igus ReBeL User manual

Version 13.4-PRERELEASE

July 13, 2022

© Commonplace Robotics GmbH

1

CONTENTS

Contents

1 Introduction 4

1.1 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Target Group and Qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 System Overview 6

2.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Mechanical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Safety Instructions 8

4 Requirements 9

4.1 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Quick Start Guide 10

5.1 Set up and Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2 Switch On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.3 Connecting and moving the robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.3.1 Preparation with the integrated computer . . . . . . . . . . . . . . . . . . . . . . . 11

5.3.2 Moving the Robot for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Moving the Robot with iRC 14

6.1 The Graphical User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1.1 Selecting the type of robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1.2 Navigation and movement of the robot in the 3D view . . . . . . . . . . . . . . . . 16

6.2 Connecting the robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2.1 Hardware connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2.2 Move the robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.3 Referencing the robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.3.1 Step by step guide of referencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.4 Moving the robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.5 Starting robot programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.6 Digital inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.7 Software interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.8 Updating the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

©2022 igus® GmbH 1

CONTENTS

7 Programming a Robot with iRC 22

7.1 Program Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1.1 Changing the Command Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1.2 Touching Up Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.3 Set Start Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 Comments and Information within the Program . . . . . . . . . . . . . . . . . . . . . . . 24

7.2.1 Information about the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2.2 Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2.3 Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3 Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.1 Abort Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.2 Acceleration and Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.3 Joint Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.3.4 Linear Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.3.5 Relative Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3.6 Circular Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3.7 Set Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.4 Gripper and Digital In-/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.4.1 Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.4.2 Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.4.3 Opening/Closing the Gripper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.5 Program Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.5.1 Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.5.2 Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.5.3 Pause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.5.4 Wait . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.5.5 If-then-else . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.5.6 Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.5.7 Matrices / Palettizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.5.8 Subprograms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.6 Variables and Variable Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.6.1 User-defined Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.6.2 System Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.6.3 Accessing Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.6.4 Calculating with Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.6.5 Observing Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.7 Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8 Hardware Configuration 36

8.1 In-/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.1.1 Electrical Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.1.2 Software-Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.1.3 Connecting sensors and buttons at the base . . . . . . . . . . . . . . . . . . . . . . 38

8.1.4 Connecting sensors and buttons at the robot arm . . . . . . . . . . . . . . . . . . . 38

8.1.5 Connect actuator at the arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2 Motor Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.3 Motor control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

©2022 igus® GmbH 2

CONTENTS

9 Software Configuration 40

9.1 Project Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.1.1 Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.1.2 Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.1.3 Inputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.1.4 Virtual Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.2 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.2.1 PLC Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.2.2 Program Selection via Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.2.3 Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.2.4 CRI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.2.5 Camera Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2.6 Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.2.7 Cloud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.2.8 Secure Shell Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2.9 SFTP Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.2.10 Uninterruptible power supply (UPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.3 Advanced configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10 Modbus 51

10.1 Licensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.2 Configuration of the Modbus Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.3 TIA-Portal Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.3.1 Creating the Robot Data Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10.3.2 Inserting the Robot Communication FB . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.3.3 Data Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

10.4 Address Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.4.1 Coils and Discrete Inputs - 1 Bit, Read Only . . . . . . . . . . . . . . . . . . . . . . 54

10.4.2 Input Registers - 16 Bit, Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10.4.3 Holding Registers - 16 Bit, Read and Write . . . . . . . . . . . . . . . . . . . . . . . 57

10.4.4 Number and Position Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

10.4.5 Meaning of Enumeration Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

11 Maintenance 62

11.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

12 Troubleshooting 63

12.1 Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

12.2 Error Codes and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

12.3 Test Software Module Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

12.4 Support Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

©2022 igus® GmbH 3

1 INTRODUCTION

1.2 Intended Use

The intended use of the product is defined by the uses within the defined limits from the technical

data. The permissible electrical parameters and the defined permissible ambient conditions must be

observed in particular. These are specified in more detail later in this manual.

The intended use for this product can be found in the following section 3.

1.3 Target Group and Qualification

The product and this documentation are intended for technically trained professionals such as:

• development engineers

• plant designers

• assemblers/service personnel

• application engineers

Installation, commissioning, as well as operation is only allowed by qualified personnel. These are

persons who meet all the following requirements.

• have appropriate training and experience in handling motors and their control.

• know and understand the contents of this technical manual.

