IML SLIDEFEEDER X80 User manual

With passion and precision

SLIDEFEEDER X80

Original operating instructions

SFx80_V1.1_210710_EN

- Blank page -

SFx80_V1.1_210710_EN

Table of contents

1About this operating instructions ........................................................................... 1

1.1 Explanation of symbols and instructions................................................................................. 1

1.2 Applicable Documents ............................................................................................................ 2

1.3 Representational conventions................................................................................................. 2

2Product information................................................................................................. 3

2.1 Product name and type designation ....................................................................................... 3

2.2 Manufacturer details................................................................................................................ 3

2.3 Customer Service Information ................................................................................................ 3

3Safety ........................................................................................................................ 4

3.1 Safety instructions................................................................................................................... 4

3.2 Procedure in a case of emergency......................................................................................... 4

3.3 Intended use ........................................................................................................................... 5

3.4 Duties of the operator.............................................................................................................. 6

3.5 Operating the machine safely ................................................................................................. 7

3.6 Transport, installation.............................................................................................................. 8

3.7 Commissioning, maintenance/repair, troubleshooting, conversion and service..................... 8

3.8 Personal protective equipment ............................................................................................... 9

3.9 Ergonomics, workplace safety ................................................................................................ 9

3.10 Emergency stop safety device................................................................................................ 9

3.11 Labels on the machine.......................................................................................................... 10

3.11.1 Warning and information signs on the machine................................................................. 10

3.11.2 Type plate .......................................................................................................................... 10

4Structure and function............................................................................................11

4.1 SlideFeeder x80.................................................................................................................... 11

4.2 Technical Data ...................................................................................................................... 12

4.2.1 Electrical and pneumatic specifications............................................................................. 13

4.2.2 Temporal Specifications..................................................................................................... 13

4.2.3 Ambient conditions for operation and storage ................................................................... 13

4.2.4 Interfaces ........................................................................................................................... 14

5Transport .................................................................................................................15

5.1 Symbols on the packaging.................................................................................................... 15

5.2 Incoming goods inspection ................................................................................................... 15

6Installation and commissioning.............................................................................16

6.1 Requirements for the installation site.................................................................................... 16

6.2 Setting up the machine and putting it into operation............................................................. 16

7Operating.................................................................................................................17

7.1 Checks before switching on the machine ............................................................................. 17

7.2 Switching the machine on and off......................................................................................... 17

8Maintenance and repair...........................................................................................19

8.1 Maintenance schedule.......................................................................................................... 19

9Decommissioning, dismantling and disposal .......................................................20

9.1 Laws and regulations ............................................................................................................ 20

9.2 Shut down and decommission the machine ......................................................................... 20

9.3 Storage conditions ................................................................................................................ 21

9.4 Instructions on disposal......................................................................................................... 21

9.4.1 Disassembly....................................................................................................................... 21

SFx80_V1.1_210710_EN

9.4.2 Dispose of materials...........................................................................................................21

10 Service.....................................................................................................................23

11 Record of changes..................................................................................................24

Appendix A: Declaration of conformity .......................................................................25

SFx80_V1.1_210710_EN

1

About this operating instructions

1About this operating instructions

This documentation is primarily intended for the operator's operating personnel.

For the purposes of these instructions, operating personnel is the group of people who are

responsible for operation, maintenance including cleaning and troubleshooting.

•The machine may only be operated or serviced by trained and authorised per-

sons.

•The responsibility for the individual work on this machine must be clearly defined

and adhered to. From the point of view of safety, there must be no unclear com-

petences.

•Every person who is part of the operator's operating personnel must have read

and understood these instructions and in particular the chapter "Safety".

1.1 Explanation of symbols and instructions

The following instructions warn the user against personal injury and damage to property.

DANGER

This symbol indicates an imminent danger to the life and health of per-

sons.

Failure to observe these instructions can result in serious damage to

health or even life-threatening injuries.

WARNING

This symbol indicates a potentially imminent danger to the life and health

of persons.

Failure to observe these instructions can result in serious damage to

health or even life-threatening injuries.

CAUTION

This symbol indicates a potentially dangerous situation.

Failure to follow these instructions can result in injury or damage to prop-

erty.

NOTE

This symbol indicates important information for the proper use of the ma-

chine.

