Imesa ECC User manual

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

1

HOW TO REPLACE

A “ECC” CONTROL BOARD WITH

A “IM7” CONTROL BOARD

TUMBLE DRYER “E” SERIES

MOD. 10/14/18/23/34 Kg

FROM MARCH 2002 SERIAL NUMBER E200912064

IMESA S.p.A.

Via degli Olmi 22

31040 Cessalto (TV), Italia

tel. +39.0421.468011

fax +39.0421.468000

www.imesa.it

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

2

INDEX:

1. MANUAL CONTENTS...........................2

2. SAFETY RULES....................................2

3. MANUFACTURER LIABILITY...............3

4. NECESSARY TOOLS............................3

5. COMPOSITION OF THE KIT.................4

6. 2950SCHEDESS_01 INSTALLATION

OF ELECTRONICS PART............................4

7. INSTALLATION OF THE KIT

K2950SCHEDESS_01 –ECC/IM7 CABLING

(6141102X)...................................................7

8. INSTALLATION OF THE KIT

K2950SCHEDESS_01 –CONTACTORS

CONNECTION..............................................9

9. KEYPAD AND DISPLAY

INSTALLATION..........................................10

10. INSTALLATION OF THE

K2950SCHEDESS_02 KIT –COIN

OPERATED DRYERS................................12

11. ELECTRIC DIAGRAMS -

CONVERSION CABLING ECC/IM7

6141102X....................................................14

12. ELECTRIC DIAGRAM OF IM7

CONTROLLED DRYERS...........................15

1. MANUAL CONTENTS

The received kit can be installed in tumble

dryers “E” series, capacity: 10/14/18/23/34

Kg.

This instructions are valid for machines

produced starting from March 2002 until the

serial number E200912064 (December

2009), which were originally equipped with an

ECC –ENTITY control board.

This kit is necessary to update the dryer with

the latest IM7 microprocessor, which has

replaced the old electronic timer since

January 2010.

This document complies with the European

Community Directives in force.

The here written information are addressed to

the technician, who must be sure to fully

understand them before to service the

machine.

These instructions must always be available

for consultation. In case of lost or damage,

please ask to the manufacture for a new

copy.

The manufacturer is not responsible for

consequences arising from the improper use

of the new device installed due to missing or

incomplete reading of this manual.

The manufacturer reserves the right to

change the specifications mentioned in this

manual or the characteristics of each

machine.

Some illustrations in this manual may be

partially different from those assembled on

the machines. Diagram and technical data

may be modified without any previous notice.

The manual, its attachment and this

instruction are part themselves of the

machine, they must be stored near the

machine and follow the machine in case of

sale to another user or technician.

2. SAFETY RULES

Ignoring the following safety rules can cause

damages to people, things and animals.

The installation and maintenance of the here

described component must be performed by

authorized personnel who knows the product

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

3

and in compliance with European standards

on the installation and repair of industrial

machines.

The here describe tumble dryer must be used

for a professional drying of garment and

linen.

Any other use is forbidden if not previously

authorized in written by the manufacturer.

Do not introduce into the machine items other

than the one to be dried. Linen to be dried

must not have been in contact with

hazardous material such as explosives,

detonating and inflammable. In this case the

linen must be rinsed, aired or partially dried.

It is forbidden to dry linen soaked with

substances manifestly dangerous for the

operator health, such as poison or

carcinogenic products.

Do not approach the machine with

combustible or flammable material in order to

avoid the risk of fires and explosions.

Always stick to the drying instructions on the

linen.

The use of the machine is forbidden for

people under 14 years age.

Additional external connection to the

machine, if not duly performed, release the

manufacturer from any responsibility.

These instructions do not cover all

possible risks. User must always pay

high attention and respect carefully the

rules.

3. MANUFACTURER LIABILITY

The instructions written in this manual are not

replacing, but completing the duties deriving

from the safety and accident prevention laws.

With reference to what is written in this

manual, the manufacture is not responsible

for:

Use of the machine not in compliance

with the EU law in matter of safety

and accident prevention.

Wrong machine installation.

Missing of the ordinary and scheduled

maintenance.

Disregarded or not correct application

of the instruction written in the

manual.

difetti di tensione e di alimentazione

di rete.

Not authorized modifications to the

machine.

Machine used by not authorized

personnel.