• know the applicable regulations

1.4 Symbols Used

All notes in this document follow a consistent form and are structured according to the following

classes.

,The WARNING notice alerts the reader to possible dangerous situations.

Disregarding a warning can possibly result in moderate injury to the user.

• Within a warning, this describes ways to avoid hazards.

ðThis note indicates possible incorrect operation of the product.

Failure to comply with this notice may possibly result in damage to this product

or other products.

1.5 Product Safety

The following EU directives were observed:

• RoHS-Directive (2011/65/EU, 2015/863/EU)

• EMV-Directive (2014/30/EU)

1.6 Regulations

In addition to this technical manual, operation, commissioning is subject to the applicable local reg-

ulations, such as:

• Accident prevention regulations

• Local regulations for occupational safety

©2022 igus® GmbH 5

2 SYSTEM OVERVIEW

2 System Overview

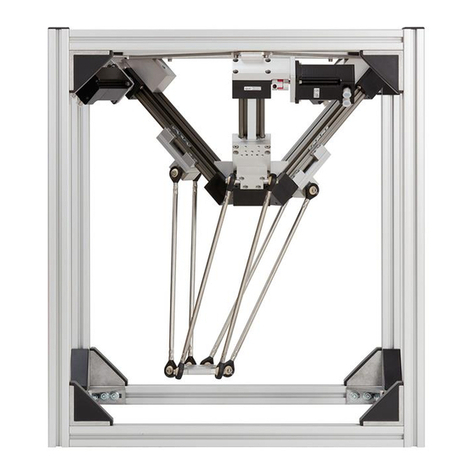

The robot controller described here is part of a robot system that consists of four basic components:

1. Robot: the mechanical robot arm

2. Robot control: modular robot controller consisting of embedded computer, motor driver mod-

ules for controlling the robot axes and IO modules.

3. Robot control software: Control software for moving the robot and executing robot programs.

4. Programming environment: Graphical software for setting up robot programs

The robot controller is used to control the movement of the robot’s motors. The robot controllers

are available with 48V motor voltage or 24V motor voltage. The stepper motor driver modules are for

bipolar stepper motors of different sizes and configurable, or preconfigured. For precise positioning

and control, quadrature encoder signals are normally read in, which feed back the actual motor or

axis position to the stepper motor driver modules. In addition, different referencing methods and

movements are supported to transmit the "actual position" of the robot to the software after a cold

start of the robot system. Different inverse kinematics are supported in the software, so that e.g.

controlled linear movements of a robot arm are as easy to program as those of a gantry robot.

2.1 Specifications

Modular Control Feature

Power supply 24V

Type DIN rail modules with 5-pole bus connector

Communication with PC/PLC CRI or Modbus via Ethernet

Internal communication CAN

Joint modules Closed Loop motor modules

absolute encoder

integrated brake

Digital IO module in the base: 4 digital inputs

in the robot arm: digital 2 inputs and outputs

solid state relay, max 500 mA

Table 2: Modular Robot Control - Components

The features of the embedded control can be seen in the table 3.

Embedded control Features

Type Single board computer with daughter module

Operating system Linux based

Software TinyCtrl robot control software

Interfaces CAN Bus (connection to the modules)

Ethernet (connection to Windows PC)

USB

©2022 igus® GmbH 6

2 SYSTEM OVERVIEW

Embedded control Features

RS232 display connection

Digital inputs for enabling switch

DC/DC converter 5V/4A

Table 3: Integrated Computer - Specifications

2.2 Mechanical Dimensions

For mechanical dimensions, please refer to the data sheet of the ReBeL.

©2022 igus® GmbH 7

3 SAFETY INSTRUCTIONS

3 Safety Instructions

,Operate the robot carefully!

When operating a robot arm or commissioning a robot cell, always pay attention to the

personal safety of the users and other persons! In particular, there must be no persons

or obstacles in the working area of the robot.

• In the basic version, the robot control package does not contain any safety-related functions.

Depending on the application, these may have to be added. See also "CE marking" below.

• CE marking: The robot arm and robot controller are part of a system that must be risk assessed

in its entirety and comply with the applicable safety regulations to ensure personal safety. De-

pending on the outcome of the assessment, other safety components may need to be inte-

grated. These are usually safety relays and door switches. The engineer commissioning the

system is responsible.

