RL-P1(-E)

100 134

-

-

-

134

270

89 62

2

14

RL-01(-E)

100 202

134

-

-

336

400

89 62

14

RL-T1P1(-E)

100 207

134

-

-

341

535

89 62

14

RL-P1P1(-E)

100 173

207

134

-

514

555

33 15

3

15

RL-01P1(-E)

100 202

207

134

-

543

665

33 15

15

RL-P1P1P1(-E)

100 173

207

207

134

721

815

18 5

15

RL-T1P1P1(-E)

100 207

207

134

-

548

800

33 15

15

RL-B1P1(-E)

100 252

134

-

-

386

1.585

49 21

4

16

RL-0101(-E)

100 202

236

134

-

572

775

30 12

16

RL-B103(-E)

100 282

134

-

-

416

1.750

44 18

16

RL-T1P101(-E)

100 207

236

134

-

577

910

30 12

16

RL-T1P1P1P1(-E)

100 207

207

207

134

755

1.060

18 5

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

DOF

Fig.

Version

LT

[mm]

(Stand.)

x1*)

[mm] x2*)

[mm] x3*)

[mm] x4*)

[mm]

x

tot

.

[mm]

*)

weight

[gr]

*)

max. stat.

load [N]

*)

max. dyn.

load [N]

*)**)

5

17

RL-T10101(-E)

100 236

236

134

-

606

1.020

30 12

17

RL-T101P1P1(-E)

100 236

207

207

134

784

1.170

18 5

17

RL-B101P1(-E)

100 252

207

134

-

593

1.960

30 9

6

18

RL-B10101(-E)

100 252

236

134

-

622

2.060

29 8

18

RL-B10301(-E)

100 282

236

134

-

652

2.115

28 7,5

*) only applies to geometric configurations with standard tube length = 100mm

**) at 30 RPMs and 0.1 sec. ramp time

Table 1: Specification for articulated arms with 1-6 DOF

All articulated arms can be optionally equipped with angle sensors (=> Section - Angle

sensors). The shown end-plates (for rotating joints) or end-flanges (for 2 axes and swivel

joints) are not part of the delivery scope, but can be ordered as accessories.

When the articulated arm is equipped with a rotating joint, RL-50-TL1, in the first position,

the assembled wires already exit the arm in pairs.

Fig. 19: Dimensioned drawing for an optional mounting plate for the rotating joint, rotating

joint view from below

When the articulated arm is equipped with a 2 axes or a swivel joint in the first position,

the use of a wire splitting unit (RL-WSU8-001) is generally recommended starting at 3

DOF for a controlled distribution of the drive wires.

The 3D STEP data for all articulated arms is available for download at:

www.igus.de/robolink/support&service.

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Fig. 20: RL-WSU8-001 to connect an articulated arm with a 2 axes or swivel joint in the

first joint

Fig. 21: Dimensioned drawing for an optional mounting plate for the mounting component

RL-WSU8-001

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Angle sensors

robolink

®

sensors are magnetic incremental angle sensors. Each axis (DOF) has

(optional) one magnetic ring and one associated sensor chip. The magnetic rings are

specified as follows:

Swivel motion RL-50-xxx 31 pole pairs 1 additional south pole

Rotating motion RL-50-xxx 29 pole pairs 1 additional south pole

Swivel and rotating motion RL-90-xxx 29 pole pairs 1 additional south pole

Fig. 22: Magnetic rings - swiveling (1) and

rotating (2) for RL-50-xxx Fig. 23: Sensor unit for 2 axes joint

RL-50-001 /-002 /-003

Fig. 24: Installation situation of the sensor in the joint RL-50-001 /-002 /-003

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

The encoder from Austriamicrosystems (=> Spec sheet download at

www.igus.de/robolink/support&service ) determines 4x40=160 A/B signals per pole pair.

This permits the following resolutions per axis:

Number of pulses

/

chanel

Number of

signals

(Quadratur)

Resolution

Swivel RL-50-xxx 1.240 4.960 0,073°

Rotation RL-50-xxx 1.160 4.640 0,078°

Swivel / Rotation

RL90-xxx 2.480 9.920 0,036°

Fig. 25: A/B and index signals from the encoder

The resolution of the individual axis approximately corresponds to the following

positioning errors at the corresponding tube lengths:

Distance from center point (x) [mm] Positioning accuracy [mm]

200 0,24

400 0,49

500 0,61

Table 2: Positioning accuracy with angle sensors

Since the positioning errors for multiple axis are compounded, system designs have a

positioning inaccuracy, or repeatability accuracy of approx. 1-2mm for multi-axes systems

(depending on the number of axes and tube lengths).