Not correct installation of the kit.

4. NECESSARY TOOLS

The below listed tools, necessary to install

this kit, are not supplied with this kit, as they

are part of a standard technician kit.

Cordless screw gun;

Cross headed insert;

TORX T30 and T40 screwdriver or insert

for screw gun;

Key No. 8 and No. 10;

Drill insert 5,5 mm diameter;

Stepladder.

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

4

5. COMPOSITION OF THE KIT

The here described kit is available in two

versions:

- Standard with extension “_01”;

- Coin-op with extension “_02”.

- K2950SCHEDESS_01 (standard)

ITEM

DESCRIPTION

Q.TY

6111105B

ES 10/34 IM7 box wiring

1

4141103X

ECC>IM7 Keypad std

1

2141141

ECC>IM7 Keypad support

1

2950DISESIM7

IM7 Display board

1

2950DISTA015

Rounded spacer

Nylon F/F L=15mm

4

4936RGZ10X30

Washer Fe 10x30x2.5

ZINB

4

4936DAF003M

Self-Locking Nut

DIN 982 M3 ZINB

4

6141102X

Wiring to convert

ECC –IM7

1

2950SENSOPT1

Temperature Probe

PT1000 Class B

1

6110807X

Flat Cable IM7>Display

10-20 PIN ES 10/34

1

1936FERCAVNY

Cable Fastener in Nylon

Richco

3

4936VITBO516

Screw TBEI INOX M5X16

4

4936RPZ0005M

Washer Fe 5 ZINB

4

4936DAFA005M

Self-Locking Nut

Din 982 M5 Zinb

4

2950CONMA02V

Two ways male connector

Mate-N-Lock

1

2950GU643TER

Shrinkt Tubing D.6,4/4,2

NE

50 cm

4936FASSN14B

Clamps NB 14B

1

2950FASCV140

Cable Tye 140x2.5 Cod.

CV –140S

10

2950GVS15018

Silicon tube

140x2.5cod.CV-14S

10 cm

2950MORSP025

Borne Mammuth 2 ways

2

4936VAN3913Z

Self-Treating Screw

ZN 3,9x13 UNI 7981

3

E100301X_ENG

IM 7 User notice

1

E141203X

These instructions

1

- K2950SCHEDESS_02 (Coin Op)

ITEM

DESCRIPTION

Q.TY

6111105B

ES 10/34 IM7 box wiring

1

4141102X

ECC>IM7 Keypad Coin

1

2141141

ECC>IM7 Keypad support

1

2950DISESIM7

IM7 Display board

1

2950DISTA015

Rounded spacer

Nylon F/F L=15mm

4

4936RGZ10X30

Washer Fe 10x30x2.5

4

ZINB

4936DAF003M

Self-Locking Nut

DIN 982 M3 ZINB

4

6141102X

Wiring to convert

ECC –IM7

1

2950SENSOPT1

Temperature Probe

PT1000 Class B

1

6110807X

Flat Cable IM7>Display

10-20 PIN ES 10/34

1

1936FERCAVNY

Cable Fastener in Nylon

Richco

3

4936VITBO516

Screw TBEI INOX M5X16

4

4936RPZ0005M

Washer Fe 5 ZINB

4

4936DAFA005M

Self-Locking Nut

Din 982 M5 Zinb

4

2950CONMA02V

Two ways male connector

Mate-N-Lock

1

2950GU643TER

Shrinkt Tubing D.6,4/4,2

NE

50 cm

4936FASSN14B

Clamps NB 14B

1

2950FASCV140

Cable Tye 140x2.5 Cod.

CV –140S

10

2950GVS15018

Silicon tube

140x2.5cod.CV-14S

10 cm

2950MORSP025

Borne Mammuth 2 ways

2

4936VAN3913Z

Self-Treating Screw

ZN 3,9x13 UNI 7981

3

6111123X

Additional Cabling IM7 for

Coin box

1

E100301X_ENG

IM 7 User notice

1

E141203X

These instructions

1

6. 2950SCHEDESS_01 INSTALLATION

OF ELECTRONICS PART

Before to service the machine, it must be

completely switch off and the temperature

must be the room temperature. Suppling

cable must be disconnected from the plug

and from the electric board. Compressed

air and gas supply, if provided, must also

be disconnected.

a) Open the above frontal cover, open the

filter door, remove the above cover (if

present), remove the back panels;

b) The ECC board is placed inside the

programmer box, together with the display

and the keypad.