• Depending on the equipment, the robot controller contains one or more 24V or 48V power

supplies up to 10A, which themselves require mains voltage (120 V / 240 V) depending on the

configuration. Please check the label on the power supply. Only qualified personnel may con-

nect the power supply to the mains and put it into operation.

• Work on the robot electronics should only be performed by qualified personnel. Check the

guidelines for electrostatic discharge (ESD).

• Always disconnect the robot controller from the mains (120 V / 240 V) when working in the

control cabinet or on electronics connected to the robot controller.

• DO NOT hot plug! This can cause permanent damage to the motor modules. Do not install

or remove any modules or connectors (e.g. manual control unit, emergency stop switch, DIO

modules or external relays, motor connections...) while powered up.

• The robot arm must be set up on a robust surface and screwed down or otherwise secured.

• Use and store the system only in a dry and clean environment.

• Use the system only at room temperature (15° to 32°C).

• The ventilation of the system must be able to work unhindered to ensure sufficient air flow for

cooling the stepper motor modules. There must be at least 10 cm of space next to the fan of the

robot controller. The fan must ideally point upwards or to the side (reduced efficiency). The fan

must not point downwards.

• Save important data before installing the iRC - igus Robot Control.

©2022 igus® GmbH 8

4 REQUIREMENTS

4 Requirements

4.1 Environmental Conditions

Ambient conditions Wert

Protection class IP20

Ambient temperature (operating) +10. . . +32°C

Ambient temperature (storage) -10. . . +85°C

Humidity (non-condensing) 0. . . 90%

Installation height above sea level (without power restriction) 1500m

Table 4: Ambient conditions

4.2 Software Requirements

To use iRC a computer with the following features is required:

• PC (min. Intel i5 CPU) with Windows 10 or 11 (64 Bit)

• .NET Framework 4.7.2 or newer

• at least 500MB free disk space

• graphics card (integrated or dedicated)

–OpenGL 3.0 or newer

–manufacturer driver (the standard Microsoft driver is not supported)

• a free Ethernet port

©2022 igus® GmbH 9

5 QUICK START GUIDE

5 Quick Start Guide

5.1 Set up and Connect

,Before Starting the Work

To avoid injuries as well as damage to the components, observe the following

instructions:

• Follow the safety instructions in section 3.

• Disconnect the robot or the controller from the mains. Never work on

live parts. Work on control cabinets may only be carried out by qualified

electricians.

• No hot plugging! Before plugging in or disconnecting modules/plugs/-

electrical connections, disconnect the controller/robot from the mains.

• Ensure a safe stand of the robot and the controller.

• Observe the requirements for the environment 4.1.

• During the movements of the robot, no persons may be in the working

area of the robot.

To set up and commission the robot, proceed in the following order:

1. Make sure that the controller is disconnected from the power supply: Unplug the power cord.

2. Mount the robot on a suitable base. Make sure that the cables are not under tension.

3. Feed the robot cables through the large circular hole in the control cabinet and plug them into

the stepper motor modules. Each motor with its associated reference sensor is connected to

its stepper motor module via 4 connectors (see Fig. 3). All connectors are labeled and coded to

support this process. The following cables each belong to a motor the affiliation between motor

and cable set is also numbered on the connectors:

• motor cable (with the designation motor)

• encoder cable (2 connectors labeled ENC-1 and ENC-2)

• reference sensor (labeled End-Stop)

4. Connect the shield and ground wires of the encoder and motor cables, if present.

• motor cable ground: green-yellow

• encoder shield (ground): black

5. All motor and encoder cable ground wires are plugged into the ground block next to the con-

troller.

6. Secure the robot cables against voltage, e.g. with a cable tie to one of the holes in the control

cabinet. If present, plug in the teach pendant cable and secure it via the screw connection.

7. The robot is ready to be switched on after completing these steps.

©2022 igus® GmbH 10

5 QUICK START GUIDE

5.2 Switch On

,Danger of Electric Shock! Before commissioning the components, make sure

that all cables and control cabinet components are properly connected. Check

all cables for tight fit and make sure that there are no loose cables in the control

cabinet.

1. Connect the robot to your power supply using the enclosed power cable.

2. Switch on the robot using the On/Off switch on the control cabinet.

3. The green light emitting diodes (LEDs) on the modules will now light up, as will most of the red

LEDs and possibly some of the yellow LEDs.

4. After the control computer has finished booting (after about 60s), the green LEDs will start

flashing. This indicates communication with the modules. Now the robot controller is in oper-

ation. If available, you can now move the robot via the optional handheld operating device (see

section ??).