Failure to observe these instructions can result in damage to property.

2

SFx80_V1.1_210710_EN

About this operating instructions

1.2 Applicable Documents

The applicable documents contain technical documents with further information. They are

an integral part of the technical documentation.

Upon delivery, IML GmbH provides the supplier documentation for assemblies that have

only been further processed.

1.3 Representational conventions

Emphasis in the text

To simplify readability and overview, various paragraphs/information are highlighted.

The symbols have the following meaning:

1. Carry out guidelines one after the other in the order described.

✓Action results show the result after an action step.

1.1. Carry out ancillary guidelines in the described order.

•Bullets.

References to external documents are shown in italics and delimited with a top and bot-

tom line.

Key figures

Where necessary, texts are illustrated with figures. A caption is placed below the figures.

The reference from the text to a position in the picture is established by a set position num-

ber (e.g. S1).

Illustrations

All illustrations are schematic representations and do not claim to be complete.

SFx80_V1.1_210710_EN

3

Product information

2Product information

2.1 Product name and type designation

Product name:

SlideFeeder x80

Machine type:

SFx80

Year of manufacture

(see type plate)

2021

2.2 Manufacturer details

Name:

IML Instrumenta Mechanik Labor System GmbH

Address:

Parkstraße 33, 69168 Wiesloch, Deutschland

E-Mail:

Telephone:

+49 (0) 6222 6797-0

Fax:

+49 (0) 6222 6797-10

2.3 Customer Service Information

Name:

IML Instrumenta Mechanik Labor System GmbH

E-Mail:

Telephone:

+49 (0) 6222 6797-0

4

SFx80_V1.1_210710_EN

Safety

3Safety

3.1 Safety instructions

DANGER

Risk of fatal electric shock or serious injury when touching live parts.

•Do not use the SlideFeeder x80 if the power cable, plug or other

parts of the electrical equipment are damaged.

•Check electrical equipment regularly.

•Any defects found in electrical components must be reported immedi-

ately and rectified by a qualified electrician.

•Work on electrical components may only be carried out by a qualified

electrician. Observe the locally applicable regulations and guidelines

for installation and operation.

CAUTION

Risk of injury from slipping, tripping and falling.

•Lay cables carefully.

•Do not leave any tools or machine parts on the floor.

•Wear personal protective equipment (PPE).

CAUTION

Risk of injury from carrying loads that are too heavy.

•Observe the limit values for lifting and carrying loads.

•Use suitable lifting gear for transport.

CAUTION

Danger of crushing due to moving machine parts.

•Before starting maintenance and repair work, safely switch off mov-

ing parts of the machine and allow it to come to a complete standstill.

•Secure moving parts and power supply against being switched on

again.

•The machine may only be repaired by trained specialists.

•The safety instructions in the operating manual must be observed.

3.2 Procedure in a case of emergency

•In an emergency, immediately disconnect the machine from the operator's power

supply.

•Secure the work area extensively with suitable measures.

•Inform the operating personnel and designate a supervisor.

SFx80_V1.1_210710_EN

5

Safety

3.3 Intended use

Purpose

The machine is used exclusively to remove frames with customer-supplied slides from their

magazines and place them on a customer-supplied microscope.

The limits of the machine within the meaning of the Machinery Directive (2006/42/EC) and

the products that can be processed are defined by the Technical Data (section 4.2).

Foreseeable misuse

Operating the machine with tools, parameters, materials equipments other than those spec-

ified by the manufacturer is considered misuse.

Furthermore, the following are considered misuse:

•Unauthorised modification or conversion of the machine and its protective devices

without complying with the applicable regulations

•Bypassing or deactivation of safety and protective devices

•Improper use of accessories or peripheral devices linked to the machine

•Use of unsuitable slides in the insert frame

•Use of hazardous specimens on the slides (biological, thermal hazards)

Rights and duties of the operator

Only the activities described in these operating instructions are permitted.

In addition, the operator must ensure the following:

•Observe all instructions in the operating instructions and the applicable documents.

•Carry out all maintenance measures according to the maintenance plan.

6

SFx80_V1.1_210710_EN

Safety

3.4 Duties of the operator

Qualify personnel and deploy them according to qualification

The operator must ensure the following:

•The personnel is familiar with and instructed in the basic regulations on occupational

safety and accident prevention.