The Hall Sensor Honeywell SS443A is used to reference the system (home position). It

has an Open-Collector-Output. This is designed for the connection to a TTL/CMOS-circuit

– the 10kΩpull-up-resistance exists on the board already.

If the output has to be adapted to a 24V-circuit (e.g. PLC), it is realizable e.g. with the

following circuit diagram with an optical coupler device. The components have to be

adjusted to the respective loads. For this case, a possible electrical configuration is shown

in Fig. 26.

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Fig. 26: Wiring the Hall sensors

Electrical circuit diagrams for the sensors are at www.igus.de/robolink/support&service .

Each joint axis must be reinitialized (homed) after a power failure.

Each axis (DOF) has 6 conductors. The corresponding strands are assigned as follows:

State

2012-08

producer igus

line name FIXFLEX

FF900.11.282

number of conductors 12

conductor cross section 0,09

line diameter [mm] 3,9

usage from 04.2012

pivoting movement

+5V red

GND black

Hall-Sensor white

Encoder Index green

Encoder Channel A blue

Encoder Channel B yellow

turning movement

+5V red/blue

GND brown

Hall-Sensor grey

Encoder Index grey/rose

Encoder Channel A violet

Encoder Channel B rose

Fig. 27: Cable definition - igus

®

sensor cables

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Actuators

It is possible to connect various actuators to the last connecting tube of the articulated

arm. We generally recommend a plastic adapter element for this. igus

®

GmbH already

provides standard adapter elements for pneumatic grippers from FESTO

®

and SCHUNK

®

,

for electrical grippers from GIMATIC

®

, and also for suction systems. Cameras or lighting

sources (e.g. LED) can also be adapted.

Fig. 28: standardized adaptable pneumatic grippers

Our own draw wire gripper from igus

®

GmbH can also be mounted on the tube. 2 versions

are possible:

1) Wire force opens, spring force closes,

2) wire force closes, spring force opens.

The spring force can be configured between 20 and 100 N.

(technical documentation of the gripper under design, status 08-2012)

Fig. 29: igus

®

electrical gripper RL-50-GRI-03-xx with standard (left) and universal jaws

(right)

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Draw wires

The construction kit components are generally driven by draw wires. Standard wires are

made from Dyneema

®

, 12-strand braiding, d=2mm, approx. 1.8 g/m, breaking strength >

3.500 N, operating elongation approx. 1%. A special coating ensures the best possible

service life and low friction.

The wires are installed and held in the joints and the drive (see Fig. 30) by means of wire

end nipples (wire end plate assembly instructions at the end of this chapter).

Fig. 30: Wire (2) with nipple (1) Fig.31 : assembled drive wire in a

tensionable drive wheel

The wire tension in an assembled robolink

®

system should be 5-10 N at idle. The joint has

(generally undesirable) play when the wire tension is inadequate. When the wire tension

is too high, the wire friction in the system and the service life of the wires are negatively

impacted. The tensionable drive wheels from igus

®

(see Fig. 25) are ideally suited for

adjusting the pretension in the draw wires. These come in two parts and can be easily

adjusted to the correct pretension by hand or with an igus

®

tensioning tool (instructions at

the end of this chapter). Readjusting the antagonistic draw wires is generally only needed

during initial operation (2-3 times) or after extended down-time.

The wire guidance for rotating motions is accomplished with Bowden cable segments

from igus

®

GmbH. For this application, the Bowden cables fulfill the following

requirements:

•high compressive strength up to max. 1,500 N wire tension force;

•continuous motion possible, because the segments are made from RN54 material;

•low bending radii, optionally as small as 30mm.

Fig. 32: igus

®

Bowden

cable Fig. 33: Bowden cable segments / schematic

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

All draw wire components are available for reorder from igus

®

GmbH as replacement

parts or as individual components. The article numbers are:

Wire: RL-SD02-01-xxxx xxxx = desired wire length in mm

Nipple: RL-SD02-SN01 2 parts, brass

Bowden cable: RL-SD02-BZ01-xxxx xxxx = Bowden cable length in mm

Tensionable

drive wheel RL-ZA011-0250-xx xx = shaft diameter of the drive

The following instructions for feeding robolink

®

wires must be observed:

•wires must never travel across sharp edges,

•surfaces that are in contact with moving wires should as flat as possible,

•maintain a bending radius of 30mm for wire deflections,

•always slightly pretension wires in robolink

®

systems (approx. 10N),

•inadequately tensioned wires result in undesirable play in the joint,

•excessively tensioned wires cause increased friction and wear,

•igus

®

GmbH recommends using tensionable drive wheels, RL-ZA011-0250-xx,

•igus

®

GmbH recommends using the igus

®

Bowden cable RL-SD02—BZ01 to feed

wires on sections that are not straight,

•whenever possible, feed wires in a straight line and in a free-floating manner

(minimize the use of Bowden cables),

•using deflection pulleys is only recommended for systems with low loads.