5.3 Connecting and moving the robot

5.3.1 Preparation with the integrated computer

The following steps establish the LAN connection between the robot controller and the Windows PC.

1. Connect your PC to the robot controller using an Ethernet cable. Use the Ethernet port located

right next to the USB socket on the integrated computer of the robot.

2. Set the IP address of the PC to: static and 192.168.3.1 with a subnet mask of 255.255.255.0.

Instructions for changing the IP address of your computer can be found on the Internet under

the keyword "Change IP address Windows 10"..

5.3.2 Moving the Robot for the First Time

1. Install the iRC software on your PC.

2. Start the iRC software. At startup, you can select the project that applies to your robot. Please

refer to the product number or product name, the project names are based on these (see Fig.

1).

3. You can now activate the robot by pressing the following buttons in the given order (see also

Fig. 2):

3.1 "Connect"

3.2 "Reset"

3.3 "Enable"

4. Now the status LED light on the left in iRC should be green and the status should show "No

Error".

5. You can now move the robot’s joints using the buttons on the "Jogging" tab (see Fig. 2).

©2022 igus® GmbH 11

5 QUICK START GUIDE

Figure 1: Choosing a project

Figure 2: Jog Commands

©2022 igus® GmbH 12

5 QUICK START GUIDE

ðCartesian movements and programs

For the use of Cartesian commands and the playing of robot programs a refer-

encing of the robot is mandatory.

©2022 igus® GmbH 13

6 MOVING THE ROBOT WITH IRC

6 Moving the Robot with iRC

iRC - igus Robot Control is a control and programming environment for robots. The 3D user interface

helps to get the robot up and running quickly. Due to the modular structure, different kinematics and

motor drivers can be controlled.

6.1 The Graphical User Interface

This section explains the iRC software. All steps can be simulated even without a robot connected. In

section 6.2 the real robot is then connected and moved.

The programming environment iRC enables the control and programming of the robot. You can work

both online and offline, i.e. with the robot or in simulation (with the robot switched off or not con-

nected).

Figure 3: User interface of the iRC - igus Robot Control

In the upper left corner, the three tabs "File", "Scene", "Motion" and "Help" provide access to the

main functions. In the left corner, information about the current state of the physical robot is dis-

played. Additional functions like loading another project ("Open Project") or "Robot Referencing"

can be found in the "File" tab (see Fig. 3).

There are seven tabs at the bottom of the window:

• "Log messages": Messages from the program about status or errors.

• "Infocenter": displays the axis values, Cartesian position and other information.

• "Jogging": keys to move the robot.

• "Input/Output": Display and set the DIO interfaces of the robot controller.

©2022 igus® GmbH 14

6 MOVING THE ROBOT WITH IRC

• "Programs & Variables": displays the current values of the program variables.

• "Cameras": Images of the connected cameras and detected object positions.

• "Statistics": Statistics about the system and the running robot program.

The "Help" icon in the lower right corner contains links to the wiki pages ("Online Doc-

umentation", "Software Updates", "Examples", "Troubleshooting") and a link to "Con-

tact Support". The log files of iRC and the integrated controller can also be accessed

here.

6.1.1 Selecting the type of robot

iRC provides project-related settings for different robot types, such as gantries, robot arms or delta

robots. Figure 4 shows the project open area, which can be used to load the corresponding project.

1. Click on the "File" tab in the upper left corner and select "Open Project".

2. Select the robot group, e.g. "robolink".

3. Make sure that the parameter set matching the operating voltage of the robot is selected. This

will affect the speed and acceleration.

4. Now click on the entry that matches your robot, e.g. RL-DP-5.

Figure 4: Selection of the robot type via the menu item "File" →"Open Project"

©2022 igus® GmbH 15

6 MOVING THE ROBOT WITH IRC

6.1.2 Navigation and movement of the robot in the 3D view

A 3-button mouse is recommended for navigating in the iRC - igus Robot Control 3D environment:

• Left button:

–Selecting icons and functions in the menu.

–Moving a robot axis: Place the cursor over a joint (it will be highlighted), then click and

move the cursor up and down while holding down the left mouse button.

• middle button/mouse wheel:

–Navigate the scene to rotate the robot: Move the cursor while holding down the middle

mouse button.

–Mouse wheel rotation: Zoom in/out to the current cursor position.

