6. Maintenance

9

Properlymaintained,theHAKKO474desolderinggunshouldprovideyearsofgoodservice.

Efcientdesolderingdependsuponthetemperature,andthequalityandquantityofthesolderandux.Per-

formthefollowingserviceproceduresasdictatedbytheconditionsofthegun’susage.

WARNING :

Sincethedesolderingguncanreachaveryhightemperature,pleaseworkcarefully.

Exceptwhencleaningthenozzleandheatingelement,alwaysturnthepowerswitchoffanddiscon-

nectthepowerplugbeforeperforminganymaintenanceprocedure.

Servicing the Desoldering Gun

CAUTION

Thedesolderinggunwillbeextremelyhot.

Duringmaintenance,pleasewearglovesand

workcarefully.

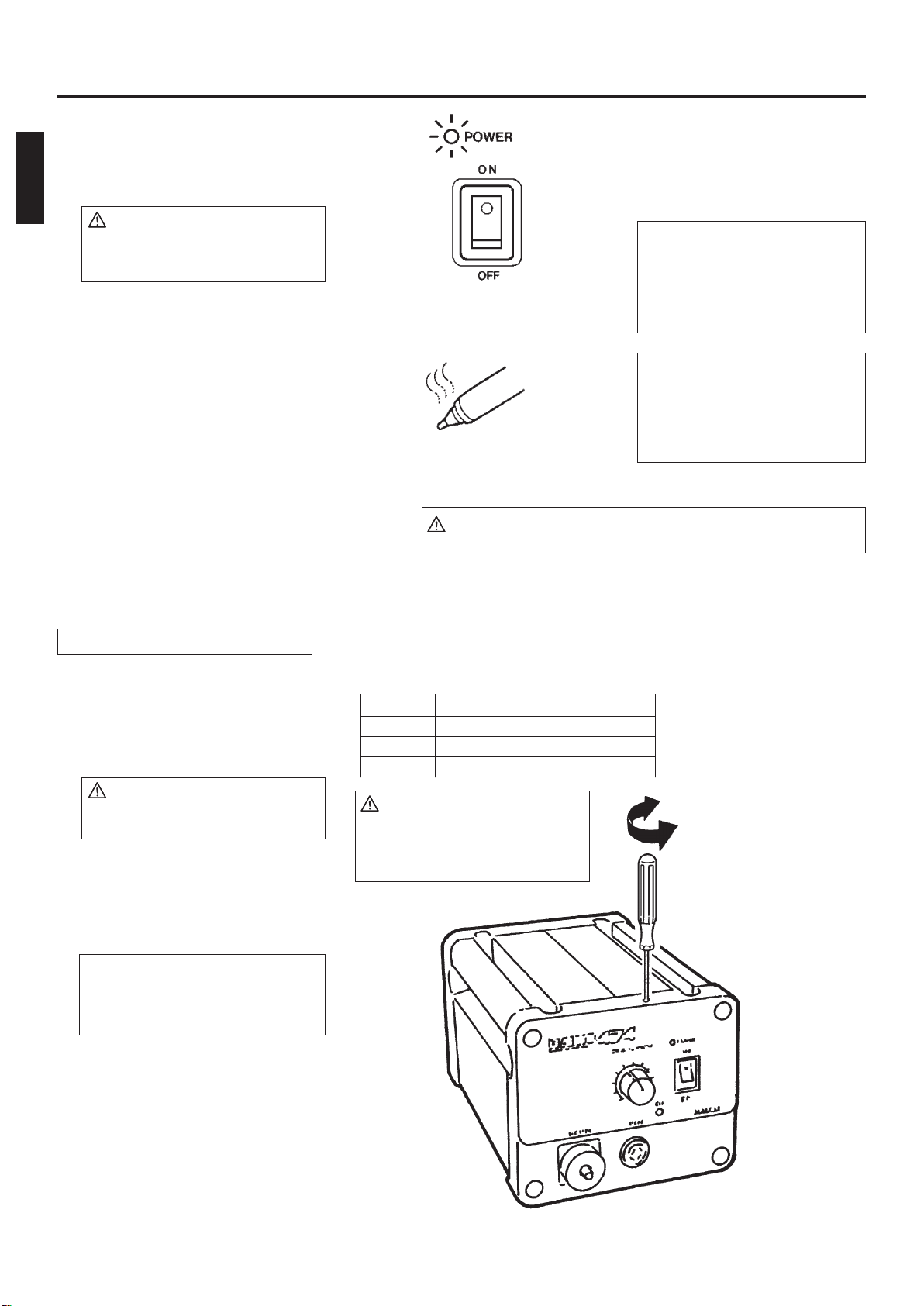

1. Inspect and clean the nozzle.

• Pluginthepowercord,turnthe

powerswitchOnandletthenozzle

heatup.

• Cleanouttheholeofthenozzle

withthenozzlecleaningpin.

CAUTION

Thecleaningpinwillnotpassthroughthe

nozzleuntilthesolderinsidethenozzleis

completelymelted.

• Ifthecleaningpindoesnotpass

throughtheholeinthenozzle,

cleanwiththecleaningdrill.

• Checktheconditionofthesolder

platingonthetipofthenozzle.

• Ifitisslightlyworn,recoatthetipwith

freshsoldertopreventoxidation.

• Checktheconditionofthesurface

andinsideholeofthenozzle.

• Ifeitheriswornoreroded,orthe

insidediameterseemsunusually

wide,replacethenozzle.

CAUTION

Theinsideholeandthesurfaceofthe

nozzleisplatedwithaspecialalloy.

Shouldthisalloybecomeerodedbyhigh-

temperaturesolder,thenozzlewillnotbe

abletomaintainthepropertemperature.

2. Disassemble the heating

element.

CAUTION

Theheatingelementisveryhotduring

operation.

3. Clean out the hole in the

heating element with the

provided cleaning pin.

CAUTION

Besurethesolderintheholeintheheat-

ingelementiscompletelyheated,before

cleaningthehole.

• Ifthecleaningpincannotpass

throughthehole,replacetheheat-

ingelement.

• Turnthepoweroffaftercleaning.

Cleaning with the nozzle cleaning pin

Cleaning with the cleaning drill

•Beforecleaning

•Aftercleaning

Solderplating

Diameterofholeiswid-

enedthrougherosion.

(DesolderingGun)

Thecleaningpinpassescom-

pletelythroughthehole.

Insertthebitwhileturningitclockwise.

Pullthedrillbitoutstraightwithoutturningit.

CAUTION

Ifthecleaningdrillisforcedintothenozzle,

thedrillbitcouldbreakorbedamaged.

CAUTION

Pleaseusethepropersizecleaningpinor

cleaningdrillforthenozzlediameter.

CAUTION

Unfortunately,itisoftendifculttoobserve

thiscondition.Therefore,ifdesoldering

efciencygoesdownandallotherparts

appeartobeOK,thenozzleisprobably

erodedandshouldbereplaced.

HeatingElement ElementCover

Nozzle Nut

Removethenutwiththeattachedwrench.

Scrapeawayalloxidationfromtheholeintheheatingelementuntilthe

cleaningpinpassescleanlythroughthehole.

Thecleaningpinpassescleanly

andcompletelythroughthehole.

English