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

5

Before to remove the ECC box, label the

male connectors (the ones with the cables)

as shown below:

ATTENZIONE

JP9 and JP11 are both 12 ways

connectors. To distinguish between one

and the other connector, check where the

door sensor back cable is addressed. The

door sensor is contained only in the JP11

connector. To check the detailed list of the

connectors, see last paragraph of this

instructions.

c) Remove the programmer box from the

above room. It is fixed by three self-drilling

cross headed screws: two at the base, on

the above bracket.

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

6

d) Remove the wiring plastic ring support

(new supports are supplied with the kit).

Remove the plastic cable ties, if present,

and remove the wiring. Place the wiring,

correctly divided, on the above shelf.

e) Using the suitable opening on the IM 7

box, bring the display double flat to the

CN14 and CN12 connector and install it.

f) Label the CO connectors on the IM7 board

box as shown in the below pictures:

g) Place the IM 7 box on the above shelf, on

the right side, 10 cm distant from the front

profile.

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

7

h) Use the plastic ring support to maintain

order in the original wiring. To fix the new

plastic ring to the shelf, hole the shelf using

a 4mm drill. The new wiring hold will keep

also the new wiring.

i) Fast the IM7 control board using the

supplied self-drilling screw. Be sure the

box is grounded by means of the

connector eyelet.

7. INSTALLATION OF THE KIT

K2950SCHEDESS_01 –ECC/IM7

CABLING (6141102X)

The wiring supplied with the kit is completed

with some interconnections to adapt the old

machine connection to the new IM 7 control.

The wiring code 6141102X was supplied

complete of labelled connectors and

numbered cables. Each connector and cable

can be easily recognized if compared with the

electric diagram reported at the end of these

instructions.

a) Connect the JP female connectors of the

new wiring to the JP male connects of the

old wiring.

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

8

b) Connect the “CO” male connectors to the

correspondent “CO” female connectors of

the IM 7 board box. The 2 poles connector

near CO12 will not be used; it must be

closed with the supplied white empty

connector.

c) Pass the wiring coming out for the CO9

connector through the back box holes.

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

9

d) See the contactor connection instructions

given at the paragraph 8.

e) Remove the original probe saving the

cable: only the last 15 cm of the cable

must be cut. Save the probe bulb and the

elastic washers needed to fix the new

probe to the dedicated bracket.

f) Join the new probe using the supplied two

ways borne. The cable colours have no

effect. Protect the borne with the red glass-

silicone sheath, to avoid the contacts

oxidation.

g) Fix the new probe in the previous position

using the elastic washers and recover the

exceeding cable.

8. INSTALLATION OF THE KIT

K2950SCHEDESS_01 –CONTACTORS

CONNECTION

a) Pass the cables through the dedicated

place behind the electric board. Enter

inside the electric board using the heating

wiring opening.

b) Label the contactors and the thermal

protections devices as shown by the next

picture:

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

10

LABEL

FUNCTIONS

VE

Ventilation

RMVE

Fan thermal protections

SX(*)

Left drum rotation

DX(*)

Right drum rotation

RMMO (*)

Drum thermal protections

(*) only in case of reversing drum

c) Insulate the cable which bring the 230V

common to the 95 NC contact of the

RMVE thermal device. In case the

machine is reversing drum equipped, open

the series with the 95NC second contact of

the RMMO thermal device.

ATTENTION

Original cable must only be insulated,

they must not be cut from the original

wiring. They should stay into the electric

board even if not used.

To insulate the cable use a shrink tubing

and a lighter.

d) The cables coming from the connector

CO9 must be wired as per the bellow table:

Cable No.

Coming from

Going to

53

CO9 –Pos 3

95NC - RMVE

54

CO9 –Pos 4

21NC –SX

55

CO9 –Pos 5

22NC –DX

56

CO9 –Pos 6

97NO –RMVE

57

CO9 –Pos 7

97NO –RMMO

58

CO9 –Pos 8

98NO –RMMO

59

CO9 –Pos 9

98NO –RMVE

e) The kit is comprehensive of single

connectors to be used to interconnect the

contactors and the main terminals:

Cable No.

