Safety Precautions

• The LS-12000E fixture has been designed for professional use and must be operated by qualified personnel only.

• Electrical Connections: Do not attach the ballast directly to any electrical mains.

• The 12000/6000 Watt Electronic Ballast can only be used with a Lightstar 12000 watt or 6000 watt light fixture.

• Before connecting the electronic ballast to the power supply, make sure that the socket is correctly wired.

• Lamp head must be disconnected from the electronic ballast or electronic ballast must be disconnected from main power supply before fitting or

replacing a lamp or bulb.

• The electronic ballast must be switched off before connecting or disconnecting either head to ballast cable or power supply cable.

• The electronic ballast must be placed only on a solid, flat, and dry ground. Do NOT place the electronic ballast in direct sunlight. Do NOT operate the

electronic ballast in high humidity areas or near easily flammable materials.

Working Conditions

• The MAX ambient temperature limit is ±45°C (113°F)

• Please keep a minimum distance of 2 feet when close to inflammable objects.

• Do not cover the ventilation holes on the fixture housing. They are necessary for proper ventilation.

• Use only original parts and accessories from Lightstar.

• Before hanging the fixture, make sure the suspension points are properly rated to handle the weight of the fixture.

• It is ALWAYS advisable to add a safety cable or chain through the yoke to properly suspend the fixture in place.

WARNING: DO NOT USE THE FIXTURE IN A SPACE WITH FLAMMABLE SUBSTANCES.

WARNING: UV RISK / HEALTH RISK. THE LAMPS USED WITH THE LS-12000E EMIT AN AMOUNT OF UV RADIATION WHICH CAN BE

DANGEROUS TO HUMAN HEALTH IF NOT PROPERLY SHIELDED AGAINST.

THE FIXTURE MUST NEVER BE USED IN SITUATIONS WHEN DIRECT LIGHT EMISSIONS FROM THE LAMP CAN OCCUR. (Ex: No front

glass, no intentional mirror, damaged front housing).