•Only qualified and instructed personnel may work on the machine.

•The operating instructions must be made available to the personnel at all times.

•The personnel must have read and understood the safety instructions in these oper-

ating instructions and have confirmed this by signing them.

The competence for work in the life cycles of the machine are assigned to the employees

according to the table below:

Qualification-

level

Description

Tasks permissible in

the life cycle

Trained person-

nel

An trained personnel is a person who has

been instructed about the tasks assigned to

him/her and possible dangers in case of im-

proper behaviour and, if necessary, has been

trained and instructed about the necessary

protective devices and protective measures.

Operating

Skilled personnel

Skilled personnel are those who, on the basis

of their technical training, knowledge and ex-

perience as well as knowledge of the relevant

regulations, are able to assess the work as-

signed to them and recognise possible haz-

ards.

Note: Professional training of equivalent quali-

fication can also have been acquired through

several years of work in the relevant field of

work.

Transport

Installation

Commissioning

Operating

Maintenance

Decommissioning /

Storage

Qualified electri-

cian

Due to their professional training, knowledge

and experience as well as knowledge of the

relevant standards and regulations, the electri-

cians are able to carry out work on electrical

installations and to independently recognise

and avoid possible hazards.

The electrician is specially trained for the

working environment in which he works and

knows the relevant standards and regulations.

Commissioning

Operating

Maintenance

Decommissioning /

Storage

SFx80_V1.1_210710_EN

7

Safety

Uncovering undetected risks

The operator is obliged to cooperate in the detection of unrecognised risks. In particular,

the operator must do the following:

•Carry out a risk assessment on the basis of the Occupational Health and Safety Act,

the Ordinance on Industrial Safety and Health or national regulations.

•Report any undetected hazards that have not yet been warned of in these operating

instructions to the manufacturer.

•Report accidents and near-accidents to the manufacturer.

3.5 Operating the machine safely

The following must be ensured in all life phases of the machine:

•Operate the machine as intended, only in technically perfect condition and with an

awareness of safety and the dangers involved.

•Observe the operating data.

•Stop the machine immediately in the following cases:

•Suspicion of faults in the power supply or fault currents.

•Faults in the machine monitoring/control system or other incorrect functioning of

the machine.

•Wear the prescribed personal protective equipment.

•Do not touch moving parts during operation.

•Lay cables carefully so that they do not become a trip hazards. Always store tools

and machine parts in the designated place after use. Make sure the surface is clean

and non-slip.

8

SFx80_V1.1_210710_EN

Safety

3.6 Transport, installation

CAUTION

Risk of injury from slipping, tripping and falling.

•Lay cables carefully.

•Do not leave any tools or machine parts on the floor.

•Wear personal protective equipment (PPE).

CAUTION

Risk of injury from carrying loads that are too heavy.

•Observe the limit values for lifting and carrying loads.

•Use suitable lifting gear for transport.

The following must be ensured for all transport work and installation:

•Observe centre of gravity, weight specification and transport speed for lifting.

•Wear personal protective equipment.

•Dimension the lighting in the surrounding area so that the working areas of the ma-

chine are well illuminated.

3.7 Commissioning, maintenance/repair, troubleshooting, conversion and

service

The following must be ensured during and until the final completion of the work:

•Switch off the machine electrically, allow it to come to a complete standstill and se-

cure it against being switched on again.

•Inform the operating personnel about the work.

•Have electrical work carried out by qualified electricians only. Observe the five safety

rules of electrical engineering.

•Use state-of-the-art workshop equipment including the prescribed special tools or

mounting devices.

•Restore the original setting ranges after repairs, refitting or modifications.

SFx80_V1.1_210710_EN

9

Safety

3.8 Personal protective equipment

All persons working on the machine are recommended to wear the following personal pro-

tective equipment:

Pictogram

Description

Life phase

Foot protection must be worn

Foot protection protects the feet

from bruising, falling parts and slip-

ping on slippery surfaces.

Transport

Assembly

Commissioning

Wear protective gloves

Hand protection is used to protect

hands from hazardous substances,

friction, abrasions, punctures or

deeper injuries, as well as from

burns from contact with hot surfaces.

Transport

Assembly

Safety goggles must be worn

Eye protection prevents the ingress

of hazardous substances and for-

eign bodies.