• Right button: move the image section.

The function of the left mouse button can be changed

in the "Scene" tab under "Navigate". The movement

options "Select", "Move", "Rotate" and "Zoom" are

available. "Reset" returns you to the home screen.

6.2 Connecting the robot

6.2.1 Hardware connection

The real robot can be controlled in the same way as the simulated one, only the hardware must first

be connected and activated by clicking the "Connect", "Reset" and "Activate" icons in the "Physical

Robot" button group in the "Motion" tab (see Fig. 5). After that, the robot must be referenced.

Figure 5: Buttons for connecting to the hardware, resetting errors and activating the motors, refer-

encing and "Status" display.

1. "Connect": Establish the connection to the hardware.

• This initializes the connection (mostly via Ethernet, in some cases via USB CAN adapter).

• The "Status" indicator on the left side changes from gray to red.

• Several error messages are displayed below the "Status" indicator.

2. "Reset": Resets the errors.

• This key is used to reset the error memories of the electronic modules of the robot con-

troller.

©2022 igus® GmbH 16

6 MOVING THE ROBOT WITH IRC

• The axis positions are transferred from the real robot to the simulation environment. The

3D visualization of the robot should now correspond to the current position of the real

robot.

,This must be checked with every error reset! If the values do not match,

referencing must be performed, which is described in section 6.3.

• The "Status" display remains red. The error messages are cleared, only "Motors not en-

abled" remains. If other error messages are displayed, try again and follow the instructions

in the robot documentation.

3. "Activate": Activation of the motors.

• The "Status" indicator is now green.

6.2.2 Move the robot

It is now possible to move the robot using the jog keys, a mouse in the user interface or a gamepad,

see section 6.4.

6.3 Referencing the robot

,• After startup, the robot must be referenced. Before referencing, the robot’s axes

can only perform motions in joint mode. This is to avoid collisions during unref-

erenced robot operation.

• Cartesian movements or the start of a program are only possible after referencing.

• The status is displayed on the left side of the iRC - igus Robot Control.

The motor modules store the position in an EEPROM. However, due to gravity or other forces, the axes

may move when the motor power is switched off. In this case, the motor modules no longer report

the correct position to the software. In order to synchronize the position between software, stepper

motor module and robot axis, referencing must be performed.

6.3.1 Step by step guide of referencing

1. Start the robot controller and the iRC - igus Robot Control.

2. Press the buttons "Connect", "Reset" and "Activate" (see fig. 5).

3. Click the "Reference" button (Fig. 5) in the button group "Physical Robot" in the "Motion" tab

(or "Robot Reference" in the "File" tab) to open the referencing window.

4. Click on the "Reference Axis" buttons to start referencing an axis, see Fig. 6. Multiple joints can

perform referencing in parallel.

5. You can also click on "Reference all", then the axes will start referencing in an order defined in

the project file.

6. Once all movements have been executed and the robot is at rest again, click on "Reset" and

"Activate". Now the robot is fully functional.

©2022 igus® GmbH 17

6 MOVING THE ROBOT WITH IRC

Figure 6: Referencing of the axes.

6.4 Moving the robot

The robot can be moved manually (or "jogged") when no program is running. The following options

are available for this purpose:

• Software keys

• dragging joints in 3D area

• gamepad

The most important settings can be found in the "Movement" tab (see Fig. 7):

• "Input": Connecting a gamepad

• "Motion parameters": Selection of movement modes and speed

Figure 7: Control panels for moving the robot (highlighted in blue).

A gamepad is possibly the most intuitive way to move the robot. The fig. 8 shows the key assignment.

Pressing "Connect Gamepad" will connect iRC to a gamepad. If the connection is successful, an OK

sign will be displayed under the icon. The device must be of type "Joystick" or "Gamepad". For more

information about the connection, see the "LogMessages" tab (at the bottom of the window area).

©2022 igus® GmbH 18

Table of contents

Other igus Robotics manuals

Popular Robotics manuals by other brands

Kuka

Kuka KR 350 Installation & connection manual

AC Air Technology

AC Air Technology T1V2 instruction manual

Kuka

Kuka VisionTech 2.1 manual

Mitsubishi Electric

Mitsubishi Electric MELFA RV-2SD Standard Specifications Manual

Mindsets

Mindsets BCE 003A instructions

Patton Robotics

Patton Robotics ESRA II Assembly and operation instructions