Coming from

Going to

61

A2 –VE

96NO –RMVE

62

A2 –SX

21NC –DX

63

A1 –DX

22NC –SX

0C

N (blue main

inlet terminal)

95NC - RMMO

0D

A2 –DX

A1 –SX*

0D

A1 –SX *

96NC - RMMO

ATTENTION

If the machine is not reversing drum

equipped, the contactors SX and DX and

the thermal contactor RMMO are not

present. Therefore the cables referring to

the contactors SX, DX and RMMO must be

insulated, as not used.

Please go back to paragraph 7 to fit the new

temperature probe.

9. KEYPAD AND DISPLAY

INSTALLATION

a) Stick the keypad (code: 4141103X) on

the dedicated squared iron support (code:

2141141X). The flat cable must be

passed through the dedicated hole,

paying attention not to arm it.

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

11

b) Insert the 4 white spacers, 15 mm high

(code: 2950DISTA015) on the 4 pinion on

the support back. Install the display and

closet he washers and the nut M3

(supplied). Connect the flat to the keypad.

c) Place the keypad in the middle of the

cover opening. Using a marking pen,

mark the 4 holes position on the cover

inner side.

d) Use a 5,5 mm drill to hole the panel and

fix the display using the supplied TORX

M5 screws.

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

12

e) Connect the double sheathed flat to the

connectors on beck of the display board.

10. INSTALLATION OF THE

K2950SCHEDESS_02 KIT –COIN

OPERATED DRYERS

Install the CO6 connector only on coin

operated dryers. On the contrary, do not

install this connector, as the cable 3 and 0F

conducts 230V tension. These two cables are

used to supply the coin mechanism coil or the

electronic coin mechanism board. These two

cables must not be used for other purposes.

The coin mechanism wiring is composed by

two parts, one wiring inside the IM7 board

box (code: 6111123X, 6 poles green

connector), the other wiring is developed

outside the IM7 box and it reachs the

payment systems.

First of all, install the wiring identified by the

code 611123X inside the IM7 box, connecting

the green connector to the slot called CN19.

Pass the CO6 white female connector

through the dedicated hole (above CO5). The

cable nr 3 and nr 0 of the inside wiring must

be connected as show in the next table. The

cable nr 0 must be connected to the terminal

nr 2 of the connector CO9. The cable nr 3

must be connected to the terminal nr 3 of the

CO12.

Connect the sheathed wiring to the CO6

connector and reach the coin mechanism

installed on the machine.

The wiring of the connector CO6 must follow

the below chart:

Wire Nr

Coming from

Going to

" 3

CO6 –Pos 1

230V (max 0,5 A)

0F

CO6 –Pos 2

Neutral

43

CO6 –Pos 3

Common Coin 1

44

CO6 –Pos 4

Back Coin 1

45

CO6 –Pos 5

Common Coin 2

46

CO6 –Pos 6

Back Coin 2

Below the diagram.

Please note the “G1” and “G2” are two

different entrances dedicated to two different

payment systems. The entrance can be

programmed using the coin menu from the

control board. In the programming menu, the

entrances are called COIN 1 and COIN 2.

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

11. ELECTRIC DIAGRAMS - CONVERSION CABLING ECC/IM7 6141102X

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

12. ELECTRIC DIAGRAM OF IM7 CONTROLLED DRYERS

K2950SCHEDESS_01 –K2950SCHEDESS_02 (E141203X)

25/08/2015

This manual suits for next models

1

Table of contents

Other Imesa Control System manuals

Popular Control System manuals by other brands

Alpha Communications

Alpha Communications TekTone Tek-CARE NC110A Operation, installation and service manual