Commissioning

Operating

3.9 Ergonomics, workplace safety

•Ensure sufficiently dimensioned lighting in the surrounding area.

•Ensure good visibility of the machining process.

3.10 Emergency stop safety device

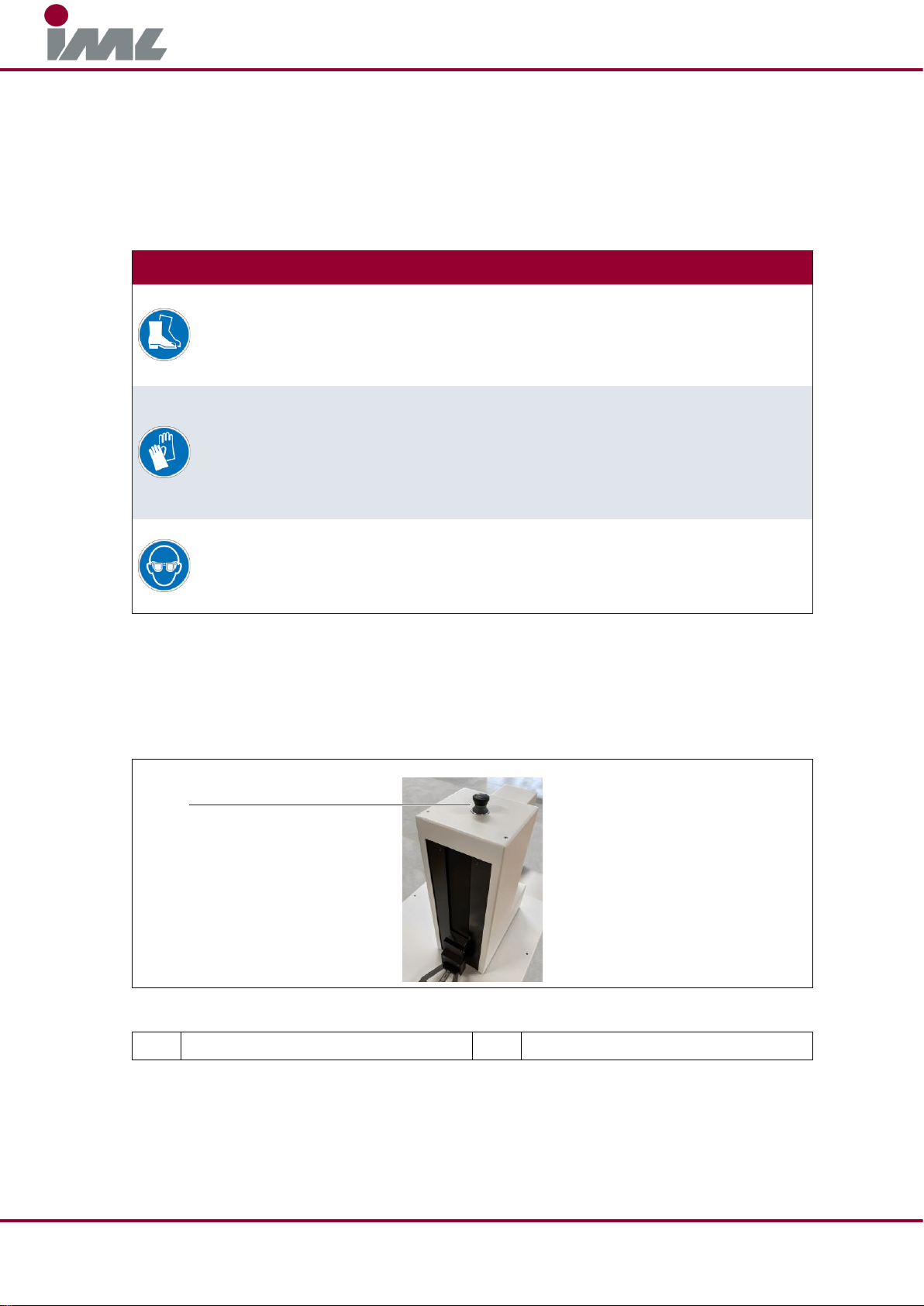

Figure 1: Emergency stop

1

EMERGENCY stop button

The emergency stop circuit is a safety device with which all safety-relevant components

are switched off in an emergency when the emergency stop button (1) is pressed. The

triggered button is unlocked by turning it anti-clockwise.