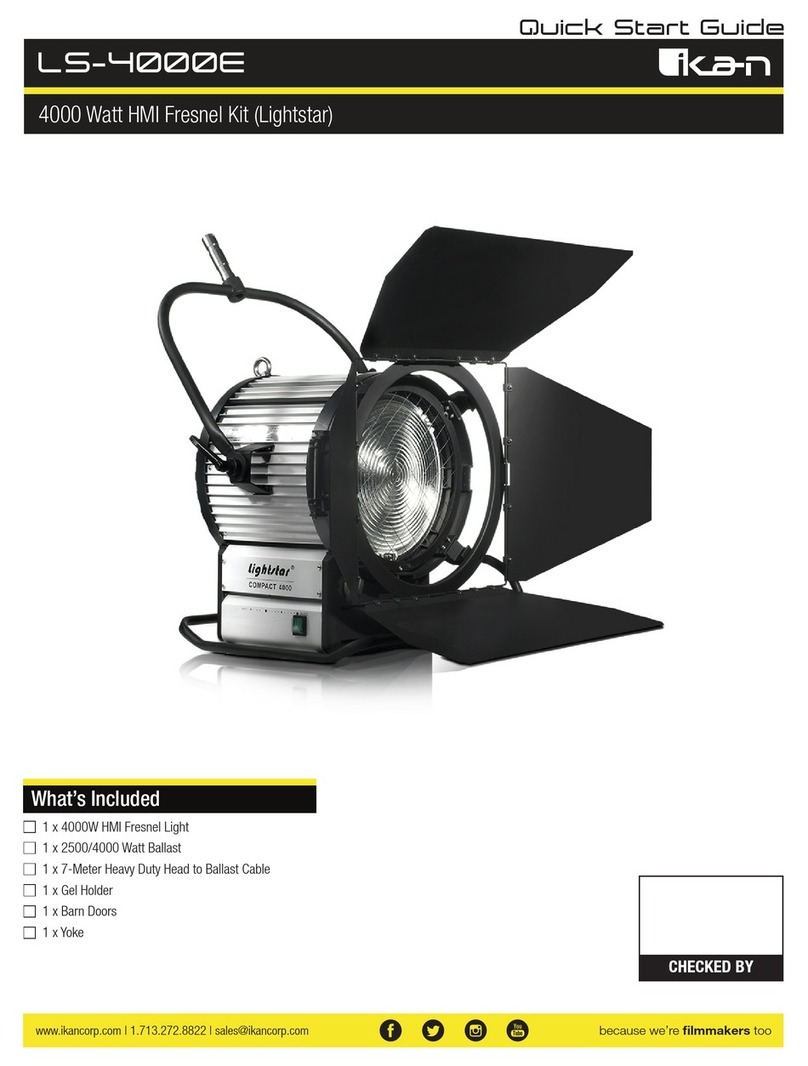

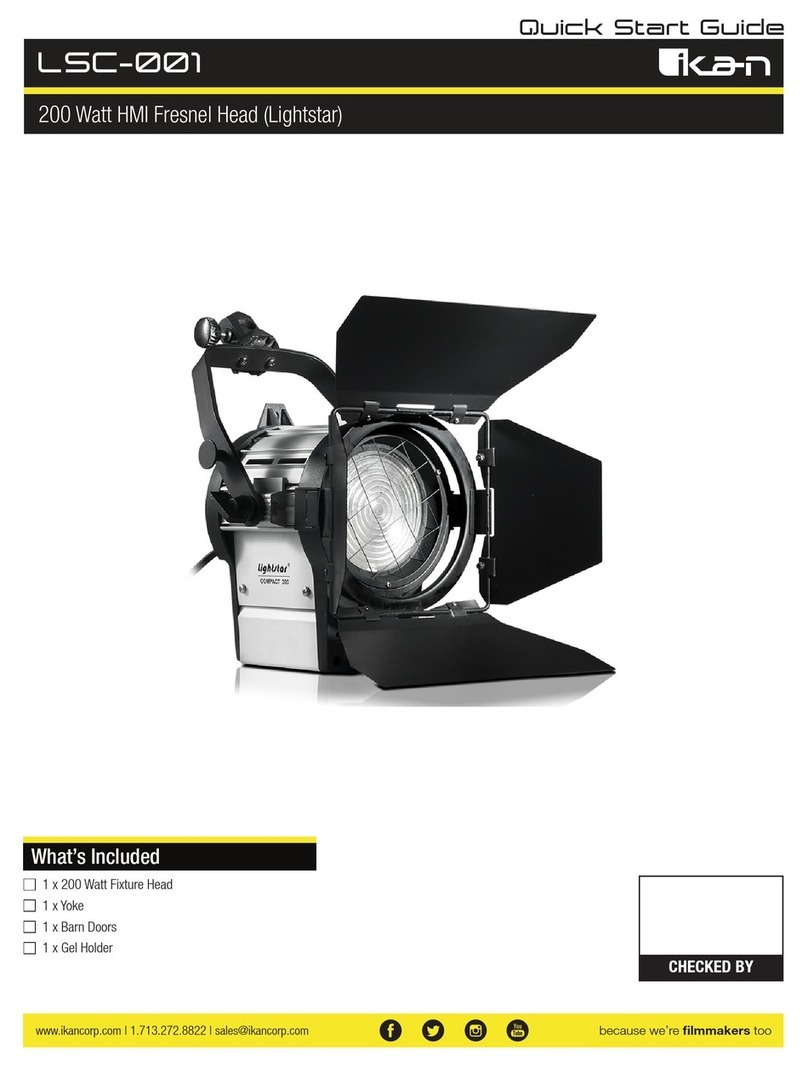

Lamp Installation & Replacement

• Ensure the fixture is disconnected from the main power supply.

WARNING! LAMP WILL STILL BE HOT TO TOUCH EVEN AFTER THE ALLOTED LAMP REST PERIOD.

THERMAL GLOVES ARE RECOMMENDED FOR WORKING WITH THE FIXTURE AND THE BULB.

• Check to see that the new lamp is the correct wattage.

• Release the lamp clamp level inside the front of the fixture.

• To replace the lamp pull up and out to remove the old lamp.

• Re-tighten the lamp clamping device.

Re-clamp procedures: DO NOT TOUCH THE BULB WITH YOUR BARE-HANDS. This can cause oil to accumulate

on the glass and reduce the performance of the lamp life. The plastic/foam cover which protects the lamp should

NOT be removed until after the lamp is fitted into the fixture. If bulb becomes dirty due to hand contact or foam

contaminant, it can be cleaned with a cloth moistened with alcohol.

• Close the lens door and secure latch.

Ikan is the exclusive distributor of Lightstar products in the United States.