Airzone

Airzone RADIANT365 installation manual

Philips

Philips Lytemode 6-Button Remote Station user guide

PendoTECH

PendoTECH NFF Technical notes

Tume

Tume AgroCont manual

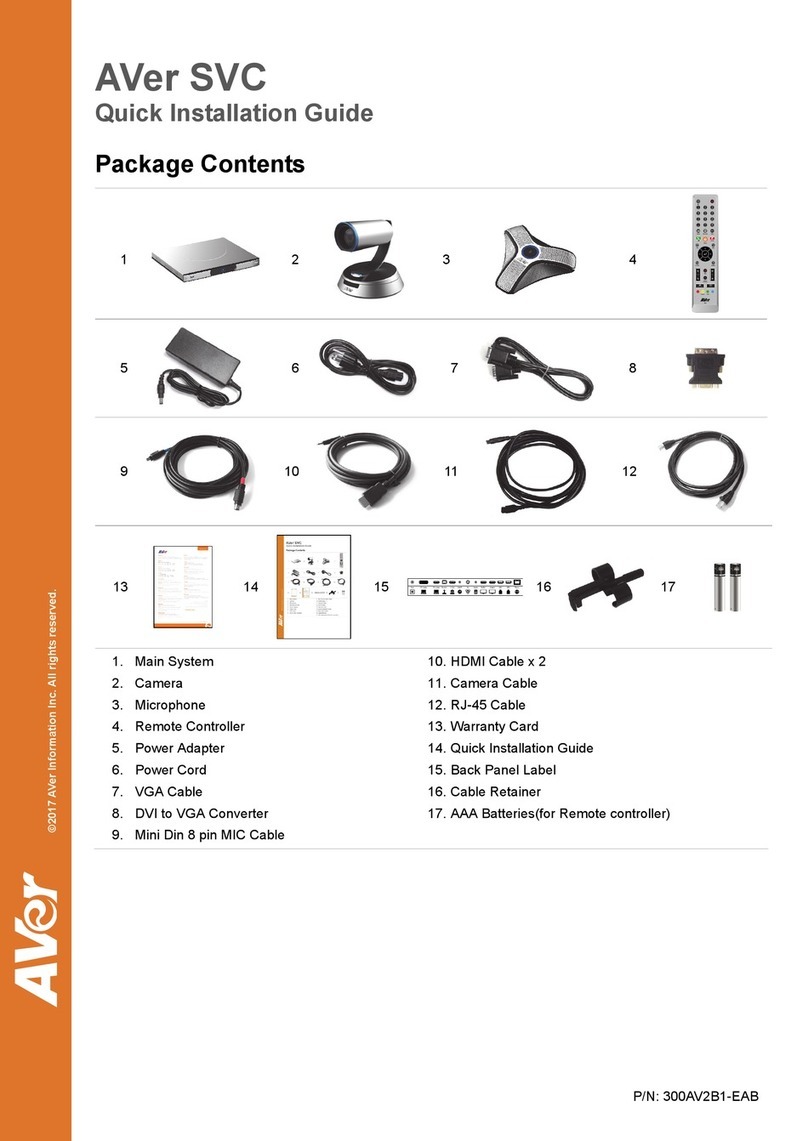

AVer

AVer SVC Quick installation guide

DEFA

DEFA Home user manual

Highway Care