1

10

SFx80_V1.1_210710_EN

Safety

3.11 Labels on the machine

3.11.1 Warning and information signs on the machine

Labels are attached to the machine to provide additional information and warn of hazards

when handling the machine. The labels must be kept in legible condition throughout the

machine's service life and replaced immediately if damaged.

No.

Warning / information sign

Implications for the users

1

Follow the instructions for use!

•Read these operating instructions before switch-

ing on the machine.

3.11.2 Type plate

The type plate contains the following information:

•Name and full address of the manufacturer

•Designation of the machine

•CE mark

•Model

•Machine no.

•Year of manufacture

•Machine data

SFx80_V1.1_210710_EN

11

Structure and function

4Structure and function

4.1 SlideFeeder x80

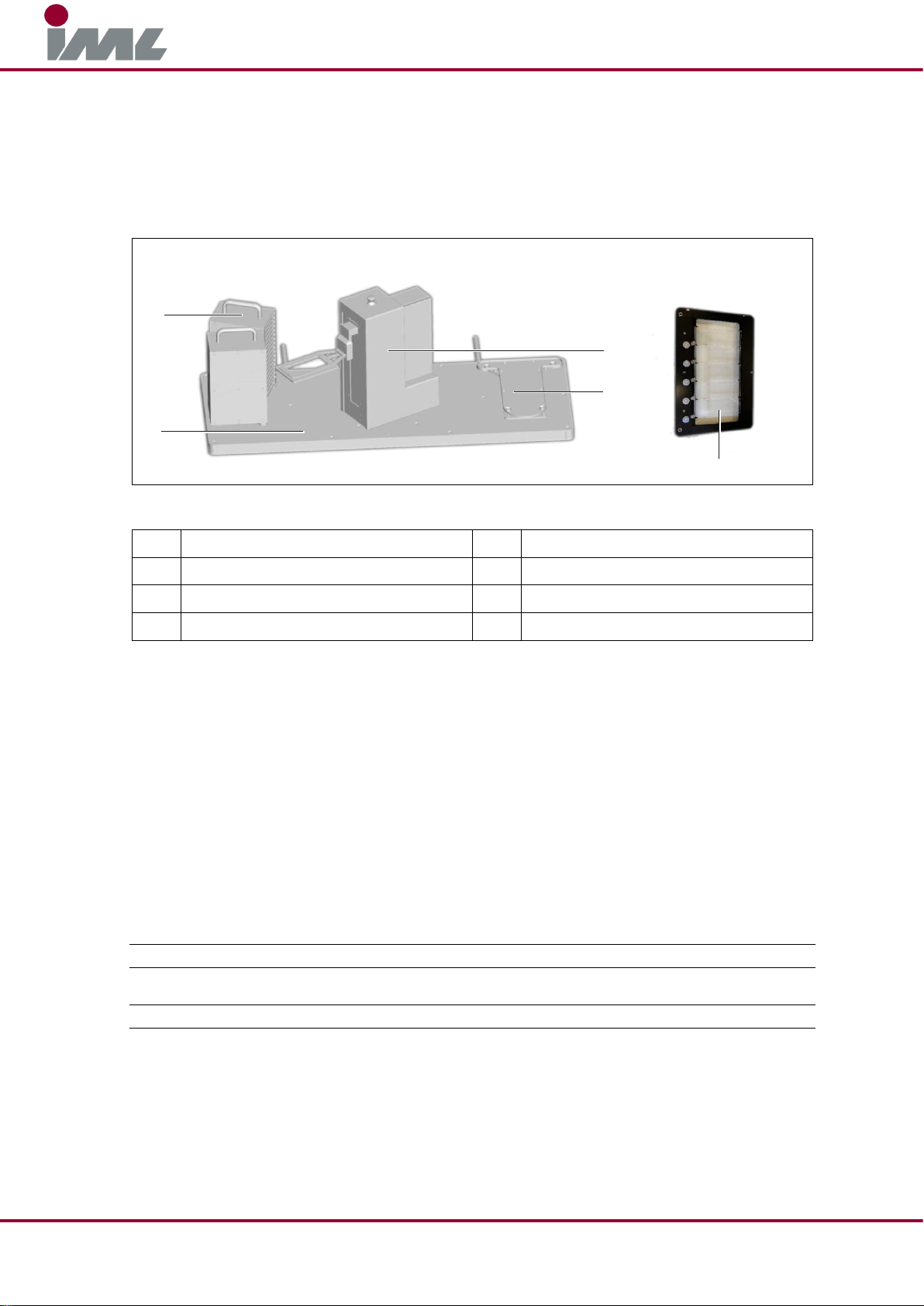

Figure 2: Machine view

1

Magazine

5

Base plate

2

Feeder

6

AutoOiler (optional)