When multiple joints are arranged in series, the draw wires of the upper joint are fed

through the lower joint. In this case, the motion of the upper joint must be independent

from the motion of the lower joint. The 4 draw wires of the second joint are therefore fed

through the first joint in a Bowden cable.

In the current configuration, a maximum of 4 wires can be fed through the lower joint. This

is the reason for the limitation of the number of joints that can be arranged in series.

The following figures show how the wires are fed through a lower joint. This feed-through

is pre-assembled by igus

®

and is not assembled by the customer.

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Fig. 34: Two wire pairs are fed through the

lower joint Fig. 35: Upper connecting element for

guiding the wire

Fig. 36: Bowden cable segments for

parallel feed-through Fig. 37: Lower connecting element

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Mounting instruction cable end bottom

1) Overview of the neccessairy accessories

4)

Wetting w

ith Loctite Nr. 4204 (alt. 401)

(1) wire, (2) terminal block, (3) wedge

-

Wire end (with the insert wedge) must

necessarily be wetted with Loctite No. 4204 or

401 (“superglue”)

2) Threading the terminal block onto the wire

5) Mounting the terminal block on the

wedge

-

with a suitable device (pliers with suitable

opening), the terminal block has to be leaded on

the wedge,

-

cable shall not be damaged,

-

bring cable end bottom in the following end

position:

-

threading the terminal block onto the wire (1)

-

smaller diameter (2) of the terminal block first on the

wire, (larger diameter (3) shows for cable-end (4))

3) Insert the wedge into the rope

6) Remove protruding wire

-

Manually insertion of the wedge in the cable end

(with the tip first)

-

Insert wedge as centrally as possible in the rope

-

Insert wedge fully into the rope

-

If necessary / desired remove the overlap with a

scalpel

7) Control / end position

The tree should look after these steps as the

following:

State 25.01.12

!

d

rying time min. 90 minutes before us

e

!

strength/retention with Loctite 4204 > 1.900N

strength/retention with Loctite 401 > 1.400N

strength/retention without Loctite > 190 N

1

2

3

1

2 3

4

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Drive pulleys with integrated wire tightening

The igus

drive unit is equipped with new pulleys RL-ZA011-0250-xx (since July 2011).

They enable the user to tighten the wires for the robolink arm easily.

The tension of the wires can be adjusted individually:

If the tension is to low: the joint will have play (will bounce).

If the tension is to high: friction in the system will rise, all components will be

wearing faster

1. RL-ZA011-0250-xx (nominal diameter 50mm) 2.

unscrew the 3 screws for ~ 2 turns

3.

tighten the rope with the 3-pin-tool that

is delivered with the drive unit

4.

tighten the 3 screws again after that

All drive pulleys can be adapted to different motor shafts (res. gear shafts) by using

different adapter pieces. The following standard dimensions can be chosen from stock:

•RL-ZA011-0250-05 for shaft diameter 5 mm

•RL-ZA011-0250-06 for shaft diameter 6 mm

•RL-ZA011-0250-08 for shaft diameter 8 mm

•RL-ZA011-0250-08PFN for shaft diameter 8 mm (with feather key groove DIN 6885)

•RL-ZA011-0250-10 for shaft diameter 10 mm

•RL-ZA011-0250-10PFN for shaft diameter 10 mm (with feather key groove DIN 6885)

•RL-ZA011-0250-12 for shaft diameter 12 mm

•RL-ZA011-0250-12PFN for shaft diameter 12 mm (with feather key groove DIN 6885)

robolink

®

Joint kit – Documentation (#4; 2016-12)

igus

®

Step motors

Step motors from igus

®

are one possible drive option for wires. These are bipolar 2-phase

hybrid motors. The following options are available: NEMA17 and NEMA23 step motors

with M12 plug connectors or as strand conductors (cost effective alternative). Technical

documentation can be found in the technical spec sheet (download at

www.igus.de/robolink/support&service).

Tab. 3: Basic technical specs for step motors

Fig. 38: Connector versions:

MOT-AN-S-060-005-042-M-A-AAAA (NEMA17)

MOT-AN-S-060-020-056-M-A-AAAA (NEMA23)

Fig. 39: Strand conductor versions:

MOT-AN-S-060-005-042-L-A-AAAA (NEMA17)

MOT-AN-S-060-020-056-L-A-AAAA (NEMA23)

Other manuals for robolink

1

Table of contents

Other igus Robotics manuals