Highway Care BarrierGuard 800 Product and installation manual

CURB

CURB CURB Installation & user guide

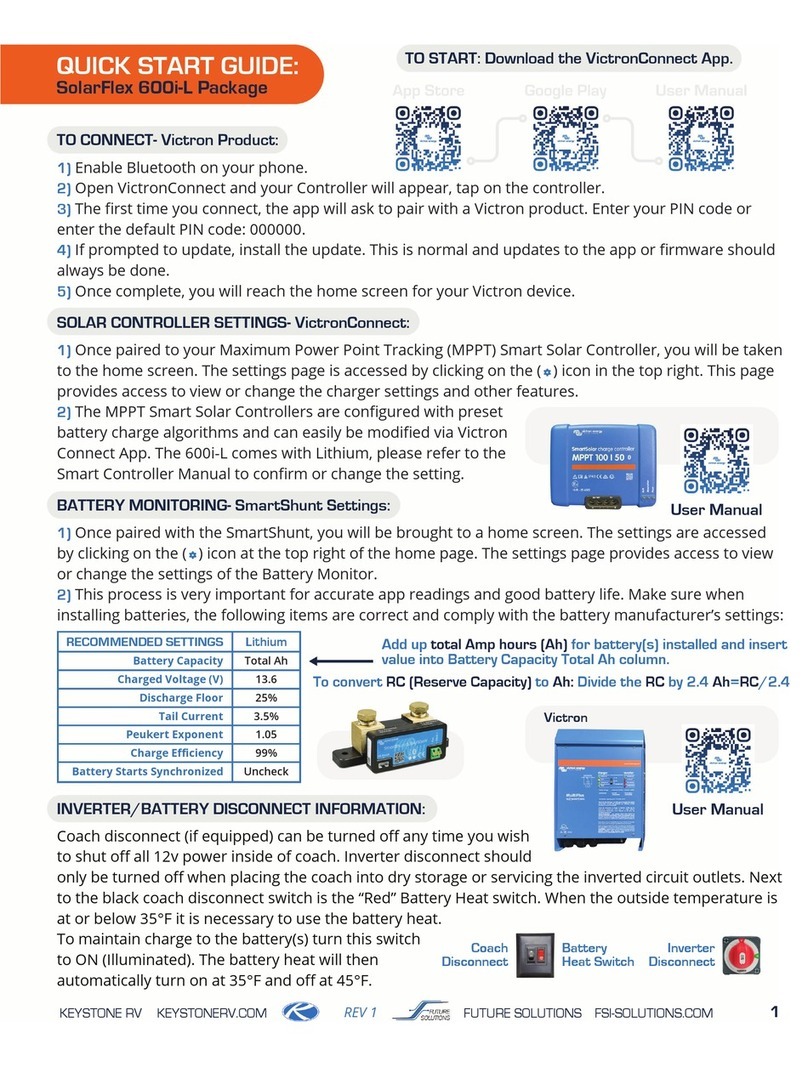

Keystone RV

Keystone RV SolarFlex 600i-L quick start guide

Alcorn Mcbride

Alcorn Mcbride DMX OverRide user guide

HandyTrac

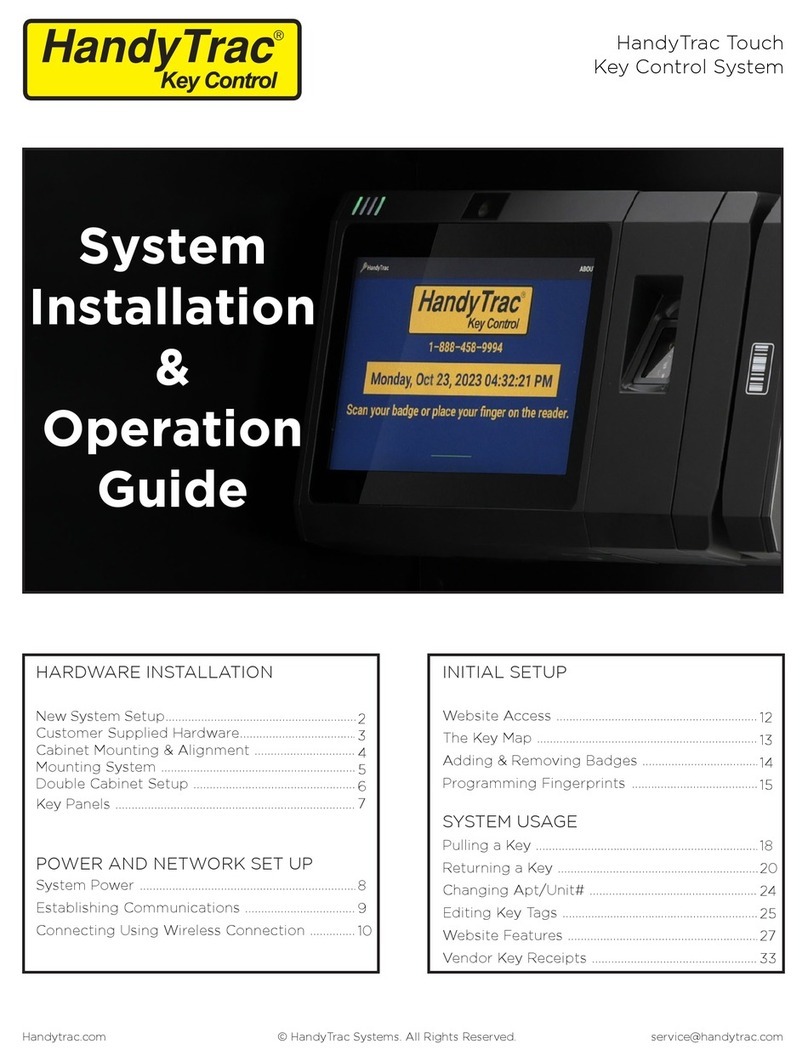

HandyTrac Touch Installation & operation guide