3

Microscope base plate

7

BCR (Optional)

4

Slide plate

The machine consists of the feeder (2), the magazines (1) and the microscope base plate

(3). Depending on the variant, the SlideFeeder x80 can be operated with 2, 7 or 11 maga-

zines. In each magazine there are 16 slots for insert frames (4).

The components are mounted on a base plate (5) designed for the selection and number

of components.

Optionally, an AutoOiler (6) and a BCR barcode scanner (7) can be mounted on the base

plate.

A customer's control is necessary for the operation of the machine.

With the commands from the customer's control, the feeder removes the insert frame from

a magazine and, after a rotary movement, places it on the customer's microscope, which is

mounted on the microscope mounting plate.

For further information on the AutoOiler, see supplier documentation.

For further information on the BCR, see supplier documentation.

1

5

4

3

2

12

SFx80_V1.1_210710_EN

Structure and function

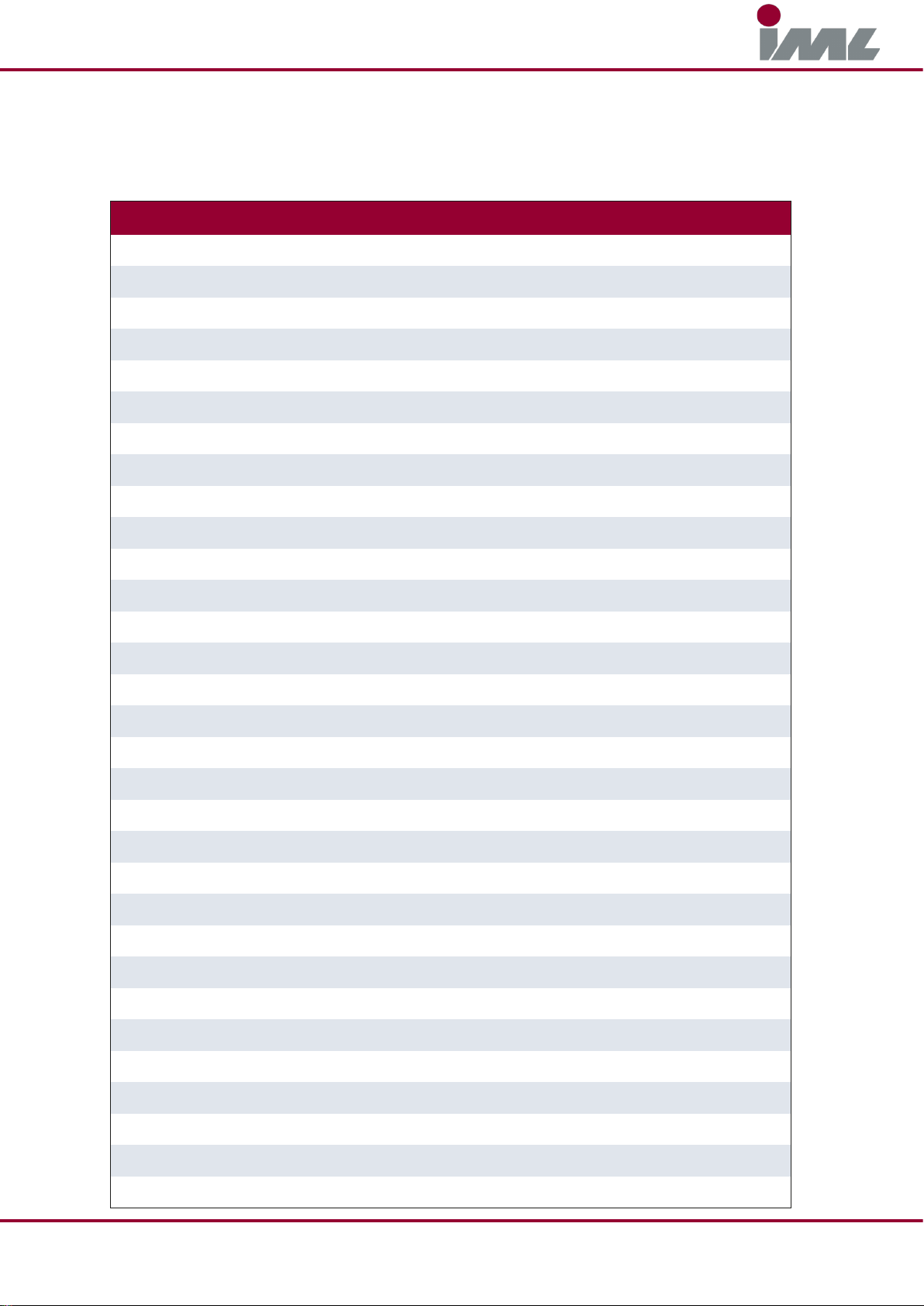

4.2 Technical Data

Parameter

Unit

Value

Machine data

Machine type

/

SFx80

Year of manufacture

/

2021

AutoOiler

Length (L)

[mm]

400

Breadth (B)

[mm]

275

Height (H)

[mm]

150

Weight

[kg]

2.95

Base plate small

Length (L)

[mm]

1390

Breadth (B)

[mm]

680

Height (H)

[mm]

160

Weight

[kg]

18.3

Base plate big

Length (L)

[mm]

1470

Breadth (B)

[mm]

1030

Height (H)

[mm]

160

Weight

[kg]

40.7

Feeder SFx80

Length (L)

[mm]

650

Breadth (B)

[mm]

560

Height (H)

[mm]

370

Weight

[kg]

10.65

Slide Magazine + Frames

Length (L)

[mm]

650

Breadth (B)

[mm]

560

Height (H)

[mm]

370

Weight

[kg]

10.65

BCR

Length (L)

[mm]

650

Breadth (B)

[mm]

560

SFx80_V1.1_210710_EN

13

Structure and function

Parameter

Unit

Value

Height (H)

[mm]

370

Weight

[kg]

9.25

Spatial limits of the machine

/

Machine contour plus 1 m around

the machine (necessary clearance

for operation and maintenance)

Noise emission

[db(A)]

<72

4.2.1 Electrical and pneumatic specifications

Parameter

Value

Power supply

Electrical via cable with socket:

5 V, 3 A, max. 15 W

4.2.2 Temporal Specifications

Parameter

Value

Maximum operating time

without interruption

24-hour operation in several shifts,

7 days per week

4.2.3 Ambient conditions for operation and storage

The machine may only be operated in a dust- and steam-free, non-corrosive atmosphere.

The machine is not suitable for use in potentially explosive environments.

Parameter

Unit

Value

Permissible ambient temperature

[°C]

+15 °C to +40 °C

Permissible relative humidity

[%]

Max. 60 %

(non-condensing)

Operating place

/

Indoors

14

SFx80_V1.1_210710_EN

Structure and function

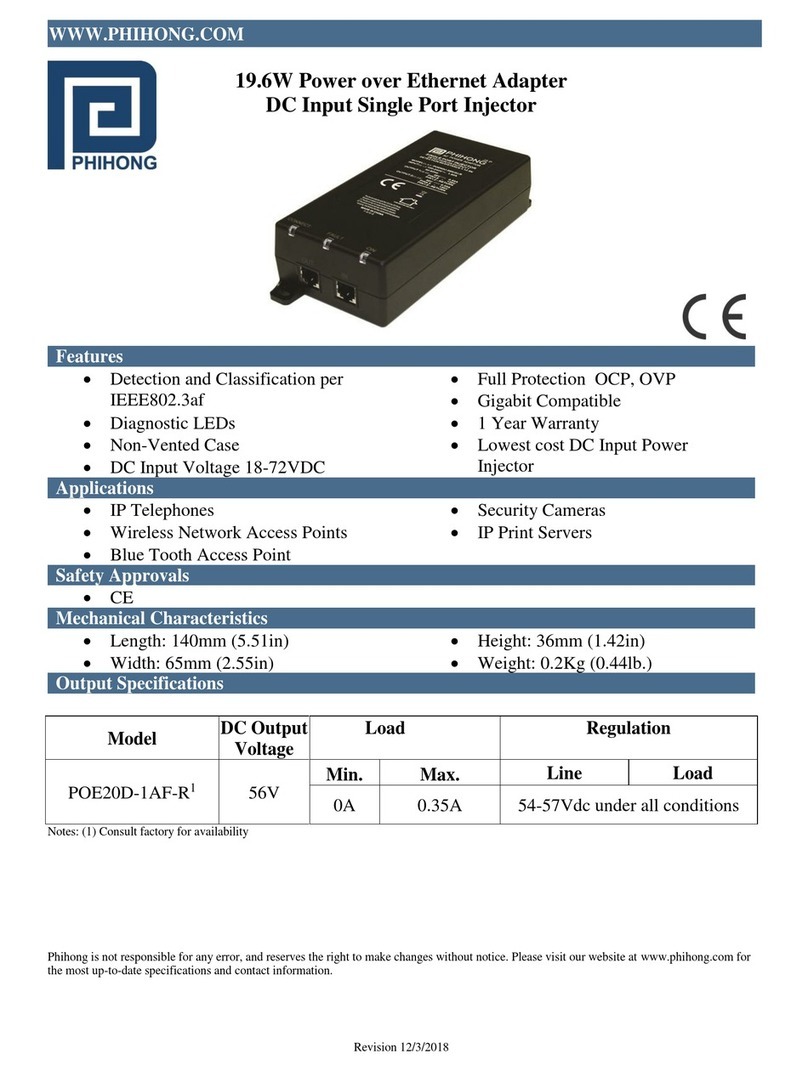

4.2.4 Interfaces

Parameter

Description

Electrical power supply and data

connection

The electrical power supply is provided via the

Lemo socket on the connection cable.

The on-site cable is connected to the external

power supply and the PC (control).

Operating

Operation as well as switching on and off are car-

ried out via the interface to the customer's control

system.

Provision of specimen

The slides provided by the customer are manually

inserted into the insert frames.

The insert frames are inserted manually into the

magazines.

The magazines are manually placed on the base

plate.

Removing the specimen

The material is removed in the reverse order of the

material being put in.

SFx80_V1.1_210710_EN

15

Transport

5Transport

5.1 Symbols on the packaging

NOTE

Observe the symbols and notes on the packaging. If there are any ques-

tions or uncertainties, do not carry out any work and contact the manu-

facturer (see chapter 10).

5.2 Incoming goods inspection

The packages are packed according to requirements upon delivery.

The following points must be checked on delivery:

•Completeness of the packages.

•Integrity of the packaging and all components contained.

•Completeness and correctness of the delivery documents.

•If defects are found on the machine or the delivery documents, report them im-

mediately to the manufacturer as well as to the responsible forwarding agent and

document them on the transport documents.

We recommend storing the transport packaging in a cool and dry place for possible later

transport.

16

SFx80_V1.1_210710_EN

Installation and commissioning

6Installation and commissioning

6.1 Requirements for the installation site

The machine may only be set up indoors on a level and sufficiently load-bearing surface.

Parameter

Unit

Value

Protective distances to adjacent in-

stallations

[m]

1

Permissible ambient temperature

[°C]

+15 °C to +40 °C

Permissible relative humidity

[%]

Max. 60

(non-condensing)

6.2 Setting up the machine and putting it into operation

The surface must be level and load-bearing. The work table underneath the machine must

be designed and constructed for the expected static and dynamic loads

.

The machine must be spatially arranged in such a way that, when used as intended, there

is safe assembly, operation, disassembly and a possibility for evasion.

Approach

CAUTION

Risk of injury from carrying loads that are too heavy.

•Observe the limit values for lifting and carrying loads.

•Use suitable lifting gear for transport.

WARNING

•Work on live components of the machine may only be carried out by

a qualified electrician.

•Observe applicable national standards and regulations for the electri-

cal connection of the machine.

Installation and commissioning may only be carried out by qualified personnel of the man-

ufacturer or by trained personnel authorised by the manufacturer in compliance with the

safety instructions.

This manual suits for next models

1

Table of contents